Professional Documents

Culture Documents

Reparación de Orbitrol - YALE GLC050VX

Reparación de Orbitrol - YALE GLC050VX

Uploaded by

John Paval0 ratings0% found this document useful (0 votes)

61 views7 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

61 views7 pagesReparación de Orbitrol - YALE GLC050VX

Reparación de Orbitrol - YALE GLC050VX

Uploaded by

John PavalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

ring Control Unit Repair

Stee!

STEERING CONTROL UNIT, REMOVE

& warnine

Lower carriage completely before working on con-

trol valve or hydraulic system. Do not work under

a raised carriage. Put mast in a vertical position

and lower carriage completely before disconnect-

ing any parts of hydraulic system. The mast can

lower suddenly and cause injury if the carriage is

not lowered.

4. Power wash the interior of the operator compart-

‘ment to remove any dirt or debris.

2. Move truck to disassembly area and shut off engine.

& warnine

Cleaning solvents can be flammable and toxic and

cause skin iritation. When cleaning solvents are

teed, always follow the solvent manufacturer's

recommended safety procedures, Wear protective

Goggles ot a face shield te prevent aye injuries,

NOTE: Take any necessary steps to prevent debris,

dust, or other contaminants from entering the valve cav-

ities, hydraulic lines, or replacement parts.

3. Remove the floor plate, kick panel, seal plate, and

dashboard.

‘Soe Frame 100 YRM 1120 for lft truck models

+ GCIGLCO30VX, GCIGLCO35VX

GCIGLCO40SVx (C809)

+ GLPIGDP16VX, GLP/GDP18Vx,

GLP/GDP20SVX (GP/GLP/GDPO30Vx

GPIGLP/GDPO35VX, GP/GLP/GDPO40SVX)

(c810)

+ GLC20-38VX (GCIGLC040-070VX,

GCIGLCOSSSVX) (A910)

+ GLP/GDP20-35VX (GP/GLP/GDPO40-070VX)

(8875)

‘See Frame 100 YRM 1243 for lift truck models

+ GLC40, 45, §5VX; GLOSSSVX; (GC/GLCO8O,

100, 120VX; GC/GLC080, 100VXBCS;

GCIGLC120SVX; GC/GLC120VXPRS) (E818)

+ GLP/GDP40VXSIVX6; GLP/GDP45SVX5,

GLP/GDP45VX6; GLP/GDP50-55VX

(GPIGLP/GDPO80, 090, 100, 110, 120VX)

(F813, 6813)

78

g Control U:

2000 YRM 1137

Repair

‘See Frame 100 YRM 1316 for lft truck models

+ GLCIGDC6OVX, GLCIGDC70VX, (GC/GLO/

GDC135VX, GCIGLC/GDC155VX) (C873,

0879)

‘See Frame 100 YRM 1321 for lft truck models

+ GLP/GDP80VX, GLP/GDP70VX

(GPIGLP/GDP135VX, GP/GLP/GDP155VX)

(c878, D878)

+ GLP/GDP80VX, GLP/GDP8OVX9,

GLPIGDP9OVX (GDP170VX, GDP175Vx36,

GDP190VX) (A909)

‘See Frame 100 YRM 1423 for lft truck models.

+ GLCOSOLX (A967)

+ GLPOSOLX (A974)

&\ caution

To prevent any foreign matter from getting into

either the hydraulic hoses or the hydraulic control

valve sections, all openings must have plugs or

covers installed immediately after hoses are dis-

connected from the control valve. This also applies

if any other items are removed from the control

valve.

NOTE: To aid in the correct connection of hydraulic,

hoses during installation, tag each hose prior to discon-

necting from the control valve.

‘4, Disconnect hydraulic hoses from the steering con-

trol unit, Install plugs or caps on all open hose ends

and control valve ports to prevent contamination,

See Figure 61 or Figure 62

Remove the two SCU mounting bolts and move

the SCU approximately 1.3 om (0.5 in.) to the left,

and lower the SCU unti the steering shaft is disen-

gaged. Remove the SCU from the lift truck. See

Figure 61 or Figure 62.

6. Remove and discard two O-rings from between the

‘SCU and the main control valve.

7. Coatthe machined surface of the main control valve

with a light coat of hydraulic oil to prevent the possi-

bility of rust. Cover the exposed machined surface

of the main control valve to prevent the possibility

of foreign matter getting into the main control vaive.

