Professional Documents

Culture Documents

Deluge Valve Model-H3

Uploaded by

AJ MolinaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deluge Valve Model-H3

Uploaded by

AJ MolinaCopyright:

Available Formats

DELUGE VALVE MODEL-H3

(DUCTILE IRON)

TECHNICAL DATA

MODEL H3-Ductile Iron ASTM A

536-77 GRADE 65-45-12

NOMINAL SIZE 200, 150, 100, 80 and 50NB

SERVICE PRESSURE 1.4 to 17.5 Bar

(20 to 250 PSI)

THREADED OPENING BSPT

MOUNTING Vertical or Horizontal

mounting

FACTORY 35 Kg./sq.cm. (500 PSI)

HYDROSTATIC

LISTED

TEST PRESSURE 9P76

FLANGE CONNECTION ANSI B 16.5 #150FF

(RF-Optional) pressure design.On detection of fire the top chamber

WET PILOT As per graph in the is vented to atmosphere through the outlet port via

SPRINKLER catalogue opened actuation devices. The top chamber pressure

HEIGHT LIMITATION cannot be replenished through the restricted inlet

port, and the upward force of the supply pressure

NET WEIGHT 200 NB - 153 Kg lifts the clapper allowing the water flow to the system

WITHOUT TRIM 150 NB - 79 Kg piping network and alarm devices.

100 NB - 50 Kg

80 NB - 35 Kg TRIM DESCRIPTION

50 NB - 32 Kg

The trims are functionally termed as Dry Pilot Trim,

FINISH RAL 3000 Wet Pilot Trim, Electric Trim and Test and Alarm Trim

APPROVAL UL Listed as per the mehod of actuation of the deluge valve.

ORDERING 1. Size of valve The functionality of these trims is described below..

INFORMATION 2. Flange specification a) DRY PILOT TRIM (PNEUMATIC RELEASE)

3. Valve trim vertical or

horizontal Dry pilot operation uses a pilot line of closed

4. Trim type Sprinkles/QB detectors containing air under

pressure, located in the areato be protected.

It requires regulated dry air supply with main supply

DESCRIPTION point through restricted orifice. The air pressure

Deluge Valve is known as a system control valve in a to bemaintained as specified in the catalogue of

deluge system, used for fast application of water in a Dry Pilot Actuator. The pilot line is connected to air

spray system. Deluge valve protects areas such as inlet side of actuator. The top chamber of the

power transformer installation, storage tank, conveyor deluge valve is connected to water inlet side of

protection and other industrial application etc. With actuator.

the addition of foaming agent deluge valve can be used When there is an air pressure drop, or due to

to protect aircraft hanger and inflammable liquid fire. release of any of the release device on detection

of fire, the diaphragm of actuator is lifted and

VALVE OPERATION allows the water to drain. This releases the water

HD Deluge valve is a quick release, hydraulically pressure in the top chamber of the deluge valve,

operated diaphragm valve. It has three chambers, allowing the deluge valve to open and water to flow

isolated from each other by the diaphragm operated into the system piping & alarm devices.

clapper and seat seal. While in SET position, water Recommended air supply pressure for dry pilot

pressure is transmitted through an external bypass trim system is 3.5 kg/sq.cm.

check valve and restriction orifice from the system User must install non return valve at air supply

supply side to the top chamber, so that supply connection to deluge valve trim.

pressure in the top chamber act across the diaphragm

operated clapper which holds the seat against the In dry pilot trim, an actuator (DPA) is provided.

inlet supply pressure because of the differential An optional Pneumatic Reset Device (PRD) can

OCTOBER, 2014 PAGE 1 OF 16 HD 235

be provided, which acts as a manual reset device TRIM TYPES

in the dry pilot line.

The trims are designated as follwing.

b) WET PILOT TRIM (HYDRAULIC RELEASE)

W =Wet Pilot trim. D = Dry Pilot Trim

Wet pilot operation uses a pilot line of closed

Sprinklers/QB detectors containing pressurized a) Type ET-W and ET-D

water, supplied through the upstream side of This type of trim is basic trim required to

the Deluge valve, through a restricted orifice. All operate the deluge valve. A solenoid valve for

the release lines are connected to a common electric remote actuation and pressure switch

release line. Due to release of any one of the for sensing & announciation are optional.

release device, the water pressure in the top

chamber of the Deluge valve drops and the Deluge b) Type ETW-D and ETD-D

valve opens.

This trim type is a combination of components

c) ELECTRIC RELEASE TRIM of the ET trim along with the drip and drain

trim. A solenoid valve for electric remote actuation

To actuate a Deluge valve electrically, a solenoid and pressure switch for sensing & announciation

valve is provided to drain the water from the top are optional.

chamber of the Deluge valve. A pressure switch is

provided to activate an electric alarm, to shut c) Type ETW-T and ETD-T

down the desired equipment or to give “Tripped”

This trim type is a combination of components of

indication of the Deluge valve. In addition to this a

the ET trims along with the test and alarm trim.

pressure switch can also monitor “Low air

In dry pilot trim, an actuator DPA-H1 is provided

pressure” and “Fire condition” when used in dry

with optional Pneumatic Reset Device (PRD-1).

pilot air line.

A solenoid valve for electric remote actuation

d) TEST AND ALARM TRIM and pressure switch for sensing & announciation

are optional.

