Professional Documents

Culture Documents

Oil-AW-100 MSDS

Uploaded by

Andres GonzalezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil-AW-100 MSDS

Uploaded by

Andres GonzalezCopyright:

Available Formats

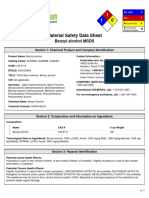

GENERAL PUMP MATERIAL SAFETY DATA SHEET

General Pump

Emergency 800-424-9300

1174 Northland Drive

Mendota Heights, MN USA Information: 651-454-6500

55120 Fax:: 651-454-8015

info@gpcompanies.com

SECTION 1 CHEMICAL PRODUCT IDENTIFICATION

Product: General Pump Oil-AW-100

Synonyms/Other: Not Applicable

Item Numbers: 805-100214, 805-100216, 805-100219, 805-100295, 805-100379

805-100551, 805-100552, 805-100553

MSDS Number: 0447

Product Type: Hydraulic fluid

Preparation/Revision Date: 08/01/2002

SECTION 2 COMPOSITION INFORMATION

INGREDIENTS CAS # % OSHA OSHA ACGIH SKIN

TWA STEL TWA

Hydrotreated heavy paraffinic 64742-54-7 -- 5 mg/m3 10mg/m3 5mg/m3 NO

distillates* (PEL) (TLV)

and/or

Solvent-dewaxed heavy paraffinic 64742-65-0 -- 5 mg/m3 10mg/m3 5mg/m3 NO

distillates* (PEL) (TLV)

Proprietary additives Mixture -- -- -- -- NO

Zinc alkyl dithiophosphate 68649-42-3 <0.6 -- -- -- NO

Comments: * Exposure limits not defined. Limits used are for, “oil mist”.

All base oils, including additive carriers, contain <3.0% DMSO extractable

Material

TWA - Time Weighted Average is the employee’s average airborne exposure in any 8-hour work shift

of a 40-hour work week which shall not be exceeded.

STEL - Short Term Exposure Limit is the employee’s 15-minute time weighted average exposure

which shall not be exceeded at any time during a work day unless another time limit is specified.

SECTION 3 HAZARDOUS IDENTIFICATION

WARNING: - MAY CAUSE EYE IRRITATION

- MAY CAUSE SKIN IRRITATION

Eye contact: Direct contact may cause irritation, redness, tearing and blurred vision.

Skin contact: Avoid prolonged skin contact. This product contains materials that may cause

skin irritation. Prolonged or repeated contact may result in dermatitis (dryness,

chapping and reddening of skin).

Inhalation: Overexposure by inhalation of hot material may cause nonspecific discomfort,

such as nausea, headache, or weakness. Caution should be taken to prevent

aerosolization or misting of this product without proper respiratory protection.

Ingestion: Do not ingest. Product is expected to be relatively non-toxic unless lung

aspiration occurs. Aspiration is not expected with this material due to heavy

viscosity. Should aspiration occur, may lead to chemical pneumonitis which is

characterized by pulmonary edema and hemorrhage and may be fatal. Signs of

lung involvement include increased respiratory rate, increased heart rate, and a

bluish discolorization of the skin. Coughing, choking and gagging are often noted

at the time of aspiration. This product has laxative properties and may result in

abdominal cramps and diarrhea.

Other: Not applicable.

SECTION 4 FIRST AID MEASURES

Eye contact: Flush immediately with large amounts of water for at least 15 minutes. Eyelids

should be held away from the eyeball to ensure thorough rinsing. Get medical

attention if irritation persists. If material is hot, treat for thermal burns and take

GENERAL PUMP • MSDS Series 100 Oil • PAGE 1 of 6

1174 Northland Drive • Mendota Heights, MN 55120 • Phone: 651.454.6500 • Fax: 651.454.8015

GENERAL PUMP MATERIAL SAFETY DATA SHEET

victim to hospital immediately.

Skin contact: Remove contaminated clothing. Wash contaminated area thoroughly with soap

and water. If redness or irritation occurs, seek medical attention. If material is

hot, submerge injured area in cold water. If victim is severely burned, remove

To a hospital immediately. Wash contaminated clothing before reuse.

