Professional Documents

Culture Documents

TP Suryavanshi Cie 2

TP Suryavanshi Cie 2

Uploaded by

1DS19CH011 Jashwanth C R0 ratings0% found this document useful (0 votes)

164 views38 pagestp survanshi

Original Title

TP suryavanshi cie 2

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttp survanshi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

164 views38 pagesTP Suryavanshi Cie 2

TP Suryavanshi Cie 2

Uploaded by

1DS19CH011 Jashwanth C Rtp survanshi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 38

Chapter 8

THERMAL CONDUCTIVITY AND

THE MECHANISM OF ENERGY

TRANSPORT

8.1 INTRODUCTION

Heat transfer is the transfer of energy occurring as a result of a driving force, which

we call a temperature gradient. There are three distinct ways in which heat may pass from

a source to.a receiver, although most engineering applications are combinations of two or

three. These are conduction, convection and radiation.

Conduetion : In conduction, heat can be conducted through solids, liquids and gases

The heat is conducted by transfer of the energy of motion between the adjacent molecule:

Convection : This term implies transfer of heat due to bulk transport and mixing of

macroscopic elements of liquid or gas. Since motion of a fluid is involved, heat transfer by

convection is partially governed by the law of Fluid Mechanics such as natural convection

and forced convection.

Radiation : The transfer of heat by radiation is the energy transferred by

electromagnetic radiation, or photons, having a certain range of wavelengths. The most

important example of radiation is transfer of heat to the earth from the sun.

8.2 FOURIER'S LAW OF HEAT CONDUCTION

The basic equation for steady-state heat conduction is known as Fourier's law of heat

conduction in one direction. It is

Q=-kA Fy

aes o + (8.1)

where

Heat transfer rate in 'x' direction in watts (W)

f = Cross-sectional area normal to heat flow.

k = Thermal conductivity

q = Heat flux

T = Temperature.

(8.1)

aR Rary SSS RA S TAM MS

hese three relations are the components of the single vector equation :

4

In addition to the thermal conductivity k, defined by equation (8.1), a quantity

as the thermal diffusivity, a is widely used in the heat transfer,

r

rea

ja =

"6

8.3 ANALOGY BETWEEN HEAT ANI

| | Momentum Transfer

1.1] Tecie: goveraedbpiRtantaelan Ree

| viscosity. Zz

ee ae

| | Sacmies

} + — dy i ad

3. | Momentum flux is proportional to the

| | velocity gradient.

ji ty gre ca fe

4. |Momentum is transferred from a

| region of high velocity to'a region of low

| velocity. as

[ 5. [Momentum diffusivity is

=" (ms)

¥: p (m/s, oe ae

8.4 TEMPERA

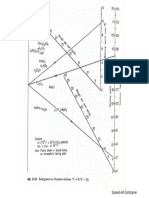

‘The reduced thermal conductivity is the thermal conductivity at a given temperatur

and pressure divided by the thermal conductivity at a critical point. This quantity is plott

T

as a function of reduced temperature T, = To and reduced pressure P, =

c

k

ke

{tis analogous to the reduced viscosity plot.

The thermal

temperature,

temperature.

Hence é

conductivities of gases a

Le. For Gases : k F

(Liquids =

__| temperature gradient.

TURE AND PRESSURE DEPENDENCE OF THERM.

CONDUCTIVITY IN GASES AND LIQUIDS

ereas the thermal conductivities of most liquids decrease with increasin

iD MOMENTUM TRANSFER

It is governed by Fourier's law of h

conduction,

Heat flux is proportional

Heat is transferred from hi

temperature region to a low temperatur

region.

Thermal diffusivity is

a

(m°/s)

Pe

t low density increase with increasing.

‘Transport Phenomena, Ace 83. Thermal Cond. & the Mecharasm of Energy Tramsport

8.5 THEORY OF THERMAL CONDUCTIVITY OF GASES AT LOW

In gases, the mechanism of thermal conduction is relatively simple The molecules

are in continuous random motion, colliding with one another and exchanging energy end

somentum. The thermal conductivity increases approximately as the square rect of the

where,

m = mass, K = Boltzmann constant

d@ = diameter, n = moles volume

The molecules reaching any plane in the gas have, on an average, had their lest

(89)

The energy exchanged by smooth rigid sphere in collision is translational energy. the

ranslational energy per molecule under equilibrium conditions is

3

1

gm = 5KT (8.10)

For such gas, the heat capacity per mole at constant volume is

dsl 2) _3.

c= Grae )=28 1)

which R is gas constant. This equation is satisfactory for monoatomic gases upto very

Fig. 8.1 : Molecular transport of energy irom plane at (y ~ 2) to plane at y

Mein oe sve

in the ~ ve 'y! direction,

lemperature Je of molecule is linear for a distance of several mean free path,

The t profile of molecule is linear for a dista oan free pat

\e temper

We may write

2 aT.

Tlyw ® anne hay

av

Tlysa = Thy aay

Combining equations (8.7), (8.12) and (8.13), we get i

a Raney 8.14) |

a, = -}aKWAg

This corresponds to Fourier's law of heat conduction, with the thermal conductivity

giventby

k = JoKaa= BGT dias (monoatomic)

where

P =nm, is the mass density of gas.

«. (monoatomic) s+ (8.15)

This equation gives thermal conductivity of rigid sphere for dilute gas.