This trim is supplied with a test valve is provided

to test thenormal operation of the sprinkler alarm d) Type NT-W and NT-D

bell. The sprinkler alarmcan be supplied additionally,

This trim type is a combination of components of

which bells on actuation of the Deluge valve.

the ET trim along with the test and alarm trim

e) DRAIN AND DRIP TRIM as well as the drip and drain trim. A solenoid valve

for electric remote actuation and pressure switch

This consists of main and system drain valve in for sensing & announciation are optional.

addition with drip valve.

TRIM TRIM DESCRIPTION MOUNTING SCHEMATIC

MODEL NO.

NO.

ETW Basic Wet Pilot Trim Vertical Schematic 1

ETD Basic Dry Pilot Trim Vertical Schematic 2

ETW-T Basic Wet Pilot Trim with Test & Alarm Trim Vertical Schematic 3

ETD-T Basic Dry Pilot Trim with Test & Alarm Trim Vertical Schematic 4

ETW-D Basic Wet Pilot Trim with Drip & Drain Trim Vertical Schematic 5

ETD-D Basic Dry Pilot Trim with Drip & Drain Trim Vertical Schematic 6

NTW Basic Wet Pilot Trim with Test & Alarm Trim and Drip & Drain Trim Vertical Schematic 7

NTD Basic Dry Pilot Trim with Test & Alarm Trim and Drip & Drain Trim Vertical Schematic 8

ETW Basic Wet Pilot Trim Horizontal Schematic 9

ETD Basic Dry Pilot Trim Horizontal Schematic 10

ETW-T Basic Wet Pilot Trim with Test & Alarm Trim Horizontal Schematic 11

ETD-T Basic Dry Pilot Trim with Test & Alarm Trim Horizontal Schematic 12

ETW-D Basic Wet Pilot Trim with Drip & Drain Trim Horizontal Schematic 13

ETD-D Basic Dry Pilot Trim with Drip & Drain Trim Horizontal Schematic 14

NTW Basic Wet Pilot Trim with Test & Alarm Trim and Drip & Drain Trim Horizontal Schematic 15

NTD Basic Dry Pilot Trim with Test & Alarm Trim and Drip & Drain Trim Horizontal Schematic 16

OCTOBER, 2014 PAGE 2 OF 16 HD 235

RESETTING PROCEDURE FOR THE open the deluge valve. Close the upstream side

stop valve immediately

DELUGE VALVE

(iii) Reset the valve as per the procedure given

(i) Close the upstream side stop valve provided below

under heading “RESETTING PROCEDURE FOR THE

the deluge valve

DELUGE VALVE”

ii) Open both the drain valves/ drain plugs and close

when the flow of water has ceased INSPECTION AND MAINTENANCE

(iii) Close the release device/replace the Sprinkler if Installed system piping network must be flushed

release was through Sprinkler/QB Detector properly before placing the Deluge valve in service.

iv) Inspect and release if required, or close the A qualified and trained person must commission the

section of the detection system subjected to system. After few initial successful tests, an authorized

“Fire condition” person must be trained to perform inspection and

testing of the system. It is recommended to have

(v) In case of dry pilot detection system, open the air regular inspection and test run of the system as per

supply valve to build-up air pressure. Open the NFPA guideline or in accordance to the organisation

priming valve fully. Open the upstream side of the having local jurisdiction.

stop valve provided below the Deluge valve. No

water should flow into the system (i) WARNING

vi) Where priming shut off valve is provided for Inspection and testing is to be carried out only by

resetting, in addition to above steps press the authorised and trained personnel. DO NOT TURN

knob on actuator while resetting OFF the water supply or close any valve to make

repair(s) or test the valve, without placing a

CAUTION roving fire patrol in the area covered by the

system. Also inform the local security personnel

(a) Do not close the priming valve, downstream and

and central alarm station, so that there is no

upstream stop valves, while the system is in

false alarm signal.

service

It is recommended to carry out physical inspection

(b) The releasing device must be maintained in the

of the system at least twice in a week. The

open position, when actuated, to prevent the

inspection should verify that all the control valves

deluge valve from closure if anti shut off valve is

are in proper position as per the system

not provided

requirement and that there are no damages to

(c) While using a Deluge valve in the wet pilot system any component.

the height and the length of the wet pilot

The frequency of inspections must be increased

detection line is to be limited as shown in

in the presence of contaminated water supplies,

the wet pilot sprinkler height limitation graph

corrosive/ scaling water supplies, and corrosive

(d) Do not connect the Sprinkler Alarm outlet drain atmospheres.

line to close a common drain as it may create

back pressure and Sprinkler Alarm may not (ii) NORMAL CONDITION

function (a) All main valves are open and are sealed with

(e) Deluge valve must have support to absorb sudden tamper proof seal

opening or closing vibration shock to the piping (b) Drain valves must be kept closed

(f) To avoid water damage, take precautions when (c) No leak or drip is detected from the drip valve

opening the water supply main control valve, since

water will flow from all open system valves (d) All the gauges except the system side water

pressure gauge, should show the required

(g) The responsibility of maintenance of the protection pressure

system and devices in proper operating condition

lies with the owner of the system. (e) There should be no leakage in the system

(iii) NORMAL CONDITION TEST

SYSTEM TESTING PROCEDURE

(a) The system should be checked for normal

(i) Keep the upstream side of the stop valve partially

condition at least once in a week

open. To avoid water flow to system side close the

system side stop valve. This valve is to be kept in (b) Test the sprinkler alarm bell or electric alarm

open position after the testing is completed by turning the alarm test valve to the test

position. The alarm should sound. This test should

(ii) Let any of the release devices to trip. This will

be carried out at least once in a week

result in a sudden drop of water pressure in

the deluge valve top chamber which in turn will

OCTOBER, 2014 PAGE 3 OF 16 HD 235

(c) Depress the drip valve knob. Significant

accumulation indicates a possible seat leakage

(d) Conduct the water flow test as per the procedure

of system testing at least once a month

(iv) PERIODIC CHECK

Conduct the water flow test by actuating few of

the release devices provided in the system. Clean all

strainer(s) and priming line restriction. This test is to

be carried out at least once in three months.