Inhalation: If overcome by inhilation of hot vapors, remove to fresh air. Use oxygen if

there is difficulty breathing or artificial respiration if breathing has stopped. Do

not leave victim unattended. Seek immediate medical attention if necessary.

Ingestion: Do not induce vomiting because of danger of aspirating liquid into lungs,

causing serious damage and chemical pneumonitis. If spontaneous vomiting

occurs keep head below hips to prevent aspiration and monitor for breathing

difficulty. Gastric lavage should be performed only by qualified medical

personnel. Keep affected person warm and at rest. Seek immediate

attention.

Other: Not applicable.

SECTION 5 FIRE FIGHTING MEASURES

Flash point: 2040 C (4000F) ASTM D-92

Flammable limits: Not determined.

Extinguishing media: Use water spray, dry chemical, alcohol foam, all purpose AFFF or carbon

dioxide to extinguish fire.

Special firefighting

procedures: Evacuate area and fight fire from a safe distance. If leak or spill has not ignited,

ventilate area and use water spray to disperse gas or vapor and to protect

personnel attempting to stop a leak.

Use water spray to cool adjacent structures and to protect personnel. Shut off

source of flow if possible (safely). Stay away from storage tank ends.

Withdraw immediately in case of rising sound from venting safety device or any

discoloration of storage tank due to fire.

Fire fighters must wear MSHA/NIOSH approved positive pressure breathing

apparatus (SCBA) with full face mask and full protective equipment.

Unusual fire &

explosion hazards: Dense smoke may be generated while burning. Toxic fumes, gases or vapors

may evolve on burning. Heavy flammable vapors may settle along ground level

and low spots to create an invisible fire hazard. The vapors may extend to

sources of ignition and flash back.

Byproducts of

combustion: Fires involving this product may release oxides of carbon, nitrogen, sulfur,

phosphorous; reactive hydrocarbons and irritating vapors.

Autoignition

temperature: Not determined.

Explosion data: Not determined.

Other: Not applicable.

SECTION 6 ACCIDENTAL RELEASE MEASURES

Spill control

procedures (land): Immediately turn off or isolate any source of ignition (pilot lights, electrical

equipment, flames, heaters, etc.). Evacuate area and ventilate. Personnel

wearing proper protective equipment should contain spill immediately with inert

materials (sand, earth, chemical spill pads of cotton) by forming dikes. Dikes

should be placed to contain spill in a manner that will prevent material from

entering sewers and waterways. Large spill, once contained, may be picked up

using explosion proof, non-sparking vacuum pumps, shovels, or buckets, and

disposed of in suitable containers for disposal. If a large spill occurs notify

appropriate authorities.

Spill control

procedures (water): Remove from surface by skimming or with suitable absorbents. If a large spill

occurs notify appropriate authorities (normally the National Response Center or

GENERAL PUMP • MSDS Series 100 Oil • PAGE 2 of 6

1174 Northland Drive • Mendota Heights, MN 55120 • Phone: 651.454.6500 • Fax: 651.454.8015

GENERAL PUMP MATERIAL SAFETY DATA SHEET

Coast Guard).

Waste disposal

method: Most oil based products are incinerated, land-filled or reclaimed. All disosals

must comply with federal, state, and local regulations. The material, if spilled or

discarded may be a regulated waste. Refer to state and local regulations.

Department of Transportation (DOT) regulations may apply for transporting this

material when spilled. See section 14.

Other: CAUTION - If spilled material is cleaned up using a regulated solvent, the

resulting waste mixture will be regulated.

SECTION 7 HANDLING AND STORAGE

Handling Procedures: Keep containers closed when not in use. Do not transfer to unmarked

containers. Fire extinguishers should be kept readily available. See NFPA 30

and OSHA 1910.106 -- Flammable and Combustible Liquids. Empty containers

retain product residue which may exhibit hazards of material, therefore do not

pressurize, cut, glaze, weld, or use for any other purposes. Return drums to

reclamation centers for proper cleaning and reuse.

Storage procedures: Store containers away from heat, sparks, open flame, or oxidizing materials.

Additional information: No additional information.

SECTION 8 EXPOSURE CONTROLS / PERSONAL PROTECTION

Personal protection: Applicable mainly to persons in repeated contact situations such as packaging

of product, service/maintenance, and cleanup/spill control personnel.