Confidential/Proprietary - Do Not Copy or Dupli

2000 YRM 1137 Steering Control Unit Repair

NOTE: ELECTRO-HYDRAULIC MAIN CONTROL VALVE SHOWN. LIFT TRUCK MODELS GLCOSOLX (A967) AND

GLPOSOLX (A974) EQUIPPED WITH MANUAL MAIN CONTROL VALVE ONLY, BUT REPAIR OF STEERING CON-

TROL UNIT THE SAME.

1. "LY STEERING SYSTEM HOSE 4, SCU MOUNTING CAPSCREWS,

2. "RY STEERING SYSTEM HOSE 5. STEERING CONTROL UNIT (SCU)

3. HYDRAULIC INPUT HOSE 6. STEERING COLUMN

Figure 61. Steering Control Unit, Lift Truck Models GCIGLCO30VX, GCIGLCO35VX, GCIGLCO40SVX

(C809), GLPIGDP16VX, GLPIGDP18VX, GLPIGDP20SVX (GPIGLPIGDPO30VX, GPIGLPIGDPO35VX,

GPIGLPIGDPO40SVX) (C810), GLC20-35VX (GCIGLC040-070VX, GCIGLCOSSSVX) (A910), GLPIGDP20-35VX

(GPIGLPIGDP040-070VX) (B875), GLC40, 45, 55VX; GLCS5SVX; (GCIGLC080, 100, 120VX; GCIGLCO8O,

100VXBCS; GCIGLC120SVX; GCIGLC120VXPRS) (E818), GLPIGDP40VXSIVX6; GLPIGDP45SVX5,

GLPIGDP45VX6, GLPIGDP50-55VX (GPIGLPIGDPO8O, 090, 100, 110, 120VX) (F813, G813)

Confidenti

liProprietary - Do Not Copy or Duplicate 79

ring Control Unit Repair 2000 YRM 1137

" STEERING SYSTEM HOSE 4, STEERING COLUMN

2) "LY STEERING SYSTEM HOSE 5. SCU MOUNTING CAPSCREWS

3, STEERING CONTROL UNIT (SCU) 6. HYDRAULIC INPUT HOSE

Figure 62. Steering Control Unit, Lift Truck Models GLCIGDCS0VX, GLCIGDC7OVX (GCIGLCIGDC135VX,

GCIGLCIGDC155VX) (C879, D878), GLPIGDP60VX, GLPIGDP7OVX (GPIGLPIGDP135VX,

GPIGLPIGDP155VX) (C878, D878), and GLPIGDP80VX, GLPIGDP80VX9, GLPIGDPSOVX (GDP170VX,

GDP175VX36, GDP190VX) (A908)

STEERING CONTROL UNIT, ‘4, Remove the cardan shaft from the spool assembly.

DISASSEMBLE

5. Remove the spool assembly rom the steering con-

4. Place the steering pump into a softjaw vise with the trol unit housing

splined end facing down 6. Remove the thrust washer, thrust bearing, and

NOTE: Note the position of the special screws when thrust washer from the shaft end of the spool as-

removed, so that they will be installed in the same po- sembly.

sions at sssembly of the steering control unit 7. Remove the retaining ring from the spool assembly.

2. Remove the capscrews, special screws, andwash- B12. the cross pin out ofthe spool assembh

ers. Rotate the steering pump 90 degrees sideways ress pin ou Ps mbly.

in the vise. See Figure 63. 9. Press the spool from the sleeve. Remove the

3. Remove the end cover, O-ring, gear ring, O-ring, springs from the spool

gear, distributor plate, and O-ring from the steering

control unit, Discard the O-rings.

80 Confidential/Proprietary - Do Not Copy or Duplicate

2000 YRM 1137 Steering Control Unit Repair

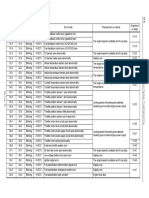

1. CAPSCREW 418. THRUST WASHER

2, SPECIAL SCREW 46. THRUST BEARING

3. WASHER 17. SEAL

4. END COVER 48. EMERGENCY STEER SEAT

5. O-RING 19. EMERGENCY STEER CHECK BALL

8 GEAR RING 20. STEERING CONTROL UNIT HOUSING

7. GEAR 21. SYSTEM RELIEF VALVE

8, DISTRIBUTOR PLATE 22. CAP

9. CARDAN SHAFT 23. MOUNTING BOLT

40. SPRING SET 24. LOCKWASHER

11. SLEEVE 25. LOAD SENSE PLUG

12. CROSS PIN 26. LOAD SENSE CHECK BALL

13. SPOOL 27. LOAD SENSE SEAT

14. RETAINING RING

Figure 63. Steering Control Unit

NOTE: To aid in installation of the emergency steering 10. Remove the emergency steering seat and emer

seat and emergency steering check ball, note the hole gency steering check ball from the steering control

position of the emergency steering seat and emergency Unit housing

steering check ball during removal.