ABNORMAL CONDITION

(i) ALARM FAILS TO SOUND

(a) Check for any obstruction in the alarm test

line, make certain that the sprinkler alarm is free

to operate

(b) If an electric alarm is provided, check the

electrical circuitry to the alarm

(ii) FALSE TRIPS

(a) Check for clogging in priming line, restriction

orifice check valve, priming valve & strainer

(b) Leakage in the release system

(c) The deluge air panel orifice clogged or low

supply pressure

(iii) LEAKAGE THROUGH THE DELUGE VALVE

(a) Damaged deluge valve seat or obstruction on

the seat face by foreign object

(b) Leakage in release system

(c) Partly clogged priming line restriction orifice

check valve

(d) Low air pressure on release system line or

leakage in release system

OCTOBER, 2014 PAGE 4 OF 16 HD 235

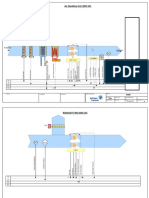

DELUGE VALVE MODEL - H3 SIZE 200 / 150 / 100 / 80/ 50 NB

20

19

18

17

16

15

14

13

12

11

10

6

21

4

3

OCTOBER, 2014 PAGE 5 OF 16 HD 235

DELUGE VALVE MODEL - H3 SIZE 200 / 150 / 100 / 80 / 50 NB

DIMENSION in millimeter (Approximate)

B

VALVE

NOMINAL A B

SIZE

200 NB 552 332

150 NB 462 282

100 NB 412 245

80 NB 372 232

50 NB 320 232

A

PART NO. QTY

ITEM MATERIAL

DESCRIPTION 200

NO. 200 150 100 80 50 150 100 80/50 SPECIFICATION

NB NB NB NB NB NB NB NB NB

1 NA NA NA NA NA HOUSING 1 1 1 1 DUCTILE IRON

2 8561 9783 9784 9791 9791 “O” RING 1 1 1 1 NEOPRENE RUBBER

3 4025 3993 4003 4017 4017 SEAT 1 1 1 1 STAINLESS STEEL *

4 9151 9112 9112 - - BOLT 8 4 4 - STAINLESS STEEL

5 4026 3994 4004 4018 4018 RUBBER CLAMP 1 1 1 1 DUCTILE IRON **

6 4027 4000 4005 4023 4023 RUBBER SEAT 1 1 1 1 NEOPRENE RUBBER

7 4034 3990 4011 4041 4041 CLAPPER 1 1 1 1 DUCTILE IRON **

8 4035 2427 2507 2786 2786 DIAPHRAGM 1 1 1 1 NEOPRENE RUBBER

9 4030 2424 2504 2788 2788 CLAMP RING 1 1 1 1 DUCTILE IRON **

10 8806 9151 9151 9187 9187 BOLT 12 8 8 8 STAINLESS STEEL

11 9986 9986 9986 9986 9986 “O” RING 1 1 1 1 NEOPRENE RUBBER

12 4029 3996 4007 4020 4020 SPINDLE 1 1 1 1 STAINLESS STEEL

13 9185 8838 8838 9185 9185 NUT 1 1 1 1 STAINLESS STEEL

14 9186 9184 9184 9186 9186 LOCK NUT 1 1 1 1 STAINLESS STEEL

15 2980 2979 2978 2977 2977 SPRING 1 1 1 1 STAINLESS STEEL

16 4033 3998 4010 3983 3983 ADAPTOR 1 1 1 1 BRASS

17 NA NA NA NA NA COVER 1 1 1 1 DUCTILE IRON

18 9008 9049 9051 8692 8692 BOLT 16 12 12 12 CARBON STEEL

19 9982 9982 9982 9982 9982 “O” RING 1 1 1 1 NEOPRENE RUBBER

20 2514 2514 2514 2514 2514 PLUG 1 1 1 1 STEEL PLATED

21 8843 - - - - ALLEN BOLT 6 - - - STAINLESS STEEL

NA - PART REPLACEMENT NOT AVAILABLE

* Stainless Steel is standard supply Bronze is optional supply.

** Ductile Iron is standard supply Bronze/Stainless Steel is optional supply.

OCTOBER, 2014 PAGE 6 OF 16 HD 235

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

ETW

OUTLET

TO DETECTION

LINE

**

PS2

PG

PG

SCV DV

RN

**

SV

OD

~

M

~

OD

INLET

SCHEMATIC 1

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

TO DETECTION

ETD LINE

PG

**

PS1

AIR SUPPLY

CV RN-A

OUTLET

**

PS2

PG DPA

PG

OD

CV DV

RN

**

SV

OD

~

M

~

OD

INLET

SCHEMATIC 2

ABBREVIATION & SYMBOLS

DV DELUGE VALVE VALVE SWING CHECK VALVE

SV SOLENOID VALVE --- BY USER ANGLE VALVE

G SPRINKLER ALARM (WMG) ** OPTIONAL DPA DRY PILOT ACTUATOR

M EMERGENCY RELEASE STATION STRAINER RN-A RESTRICTION NOZZLE (AIR LINE)