Respiratory protection: None required if airborne concentrations are maintained below threshold limits

listed on page one. Otherwise a respiratory protection program meeting OSHA

101,.134 and ANSI Z88.2 requirements must be followed. Where misting may

occur, wear an MSHA/NIOSH approved (or equivalent) half-mask form

dust/mist purifying respirator.

Eye protection: Eye protection is strongly recommended. If material is handled such that it

could be splashed into the eyes, wear safety glasses with side shields or

vented/splash proof goggles (ANSI Z87.1 or approved equivalent).

Hand protection: Impervious gloves such as neoprene or nitrile rubber to avoid skin sensitization

and absorption.

Other protection: Use of an apron and overboots or chemically impervious materials such as

neoprene or nitrile rubber is recommended to avoid skin sensitization and

absorption. If handling hot material use insulated protective equipment.

Launder soiled clothes. Properly dispose of contaminated leather articles and

other materials which cannot be decontaminated.

Local control

measures: Use adequate ventilation when working with material in an enclosed area.

Mechanical methods such as fume hoods or area fans may be used to reduce

localized vapor/mist areas. If vapor or mist is generated when the material

is handled, adequate ventilation in accordance with good engineering practice

must be provided to maintain concentrations below the specified exposure.

Eyewash stations and showers should be available in areas where this material

is used and stored.

Other: Consumption of food and drink should be avoided in work areas where product

is present. Always wash hands and face with soap and water before eating.,

drinking or smoking.

SECTION 9 PHYSICAL AND CHEMICAL PROPERTIES

Vapor pressure: 0.1 mm Hg at 200C (680F).

API gravity: 28.40 @ 600F

Density: 7.37 pounds/gallon

Specific gravity: 0.88

Solubility: Negligible in water, miscible in most petroleum solvents.

Percent volatile: Negligible.

Vapor density(air=1): >1.

Evaporation rate

(n-ButylAcetate=1): Negligible.

GENERAL PUMP • MSDS Series 100 Oil • PAGE 3 of 6

1174 Northland Drive • Mendota Heights, MN 55120 • Phone: 651.454.6500 • Fax: 651.454.8015

GENERAL PUMP MATERIAL SAFETY DATA SHEET

Odor: Mild, oily odor.

Appearance: Clear, red fluid.

Viscosity: 100cSt @ 400C

Boiling point: >2600C (5000F) IBP.

Pour/Freeze point: Not determined.

Other: Not applicable.

SECTION 10 STABILITY AND REACTIVITY

Stability: Material is stable at room temperatures and pressure.

Conditions to avoid: Avoid high temperatures and product contamination.

Incompatibility with

other materials: Avoid contact with acids and oxidizing materials.

Decomposition

products: Smoke, carbon monoxide and dioxide, and other aldehydes of incomplete

combustion. Oxides of carbon, nitrogen, sulfur, and phosphorous; reactive

hydrocarbons and irritating vapors.

Hazardous

polymerization: Will not occur.

Other: Not applicable.

SECTION 11 TOXICOLOGICAL INFORMATION

Oral toxicity: RATS: Practically non-toxic (LD50: greater than 2000 mg/kg). -- Based on

testing of similar products and/or the components.

Dermal toxicity: RABBITS: Practically non-toxic (LD50: greater than 2000 mg/kg). -- Based on

testing of similar products and/or the components.

Inhalation toxicity: On rare occasions, prolonged and repeated exposure to oil mist poses a risk of

pulmonary disease such a chronic lung inflammation. This condition is usually

asymptomatic as a result of repeated small aspirations. Shortness of breath and

cough are the most common symptoms. Based on data from similar materials.

Dermal sensitization: RABBITS: Practically non-irritating. (Primary Irritation Index: greater than 0.5

but less than 3). -- Based on testing of similar products and/or the components.

Chronic toxicity: Not determined.

Carcinogenicity: Not determined.

Mutagenicity: Not determined

Reproductive toxicity: Dermal exposure of pregnant rats to representative formulations did not cause

adverse affects in either the mothers or their offspring.

