Professional Documents

Culture Documents

41 Acetylene

Uploaded by

AKHIL KUNNATHDASCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

41 Acetylene

Uploaded by

AKHIL KUNNATHDASCopyright:

Available Formats

Page Number

MATERIAL SAFETY DATA SHEET 1/5

Date: 28/10/2018

MSDS V1.1 Acetylene DG008G

Label 2.1: flammable F+ : Extremely NFPA RATINGS

gas. flammable

1 IDENTIFICATION OF THE SUBSTANCE / PREPARATION AND OF THE COMPANY / UNDERTAKING

Trade Name : Acetylene

Chemical Formula : C2H2

Chemical Family : Alkyne

MSDS No : DG008G

Company Identification : Aldakheel Industrial Gases Plant (DIGAS)

Emergency Phone Number : 04-8455-101

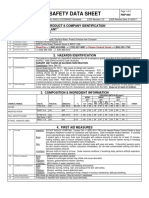

2 COMPOSITION / INFORMATION ON INGREDIENTS

COMPONENT CAS NUMBER CONCENTRATION

Acetylene 74-86-2 >99%*

*The symbol > means "greater than"

3 HAZARDS IDENTIFICATION

Emergency Overview : Danger! Flammable gas under pressure. Can form explosive mixtures with air. Fusible plugs

in top, bottom, or valve melt at 98-107°C (208-224°F). Do not discharge at pressures above

15 psig (103 kPa). pressures above 15 psig (103 kPa). Self-contained breathing apparatus

may be required by rescue workers.

Inhalation: : Asphyxiant. Effects are due to lack of oxygen. Moderate concentrations may cause

headache, drowsiness, dizziness, excitation, excess salivation, nausea, vomiting, and

unconciousness. The vapor from a liquid release may also cause in-coordination, abdominal

pain. Effects may be delayed.Lack of oxygen can kill.

Skin Contact : No harm expected from vapor. Liquid (acetone) may cause frostbite..

Swallowing : An unlikely route of exposure, but frostbite of the lips and mouth may result from contact with

the liquid. If swallowed, the liquid may cause nausea.

Eye Contact : Vapour containing acetone may cause irritation. Liquid (acetone) may cause irritation and

frosbite.

Effects of Repeated (Chronic) : NOTE: Acetylene cylinders are filled with a porous material containg acetone into which the

Overexposure acetylene is dissolved. ACGIH has established a TLV-TWA of 500 ppm for acetone and a

STEL of 750 ppm.

WORKING WITH WELDING AND CUTTING MAY CREATE ADDITIONAL HEALTH

HAZARDS. FUMES AND GASES can be dangerous to your health and may cause serious

lung disease.* Keep your head out of the fumes. Do not breathe fumes and gases caused by

the process. Use enough ventilation, local exhaust, or both to keep fumes and gases from

your breathing zone and the general area. The type and amount of fumes and gases depend

on the equipment and supplies used. Possibly dangerous materials may be found in fluxes,

coatings, gases, metals etc. Obtain a Material Safety Data Sheet (MSDS) for each material

used. Air samples can be used to find out what respiratory protection is needed. Short term

overexposure to fumes may result in discomfort such as dizziness, nausea, or dryness or

irritation of nose, throat, or eyes.

Other Effects of Overexposure : None known.

Medical Conditions Aggravated by

Overexposure : Repeated or prolonged exposure is not known to aggravate medical condition.

Potential Environmental Effects : None expected.

Aldakheel Industrial Gases Plants (DI GAS )

Medina K.S.A.

Page Number

MATERIAL SAFETY DATA SHEET 1/5

Date: 28/10/2018

MSDS V1.1 Acetylene DG008G

4 FIRST AID MEASURES

Inhalation : Remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult,

qualified personnel may give oxygen. Get medical attention immediately.

Skin Contact : Incase of contact, immediately flush skin with plenty of water. Remove contaminated

clothing and shoes. Cold water may be used. Wash clothing before reuse. Thoroughly clean

shoes before reuse. Get medical attention.

Swallowing : If liquid is swallowed, immediately give two glasses of water and induce vomiting if victim is

conscious. Call a physician.

Eye Contact : Check for and remove any contact lenses. In case of contact, immediately flush eyes with

plenty of water for at least 15 minutes. Cold water may be used. See a physician, preferably

an ophthalmologist, immediately.