Chapman-Enskog equation for the thermal conductivity of a monoatomic gas at low

density at temperature T (K) is

: VT/M)

a

k = 19891 x10 oa, |

7 - (monoatomic) ++» (8.16)

where

“en

Q, = 9, '= LennarddJones intermolecular potential model

ken developed equation for

* Polyatomic gases at low density as

+» (8.17)

Phenomena 85 ‘Thermal Cond. & the Mechanism of Energy Transport

Equation (8.17) gives a simple method of estimating the Prandtl number,

Co

reo

a dimensionless quantity of importance in convective heat transfer.

out &

Pra = Gy 1a5R “*(Polyatomic) .. (8.18)

For mixture kg

ie So

=X xy

int

where,

y 1 1?

© My 3 (MY

5) = e(a+at) 1+( SF GE +. (8.19)

SA veya 4) (Mi

8.6 THEORY OF THERMAL CONDUCTIVITY OF LIQUID

The physical mechanism of conduction of energy in liquids is somewhat similar to

that of gases, where higher-energy molecules collide with lower-energy molecules. The

thermal conductivity of liquid varies moderately with temperature and often can be

expressed as a linear variation.

k = a+bT +++ (8.20)

where a and b are empirical constants. Thermal conductivities of liquids are essentially

independent of pressure. Water has a high thermal conductivity compared to organic -

liquid such as benzene.

‘The development here is based on the rigid sphere gas theory.

k = 3 pGar=pC, Ile (8.21)

When pC, = (7) v= (8.22)

luyl = Vs (8.23)

The distance ‘a' that energy travels per single collision is taken to be the lattice

spacing, (¥ yr Substituting this in equation (8.21), we obtain equation of thermal

XN

conductivity for monoatomic liquid.

«++ (8.24)

‘Tho velocity of low-frequency sound, 'V,’ is given by the relation

C, /aP

Y= a >),

The quantity (s), is readily obtainable from isothermal compressibili

G, 5 ag .

measurements and e is of the order of unity for liquids except near the critical point.

8.7 THERMAL CONDUCTIVITY OF SOLIDS

The thermal conductivity of homogeneous solids varies widely. The metallic solids of

copper and aluminium have very high thermal conductivities, while some insulating

non-metallic materials such as rock, wool and cork board have very low conductivities.

Heat or energy is conducted through solids by two mechanisms. In the first, which

applies primarily to metallic solids, heat, like electricity, is conducted by free electrons

which move through the metal lattice. The second mechanism, present in all solids, heat is_

conducted by the transmission of energy of vibration between adjacent atoms.

In porous solids, the thermal conductivity is strongly dependent on the void fraction,

the pore size and the fluid containing in pores. In crystalline materials, the phase and

crystallite size are important. In amorphous solids, the degree of molecular orientation

has considerable effect.

For pure metals, the thermal conductivity k and the electrical conductivity k,

related approximately as follows.

a = L = constant

This is famous equation of Wiedemann, Franz and Lorenz.

where

L = Lorenz number, of about 22 to 29 x 10? (x)

K

le ie

lee has a thermal conductivity much greater than water.

as Hence, the thermal

ities of frozen foods are much higher than for unfrozen food: a

apter 9

TEMPERATURE DISTRIBUTIONS IN

SOLIDS AND IN LAMINAR FLOW

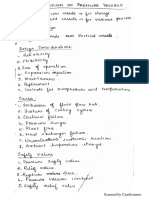

9.1 APPROACH TO SOLVE HEAT TRANSPORT PROBLEMS

We will select a particular thin slab or shell perpendicular to the direction of heat

flow

2. Write the energy balance equation for this thin slab.

3. Let, this thickness approach to zero and make use of definitions of first-order

differential equation for heat flux.

4. Insert Fourier's law of heat conduction to obtain second-order differential equation

for temperature distribution,

Integration of these two equations for whole system will give two constants of

integrations which are found by applying suitable boundary conditions.

6. From above two equations, various other quantities like maximum temperature,

average temperature, ete. can be calculated.

9.2 BOUNDARY CONDITIONS USED IN THE HEAT TRANSPORT

PROBLEMS

1. The temperature at the surface may be specified, T = T,.

2. Heat flux at the surface may be specified, q = q,.

3. At solid-fluid interface, heat flux is given by Newton's law of cooling.

q = h(T-T) + 9.1)

where, h = Film heat transfer coefficient

T, = Temperature of fluid

4. At solid-solid interface, heat flux and temperature are continuous across the

interface.

3 SHELL-HEAT BALANCE

The shell-heat balance is given by :

ests of Thermal Rate of ree) ( Rate of Thermal ) ae (02)

Energy In ) (0 Energy Out 7 * \Energy Production

a)

‘This equation gives the temperature distribution for aluminium cladding.

BC.2:Atr=Ry,T,=Ty

Equating equations (9.62) and (9.64), we get

S,,[Rt_ b Re 8K

Su[BE, BRE) ot | Sei bya 4

ky [5 DRe\*? * ke (+5) ®-Re|*7 (9.65)

S,oRe (1, b R

‘2 bar a pe, i a SR (1, b

Hence, Cz = T, +o (aes) eoneleert (+m) (9.66)

Substituting this value in equation (9.62), we get,

S,.[r2 ._br* S,Rr (1, b

(Tp= Tp ve aoe [Eg BE) Snot (2,

if ky [i 20K] 4

We 6. 1, .b

er ia) kr 6 »)

non LOG) BEI C-

gives temperature distribution in Nuclear fuel sphere element.

T; ea mae

8, Rr{. au) Sela ab Ry

op yz SmeBel, 2], SooBt[(, By Br

aus ~ Te [a+ les ae [0+ al “a (9.68)

9.7 HEAT CONDUCTION WITH CHEMICAL HEAT SOURCE

Consider fixed bed axial flow reactor as shown in Fig. 9.3, The reactor is divided into

three zones. Entrance and exit zones are packed with inert particles. Chemical reaction is

carried out in a region between z = 0 and z = L which is packed with catalyst pellets. Here,

we will assume plug flow conditions. The walls of the reactor are well insulated. We want

to find axial temperature distribution, T (2).