Confidenti

liProprietary - Do Not Copy or Duplicate a

Steering Control Unit Repair

NOTE: To aid in installation of the load sense check ball

and seat, note the hole position of the load sense seat

and load sense check ball during removal.

11. Remove the load sense seat and load sense check

ball from the steering control unit

12, Remove the shaft seals from the pump housing.

Discard the seals.

13. Remove the cap and system relief valve from the

steering control unit. If the system relief valve

needs to be repaired, go to Relief Valve, Disas-

semble,

STEERING CONTROL UNIT, CLEAN

A warnine

Cleaning selvents can be flammable and toxic and

can cause skin irritation. When using cleaning

solvents, always follow the solvent manufacturer's

recommended safety precautions.

A warnine

Compressed air can move particles so that they

cause injury to the user or to other personnel

Make sure that the path of the compressed air Is

away from all personnel. Wear protective goggles

or a face shield to prevent injury to the eyes.

Clean all the parts in solvent. Dry the parts with com-

pressed air. Donot dry the parts with a cloth, Make sure

all surfaces are free of scratches and sharp edges.

STEERING CONTROL UNIT, INSPECT

Inspect all parts for damage, if any parts other than

those parts contained in parts kits Yale 580054569 (seal

kit) or Yale PIN 58006021 (capscrew kit) are damaged,

replace the steering control unit. If he Steering control

Unit is not going to be installed on the main control valve

immediately, coat the machined mating surface with a

light coat of hydraulic oil and install plugs in any open

ports to prevent the possibility of any foreign matter get-

ting into the steering control unit.

STEERING CONTROL UNIT, ASSEMBLE

NOTE: Apply alight coat of clean hydraulic oilto O-rings.

and seals to assist in installation,

4. Using a seal installer, install the shaft seals in the

steering control unit housing.

82

2000 YRM 1137

2. Install the spool into the sleeve with the key slots

opposite each other. See Figure 63,

3. Insert the curved springs between the flat springs.

NOTE: The retaining ring must be able to rotate unim-

eded by the springs.

‘4, Center the springs n the spool assembly, and install

the retaining ring over the springs.

5. Install the cross pin into the spool assembly.

6. Install the thrust washer, thrust bearing, and thrust,

washer on the spool

7. Place the pump housing in a soft jawed vise in the

horizontal position. Install the spool assembly into

the housing while holding the cross pin in a hori-

zontal position.

8. With the pump housing stil in the horizontal posi-

tion, install the spool so that the pin in the spool

is in the horizontal position. When the spool is in-

stalled rotate the steering control unit to the vertical

position,

9, Install the emergency steering check ball, and

‘emergency steering seat in the steering control

unit housing as noted during removal. Tighten

the emergency steering seat to 1.5 40.3 Nem (13

#25 Ibf in),

10. Install the load sense check ball and load sense

seat in the steering control unit as noted during re-

moval. Tighten the load sense seat to 1.5 +0.3 Nem

(13 42.5 Ibf in)

14. Install a new O-ring on the steering control unit

housing, and place the distributor plate on the

steering control unit housing, with the holes prop-

erly aligned with the steering control unit housing.

12. Install the cardan shaft and rotate it until it is en-

gaged with the pin in the spool assembly.

13. Install the gear ring onto the cardan shaft

14, Install new O-ring, gear, and new O-ring onto the

gear ring and install the gear ring onto the distrib-

Utor plate, making sure that the holes are properly

aligned,

16. Install a new O-ring onto the gear ring. Install ond.

cover, special capscrews, and washers as noted

during disassembly. Tighten all capscrews to 30

46 Nem (265 253 lf in),

Confidential/Proprietary - Do Not Copy or Duplicate

2000 YRM 1137

16. If removed, install the system relief valve. Place

the torque tool in the notches on the cartridge

body (see Figure 64). Tighten to 18 +6 N-m (160

+453 Ibf in). Install the tamper proof cap into the

steering control unit housing.