Notes to Physician : Aspirated acetone may cause severe lung damage. If a large quantity of material has been

swallowed, stomach contents should be evacuated quickly in a manner that avoids

aspiration. Otherwise, there is no specific antidote. Treatment of overexposure should be

directed at the control of symptoms and the clinical condition of the patient.

5 FIRE-FIGHTING MEASURES

Flammable class : Extremely flammable.

Extinguishing media

Suitable extinguishing media : All known extinguishants can be used.

Hazardous combustion products : Incomplete combustion may form carbon monoxide.

Protection of firefighters : DANGER! Flammable gas under pressure. Evacuate all personnel from danger area.

Immediately cool cylinders with water spray from maximum distance, taking care not to

extinguish flames. If flames are accidentally extinguished, explosive re-ignition may occur.

Use self-contained reathing apparatus. Remove ignition sources if without risk. Stop flow of

gas if without risk while continuing cooling water spray. Remove all cylinders from area of fire

if without risk. Allow fire to burn out.

Specific physical and chemical hazards : Heat of fire can build pressure in cylinder and cause it to rupture. Acetylene cylinders are

provided with pressure relief devices designed to vent contents when exposed to elevated

temperature. No part of a cylinder should be subjected to a temperature higher than 52°C

(125°F). If venting or leaking acetylene catches fire, do not extinguish flames. Flammable

vapors may spread from leak, creating an explosive reignition hazard. Vapors can be ignited

by pilot lights, other flames, smoking, sparks, heaters, electrical equipment, static discharge,

or other ignition sources at locations distant from product handling point. Explosive

atmospheres may linger. Before entering area, especially confined areas, check atmosphere

with an approved explosion meter.

Protective equipment and precautions : Firefighters should wear self-contained breathing apparatus and full fire-fighting turnout gear.

for firefighters

6 ACCIDENTAL RELEASE MEASURES

Personal precautions : Evacuate area. Wear self-contained breathing apparatus when entering unless atmosphere

. is proved to be safe. Ensure adequate air ventilation.

Environmental precautions : Try to stop release. Eliminate ignition sources.

Clean up methods : Ventilate area.

7 HANDLING AND STORAGE

Precautions to be taken in handling : Keep away from heat, sparks, and open flame. Use only spark-proof tools and explosion-

proof equipment. Never use acetylene at pressures exceeding 15 psig (103.5 kPa). Can

cause rapid suffocation due to oxygen deficiency. Close valve after each use; keep closed

even when empty. Arcs and sparks can ignite combustible materials. Prevent fires.

Aldakheel Industrial Gases Plants (DI GAS )

Medina K.S.A.

Page Number

MATERIAL SAFETY DATA SHEET 1/5

Date: 28/10/2018

MSDS V1.1 Acetylene DG008G

7 HANDLING AND STORAGE (Continued)

Precautions to be taken in storage & use : Acetylene storage in excess of 2,500 cu ft (70.79 m3) is prohibited in buildings with other

occupancies. Store and use with adequate ventilation. Separate acetylene cylinders from

oxygen and other oxidizers by at least 20 ft i(6.1 m), or use a barricade of noncombustible

material. This barricade should be at least 5ft (1.53 m) high and have a fire resistance rating

of at least ½ hour. Post “No Smoking or Open Flames” signs in storage and use areas.

There must be no sources of ignition. All electrical equipment in storage areas must be

explosion-proof. Storage areas must meet national electric codes for Class 1 hazardous

areas. Store only where temperature will not exceed 52°C(125°F).

8 EXPOSURE CONTROLS / PERSONAL PROTECTION

Engineering controls : Use a local exhaust system, if necessary, to prevent oxygen deficiency and to keep

Local exhaust hazardous fumes and gases in the worker’s breathing zone below all applicable exposure

limits.

Mechanical (General) : General exhaust ventilation may be acceptable if it can maintain an adequate supply of air

and keep hazardous fumes and gases in the worker’s breathing zone below all applicable

exposure limits.

Special : None.

Other : None.

Personal protective equipment

Skin Protection : Wear work gloves when handling cylinders; welding gloves for welding and cutting.

Eye/Face Protection : Wear goggles with filter lenses. Provide protective screens and goggles, if necessary, to

protect others.

Respiratory Protection : Use air-purifying or air-supplied respirators, as appropriate, where local or general exhaust

ventilation is inadequate. Adequate ventilation must keep worker exposure below all

applicable limits for fumes, gases, and other by-products of welding with acetylene.

Other Protective Equipment : As needed, wear hand, head, and body protection, which help to prevent injury from

radiation and sparks. At a minimum, this includes welder’s gloves and protective goggles,

and may include arm protectors, aprons, hats, and shoulder protection, as well as

substantial clothing. Regardless of protective equipment, never touch live electrical parts.