RN RESTRICTIOIN NOZZLE (PRIMING LINE) OD OPEN DRAIN SCV SWING CHECK VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH PG PRESSURE GUAGE

PS2 WATER FLOW PRESSURE ALARM SWITCH

OCTOBER, 2014 PAGE 7 OF 16 HD 235

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

ETWT

**

OUTLET

PS2 TO DETECTION

**

G LINE

SCV

OD PG

PG

SCV DV

RN

**

SV

OD

~

M

~

OD

INLET

SCHEMATIC 3

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

TO DETECTION

ETDT LINE

PG

**

PS1

AIR SUPPLY

SCV RN-A

**

OUTLET

PS2

**

G

SCV

OD PG DPA

PG

OD

SCV DV

RN

**

SV

OD

~

M

~

OD

INLET

SCHEMATIC 4

ABBREVIATION & SYMBOLS

DV DELUGE VALVE VALVE SWING CHECK VALVE

SV SOLENOID VALVE --- BY USER ANGLE VALVE

G SPRINKLER ALARM (WMG) ** OPTIONAL DPA DRY PILOT ACTUATOR

M EMERGENCY RELEASE STATION STRAINER RN-A RESTRICTION NOZZLE (AIR LINE)

RN RESTRICTIOIN NOZZLE (PRIMING LINE) OD OPEN DRAIN SCV SWING CHECK VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH PG PRESSURE GUAGE

PS2 WATER FLOW PRESSURE ALARM SWITCH

OCTOBER, 2014 PAGE 8 OF 16 HD 235

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

OUTLET

TO DETECTION

ETWD LINE

**

PS2 DR.V

~

PG OD

PG

OD

OD

SCV DV

RN

**

SV

OD

~

M

~

OD

INLET

SCHEMATIC 5

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

ETDD TO DETECTION

LINE

PG

**

PS1

AIR SUPPLY

RN-A

OUTLET

SCV

**

PS2

DR.V

~

PG OD

PG

OD DPA

OD OD

SCV DV

RN

**

SV

OD

~

M

~

OD

INLET

SCHEMATIC 6

ABBREVIATION & SYMBOLS

DV DELUGE VALVE VALVE SWING CHECK VALVE

SV SOLENOID VALVE --- BY USER ANGLE VALVE

G SPRINKLER ALARM (WMG) ** OPTIONAL DPA DRY PILOT ACTUATOR

M EMERGENCY RELEASE STATION STRAINER RN-A RESTRICTION NOZZLE (AIR LINE)

RN RESTRICTIOIN NOZZLE (PRIMING LINE) OD OPEN DRAIN SCV SWING CHECK VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH PG PRESSURE GUAGE

PS2 WATER FLOW PRESSURE ALARM SWITCH

OCTOBER, 2014 PAGE 9 OF 16 HD 235

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

NTW TO DETECTION

LINE

**

OUTLET

PS2

**

G

DR.V

SCV

OD ~

PG OD

PG

OD

OD

SCV DV

RN

**

SV

OD

~

M

~

OD

INLET

SCHEMATIC 7

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

TO DETECTION

NTD LINE

PG

**

PS1

AIR SUPPLY

** SCV RN-A

OUTLET

PS2

**

G

DR.V

SCV

OD ~

PG OD

PG

OD DPA

OD OD

SCV DV

RN

**

SV

OD

~

M

~

OD

INLET

SCHEMATIC 8

ABBREVIATION & SYMBOLS

DV DELUGE VALVE VALVE SWING CHECK VALVE

SV SOLENOID VALVE --- BY USER ANGLE VALVE

G SPRINKLER ALARM (WMG) ** OPTIONAL DPA DRY PILOT ACTUATOR

M EMERGENCY RELEASE STATION STRAINER RN-A RESTRICTION NOZZLE (AIR LINE)

RN RESTRICTIOIN NOZZLE (PRIMING LINE) OD OPEN DRAIN SCV SWING CHECK VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH PG PRESSURE GUAGE

PS2 WATER FLOW PRESSURE ALARM SWITCH

OCTOBER, 2014 PAGE 10 OF 16 HD 235

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

ETW TO DETECTION

LINE

**

OD

~

SCV RN SV

M

~

PG OD

**

PS2

DV

INLET OUTLET

PG

SCHEMATIC 9

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

ETD TO DETECTION

LINE

PG

**

PS1

AIR SUPPLY

RN-A SCV

DPA

OD

** OD

~

RN M SV

~

PG OD

PS2 **

INLET

DV OUTLET

PG

SCHEMATIC 10

ABBREVIATION & SYMBOLS

DV DELUGE VALVE VALVE SWING CHECK VALVE

SV SOLENOID VALVE --- BY USER ANGLE VALVE

G SPRINKLER ALARM (WMG) ** OPTIONAL DPA DRY PILOT ACTUATOR

M EMERGENCY RELEASE STATION STRAINER RN-A RESTRICTION NOZZLE (AIR LINE)

RN RESTRICTIOIN NOZZLE (PRIMING LINE) OD OPEN DRAIN SCV SWING CHECK VALVE

PS1 WATER FLOW PRESSURE ALARM SWITCH PG PRESSURE GUAGE

PS2 LOW AIR ALARM PRESSURE SWITCH

OCTOBER, 2014 PAGE 11 OF 16 HD 235

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

ETWT TO DETECTION

LINE

**

OD

~

SCV RN SV

M

~

PG

**

PS2

OD

** G

~

OD

SCV

DV

INLET OUTLET

PG

SCHEMATIC 11

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

ETDT TO DETECTION

LINE

PG

**

PS1

AIR SUPPLY

RN-A SCV

DPA

OD

** OD

~

RN M SV

~

PG

**

PS2

OD

** G

~

OD

DV

INLET OUTLET

PG

SCHEMATIC 12

ABBREVIATION & SYMBOLS

DV DELUGE VALVE VALVE SWING CHECK VALVE

SV SOLENOID VALVE --- BY USER ANGLE VALVE

G SPRINKLER ALARM (WMG) ** OPTIONAL DPA DRY PILOT ACTUATOR

M EMERGENCY RELEASE STATION STRAINER RN-A RESTRICTION NOZZLE (AIR LINE)