Other: These products contain petroleum base oils which may be refined by various

processes including severe solvent extraction, severe hydrocracking, or severe

hydrotreating. None of the oils require a cancer warning under the OSHA

Hazard Communication Standard (29 CFR 1910.1200). These oils have not

been listed in the National Toxicology Program (NTP) Annual Report nor have

they been classified by the International Agency for Research on Cancer

(IARC) as; carcinogenic to humans (Group 1), probably carcinogenic to

humans (Group 2A), or possibly carcinogenic to humans (Group 2B).

SECTION 12 ECOLOGICAL INFORMATION

Environmental toxicity: These materials are not expected to be toxic to aquatic organisms. Accidental

spillage may lead to penetration in the soil and groundwater. However, there is

no evidence that this would cause adverse ecological effects.

Environmental fate: These products are expected to be inherently biodegradable. There is no

evidence to suggest bioaccumulation will occur.

Other: Not applicable.

SECTION 13 DISPOSAL CONSIDERATIONS

Waste disposal: Under RCRA it is the responsibility of the user of the product to determine at the

time of disposal whether the product meets RCRA criteria for hazardous waste.

This product unadulterated by other materials may be classified as a non-

GENERAL PUMP • MSDS Series 100 Oil • PAGE 4 of 6

1174 Northland Drive • Mendota Heights, MN 55120 • Phone: 651.454.6500 • Fax: 651.454.8015

GENERAL PUMP MATERIAL SAFETY DATA SHEET

regulated waste in some areas - but still needs to be disposed of at an approved

facilities. Waste management should be in full compliance with federal, state,

and local laws.

Disposal consideration: Most used and non-use oils are incinerated by licensed burner facilities for heat

value, or reclaimed by oil recycling services. Look in a local telephone directory

or internet for headings under ‘Waste’, ‘Waste Services’, ‘Waste Disposal” for

companies licensed to handle such material. Additional information can be

obtained from local EPA, DNR, Sewer and Land-Fill sites. Unused, packaged

fluids may be donated to other companies or charities (fluids MUST be unused).

Other: The transportation, storage, treatment and disposal of RCRA waste material

must be conducted in compliance with 40 CFR 262, 263, 264, 268 and 270.

Disposal can only occur in properly permitted facilities. Check state and local

regulations for any additional requirements as these may be more restrictive

than federal laws and regulations. chemical additions, processing or otherwise

altering this material may make the waste management information presented

in this MSDS incomplete, inaccurate or otherwise inappropriate. Disposal of

this material must be conducted in compliance with all federal, state, and local

regulations.

SECTION 14 STABILITY AND REACTIVITY

U.S. DOT shipping

description: Not regulated by DOT.

U.S. DOT identification

number: Not regulated by DOT

U.S. DOT hazard

classification: Not applicable

Packaging class: Not applicable.

Other: Not applicable.

SECTION 15 REGULATORY INFORMATION

Clean water act/oil

pollution act: Under section 311 of the Clean Water Act (40 CFR 110) and the Oil Pollution

Control Act of 1990, this material is considered an oil. Any spill or discharges

that produce a visible sheen or film on surface of water, or in waterways,

ditches, or sewers leading to surface water must be reported. Contact the

National Response Center at 800-424-8802.

This product contains zinc, a Clean Water Act Priority Pollutant.

TSCA: All components of this material are listed in the U.S. TSCA Inventory.

Other TSCA: Not applicable.

SARA Title III: Section 302/304 extremely hazardous substances:

None.

Section 311, 312 hazard categorization:

Acute (immediate health effects): NO

Chronic (delayed health effects): NO

Fire (hazard): NO

Reactivity: NO

Pressure (sudden release hazard): NO

Section 313 toxic chemicals:

Zinc alkyl dithiophosphate

(CAS 68649-42-3) <0.6% wt.

Zinc - elemental

(CAS 7440-66-6) <0.1% wt.

CERCLA: For stationary/moving sources - reportable quantity (due to):

Exempt due to petroleum exclusion.

Other: A release of this product, as supplied, is exempt from reporting under the

Comprehensive Environmental Response Compensation and Liability Act

(CERCLA) by the petroleum exclusion. However, releases may be reportable

to the National Response Center under the Clean Water Act, 33 U.S.C.