9 PHYSICAL AND CHEMICAL PROPERTIES

Appearance : Colorless gas.

Odor : Acetylene of 100% purity is odorless, but commercial acetylene has a distinctive, garlic-like

odor.

Odor Thresold : Not available.

Physical State : Gas at normal temperature and pressure

pH : Not applicable.

Melting Point at 10 psig (170 kPa abs) : -82.2°C (116°F)

Boiling Point at 10 psig (170 kPa abs) : -75.2°C (-103.4°F)

Evaporation Rate (Butyl Acetate = 1) : Not applicable.

Flammability : Flammable.

Flammable Limits In Air, % by volume: : Lower 2.5% Upper 100%

Vapor Pressure at 21.1°C (70°F) : 649.6 psia (4479 kPa abs)*

Vapor Density at 0°C (32°F) : 0.00117 g/ml

Specific Gravity (H2O = 1) : Not applicable.

Molecular Weight : 26.04 g/mole

Molecular Formula : C2H2

Aldakheel Industrial Gases Plants (DI GAS )

Medina K.S.A.

Page Number

MATERIAL SAFETY DATA SHEET 1/5

Date: 28/10/2018

MSDS V1.1 Acetylene DG008G

10 RAW MATERIALS INFORMATION

COMMODITY SYNONYM FORMULA

Calcium Carbide CALCIUM CARBIDE CaC2

ITEM MEASUITE STANDARD RESULT

H2S % (v/v) 0.12< 0.08

PH3 % (v/v) 0.08< 0.06

Gas Yield L/KG 285-295 295

Size MM 25-50 25-50

11 STABILITY AND REACTIVITY

Chemical Stability : Unstable. Stable.

Acetylene is stable as shipped. Avoid use at pressures above 15 psig (103kPa).

Conditions to Avoid : Elevated temperature and pressure and/or the presence of a catalyst.

Incompatible Materials : Copper, silver, mercury, or their alloys; oxidizing agents; acids; halogens; moisture.

Hazardous Decomposition Products : Thermal decomposition or burning may produce CO/CO2H2. The welding and cutting

process may form reaction products such as CO and CO2. Other decomposition products of

normal operation originate from the volatilization, reaction, or oxidation of the material being

worked.

Possible Of Hazardous Reactions : May Occur. Will Not Occur.

Fire or explosion may result from use at elevated temperatures and pressures or from use

with incompatible materials.

12 TOXICOLOGICAL INFORMATION

Acute Dose Effect : No known effects from acetylene gas. The welding process may generate hazardous fumes

and gases.

13 ECOLOGICAL INFORMATION

Ecotoxicity : No adverse ecological effects expected.

Other Adverse Effects : None known. Acetylene does not contain any Class I or Class II ozone-depleting chemicals.

14 DISPOSAL CONSIDERATION

Waste Disposal Method : Do not attempt to dispose of residual or unused quantities. Return cylinder to DIGAS.

15 TRANSPORT INFORMATION

Transport Information : Avoid transport on vehicles where the load space is not separated from the driver's

: compartment.

Ensure vehicle driver is aware of the potential hazards of the load and knows what to do in

the event

: Before of an accident

transporting or an

product emergency.

containers:

- Ensure that containers are firmly secured.

- Ensure cylinder valve is closed and not leaking.

- Ensure valve outlet cap nut or plug (where provided) is correctly fitted.

- Ensure valve protection device (where provided) is correctly fitted.

- Ensure there is adequate ventilation.

- Compliance with applicable regulations.

Aldakheel Industrial Gases Plants (DI GAS )

Medina K.S.A.

Page Number

MATERIAL SAFETY DATA SHEET 1/5

Date: 28/10/2018

MSDS V1.1 Acetylene DG008G

16 OTHER INFORMATION

Ensure all national/local regulations are observed.

Ensure operators understand the flammability hazard.

The hazard of asphyxiation is often overlooked and must be stressed during operator training.

FUMES AND GASES can be dangerous to your health and may cause serious lung disease. Keep your head out of fumes. Do

not breathe fumes and gases. Use enough ventilation, local exhaust, or both to keep fumes and gases from your breathing zone

and the general area. Short-term overexposure to fumes may cause dizziness, nausea, and dryness or irritation of the nose,

throat, and eyes or may cause other similar discomfort.