RELIEF VALVE, DISASSEMBLE

41. Remove the snap ring and ant-tamperring from the

cartridge body. See Figure 64.

ig

™ $6

° 4 By

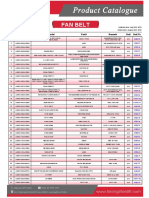

4. SNAP RING 5. SEAT

2, ANTI-TAMPER 8 CARTRIDGE BODY

RING 7. O-RING

3. PLUG. 8 BACKUP RING

4. SPRING

Figure 64. System Relief Valve

NOTE: Note the number of turns to remove plug from

cartridge body to aid in installation.

2. Remove the plug, spring, and seat from the car-

tridge body.

3. Remove and discard small O-ring, backup ring, and.

large O-ring from the cartridge body.

RELIEF VALVE, CLEAN

& warnine

Cleaning solvents can be flammable and toxic and

can cause skin initation. When using cleaning

solvents, always follow the selvent manufacturer's

recommended safety precautions

& warnine

Compressed air can move particles so that they

cause injury to the user of to other personnel

Make sure that the path of the compressed ai

Confidenti

liProprietary - Do Not Copy or Duplicate

Steering Control Unit Repair

away from all personnel. Wear protective goggles

or a face shield to prevent injury to the eyes.

Clean all the parts in solvent. Dry the parts with com-

pressed alr. Donot dry the parts with a cloth. Make sure

all surfaces are free of scratches and sharp edges.

RELIEF VALVE, INSPECT

Inspect all parts for damage, if any parts other than

those parts contained in parts kits Yale P/N 580054569,

{seal kit) are damaged, replace the relief valve. If the

relief valve is not going to be installed in the steering

control housing immediately, coat the valve with a light

coat of hydraulic ol.

RELIEF VALVE, ASSEMBLE

NOTE: Apply a light coat of clean hydraulic oilto O-rings

and seals to assist in installation.

1. Install the large O-ring, backup ring, and small

O-ring on the cartridge body. See Figure 64.

Install the seat and spring into the cartridge body.

Install plug the number of turns noted during disas-

sembly.

4. Install the anti-tamper ring and snap ring into the

cartridge body.

5. Install the system relief valve into steering control

Unit housing. Place the torque tool in the notches

on the cartridge body (see Figure 64). Tighten to 18

+6 Nem (160 +53 [bf in). Install the cap onto system

relief valve. See Figure 63,

STEERING CONTROL UNIT, INSTALL

1. Coat the two O-rings to be installed on the main

control valve with clean hydraulic oil. Install the

‘two O-rings between the main control valve and the

cu

NOTE: During the performance of Step 2, use care not,

to damage the O-rings on the main control valve.

2. Position the SCU under the steering shaft and raise

the SCU to completely engage the steering shaft.

When the steering shaft is completely engaged,

position the SCU against the main control valve,

and install two mounting capscrews and washers.

Tighten to 45 to 55 Nem (33 to 41 Ibf ft.

3. Remove all plugs and caps and install the hydraulic,

hoses as noted during removal.

83

ring Control Unit Repair

4, Install dashboard, seal plate, kick panel, and floor

plate.

‘See Frame 100 YRM 1120 for lft truck models

+ GCIGLCO30VX, GC/GLCO35VX,

GCIGLCO40SVX (C809)

+ GLP/GDP16VX, GLP/GDP18VXx,

GLP/GDP208VX (GP/GLP/GDPO30VX,

GPIGLP/GDPO35VX, GP/GLP/GDPO40SVX)

(C810)

+ GLO20-35VX (GC/GLC040-070VX,

GCIGLCOSSSVX) (A910)

+ GLP/GDP20-35VX (GP/GLP/GDP040-070VX)

(6875)

‘See Frame 100 YRM 1243 for lift truck models

+ GLC40, 45, 55VX; GLCSSSVX; (GCIGLC0BO,

100, 120VX; GC/GLCO80, 100VXBCS;

GCIGLC120SVX; GC/GLC120VXPRS) (E818)

+ GLP/GDP40VXSIVX6; GLP/GDP45SVX5,

GLP/GDP45VX6; GLP/GDPS0-55VX

(GPIGLP/GDPO80, 090, 100, 110, 120VX)

(F813, G13)

2000 YRM 1137

‘See Frame 100 YRM 1316 for lft truck models

+ GLCIGDC60VX, GLCIGDC70VX, (GC/GLC/

GDC135VX, GCIGLC/GDC155Vx) (C879,

D879)

See Frame 100 YRM 1321 for lift truck models

+ GLP/GDP6OVX, GLP/GDP70Vx

(GPIGLP/GDP135VX, GP/GLP/GDP155VX)

(c878, D878)

+ GLP/GDP8OVX, GLP/GDPEOVX9,

GLP/GDP90VX (GDP170VX, GDP175Vx36,

GDP190VX) (A809)

‘See Frame 100 YRM 1423 for lft truck models.