1321(b)(3) and (5) - see head of section 15. Failure to report may result in

GENERAL PUMP • MSDS Series 100 Oil • PAGE 5 of 6

1174 Northland Drive • Mendota Heights, MN 55120 • Phone: 651.454.6500 • Fax: 651.454.8015

GENERAL PUMP MATERIAL SAFETY DATA SHEET

substantial civil and criminal penalties.

Recommend contacting the local authorities in the event of any type of spill to

determine local reporting requirements and also to aid in the cleanup.

Zinc appears on the following State Regulatory Lists:

Pennsylvania Environmental Hazard.

SECTION 16 OTHER INFORMATION

NFPA 704 NPCA-HMIS KEY

HEALTH: 1 1 0 = Minimal

FIRE: 1 1 1 = Slight

REACTIVITY: 0 0 2 = Moderate

SPECIFIC HAZARD: NONE N/A 3+ Serious

PROTECTION INDEX: N/A B 4 = Severe

Precautionary labels: - MAY CAUSE EYE IRRITATION

- MAY CAUSE SKIN IRRITATION

External information: This product may be formulated in part with components purchased from other

companies. In many instances, especially when proprietary or trade secret

materials are used, Lube-Tech must rely upon information provided by these

materials manufacturers or distributors.

Creation date: 8/01/2002

File: General Pump Oil AW-100 (0448)

Version: III

INFORMATION PROVIDED IN THIS MSDS IS CONSIDERED ACCURATE AND RELIABLE BASED ON INFORMATION FROM INTERNAL AND

OUTSIDE SOURCES TO THE BEST OF LUBE-TECH’S KNOWLEDGE. HOWEVER, LUBE-TECH MAKES NO REPRESENTATIONS, GUARANTEES OR

WARRANTIES, EXPRESSED OR IMPLIED, OF MERCHANTABILITY OR FITNESS FOR THE PARTICULAR PURPOSE, REGARDING THE ACCURACY OF

SUCH INFORMATION OR THE RESULT TO BE OBTAINED FROM THE USE THEREOF, OR AS TO THE SUFFICIENCY OF THE INFORMATION HEREIN

PRESENTED. LUBE-TECH ASSUMES NO RESPONSIBILITY FOR INJURY TO RECIPIENT OR TO THIRD PERSONS OR FOR ANY DAMAGE TO ANY

PROPERTY AND RECIPIENT ASSUMES ALL SUCH RISKS.

REVISIONS / COMMENTS:

Ref 300571 Rev C

08-10

GENERAL PUMP • MSDS Series 100 Oil • PAGE 6 of 6

1174 Northland Drive • Mendota Heights, MN 55120 • Phone: 651.454.6500 • Fax: 651.454.8015

You might also like

- After a Disaster: Information to Help You and Your Family RecoverFrom EverandAfter a Disaster: Information to Help You and Your Family RecoverNo ratings yet

- Material Safety Data Sheet: 80W-90 Gear LubeDocument4 pagesMaterial Safety Data Sheet: 80W-90 Gear LubeFrank RodriguezNo ratings yet

- Crankcase Oil ISO 100 R-Series: Company InformationDocument4 pagesCrankcase Oil ISO 100 R-Series: Company InformationFrank RodriguezNo ratings yet

- Mercury 4t Oil MSDSDocument5 pagesMercury 4t Oil MSDSCelesNo ratings yet

- 125 Anfo - AmexDocument5 pages125 Anfo - AmexJoyas MicaNo ratings yet

- 492 MSDSDocument5 pages492 MSDSsrinivignaNo ratings yet

- HS Bobcat 15W40 InglesDocument5 pagesHS Bobcat 15W40 InglesLuisa Fernanda Villalobos MirandaNo ratings yet

- MSDS Minyak Power Stering PrestoneDocument6 pagesMSDS Minyak Power Stering PrestoneJohn umumNo ratings yet

- Material Safety Data Sheet: 1. Company and Product IdentificationDocument8 pagesMaterial Safety Data Sheet: 1. Company and Product IdentificationYan MoraesNo ratings yet

- Methanol MSDS PDFDocument10 pagesMethanol MSDS PDFPutriErvinaNo ratings yet

- Minimum Oil Circuit BreakerDocument4 pagesMinimum Oil Circuit BreakergshdavidNo ratings yet

- 2016 (3) Anionic Slow Setting EmulsionDocument6 pages2016 (3) Anionic Slow Setting EmulsionRanmal AbhaNo ratings yet