HAZARD RATING SYSTEMS:

S: NFPA Ratings: HMIS Ratings:

Health =1 Health =2

Flammability =4 Flammability =4

Instability =3 Physical Hazard =2

Special = None

STANDARD VALVE CONNECTIONS:

THREADED : The CGA-300 connection is standard for cylinders.

PIN-INDEX YOKE : Not applicable

Use the proper CGA connections. DO NOT USE ADAPTERS.

This Material Safety Data Sheet has been established for the best knowledge of DIGAS.

Details given in this document are believed to be correct at the best of DIGAS knowledge. Whilst proper care has been taken in

the preparation of this document, no liability for injury or damage resulting from its use can be accepted.

End of Documents

Aldakheel Industrial Gases Plants (DI GAS )

Medina K.S.A.

You might also like

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- After a Disaster: Information to Help You and Your Family RecoverFrom EverandAfter a Disaster: Information to Help You and Your Family RecoverNo ratings yet

- Ezee Glide Plus US SDS September 2014Document9 pagesEzee Glide Plus US SDS September 2014PetrNo ratings yet

- Acetone Safety Data Sheet SDS PDFDocument10 pagesAcetone Safety Data Sheet SDS PDFkokoNo ratings yet

- Acetylene Gas C2H2 Safety Data Sheet SDS P4559Document10 pagesAcetylene Gas C2H2 Safety Data Sheet SDS P4559pranksterboyNo ratings yet

- Acetylene MSDS PDFDocument7 pagesAcetylene MSDS PDFiqbalhanif21No ratings yet

- AcetyleneDocument11 pagesAcetyleneMuhammad Habibullah [MMS]No ratings yet

- Blaster Fuel Injector MSDSDocument7 pagesBlaster Fuel Injector MSDSMohamed ElbasunyNo ratings yet

- Identification of The Material and Supplier: Page 1 of 7 SDS Date: 20 Mar 2015 Version No: 1.1Document7 pagesIdentification of The Material and Supplier: Page 1 of 7 SDS Date: 20 Mar 2015 Version No: 1.1Emelda JulianNo ratings yet

- 2016 (3) Anionic Slow Setting EmulsionDocument6 pages2016 (3) Anionic Slow Setting EmulsionRanmal AbhaNo ratings yet

- LPG MSDS-liquid-petroleum-gas-lpgDocument10 pagesLPG MSDS-liquid-petroleum-gas-lpgJumco OPS WarriNo ratings yet

- Acetone: SafetydatasheetDocument10 pagesAcetone: SafetydatasheetWais AlqurniNo ratings yet

- MSDS Contact CementDocument6 pagesMSDS Contact CementfaridanurroNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument8 pagesSafety Data Sheet: 1. IdentificationMiskaNo ratings yet

- Material Safety Data Sheet: 1. Indentification OF Material & Company Details Product Name: T180 EPOXY THINNERDocument5 pagesMaterial Safety Data Sheet: 1. Indentification OF Material & Company Details Product Name: T180 EPOXY THINNERLê TiếnNo ratings yet

- Demand Cs MsdsDocument5 pagesDemand Cs MsdsBatanNo ratings yet

- Cat Yellow Paint High Gloss Fast DryingDocument10 pagesCat Yellow Paint High Gloss Fast DryingClemente ZamudioNo ratings yet

- Material Safety Data Sheet: Section 1 X Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Section 1 X Product and Company Identificationomar benounaNo ratings yet

- MSDS - Stains 310804Document5 pagesMSDS - Stains 310804AjiWidyartaNo ratings yet

- Hilti CP620 Expanding Fire Seal 05 2008Document5 pagesHilti CP620 Expanding Fire Seal 05 2008Stone123456789No ratings yet

- Eugeny L Acetate Natural SdsDocument9 pagesEugeny L Acetate Natural SdsDiannisa SeptianaNo ratings yet

- Oil-AW-100 MSDSDocument6 pagesOil-AW-100 MSDSAndres GonzalezNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument10 pagesSafety Data Sheet: 1. Product and Company IdentificationScott PilgrimNo ratings yet

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationHenry OdulioNo ratings yet

- 820 Resin MSDSDocument5 pages820 Resin MSDSajaldacoNo ratings yet

- Abc Sealant SDSDocument5 pagesAbc Sealant SDSKissa DolautaNo ratings yet

- MSDS Minyak Power Stering PrestoneDocument6 pagesMSDS Minyak Power Stering PrestoneJohn umumNo ratings yet

- Safety Data Sheet: AcetoneDocument7 pagesSafety Data Sheet: Acetonemehdi_hoseineeNo ratings yet