RN RESTRICTIOIN NOZZLE (PRIMING LINE) OD OPEN DRAIN SCV SWING CHECK VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH PG PRESSURE GUAGE

PS2 WATER FLOW PRESSURE ALARM SWITCH

OCTOBER, 2014 PAGE 12 OF 16 HD 235

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

ETWD TO DETECTION

LINE

**

OD

~

SCV RN SV

M

~

PG OD

**

PS2

DV

INLET OUTLET

PG

DR.V ~

OD

~

OD

OD

SCHEMATIC 13

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

ETDD TO DETECTION

LINE

PG

**

PS1

AIR SUPPLY

RN-A SCV

DPA

OD

** OD

~

RN M SV

~

PG OD

**

PS2

DV

INLET

PG

DR.V ~

OD

~

OD

OD

SCHEMATIC 14

ABBREVIATION & SYMBOLS

DV DELUGE VALVE VALVE SWING CHECK VALVE

SV SOLENOID VALVE --- BY USER ANGLE VALVE

G SPRINKLER ALARM (WMG) ** OPTIONAL DPA DRY PILOT ACTUATOR

M EMERGENCY RELEASE STATION STRAINER RN-A RESTRICTION NOZZLE (AIR LINE)

RN RESTRICTIOIN NOZZLE (PRIMING LINE) OD OPEN DRAIN SCV SWING CHECK VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH PG PRESSURE GUAGE

PS2 WATER FLOW PRESSURE ALARM SWITCH

OCTOBER, 2014 PAGE 13 OF 16 HD 235

SCHEMATIC FOR WET PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

NTW TO DETECTION

LINE

**

OD

~

SCV RN SV

M

~

PG OD

**

PS2

** G

~

OD

SCV

DV

INLET OUTLET

DR.V ~

OD

~

OD

OD

SCHEMATIC 15

SCHEMATIC FOR DRY PILOT BASIC TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

TO DETECTION

NTD LINE

PG

**

PS1

AIR SUPPLY

RN-A SCV

DPA

OD **

SV

OD

~

RN M

~

PG **

PS2

OD

** G

~

OD

DV

INLET OUTLET

PG

DR.V ~

OD

~

~ OD

OD

SCHEMATIC 16

ABBREVIATION & SYMBOLS

DV DELUGE VALVE VALVE SWING CHECK VALVE

SV SOLENOID VALVE --- BY USER ANGLE VALVE

G SPRINKLER ALARM (WMG) ** OPTIONAL DPA DRY PILOT ACTUATOR

M EMERGENCY RELEASE STATION STRAINER RN-A RESTRICTION NOZZLE (AIR LINE)

RN RESTRICTIOIN NOZZLE (PRIMING LINE) OD OPEN DRAIN SCV SWING CHECK VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH PG PRESSURE GUAGE

PS2 WATER FLOW PRESSURE ALARM SWITCH

OCTOBER, 2014 PAGE 14 OF 16 HD 235

SPRINKLER HEIGHT LIMITATION

DV 200NB DV 150NB

KG/SQCM KG/SQCM

2 4 6 8 10 12 14 16 18

2 4 6 8 10 12 14 16 18 240

220. 70

65 T

220. FEE

200 60 25

65

ET 200 ET 60

180 FE 55 FE

25 0

25

MAXIMUM PILOT LINE HIGHT - FEET ------

MAXIMUM PILOT LINE HIGHT - FEET ------

T 50 180 T 55

160 EE EE

0F 0F 50

25 45 160 50

140 T 45

EE 40 140

0F

120 50 40

METERS

METERS

35

120

35

100 30

100 30

80 25

80 25

20

60 20

15 60

40 15

10 40

10

20 5 20 5

0

0

20 50 100 150 200 250

20 50 100 150 200 250

SYSTEM SUPPLY PRESSURE - PSI ------ SYSTEM SUPPLY PRESSURE - PSI ------

EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120 EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120

DV 100NB DV 80NB

KG/SQCM KG/SQCM

2 4 6 8 10 12 14 16 18 2 4 6 8 10 12 14 16 18

240 220.

70 65

220. 200

65 60

200 T

ET 60 180 F EE 55

FE

25

MAXIMUM PILOT LINE HIGHT - FEET ------

MAXIMUM PILOT LINE HIGHT - FEET ------

180 25 55 50

EET 160

EE

T

0F 0F

50

160 45

25 140 25

45

140 ET T

40

0 FE EE

50

40 120 0F

METERS

METERS

35

120 50

35

100 30

100 30

80 25

80 25

20

20 60

60

15

15

40 40

10 10

20 20 5

5

0 0

20 50 100 150 200 250 20 50 100 150 200 250

SYSTEM SUPPLY PRESSURE - PSI ------ SYSTEM SUPPLY PRESSURE - PSI ------

EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120 EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120

DV - 50NB

KG/SQCM

2 4 6 8 10 12 14 16 18

220.