Reactants

Fig. 9.3 : Fixed bed axial-flow reactor

sive the product. Rate of thernial energy production per unit volume is given by,

=S,

where,

T = Temperature of catalyst surface

T, = Inlet temperature of reactant at z= ©

S,, and, = Empirical constants.

Consider a disc of radius 'R' and thickenss Az as shown in Fig. 9.3. The therm

energy balance for this disc is,

(Rate In) ~ (Rate Out) + (Rate of Production) = 0

[ (nR?q,)|, +p VaR? C, (T mh e [ (HR?G leas an) + PVR? C, (T- Ty Ihe, al

+ (S, - mR? Az) = 0

Dividing this equation by (nR? Az), we get

lim [{ %l¢

420

a+ as) ~ Sele 4

Az +1 PV C4

d « aT

dz (+ 9VC, 5"

iz 0

“6

limi Bog =e

Az

Applying Fourier's law of heat conduction,

The above e

0)

db

(Il)

= (-* a) "V6 tt

dz (*e dz Pde

or A ar

k, ag? + PVC, dz

ae

te

uations for three different zones are

er «aT

~k Gr +pvG

d

ak Ge rov-6,a0

ape

~ kur tev: C2

] =8,

(

(9.70)

nome 2:13. Temp. Distri. in Solids and in Laminar Flow

‘The different boundary conditions those could be used are,

Boundary Condition 1:

At zee, T = T,

2, ToT

Boundary Condition 2:

At oz=L, T'=T and q'=q"

z=, T = finite

Now, om oa

ed

Hence, (T-T,) = o(r,-

aT

‘deus 2 (T, -T,) (9.76)

Now, zat

dz

CA

ve

Also, Bie woh ie cu

pV, (T, -T,)

146 a6

pata 7° (977A)

Equation (9,76) becomes a. a-y

er ae

and a > vag M-h)

kz d’@ 140 |

(1) becomes -—= ae ae

pvc,

29:

#2 ra + 8.77)

pvc,

? 9 S40

eee

(I) becomes = — Me oe ia ore

pvc, pVC, (T; -T,)

cae nage OL

eee e

dz? dz pi

oa pvG, (Ty ~ T.)

1¢e @ _ ng ..- (9.78)

“Baz ‘dz ~ N°

m .

Om nee “fees

Now, equation (8.77 A) becomes ; '

wo pee wo s

da? de

@ = O+Gje™

Rquation (9.78) becomes

ao do”

de? ~B ay

(De BD + NBO © 0

+NBO = 0

Dem, =

whore, 8 a Cr Cae

Similarly, equation (9.79) gives

(cates

m, my

O = 1) a

et

awring 2 mile

esa

9.8 HEAT CONDUCTION THROUGH COMPOSITE WALLS 3

ADDITION OF RESISTANCES

Consider

(xy =)

& composite wall made

) (ry — 2m) and (x — x4) respecti

respectively.

up of three different materials of thick

vely with thermal conductivities k®1, 12

At the boundaries, the w:

Ce

snenomena, 9.15

Temp. Distri. in Solids and in Laminar Flow

Temperature

Fig. 9.4 : Heat conduction through a composite wall

We will consider a slab of thickness Ax, width W and height H in the region of

naterial 01 as shown.

The thermal energy balance for this slab can be written as :

Rate of

thermal energy |_ (3 of thermal é

t td energy Out F

o1

(w-H- @®)|,- (Wea )iu.ay = 0

Dividing this equation by W.H.Ax

o1 01

lim 4x |xsan7 Ix |x

Ax 30 Ax Ry

deo

Hence, aa ay) =0

where q,’ = constant = q,

Similarly, for second material,

2 23

qx =4, 4x =q, and q, =q,

Applying Fourier's law of heat conduction,

47°!

o dT"

ve age

By integrating this equation, we get, ,

(x, -x, al

(T, -T)) = = ee (9.84)

4, (Xp = X1) (9.85)

Similarly, Qala ar

«+. (9.86)

a (yy =

We have Newton's law of cooling,

a, = b, (T,-T,)

(T,-,) = R

Go

Similarly, (T, -T)) = #e

Adding equations (9.84), (9.85), (9.86), (9.88) and (9.89) we get,

1 (x -x,) (x, -x,)

(T,-T,) = alg + oe +Aaarh

LD ook)

Hence, hg = ED tee

1) Goa Gas) Ge a

[i+ Shar Sear. Sa

Also,

Ch i (tin)

The above two equations describe heat flux for a composite wall, where 'U,' is o

heat transfer coefficient. In general,

|

oe ee

Temp. Distri. in Solids and in Laminar Flow

ider the fin of length L, thickness 2B, and width 'W' as shown in Fig, 9.5. Its one

is parallel to the wall to which it is attached. Heat lossed from end edges is

ble.

al energy balance oi ;

WHET es

(ccceee by conduction) = (2B-W-q,)

(Pate of thermal serey)

5 ++ (9.94)

Out by conduction FOR ale as) pee}

( Rate of thermal energy

Out by conyecdiet ) = 2W (Az) h(T-T,) -.. (9.96)

e thermal energy balance is

BB-Wea,|,— 2 BW, 2, ay [2W-dz-h (T ~ T,)] =0 (9.97)

viding this equation by (2BW Az) gives

lim ‘elect 1h |

Az 30 ‘Aaa iy - (9.98)

cording to first-order differential equation, above equation can be written as,

da h

az WS 7 Boa (9.99)

an h

~ ko = ee

eT h

[aa hae B‘T-T.| --- (9.100)

Now, Za

Dimensionless temperature :

0, ee

=a

By

T = 6(r, 0 T,

Dimensionless heat-transfer coefficient,

hl?