+ GLCOSOLX (A967)

+ GLPOSOLX (A974)

5. Check the steering relief pressure. See Table 2.

If the steering relief pressure is not correct, adjust

the pressure by turning the plug clockwise {in-

crease pressure) or counterclockwise (decrease

pressure) until the correct pressure is reached.

See Figure 64.

Table 2. Steering Relief Pressures

Lift Truck Model

Steering Relief Pressure @ 800 RPM

GCIGLCO3OVX, GC/GLCO35VX, GC/GLCO40SVX

(C809) and GLP/GDP16VX, GLP/GDP18VX,

GLP/GDP20SVX (GP/GLP/GDP030VX,

GPIGLP/GDPO35VX, GP/GLP/GDPO40SVX) (C810)

7.25 40.3 MPa (1051 243.5 psi)

‘GLC20-30VX (GC/GLC040-060VX, GC/GLCOSSSVX)

(A910) and GLP/GDP20-30VX (GP/GLP/GDP040-

060VX) (8875), GL.COSOLX (A967), GLPOSOLX (A974)

11.0 20.3 MPa (1595 £43.5 psi)

GLC35VX (GC/GLCO7OVX) (A910) and

GLP/GDP35VX (GP/GLP/GDPO70VX) (8875)

12.0 £0.3 MPa (1740 +43.5 psi)

GLC40, 45, SSVX; GLCSSSVX (GC/GLCO8O, 100,

120VX; GCIGLC080, 100VXBCS; GC/GLC120SVX;

GC/GLC120VXPRS) (E818)

10.3 20.3 MPa (1494 243.5 psi)

GLP/GDP40VXS/VX6; GLP/GDP4SSVX5, GLP/

GDP45VX6, GLP/GDPS0-55VX (GP/GLP/GDPO80,

(090, 100, 110, 120VX) (F813, G813)

12.4 20.3 MPa (1798 243.5 psi)

GLCIGDO6OVX, GLCIGDC7OVX (GC/GLCY

GDC135VX, GC/GLC/GDC155VX) (C879, D879) and

GLP/GDP60VX, GLP/GDP7OVX (GP/GLP/GDP135VX,

GPIGLP/GDP155VX) (C878, D878)

12.4 20.3 MPa (1798 243.5 psi)

GLP/GDP8OVX, GLP/GDP80VX9, GLP/GDPSOVX

(GDP170VX, GDP175VX36, GDP190VX) (A909)

15.8 20.3 MPa (2250 £43.5 psi)

84

Confidential/Proprietary - Do Not Copy or Duplicate

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Codigo de Falla - Toyota Serie 8Document7 pagesCodigo de Falla - Toyota Serie 8John Paval100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Catalogo Asientos - SMHDocument12 pagesCatalogo Asientos - SMHJohn PavalNo ratings yet

- FAJASDocument1 pageFAJASJohn PavalNo ratings yet

- Catalogo Uñas SMHDocument1 pageCatalogo Uñas SMHJohn PavalNo ratings yet

- IC4 0-Mini5 0Document88 pagesIC4 0-Mini5 0John PavalNo ratings yet

- PREFASEDocument51 pagesPREFASEJohn PavalNo ratings yet

- Catalogo de Partes - Yale FrenoDocument5 pagesCatalogo de Partes - Yale FrenoJohn PavalNo ratings yet

- Ic1 0-4 0Document101 pagesIc1 0-4 0John PavalNo ratings yet

- 4wheel ElectricDocument76 pages4wheel ElectricJohn PavalNo ratings yet

- Filtros de Combustible - FOLANGSIDocument4 pagesFiltros de Combustible - FOLANGSIJohn PavalNo ratings yet

- Ventiladores - FOLANGSIDocument3 pagesVentiladores - FOLANGSIJohn PavalNo ratings yet

- Filtros Hidráulicos - FOLANGSIDocument3 pagesFiltros Hidráulicos - FOLANGSIJohn PavalNo ratings yet

- 2012-9-14 New Forklift Alternators & Distributors 7Document2 pages2012-9-14 New Forklift Alternators & Distributors 7John PavalNo ratings yet

- Alternadores - FOLANGSIDocument3 pagesAlternadores - FOLANGSIJohn PavalNo ratings yet