65

200 60

180 ET 55

FE

MAXIMUM PILOT LINE HIGHT - FEET ------

25 50

160 T

EE

0F 45

140 25

40

T

120 EE

0F

METERS

50 35

100 30

80 25

20

60

15

40

10

20 5

0

20 50 100 150 200 250

SYSTEM SUPPLY PRESSURE - PSI ------

EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120

OCTOBER, 2014 PAGE 15 OF 16 HD 235

DELUGE VALVE MODEL H2

Nominal Pressure Loss vs Flow

(* Flow at 15 feet per second [4.57 meter per second])

40

30

20

Nominal Pressure Loss in Pounds per Square Inch (PSI)

10

8

6 * *

5

* *

)

4

CH

IN

3

(8

CH

)

*

B

2 CH

IN

N

0

IN

(6

20

)

CH

(4

B

N

IN

B

)

0

N

CH

(3

15

1.0

0

10

B

IN

0.8

(2

80

B

0.6

N

50

0.5

0.4

0.3

0.2

0.1

100 200 300 400 600 800 1000 2000 3000 5000 7000 10000 20000

Flow Rate in Liters Per Minute (LPM)

* 2.3 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having flow of 594 LPM thru 50NB DV

* 4.7 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having flow of 1308 LPM thru 80NB DV

* 4.7 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having flow of 2255 LPM thru 100NB DV

* 7.5 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having flow of 5117 LPM thru 150NB DV

* 8.4 PSI Pressure loss @ 15 feet per second (4.57 met/sec) velocity having flow of 8854 LPM thru 200NB DV

LIMITED WARRANTY

HD FIRE PROTECT PVT. LTD. hereby referred to as HD FIRE warrants to the original purchaser of the fire protection products manufactured by HD FIRE and to any other person

to whom such equipment is transferred, that such products will be free from defect in material and workmanship under normal use and care, for two (2) years from the date of

shipment by HD FIRE. Products or Components supplied or used by HD FIRE, but manufactured by others, are warranted only to the extent of the manufacturer’s warranty.

No warranty is given for product or components which have been subject to misuse, improper installation, corrosion, unauthorized repair, alteration or un-maintained.

HD FIRE shall not be responsible for system design errors or improper installation or inaccurate or incomplete information supplied by buyer or buyer’s representatives.

HD FIRE will repair or replace defective material free of charge, which is returned to our factory, transportation charge prepaid, provided after our inspection the material is

found to have been defective at the time of initial shipment from our works. HD FIRE shall not be liable for any incidental or consequential loss, damage or expense arising directly

or indirectly from the use of the product including damages for injury to person, damages to property and penalties resulting from any products and components manufactured

by HD FIRE. HD FIRE shall not be liable for any damages or labour charges or expense in making repair or adjustment to the product. HD FIRE shall not be liable for any

damages or charges sustained in the adaptation or use of its engineering data & services. In no event shall HD Fire’s product liability exceed an amount equal to the sale price.

The foregoing warranty is exclusive and in lieu of all other warranties and representation whether expressed, implied, oral or written, including but not limited

to, any implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations are hereby cancelled.

NOTICE :

The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also with

the provision of government codes or ordinances wherever applicable.

The information provided by us are to the best of our knowledge and belief, and are general guidelines only. Site handling and installation control is beyond our reach.

Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever, resulting from our suggestion, information, recommendation or

damages due to our product.

Product development is a continuous programme of HD FIRE PROTECT PVT. LTD. and hence the right to modify any specification without prior notice is reserved with

the company.

HD FIRE PROTECT PVT. LTD.

Protecting What Matters Most to You

OCTOBER, 2014 PAGE 16 OF 16 HD 235

You might also like

- Idoc - Pub - 13 Deluge Valve HD Fire PDFDocument17 pagesIdoc - Pub - 13 Deluge Valve HD Fire PDFĐinh TrọngNo ratings yet

- Deluge Valve Technical DataDocument16 pagesDeluge Valve Technical DataboxyfunNo ratings yet

- Deluge Valve Technical DataDocument16 pagesDeluge Valve Technical DataNata 1986No ratings yet

- Deluge Valve C1Document16 pagesDeluge Valve C1Rajadurai SinghNo ratings yet

- Deluge Valve - SD-DVH2Document16 pagesDeluge Valve - SD-DVH2Vijay Gaikwad0% (1)

- Valves Deluge Valve Model h2Document16 pagesValves Deluge Valve Model h2peerlessNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3Jaime RodriguezNo ratings yet

- Deluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataDocument16 pagesDeluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataNethajiNo ratings yet

- Deluge Valve Modelh5Document16 pagesDeluge Valve Modelh5Mariana HusainNo ratings yet

- Protect Critical Assets with Ductile Iron Deluge ValvesDocument16 pagesProtect Critical Assets with Ductile Iron Deluge ValvesPeter Keith Vela RuizNo ratings yet

- Valves Deluge Valve Model h3Document16 pagesValves Deluge Valve Model h3RaviNo ratings yet

- 3 Delugevalve HDocument14 pages3 Delugevalve HHarishNo ratings yet

- Deluge Valve Model-H3 Technical Data SheetDocument16 pagesDeluge Valve Model-H3 Technical Data SheetPedro Caminos BolanosNo ratings yet

- Valves Deluge Valve Model h3-bkp-03-04-2018Document16 pagesValves Deluge Valve Model h3-bkp-03-04-2018Benny Kurniawan LimNo ratings yet