Then equation (9.100) becomes

he ~

a ie kB (T-T)

Pe _ hi (T-T

dz? ~ kB (r,=7

ae

i az

Mest,

“a i-7.)

ae = No

@ = C,ek%+C,e™ .. (9.101)

Z=0, 0=1 7

Boundary Condition (2) :

qT _

At Z=L, Gp =

ao

Z=1, 4,20

1

C

+e8

Henee, equation (9.101) becomes,

Sol oodca ames

8 gM a at

+oNO tN ene

aN Dv + eNiZ-1,

ez )

0 = : adil

ctf

‘e temperature distribution for a ' fin’.

‘Phenomena 919

EFFECTIVENESS OF A FIN

1 = — Actual rate of heat loss from the fin

Rate of heat loss from an isothermal fin

n=

Saas

freee T,) dz dy

Lp ~T,) dz dy

on fee Joo va 2)

"cosh (N)- 1

w fas

= ae sinh IN ail

tanh (N)

N «+ (9.105)

.11 HEAT CONDUCTION WITH A VISCOUS HEAT SOURCE

Consider a flow of a incompressible Newtonian fluid between two coaxial cylinders as

‘Temp. Distri. in Solids and in Laminar Flow

hown in Fig. 9.6. As the outer cylinder rotates, each cylindrical shell or fluid rubs

wainst an adjacent layer, this rubbing will provide the surface for thermal energy. This

iscous heat produced per unit volume is 'S,' and it depends on local velocity gradient.

Outer cylinder moves with

Angular velocity ©

Inner cylinder

is stationary

Fig. 9.6 : Flow between cylinders with viscous heat generation

Transport Phenomena 9.20 ‘Temp. Distri. in Solids and in

If the width between two cylinders 'b' is very small as compared to radius

cylinder 'R', then, curvature effects can be neglected. The problem can then be m

Cartesian co-ordinates.

Stationary surface

Fig. 9.7 : Idealisation of portion of flow system

Volume rate of thermal energy production is

av, av,y

ae Br (Ge “(ae

As velocity distribution is linear,

av, /V-0_¥

dx b

Consider a shell of length 'L', width 'W' and thickness 'Ax'.

‘The various components of thermal energy balance are,

= (L-W-4,)

Rate of thermal energy , - (wee)

Rate of thermal energy

In by conduction at 'x' x

Out by conduction at 'x + Ax' eke

Rate of thermal energy

Coe per unit volume) = (L-W-ax-S,)

The thermal energy balance is given by,

(twa) (Wea)

Dividing this equation by (L-W-Ax) and taking ae i

hea +(L W- Ax S,) =0

lim 4x}x+ ax >

x 50 RO FO

Hence, a vy

ax = “(5)

Phenomena 9.

‘ 4 2 _Temp. Distri. in Solids and in Laminar Mow

>

Integrating this equation gives,

2

as »G) ssi) ve (Q.114)

We have, Fourier's law of heat conduction as

a = -4 St (9.115)

Substituting this equation in above equation gives,

oan y

iets “G) x+C, (9.116)

By integrating this equation gives,

2 42

-k: “a x f

k:T a HS) 2 +em-¢ + (9.117)

; at Cx

Hence, 193 mr tete ee +c, (9.118)

For evaluating constant of integration, we have,

Boundary Condition (1): At x = 0, T = 7,

Coa

andat x=b,T=T,

Equation (9.118) becomes,

-1 - oe

1-1)

2 2

So, Cc, = Elena ee] -.- (9.119)

Substituting equation (9.119) in equation (9.118), we get,

Xe v?

To EE)s -i5 [7 - -T,)- e alt. «» (9.120)

By rearranging, equation (9.120) becomes,

H(VYx x uv? x

T-T, =-E(6)3 +5 (T, - T,)+4 2bk

T-T, v? oo ee

a aan Gls ce

“3-104. »

(9.121)

ve Maal serer % |

where me it, =) een nee

eee

portance of viscous heat flow compare«

kman number measures the relative im]

hea ” resulting from temperature difference (T,, —

Transport Phenomena __ 9.22

9.12 COMPARISON ‘OF FORCED AND FREE CONVECTION

~~ Forced Convection Free Conv

determined | The alow faire are determined

buoyant effect of the heated fluid.

No.

1. |The flow patter

y some external force.

locity profiles are found,| The velocity profiles and tempe

profiles are intimately connected.

sare

primarily b:

2. | First, the ve

then they are used to find the

temperature profiles,

3. The Nusselt number depends on| The Nusselt number depends on Gri

Reynolds number and Prandtl) number and Prandtl number.

number.

[SOLVED PROBLEMS)

Problem 9.1 : Calculate the heat loss per m? of surface area for an insulating:

composed of 25.4 mm thick fibre insulating board, where the inside temperature is

and the outside temperature is 297.1 K. The thermal conductivity of fibre is 0.0048 Wh

Solution : Given Data: Ax = 0.0254m

Ww

k = 0.048%

7, = 3527K

T, = 2971K

‘The rate of heat transfer per unit area,

_ (AT) _ 0.048 x (352.7 - 297.1)

Peri: 0.0254

105.1 W/m?

Te Plo >lo

= 105.1 W/m?