- Tomadyne 102 Surfactant - Air Products - 2015-01-26Document9 pagesTomadyne 102 Surfactant - Air Products - 2015-01-26Cristian VieraNo ratings yet

- Material Safety Data Sheet: Acetic AcidDocument7 pagesMaterial Safety Data Sheet: Acetic Acideng20072007No ratings yet

- MSDS - Arena VerdeDocument12 pagesMSDS - Arena VerdeSoledad OrtegaNo ratings yet

- CRC Smoke Test SDSDocument9 pagesCRC Smoke Test SDSA RNo ratings yet

- Neo Heliopan Hydro Phenylbenzimidazole Sulfonic Acid Enuzizole All DocumentsDocument17 pagesNeo Heliopan Hydro Phenylbenzimidazole Sulfonic Acid Enuzizole All DocumentsrigolotNo ratings yet

- Acetic AcidDocument10 pagesAcetic AcidSunder Tukaram KelkarNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument10 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationprasNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument10 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationEngr SabandalNo ratings yet

- CRC Di-Electric GreaseDocument11 pagesCRC Di-Electric GreaseAxel Gerardo Espinoza TovarNo ratings yet

- Material Safety Data Sheet: Product IdentificationDocument4 pagesMaterial Safety Data Sheet: Product Identificationمحمد عزتNo ratings yet

- Safety Data Sheet: 1. Product & Company Identification Opi Nail Lacquer ThinnerDocument6 pagesSafety Data Sheet: 1. Product & Company Identification Opi Nail Lacquer ThinnerahleyaNo ratings yet

- Non Acetone Nailpolish RemoverDocument18 pagesNon Acetone Nailpolish RemoverCarolinaNo ratings yet

- Lps 3 SDS Rev 2019Document9 pagesLps 3 SDS Rev 2019JAIR GARZONNo ratings yet

- 2-Ethylhexanol: 2-Ethylhexanol Safety Data SheetDocument8 pages2-Ethylhexanol: 2-Ethylhexanol Safety Data SheetmishaNo ratings yet

- Butane Msds E4572Document8 pagesButane Msds E4572Lucious LightNo ratings yet

- Vapormate MSDS 2016Document7 pagesVapormate MSDS 2016parejayaNo ratings yet

- Gilsonite MSDSDocument6 pagesGilsonite MSDSPT. SURYAGITA NUSARAYANo ratings yet

- Tnemec-Endura Shield IiDocument20 pagesTnemec-Endura Shield IiPubcrawlNo ratings yet

- MSDS Starvvo AF11Document8 pagesMSDS Starvvo AF11vidya putraNo ratings yet

- Safety Data Sheet: Liquid Fire Starting FluidDocument10 pagesSafety Data Sheet: Liquid Fire Starting FluidPubcrawlNo ratings yet

- Msds-Thinnal 4280101Document2 pagesMsds-Thinnal 4280101محمد عزتNo ratings yet

- Safety Data SheetDocument12 pagesSafety Data SheetAngelNo ratings yet

- 0098 T8f8c5kubDocument5 pages0098 T8f8c5kubNandar Min HtetNo ratings yet

- Material Safety Data Sheet: in Case of Emergency, Call 1-800-327-8633 (FAST MED)Document6 pagesMaterial Safety Data Sheet: in Case of Emergency, Call 1-800-327-8633 (FAST MED)anon_148109600No ratings yet

- Fipronil (Altrnatif MSDS Yang Sesuai Belum Ada)Document8 pagesFipronil (Altrnatif MSDS Yang Sesuai Belum Ada)efrinov1174No ratings yet

- Mapp Gas SDS SheetDocument12 pagesMapp Gas SDS SheetAnthoney MooreNo ratings yet

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationHafidzAliyufaNo ratings yet

- 116DA Silicone SprayDocument8 pages116DA Silicone Spraykatiuska2015No ratings yet

- Titan 2T 100S-SDSDocument6 pagesTitan 2T 100S-SDSBudi SetiawanNo ratings yet

- MSDS-Ethyl AcetateDocument7 pagesMSDS-Ethyl AcetateJo SeanNo ratings yet

- Msds - MEK 1 1Document6 pagesMsds - MEK 1 1Ishaan RajNo ratings yet

- MSDS of Diesel (F)Document6 pagesMSDS of Diesel (F)Aman DhananiNo ratings yet

- Documentation: Hose Filter (SFL)Document38 pagesDocumentation: Hose Filter (SFL)keduseNo ratings yet