- Deluge Valve ADocument14 pagesDeluge Valve AirshadNo ratings yet

- Deluge Valve ADocument14 pagesDeluge Valve AKuldeep SinghNo ratings yet

- Deluge Valve: Model-A (Cast Iron)Document14 pagesDeluge Valve: Model-A (Cast Iron)Jaime RodriguezNo ratings yet

- Deluge Valve - SD-DVA PDFDocument15 pagesDeluge Valve - SD-DVA PDFboxyfunNo ratings yet

- HD 101 Deluge Valve Model ADocument15 pagesHD 101 Deluge Valve Model APiyush JainNo ratings yet

- Wet Pilot TypeDocument15 pagesWet Pilot TypeDipanjan ChakrabartiNo ratings yet

- CAST IRON DELUGE VALVE MODEL A TECHNICAL DATADocument26 pagesCAST IRON DELUGE VALVE MODEL A TECHNICAL DATABenny Kurniawan LimNo ratings yet

- Deluge Valve Technical DataDocument14 pagesDeluge Valve Technical DataKeshodbana KeshodNo ratings yet

- Tyco Alarm Check Valve AV-1 300 PDFDocument26 pagesTyco Alarm Check Valve AV-1 300 PDFRomyrNo ratings yet

- Deluge Valve Technical Data SheetDocument14 pagesDeluge Valve Technical Data SheetSiddharth GupteNo ratings yet

- hd127 Double Interlock Elec Elec Release - 2Document6 pageshd127 Double Interlock Elec Elec Release - 2Benny Kurniawan LimNo ratings yet

- DV 5 TycoDocument17 pagesDV 5 Tycoleonardo ramirezNo ratings yet

- 510 Model DDX Deluge Valve - 2Document8 pages510 Model DDX Deluge Valve - 2Edi Yahya S. NasutionNo ratings yet

- Deluge Valve 6inDocument8 pagesDeluge Valve 6inJojo Abordo FernandezNo ratings yet

- Deluge ValveDocument3 pagesDeluge ValveFarhan AhmedNo ratings yet

- HvwsDocument9 pagesHvwsHarishNo ratings yet

- Deluge Valve ADocument14 pagesDeluge Valve APatel MehulkumarNo ratings yet

- PCSU Chapter 6Document16 pagesPCSU Chapter 6rawanisephiaNo ratings yet

- Etécnica Delugevalve ADocument16 pagesEtécnica Delugevalve Avaldemarborges6929No ratings yet

- 729 Double Interlock Preaction DDXDocument22 pages729 Double Interlock Preaction DDXfarshan296015No ratings yet

- Section 2 Deluge Special Hazards Systems PDFDocument17 pagesSection 2 Deluge Special Hazards Systems PDFjulioagricola35No ratings yet

- TFP1090 08 2018 PDFDocument28 pagesTFP1090 08 2018 PDFBenga AdrianNo ratings yet

- Triplex Systems 4Document2 pagesTriplex Systems 4Eng.Gihad EladlNo ratings yet

- Reliable Bulletin 741 Rev. A Wet Pilot Line Single Interlock SystemDocument16 pagesReliable Bulletin 741 Rev. A Wet Pilot Line Single Interlock SystemDana Guerrero100% (1)

- Model A Deluge Valve Features and OperationDocument4 pagesModel A Deluge Valve Features and OperationmanbkkNo ratings yet

- Relief Valve and Trip Testing ProceduresDocument16 pagesRelief Valve and Trip Testing ProceduresDharshica MohanNo ratings yet

- Kidde Natura™ Inert Gas System IG-100 Nitrogen Agent Cylinder AssemblyDocument4 pagesKidde Natura™ Inert Gas System IG-100 Nitrogen Agent Cylinder AssemblyJoseph HoNo ratings yet

- Filesbulletins750.pdfx61662 3Document17 pagesFilesbulletins750.pdfx61662 3Ahmed Said AhmedNo ratings yet

- Duplex Tank Mounted Scroll Medical Air Plants With Desiccant Air Dryers 2 Through 5 HPDocument2 pagesDuplex Tank Mounted Scroll Medical Air Plants With Desiccant Air Dryers 2 Through 5 HPEng.Gihad EladlNo ratings yet

- Deaereator CapacityDocument8 pagesDeaereator Capacityedgardiaz5519No ratings yet

- Atr72 Air PDFDocument34 pagesAtr72 Air PDFEhsan Ul HaqueNo ratings yet

- Smith Meter VDR Vertical Deaerator SpecificationsDocument8 pagesSmith Meter VDR Vertical Deaerator SpecificationsClarkFedele27No ratings yet

- Techniical DetailDocument42 pagesTechniical DetailAhmed AbdelgawadNo ratings yet

- Series TD: Type TDL Type TDMDocument16 pagesSeries TD: Type TDL Type TDMAhmadNo ratings yet

- Progard H3Document15 pagesProgard H3afie pio pioNo ratings yet

- Models 69NT40-489-100 Series 69NT40-511,521& 531Document40 pagesModels 69NT40-489-100 Series 69NT40-511,521& 531cloviskrelling100% (1)

- VAV BoxDocument2 pagesVAV BoxCatherine MarianoNo ratings yet

- Soleusair Air Conditioner 10000 BtuDocument21 pagesSoleusair Air Conditioner 10000 BtuGreg JohnsonNo ratings yet

- Duplex Tank and Stack Mounted Systems 11Document2 pagesDuplex Tank and Stack Mounted Systems 11Eng.Gihad EladlNo ratings yet

- ERV Floating ProcedureDocument16 pagesERV Floating ProcedureDipti BhanjaNo ratings yet