Problem 9.2 : A thick-walled “gindtal tubing of hard rubber having an in!

radius of 5 mm and an outside radius of 20 mm is being used as a temporary cooling

‘ bath. Ice water is flowing rapidly inside, and the inside wall temperature is 274.9 K.

ee surface temperature is 297.1 K. A total of 14.65 W heat must be removed from

ee by the cooling coil. How many m of tubing are needed ? The thermal condueti

= 0.151 Wim-K.

Solution : Given Data:

k = 0.151 W/mK

510% m

¢ Phenomena 9.23

T, = 2749K

T, = 2971K

Q = 14.65 Ww

Temp. Distri. in Solids and in Laminar Flow

2nr, L = 2n (1.0) (0.005) L

0.0314 Lm?

0.1257 L m?

Kg

0

A,~A,

Ay,’ © peau

" In (A,/A,)

_ (0.1257 ~ 0.0314) L

ay Qa

(00si4)

= 0.068 Lm?

The rate of heat transfer is given by,

Q = kA?

a (274.9 ~ 297.1)

= 0.068 L x 0.15179 99 — 0.005)

= -152LW

14.65 = -15.2LW

Here, -ve sign shows that heat flows from r, to r,.

Problem 9.3 : A cold-storage room is constructed of an inner layer of 12.7 mm of pine,

a middle layer of 101.6 mm of cork board, and an outer layer of 76.2 mm of concrete. The

wall surface temperature is 255.4 K inside the cold room and 297.1 K at the outer surface of

the concrete. Use thermal conductivities for pine, 0.151; for cork board, 0.0433; and for

conerete, 0.762 W/m:K. Calculate the heat loss in W for 1 m? and the temperature at the

interface between the wood and cork board.

Solution : Given Data :

T, = 255.4 K, T, = 2971 K

A~ Pine material.

B Cork.

C Concrete.

9.24

ky = 0.151 W/mK

ky = 0.0433 W/mK

ko = 0.762 WimK

‘Transport Phenomena

Ax, = 0.0127m

Axy = 0.1016m

Axe = 0.0762m

=. The resistances for each material are, for an area of 1 m?,

Ax,

Ry? yk

0.0127

= (Cusp os eae

Axp

Rp

= (0.0433) (1)

AX,

Ro = nk

_ _0.0762

= (0.762) (1)

0.100 K/W

W

We have the rate of heat transfer per unit area,

AD eS Os

4 >SR TaR\ + Rp + Re

ey,

Since answer is in negative, heat flows from outside. To calculate the temperature

the interface between the pine, wood and cork,

ts Rae

Ry

_ 255.4-T,

o.0841

256.79 K

256.79 K

port Phenomena _

9.25

7 ————————__Temp. Distri, in Solids and in|

Problem 9.4 : A thick-walled tube of stainless steel (A) having k = 21,93 W/m:K with

co . mee and 9.0508 m O.D. is covered with 0.0254 m thick layer of

sulation : a a ; mS ‘The inside wall temperature of the pipe is 811 K and the

outside surface 0 4 nsulation is at 310.8 K. For a 0.305 m length of pipe, calculate the heat

Joss and also the temperature at the interface between the metal and the insulation.

Solution : Given Data : T, = 811 K, Ty = interface temperature, T, = 310.8 K

» T, = 310.

0.0508

r, = 0.0127 m, r= 5 = 0.0254 m,

ry = 0.0508 m

‘The areas are as follows for L = 0.305 m

A, = 2Lr, = 21 (0.305) (0.0127) = 0.0243 m?

A, = 2ncLr, = 2r (0.305) (0.0254) = 0.0487 m?

A, = 2nlr, = 27 (0.305) (0.0508) = 0,0974 m?

Let, A > Stainless steel; B > Insulation

ta Ay na Ay

~ Tn (AVA)

_ 0.0487 - 0.0243

~ in (0.0487/0,0243) = 0.0851 m*

ee

= Th (Ay/Ay)

0.0974 ~ 0.

oe ETE eat

in (20974

a (cous)

Agim

(Agim

The resistances can be ealeulated as,

2

A ky Agim

0.0127

= 91.68 (0.0861) ~ 001673 KW

4-F

Bs is Gah

0.0254

= 92193(0.0703) = 1491 KW

Hence, the heat transfer rate is

eae

= R,+Ry

811-310.8

2 ee | as. W

= 901673 +1491 ~ **

Temp. Distri. in Solids and in

Transport Phenomena

To calculate temperature T;

SLi

0.01673

Bu f 7

jaturated steam at 267°F is flowing inside a 4 in. steel pipe having

ID of 9.824 in. and an OD of 1.050 in. The pipe is insulated with 1.5 in. of insulation on

outside. The convec

ve coefficient for the inside steam surface of the pipe is estimated

h, = 1000 Btu.h".ft"/°F and the convective coefficient on the outside of the lagging

estimated as h, = 2 Btwhr.ft? °F. The mean thermal conductivity of the metal is 45 W/m:

or 26 Biwh.ft.°F and 0.064 W/m-K or 0.037 Btw/h.ft.°F for the insulation.

(a) Calculate the heat loss for 1 ft. of pipe using resistances if the surrounding air is

SOF.

(b) Repeat, using the overall U, based on the inside area A.

Solution : (a) Let r; the inside radius of the steel pipe, r;

and r, the outside radius of the lagging, then

0412 0.525

aay 5 ae

the outside radius of the pi

For 1 ft. of pipe, the surface areas are as follows :

A,=2nLr, = 2n Cz) = 0.2157 f2

0.52

Ay = 2nLr, = 2n Ce) = 0.2750 f?