- MSDS - JAX - Food - Grade - Penetrating - Oil - Aerosol - SDS - 020717Document5 pagesMSDS - JAX - Food - Grade - Penetrating - Oil - Aerosol - SDS - 020717Mohamad HudhaNo ratings yet

- Material Safety Data Sheet: Section 1: Product & Company IdentificationDocument6 pagesMaterial Safety Data Sheet: Section 1: Product & Company IdentificationAndrey ParchukNo ratings yet

- MSDS for VGO (Vacuum Gas OilDocument8 pagesMSDS for VGO (Vacuum Gas OilJaideepNo ratings yet

- Chevron Sri Grease MsdsDocument9 pagesChevron Sri Grease MsdsRonald AranhaNo ratings yet

- Section 1 Product Identification: Material Safety Data SheetDocument4 pagesSection 1 Product Identification: Material Safety Data SheetJery Setiadi maulanaNo ratings yet

- Havoline Super 2T SDS 31899 21 Feb 2012Document7 pagesHavoline Super 2T SDS 31899 21 Feb 2012Miguel TorresNo ratings yet

- Asphalt Emulsions Material Safety Data SheetDocument9 pagesAsphalt Emulsions Material Safety Data SheetTorero02No ratings yet

- SDS Cationic Emulsion CRS-1Document11 pagesSDS Cationic Emulsion CRS-1Torero02No ratings yet

- Safety Data Sheet: Chevron (Philippines) Diesel Fuel OilDocument8 pagesSafety Data Sheet: Chevron (Philippines) Diesel Fuel OilRenalyn TorioNo ratings yet

- MSDS Syntal HG 4230102Document2 pagesMSDS Syntal HG 4230102محمد عزتNo ratings yet

- Unocal 76' Guardol 15W/40 Motor Oil: Material Safety Data SheetDocument4 pagesUnocal 76' Guardol 15W/40 Motor Oil: Material Safety Data Sheetzubair1951No ratings yet

- Diborane MSDSDocument8 pagesDiborane MSDSankitrao31No ratings yet

- Light Cycle OilDocument4 pagesLight Cycle OilAhmed Qani AlkurdiNo ratings yet

- Safety Data Sheet: Multifak OEM Grease EP 2Document8 pagesSafety Data Sheet: Multifak OEM Grease EP 2Om Prakash RajNo ratings yet

- Grease Bearing SKFDocument6 pagesGrease Bearing SKFNNNo ratings yet

- NavGuard II AU SDS v1.0Document4 pagesNavGuard II AU SDS v1.0Aaron HeapsNo ratings yet

- Spot LifterDocument4 pagesSpot Liftereva septiaNo ratings yet

- MSDS 15W40Document4 pagesMSDS 15W40Sukhjeet SinghNo ratings yet

- 1 Chemical Product & Company Identification: Material Safety Data SheetDocument7 pages1 Chemical Product & Company Identification: Material Safety Data Sheetgazwang478No ratings yet

- Cat Yellow Paint High Gloss Fast DryingDocument10 pagesCat Yellow Paint High Gloss Fast DryingClemente ZamudioNo ratings yet

- Open Gear Lube, Aerosol: Safety Data SheetDocument7 pagesOpen Gear Lube, Aerosol: Safety Data SheetWork ForceNo ratings yet

- Material Safety Data Sheet: Remove DebonderDocument4 pagesMaterial Safety Data Sheet: Remove DebonderSales OnlineNo ratings yet

- Hiquench MT 650: Material Safety Data SheetDocument3 pagesHiquench MT 650: Material Safety Data SheetMurali Krishna100% (2)

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationCleber SilvaNo ratings yet

- HSD PDFDocument7 pagesHSD PDFsaqibNo ratings yet

- Butane Msds E4572Document8 pagesButane Msds E4572Lucious LightNo ratings yet

- Material Safety Data Sheet: Chevron Synthetic Automatic Transmission Fluid Heavy DutyDocument7 pagesMaterial Safety Data Sheet: Chevron Synthetic Automatic Transmission Fluid Heavy DutysofelsbabaNo ratings yet

- Raycol Asphalt Company Limited: Material Safety Data SheetDocument3 pagesRaycol Asphalt Company Limited: Material Safety Data SheetKongsak AkkharawongwhatthanaNo ratings yet