- Model 2400 D: Pneumatic Indicating RelayDocument4 pagesModel 2400 D: Pneumatic Indicating Relayzinstr1No ratings yet

- 744 Double Interlock Preaction System Type D 8Document20 pages744 Double Interlock Preaction System Type D 8Nirmal KvNo ratings yet

- Model RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)Document4 pagesModel RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)asimnaqvi2008No ratings yet

- 5 Dehydrator Cibred LAB 4 MPDocument4 pages5 Dehydrator Cibred LAB 4 MPaximitedzNo ratings yet

- Valvula DesaireadoraDocument4 pagesValvula DesaireadoracccNo ratings yet

- NEW PUMP STATION PS-56A HVAC INSPECTION PLANDocument28 pagesNEW PUMP STATION PS-56A HVAC INSPECTION PLANأبو محمدNo ratings yet

- UniqueFire Water Flow Detector ProductsDocument4 pagesUniqueFire Water Flow Detector ProductsAJ MolinaNo ratings yet

- K Protect - 0121 A4 40mm50mmDocument4 pagesK Protect - 0121 A4 40mm50mmtechnocyclesale1 engineerNo ratings yet

- 2-01 Insulation Material (K-Foam - 0819)Document2 pages2-01 Insulation Material (K-Foam - 0819)AJ MolinaNo ratings yet

- Reading Piping and Instrumentation DiagramsDocument18 pagesReading Piping and Instrumentation DiagramsErra ShafiraNo ratings yet

- ACMV Tender Drawing-FFDocument1 pageACMV Tender Drawing-FFVipun RandeeraNo ratings yet

- Pampered Chef August Host SpecialDocument2 pagesPampered Chef August Host SpecialStillwater's Community ConnectionNo ratings yet

- Air Handling Unit (DDC 02)Document8 pagesAir Handling Unit (DDC 02)Anonymous qOBFvINo ratings yet

- 299509Document2 pages299509Shahed FacebookNo ratings yet

- ANSI-SAAMI Z299.5 2016 Abusive MishandlingDocument12 pagesANSI-SAAMI Z299.5 2016 Abusive Mishandlingbo cephusNo ratings yet

- R2 Four Basic Components of A Refrigeration System: #3 CondensersDocument50 pagesR2 Four Basic Components of A Refrigeration System: #3 CondensersAhmad NasrudinNo ratings yet

- Moog Proportional Valve PDFDocument11 pagesMoog Proportional Valve PDFJagmohan SinghNo ratings yet

- bản vẽ tài liệu tủ as380 30kWDocument28 pagesbản vẽ tài liệu tủ as380 30kWMảimêchinhchiếnVàYêuđươngNo ratings yet

- Piping MCQDocument4 pagesPiping MCQHibaNo ratings yet

- Catalogos OthDocument180 pagesCatalogos Othcristobal50% (2)

- Dokumen - Tips - Caterpillar Cat 14m Motor Grader Prefix b9j Service Repair Manual b9j00001 and UpDocument27 pagesDokumen - Tips - Caterpillar Cat 14m Motor Grader Prefix b9j Service Repair Manual b9j00001 and UpOrrego DanielNo ratings yet

- Understanding Vernier Calliper Screw Gauge and SpherometerDocument6 pagesUnderstanding Vernier Calliper Screw Gauge and SpherometerAnonymous vRpzQ2BLNo ratings yet

- A1 (2 3 4) F./... D 6905 Af/1Document3 pagesA1 (2 3 4) F./... D 6905 Af/1GERALD SIMONNo ratings yet

- Equipment List for Construction ProjectDocument1 pageEquipment List for Construction ProjectAriel AbastillasNo ratings yet

- Mercedes Benz Power Steering PumpsDocument10 pagesMercedes Benz Power Steering PumpsFilipposNo ratings yet

- Rock DrillDocument15 pagesRock DrillESRANo ratings yet

- 777EKLJDocument5 pages777EKLJJACOB MUDONHINo ratings yet

- APS SafetyDocument8 pagesAPS SafetyBLUE TOOTHNo ratings yet

- Impact Wrenches 1121EDocument12 pagesImpact Wrenches 1121Ekevintwink17 TwinkNo ratings yet

- Roll Taps 2017 WebDocument24 pagesRoll Taps 2017 Webxmen nor100% (1)

- Bits and Sockets Guide for Screwdriver ToolsDocument3 pagesBits and Sockets Guide for Screwdriver ToolsaceportgasNo ratings yet

- Types of Actuators Used in IoT DevicesDocument7 pagesTypes of Actuators Used in IoT DevicesnananananaNo ratings yet

- Renewal Parts YK (Stype F)Document56 pagesRenewal Parts YK (Stype F)Thang TV100% (2)

- MRT 1850CL-547741D-Rev.04-00Document171 pagesMRT 1850CL-547741D-Rev.04-00meNo ratings yet

- Star PVC Fitting List Yes 11111Document182 pagesStar PVC Fitting List Yes 11111SHIROMANY GadiyaNo ratings yet

- GH Manual 2014Document24 pagesGH Manual 2014Krisvell ArmentaNo ratings yet

- Technical Specification of Brick Laying MaterialsDocument13 pagesTechnical Specification of Brick Laying MaterialsMoe Zaw OoNo ratings yet

- Shacman series transmission parts catalogDocument2 pagesShacman series transmission parts catalogMarcos Armando Torrey MenaNo ratings yet

- VARIO Parts List and Exploded ViewDocument8 pagesVARIO Parts List and Exploded ViewRoberto Damian HernándezNo ratings yet