A, = 2nLry = 2n Cz) 1.060 82

Let A — Steel, B > Lagging

The log mean areas for A and B are

A,-A,

(A, = 1

wim = in (AAD

(Anim

0

e rate of heat transfer,

Then to calculate Q,

03

se

~ 4nk

Jee

9.27 ‘Temp. Distri. in Solids and in Laminar Flow,

Sat

hy Ay

pe LO

1000x0.2157 = 00464

n-1

Ky * Ay im

(0.525 - 0.412)/12

$6245) qa eee

per

ky 7 Ag im

(2.025 ~ 0.525)/12 _

(0.087) (0.583) =

R+R +R, +R,

267 — 80

0.00464 + 0.00148 + 5.8 + 0.472

267 —80

6.278

= 29.8 btwh

an

U,A(T,-1,)= 5p

0215x6278 = 0-738 BtwhttF

U;,A; (Ti, — 3),

29.8 Btwh.

= 0.738 (0.2157) (267 — 80)

Problem 9.6 ; A 60 W bulb is buried in soil (k = 0.84 W/m-K) and burnt until a steady

ite is reached. Find the temperature 0.3 m away from it.

Solution : Consider the bulb as a spherical body and heat loss from sphere is,

Q

0

d

aie?

4nr? ky

My

Je

0

Problem 9.7 : An electric current of 200 Amp. is passed through stainless

r= 1.26 mm and length L = 91 cm. The wire has a resistance of 0.1:

having radius

js held at 422.1 K. The average thermal condi

outer surface temperature Ty

k = 22.5 W/mK. Calculate the centreline temperature.

Solution : Given Data : j

r = 126x10%m ‘

T = 200A

L = 091m

R = 0.1262

Ty = 4221K

k = 22.5 W/mK

Power =I7R = (200)?x 0.126

P = 5040 W

S.x mL = Power

ee ge

© 1x (1.26 x 10°) x 0.91

= 1.12 x 10° Wim’

Temperature variation in cylindrical wire,

Sr?

‘max ~ Tw = “gi

_ 112 10° x (1.26 x 10%)

- 4x 22.5

= 19.75

Tray = 19.75 +422.1

Tae = 441.85 K]

i Problem 9.8 : A current of 250 amp is passing through stainless steel wire havil

diameter of 5.08 mm. The wire is 2.448 m long and have a resistance of 0.0843 @. The

surface held is constant at 427.6 K. The thermal conductivity is k = 29.5 W/m-K. Cal

the centreline temperature at steady state.

~ a

Phenomena 9.29 Temp. Distri. in Solids and in Laminar Flow.

jution : Given Data :

= 2.54x10%m

= 250 amp

2.448 m

= 0.0843 2

= 22.5 Wim-K

T, = 4276K

w Woe oe

4

zg

in

"

= Heat generated per unit volume

PR

mL

(250)? x 0.0843

© wx (2.54 x10)? x 2.448

1.061 x 10° W/m®

S._ = 1.061 x 108 W/m?

=e

Trax—Tw = Gy

_ 1.061 x 108 x (2.54 x 10%)?

* 4X 22.5

= 7.605

= = 427.6 + 7.605 = 435.2 K

435.2 K|

"

max

Problem 9.9 : A copper wire has a radius of 2 mm and a length of 5 m. For what voltage

drop would the temperature rise at the wire axis be 10°C, if the surface temperature of the

wire is 20°C ?

volt?

k

Lorenz. number for copper = a = 228% 10° (ie )

0

Solution : Given Data :

Ta a

L = 5m

R = 2x10%m

We have, maximum temperature rise at r = 0

PR?

Tox To = 4 ikke

ee a

st Phenomena ae,

te erent dents ond j voltage drop are relate

ecu

Le ky

2 Re

Daag My = (ke BL) ate,

IE? R?

= LF ak ky

BER?

- Je)

EB? =

E =

z oe a — 93x 10

= 5000 (1.49 x 10) (64.1) = 40 volt

E = 40 volt

Problem 9.10 : Heat is being generated uniformly by a chemical reaction ii

cylinder of radius 91.44 mm. The generation rate is constant at 46.6 W/m*. The

the cylinder are cooled so that wall temperature is held constant at 311K. The

conductivity is 0.865 W/m-K. Calculate the centreline temperature.

Solution :

r = 914x10%m

S, = 46.6 W/m®

k = 0.865 Wim-K

1, =siK

+: The temperature rise in cylinder,

2

_ 46.6 x (91.4 x 10-3)?

4x 0.865

= 0.1125

Troe = $11 +0.1125=31111K

Trae = 311.11 K

~ ,

aii, O82 dosed

3000 * 0.138 * 0.138 * a9

@ = 293.36 W/m?

rate of heat transfer per unit area of wall,

a= 5h ty

a x

hy k

= ,-my= aT)

;

293.36 = 3000(1100-T,)

T, = 1099.9K

ae a, =T,)

1

293.36 = oa (1099.9 -T,)

1099.9-T, = 255.09

[T, = 844.81 K

perature at the interface T, = 844.81 K]

blem 9.13 : A furnace wall consists of 3 layers as shown below. First layer is of

tory bricks, second is of insulating bricks and third layer is of steel plate 0.25 inch

R.B. TBs Steel

tenp. SS —————————

9.34 i

ive minimum total wall thickness,

ickness of each layer to give minimum ae

Brie call A Btwft?-hr. Assume the layer is in good the

through the wall is

following information is available.