- Carbol Fuchsin Ziehl-Neelsen Stain Safety Data SheetDocument7 pagesCarbol Fuchsin Ziehl-Neelsen Stain Safety Data Sheetdadi hartonoNo ratings yet

- Material Safety Data SheetDocument7 pagesMaterial Safety Data SheetBryan Ramírez CaicheNo ratings yet

- MSDS for Epoxy Resin and HardenerDocument4 pagesMSDS for Epoxy Resin and HardenerShaikhRizwanNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company Decant OilDocument11 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company Decant OilZakyAlFatonyNo ratings yet

- Sds - Safety Data Sheet: 1. IdentificationDocument6 pagesSds - Safety Data Sheet: 1. IdentificationRobin JacobsonNo ratings yet

- MSDS TITLEDocument4 pagesMSDS TITLEمحمد عزتNo ratings yet

- Guidelines For Open Plant StructuresDocument6 pagesGuidelines For Open Plant StructuresIndrawNo ratings yet

- Methyl Ethyl Ketone Safety Data SheetDocument15 pagesMethyl Ethyl Ketone Safety Data SheetArjunNo ratings yet

- Section I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000Document2 pagesSection I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000sebaversaNo ratings yet

- MSDS THINNER 740Document2 pagesMSDS THINNER 740محمد عزتNo ratings yet

- SDS Gard Multi Purpose EP 2 GreaseDocument7 pagesSDS Gard Multi Purpose EP 2 GreasezigaNo ratings yet

- Exxsol D60Document10 pagesExxsol D60Adi WiraNo ratings yet

- Safety Data Sheet for Rando HD Hydraulic OilsDocument9 pagesSafety Data Sheet for Rando HD Hydraulic OilsCarlos GuashcoNo ratings yet

- VCPL SDS - Ee133Document7 pagesVCPL SDS - Ee133Dhia GhoniyyahNo ratings yet

- 09 MSDS Wax DispersantDocument8 pages09 MSDS Wax DispersantVanraj RathodNo ratings yet

- Petroleum Ether PDFDocument9 pagesPetroleum Ether PDFNeal MooreNo ratings yet

- Msds - Hfo Heavy Fuel OilDocument9 pagesMsds - Hfo Heavy Fuel OilKrishnan RajappanNo ratings yet

- MSDS for Elastomeric SealantDocument7 pagesMSDS for Elastomeric SealantNIKKA MANAHANNo ratings yet

- SDS - 110418A Fretboard Conditioner Oil 11-14-18Document5 pagesSDS - 110418A Fretboard Conditioner Oil 11-14-18Rafael FrançaNo ratings yet

- Maintenance Guide Pump TP2530j34Document20 pagesMaintenance Guide Pump TP2530j34Andres GonzalezNo ratings yet

- Item 31 - NACECARE 2016 US Cart Price ListDocument11 pagesItem 31 - NACECARE 2016 US Cart Price ListAndres GonzalezNo ratings yet

- Game Theory - Thomas S. FergusonDocument8 pagesGame Theory - Thomas S. FergusonKenneth TanNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Bluffing Beyond Poker (Johannes Horner, Nicolas Sahuguet) PDFDocument32 pagesBluffing Beyond Poker (Johannes Horner, Nicolas Sahuguet) PDFAndres GonzalezNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Surface Inspection Shielded (Absolute) ProbesDocument2 pagesSurface Inspection Shielded (Absolute) ProbesAndres GonzalezNo ratings yet

- New Section 2 Pages 1-24Document24 pagesNew Section 2 Pages 1-24Andres GonzalezNo ratings yet

- Eddy Current Testing HolesDocument12 pagesEddy Current Testing HolesAndres GonzalezNo ratings yet

- How To Write A Business Plan 4Document2 pagesHow To Write A Business Plan 4Andres GonzalezNo ratings yet

- Uh Manual Perkins 800Document78 pagesUh Manual Perkins 800Birger ErikssonNo ratings yet

- Passive Fire Protection SystemsDocument24 pagesPassive Fire Protection Systemsniyati100% (1)