- Glycerin SDSDocument11 pagesGlycerin SDSKamal BhattacharjeeNo ratings yet

- FRS Catalogue 2018 en PDFDocument495 pagesFRS Catalogue 2018 en PDFHobbyLogicNo ratings yet

- Dynacraft Fire Dampers - CBRI TestedDocument40 pagesDynacraft Fire Dampers - CBRI Testedprabhanshu241991No ratings yet

- MSDS Petron XD3Document5 pagesMSDS Petron XD3john michael medinaNo ratings yet

- Aquathol K Aquatic Herbicide MsdsDocument7 pagesAquathol K Aquatic Herbicide MsdsSouth Santee AquacultureNo ratings yet

- Indian Habitate Center Case StudyDocument25 pagesIndian Habitate Center Case StudyEram HashmiNo ratings yet

- Safety Data Sheet: Sodium PhosphateDocument9 pagesSafety Data Sheet: Sodium PhosphateMAI_AAN_KURNIAWANNo ratings yet

- NFPA Codes & Standards - 9Document1 pageNFPA Codes & Standards - 9karpanaiNo ratings yet

- G SF 240 PDFDocument29 pagesG SF 240 PDFAmirhosein605334No ratings yet

- DVN NA MSDS Iron Sponge SpentDocument6 pagesDVN NA MSDS Iron Sponge SpentAyu Sintia SyukriNo ratings yet

- MSDS-PELLASTOL 94 S - EnglishDocument13 pagesMSDS-PELLASTOL 94 S - EnglishRaajha MunibathiranNo ratings yet

- 12.senior Ground Equipment Operator Level 5Document6 pages12.senior Ground Equipment Operator Level 5Prashant GautamNo ratings yet

- TM 55-1925-273-SDCDocument236 pagesTM 55-1925-273-SDCAdvocateNo ratings yet

- Safety Data Sheet: 1.product and Company IdentificationDocument6 pagesSafety Data Sheet: 1.product and Company IdentificationGuy BOURLEAUXNo ratings yet

- UD24570B - MR-Q3-600 AMR - User Manual - V1.0.0 - 20210712Document62 pagesUD24570B - MR-Q3-600 AMR - User Manual - V1.0.0 - 20210712simonNo ratings yet

- R410a Refrigerant MsdsDocument7 pagesR410a Refrigerant MsdsYusuf AhdaNo ratings yet

- Design, Installation and Maintenance ManualDocument64 pagesDesign, Installation and Maintenance ManualSyaran BudimanNo ratings yet

- Fire Suppression Calculations PDFDocument13 pagesFire Suppression Calculations PDFripcurlzNo ratings yet

- Installation of Under Ground Chilled Water PipingDocument18 pagesInstallation of Under Ground Chilled Water PipingAnandu Ashokan100% (1)

- Book13 - Roller Screen RR1439 - P0EBD72 (TR 1-59)Document59 pagesBook13 - Roller Screen RR1439 - P0EBD72 (TR 1-59)Cuộc Sống MàNo ratings yet

- Polyethylene HHM TR-144 MSDS All EnglishDocument10 pagesPolyethylene HHM TR-144 MSDS All EnglishAkram.yishakNo ratings yet

- Berner MSDSDocument20 pagesBerner MSDSTunaNo ratings yet

- Bureau of Fire Protection Office of The Municipal Fire Marshal Basista Fire StationDocument4 pagesBureau of Fire Protection Office of The Municipal Fire Marshal Basista Fire StationBasista Pangasinan Bfp RegionOneNo ratings yet

- Safety Data Sheet: According To EC Directive 91/155/EECDocument5 pagesSafety Data Sheet: According To EC Directive 91/155/EECWong Peng ChiongNo ratings yet

- Li5 Plus MsdsDocument16 pagesLi5 Plus Msdskeshav jalanNo ratings yet

- Safety Data Sheet: Product Name: MOBILGEAR 600 XP 100Document13 pagesSafety Data Sheet: Product Name: MOBILGEAR 600 XP 100Anonymous tgUmNZkNo ratings yet

- MSDS Backing MaterialDocument5 pagesMSDS Backing MaterialJose Antonio Quintanilla CáceresNo ratings yet

- Msds Parfum Zara NewDocument6 pagesMsds Parfum Zara NewDiorama Bali100% (1)

- Jazzera Primex Plus-MsdsDocument5 pagesJazzera Primex Plus-MsdsMahmoud FlefilNo ratings yet