S ‘Thermal conductivity

[ Material | Max. eens Btwhr-ft°F

oe oe OOrA 2 | 2000°F

5 3.6

“a 18

2600°F

RF 18

LF 2000°F

Steel 2

For steel,

26.1

5000 x 0.02

Tle oe

T, = 103.83 °F)

ee rae Rar)

nO aan

+100

Thermal conductivity variation with temperature is given as

5 yee

Te 1

T-100

2000-100

(103.83 ~ 100;

Kroaaa = “Gow Son x(1.8-0.9)+0.9

3 = 0,9018 °F

1.8 + 0.9018

ky = “2+ 09018

= 1.35 Btwhr.ft.or

Solids and in Laminar F

Kggo9 ~ 1.8

=2e00= "5 _ 2600-100

36-18 = 2000-100

2600 = 4.168 Btu/hr.ft.°F

2

= 3.884 Bewhr.ft.°F

= 2600-2000

¥9/3.884

X) = 0.466 ft.

fe x,

jem 9.14 : Saturated steam at 0.276 MPa flows inside a steel pipe having an inside

of 2.09 cm and an outside diameter of 2.67 cm. The convective coefficients on the

ind outer pipe surfaces may be taken as 5680 W/m?K and 22.7 W/m?-K,

ly. The surrounding air is at 204 K. Find the heat loss per meter of bare pipe and

having 3.8 cm thickness of 85% magnesia insulation on its outer surface,

1 ft, x, = 0.466 ft

ition : In the case of the bare pipe, there are three thermal resistances to be

Ry = Reonvection tube =

Ry = Reonvection outside =

In (r,/r))

oe

Ry = Ronducton 2nkL

le inside temperature is at 0.276 MPa and saturated steam is at 404 K. The heat

T rate per meter of pipe is calculated as,

sam

q 5

404 — 294 pe)

= R, +R, +R;

110

1, lneln)

iA, 2nkL

TEMP. Distr), in Solids and in Laminar Plow

Heat transfer with fing 4 oo. 4T.

1

— ‘

' lo Min + Mvare|

200-30

0.1626,

= 1114.02 w

= 1114.02 ~ 639,09

= 474,93 W

percentage increase in rate of heat transfer

474.93,

* 639.09 “ 100 = 74.31%

Increase in rate of heat transfer

blem 9.21 : A glass rod of diameter 1.3 mm is 1 m long. One end is maintained at

boiling point of toluene at 110.6°C, ‘The other end is fixed to a block of ice. The

conduction along the rod is at Steady state. The heat of fusion of ice is

gm, k for glass = 0.86 W/m:K. Assume no heat loss from exposed surface of rod.

(i) Amount of heat transferred in watt; (ii) Number of grams of ice that melt in

lution : Given Data : d = 13x10%m

L=i1m

Heat of fusion of ice = 79.7 cal/gm

, there is no heat loss from exposed surface of rod,

s-sectional area of rod for heat conduction is

nd? _ (0.0013)

4 4

A = 1.32710 m?

ing Fourier's law of heat conduction,

Oy = i A-AT 9.86% 1.327% 10°

= 1,327 x 10% m?

(110.6 - 0)

1

Q = 0.1262 x 10% watt

Amount of heat transferred in 30 min

= 0.1262 x 10% x 30 x 60S

0.2271 J = 0.054 cal

‘ Amount of heat transfer in 30 min

‘Auibiink Obl mea= Heat of fusion of ice

0.054

= 797. = 0.00067 gm

9.46

Transport Phenom«

Problem 9.2:

velocity of outer cy

between cylinders

are at temperature of 70° C.

Viscosity

Density

Thermal conductivity

‘An oil is acting as a lubri

Jinder is 7908 rpm. Outer cy

is 0.027 em. What is the maximu

‘The physical properties of oil are,

cant for a pair

of cylindrical surface.

linder has a radius of 5.06 em and

m temperature in the oil if both

93.3 ep

1.22 gm/cm®

0.0055 cal/sec.em."C

93.3 x 10° Ne/m?

Solution : Given Data : n=

p = 1220 ke/m®

ke = 231 Jseem.°C = 2.31 Win."C

fe T7070.

R = 0.0506 m

N = 7908rpm

‘The angular velocity is given by,

@ 2 2EN _ 2xx7008

@ 60

= 827.7 rad/sec

V = R-@=0.0506 x 827.7

V = 41.88 m/s

We have, the temperature distribution in coaxial cylinders.

fia ea Re:

io, 9 Br b(1-5)

where, 1 nee

kb (T, -T,)

Br(t, -T,) = HY"

b-T) =

T-1, =F cr,-T,) 2H x, x

For temperature to be maximum 2k o( 7.

aT

dx = 0

Differentiati

ating above e

quation, we

” get

aT

dx ~

ort Phenomena a

Solids and in Laminar Flow

ature will be maximum at the centre,

(Toes eT i ete ed

Was aie 1-3)

Says

* “ak

= 92.3% 10 x 41.88

8x23

Tyo >70 = 8.798

[Tmax = 78.79°C|

blem 9.23 : Water and air are separated by a mild-steel plane wall. It is proposed to

the heat transfer rate between these fluids by adding straight rectangular fins of

thickness and 2.5 em length, spaced 1.27 em apart. The air side and water side

sfer coefficients may be assumed constant with values of 11.4 and 256 W/mK,

ively. Determine the percent change in total heat transfer when fins are placed on

jater side, (b) the air side and (c) both sides.

tion : Let us consider 1 m? section of the wall. The areas of the primary surface and

s are

A, = 1m? 79 fins) am] aa

= 0.9m?