- UNIT IOG SAMPLE MATERIAL - Hydrocarbon Process Safety PDFDocument7 pagesUNIT IOG SAMPLE MATERIAL - Hydrocarbon Process Safety PDFBakiNo ratings yet

- 08 Handout 1Document7 pages08 Handout 1Cecille Marasigan AnzuresNo ratings yet

- MMG Plus: Use and Maintenance ManualDocument32 pagesMMG Plus: Use and Maintenance ManualTahya SatriaNo ratings yet

- Bulldozer: Serial Numbers and UpDocument405 pagesBulldozer: Serial Numbers and UpJako MishyNo ratings yet

- MsdsDocument6 pagesMsdsGis GeorgeNo ratings yet

- Dabwali Fire Tragedy - 3Document36 pagesDabwali Fire Tragedy - 3Saransh Joshi67% (3)

- Armys Role in DM (Pam 7-031 Disaster Opns MGMT & Opns Manual)Document61 pagesArmys Role in DM (Pam 7-031 Disaster Opns MGMT & Opns Manual)BELANDRES, Darlene Inna C.No ratings yet

- 3) EX 5,02. Accident Analysis ExerciseDocument6 pages3) EX 5,02. Accident Analysis ExerciseAndrejSukoraNo ratings yet

- Abraham and Stollard 1999Document13 pagesAbraham and Stollard 1999Amirah BalqisNo ratings yet

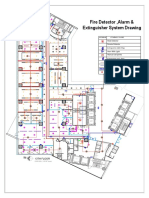

- Fire and Safety System DrawingDocument1 pageFire and Safety System DrawingSofiq100% (1)

- Emergency Response & Disaster Management Plan and Best Practices at NRLDocument41 pagesEmergency Response & Disaster Management Plan and Best Practices at NRLVinod ChaudhariNo ratings yet

- 748H Novo Monitor Repair BookTM11813 PDFDocument404 pages748H Novo Monitor Repair BookTM11813 PDFLeclerc Keven100% (1)

- Metalica Internacional 7 PDFDocument105 pagesMetalica Internacional 7 PDFLuísNo ratings yet

- Installation Manual: Commercial Mobile Generator SetDocument40 pagesInstallation Manual: Commercial Mobile Generator SetVictor EstrellaNo ratings yet

- Contraflam Lite Data Sheets-File087695Document8 pagesContraflam Lite Data Sheets-File087695Abhey VermaNo ratings yet

- Detroit Lakes Fire Department Annual Report For 2021, Jan. 11, 2022Document3 pagesDetroit Lakes Fire Department Annual Report For 2021, Jan. 11, 2022Michael AchterlingNo ratings yet

- Fire Protection & Jacket Repair of Electrical CablesDocument50 pagesFire Protection & Jacket Repair of Electrical CablesCatanescu Alexandru-LaurentiuNo ratings yet

- MDEA Safety Data SheetDocument8 pagesMDEA Safety Data SheetGhifaris VashaNo ratings yet

- Benzyl Alcohol (Corrosive)Document6 pagesBenzyl Alcohol (Corrosive)Yojana SonawaneNo ratings yet

- Laporan Praktikum KebakaranDocument10 pagesLaporan Praktikum Kebakaranafif armadaniNo ratings yet

- Quiz 2Document8 pagesQuiz 2Rogelio MordenoNo ratings yet

- Material Safety Data Sheet QA & PD Department: Standard Must Be Consulted For Specific RequirementsDocument3 pagesMaterial Safety Data Sheet QA & PD Department: Standard Must Be Consulted For Specific RequirementsfitriNo ratings yet

- Scale Inhibitor - Gyptron IT-265 - MSDS - ENGDocument5 pagesScale Inhibitor - Gyptron IT-265 - MSDS - ENGTHANGVUNo ratings yet

- Manual Ms 194tDocument128 pagesManual Ms 194tChristian SkalariNo ratings yet

- CFO 90 Mts. 31 Dec 2021 4.48 PMDocument4 pagesCFO 90 Mts. 31 Dec 2021 4.48 PMBholanath SanhotraNo ratings yet

- Fire WatcherDocument37 pagesFire WatcherSaeed MalikNo ratings yet

- MowersDocument132 pagesMowersguillermosNo ratings yet

- FM Global 2Document28 pagesFM Global 2Suciu MariusNo ratings yet