A, = 79(1) (2) - (0.025)] +0.1

= 4,05 m?

h

les of fin efficiency can now be determined from a graph of Le\f j¢¢_ versus ny.

h 4 ae

LeVice = 9975| 49.9 x 0.00127

kt

= 0.362

12

for the water side, LeVie = 0.025| ax5,sator2t|

LI

Transport Phenomena __ 19:56 —

ation (3) becomes,

Equa

(ty TB

in terms of radius 'r’

le i

‘This equation describes temperature profil

(c) Heat flux at surface is,

dT

alen = ae

(using equation ( 2))

w

acy

Rig

a kg = 7) {using equation (a))

ton's law of cooling at surface,

Also, by New!

Shaya)

Gr|r-R

Equating equations (4) and (5), we get

k (Tp - T.)

pore h(T, -T.)

Problem 9.28 : Derive the expression for heat flux for the composite cylinders of

ry Tp respectively.

Solution : The thermal energy balance for the cylindrical element of thickness

can be given by,

f

Ge of thermal) Ca of thermal

enereyin J 7. fenergyOugey 7 a

(Qn qy)|,- @nrL ar lesa =

Dividing by '2narL’,

‘i got fe

lim T° Gr lo+an7 Tr

ar>0 ie

d

ar fa) = 0

Tem. Dist. in Solids and in Laminar Flow

9.14

tegrating equation (A), we get

dy = constant =r, q, od

ly, we can have

ray = 14,

23

ray, =a

ituting Fourier's law in equation (1),

0 pot

Tae =a

(T, -T): ae n(2) (2)

ilarly, (ye pass i in(72) ; (3)

(T, —), pase (2) w)

Newton's law of cooling,

a? = h,(T,-T,)

01

qT _%*% 4s)

(T, -T,) = Feet

as

1) es

(i

195 =ra =r, 4}

(6)

-T) =i

9.58 ‘Temp. Distri. in Solids and in

Transport Phenomena feeb a

On adding equations (2), (3), (4), (5) and (6), we have,

Ty

In

1 | In (r/r,) Tp

(T,-y) = Rent RT * kt kee

In

Gi

Also, the total rate of heat flux transferred

U, (T,-T,), where,

qo

U, = Overall heat transfer coefficient

Q, = 4, (2mr,L) = 2nL (T,-T,)U

In general,

where,

In general,

Problem 9.29 : Derive the expression for heat flux for composite sph.

Solution : Refer Fig. 9.14 of previous problem. a

The thermal energy balance is given by,

(Bate of thermal ) a (Rate of thermal

energy In energy Out ei) = 0

Care? | _ deck

Dividing by azar (r+ar) = 0

lim (r7q%) 5

aro lesan (98),

Ar a9

Eq)

tograting equation (A), we have, Tem in Solids and in Laminar

qe 6

ilarly, Pq? _

2 28

r eee

qr =rq

ituting Fourier’s law, we get,

oa, @

art

wouter

dr

tegrating, we have

2

Coreen alee

ei

14 ee

* wee) (2)

2

Tod) (1

(T,-1) = 2 (eyes) (8)

1%

ha, oir k

(T,-T,) = 3a ae) a)

Newton's law of cooling,

o1

Gg subs, a),

01 2

GF

T,-7, = +3

byt

2

(T,-7,) = BS 18)

h, %

2

Th

‘larly, (T,-7,) = 23 6)

hg - rg

ing all equations from (1) to (6),

2 1 2 2 eee

(T,-T,) = rp af teeane-s +h (7,73, )*

To

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Control Exp 1Document9 pagesControl Exp 11DS19CH011 Jashwanth C RNo ratings yet

- SedimentationDocument26 pagesSedimentation1DS19CH011 Jashwanth C RNo ratings yet

- Mini Project ReportDocument7 pagesMini Project Report1DS19CH011 Jashwanth C RNo ratings yet

- BPE GraphDocument1 pageBPE Graph1DS19CH011 Jashwanth C RNo ratings yet

- BIOCHEMDocument8 pagesBIOCHEM1DS19CH011 Jashwanth C RNo ratings yet

- Freeze DryingDocument31 pagesFreeze Drying1DS19CH011 Jashwanth C RNo ratings yet

- Cell DisruptionDocument18 pagesCell Disruption1DS19CH011 Jashwanth C RNo ratings yet

- Enzyme KineticsDocument23 pagesEnzyme Kinetics1DS19CH011 Jashwanth C RNo ratings yet

- Internship Report SD 2Document20 pagesInternship Report SD 21DS19CH011 Jashwanth C R0% (1)

- Mod2, Heads, FlangesDocument27 pagesMod2, Heads, Flanges1DS19CH011 Jashwanth C RNo ratings yet

- M&E - 2 OrganisingDocument31 pagesM&E - 2 Organising1DS19CH011 Jashwanth C RNo ratings yet

- Rapid Hydrothermal Method For The Preparation of Carbon Quantum Dots in TheDocument4 pagesRapid Hydrothermal Method For The Preparation of Carbon Quantum Dots in The1DS19CH011 Jashwanth C RNo ratings yet

- 19Ma2Icmat Module 5 - Elementary Numerical MethodsDocument4 pages19Ma2Icmat Module 5 - Elementary Numerical Methods1DS19CH011 Jashwanth C RNo ratings yet

- Dayananda Sagar College of EngineeringDocument3 pagesDayananda Sagar College of Engineering1DS19CH011 Jashwanth C RNo ratings yet

- Dayananda Sagar College of Engineering-Bangalore (Autonomous Institution Affiliated To VTU, Belgaum)Document1 pageDayananda Sagar College of Engineering-Bangalore (Autonomous Institution Affiliated To VTU, Belgaum)1DS19CH011 Jashwanth C RNo ratings yet