Professional Documents

Culture Documents

An Overview of Research on Surface Coatings

Uploaded by

Rey TmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Overview of Research on Surface Coatings

Uploaded by

Rey TmCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/319207193

An Overview of Research Work in Surface Coating

Article · January 2013

CITATIONS READS

2 4,709

3 authors, including:

Vineet Shibe Vikas Chawla

Punjab Technical University Punjab Technical University

15 PUBLICATIONS 48 CITATIONS 85 PUBLICATIONS 1,026 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Characterisation of coating sprayed by D-Gun and LVOF methods View project

A Review of Surface Modification Techniques in Enhancing the Erosion Resistance of Engineering Components View project

All content following this page was uploaded by Vineet Shibe on 22 August 2017.

The user has requested enhancement of the downloaded file.

ISSN : 2249-5762 (Online) | ISSN : 2249-5770 (Print) IJRMET Vol. 3, Issue 2, May - Oct 2013

An Overview of Research Work in Surface Coating

1

Vineet Shibe, 2Vikas Chawla

1

Ph.D. Research Scholar, Dept. of Mechanical Engg., Punjab Tech. University, Jalandhar, Punjab, India

2

DAV College of Engineering and Technology, Kanina, Mohindergarh, Haryana, India

Abstract surface characteristics of engineering materials have a significant

Surface coating is an economic method for the production of effect on the serviceability and life of a component thus cannot

materials, tools and machine parts that require the desired be neglected in design [4]. Wear resistance of materials can be

surface properties such as corrosion, erosion and wear resistance. improved through surface modification techniques. Surface

Individuals and industry tend to focus on the wearing surface coatings may improve the surface’s resistance to corrosion,

that has the greatest impact on their own economic situation. erosion, impact breaks and abrasive wear.

Research is going on over years to reduce the corrosion, erosion Surface engineering can be defined as the branch of science that

and wear either in the form of using a new corrosion, erosion deals with methods for achieving the desired surface requirements

and wear resistant material or by improving these properties in and their behavior in service for engineering components [5].

the existing material by using surface coating methods. In this The effect of surfacing on component life and performance will

paper an attempt has been made to review the work of some depend upon the surface material, alloy, service conditions and

researchers who conducted the experimental studies on different the application process [6].

surface coatings, which are employed on the substrate surface of In this paper an attempt has been made to review the work of some

material by different methods. The various coating methods used researchers who conducted the experimental studies on different

and their advantages have been discussed. surface coatings. The various coating methods used and their

advantages have been discussed.

Keywords

Surface coatings, Thermal Spraying, Abrasive Wear II. Surface Coating Methods

Surface coating methods are classified as under:

I. Introduction • Thermal Spraying (Metal Spraying)

Corrosion is an unintentional gradual degradation of metal that • Chemical Vapor Deposition (CVD)

occurs because of chemical or electrochemical attack. As a result • Physical Vapor Deposition (PVD)

of corrosion metal gets converted to its compounds such as oxides,

chlorides, nitrides, sulphides, etc depending upon the environment. A. Thermal Spraying

Corrosion may be classified as dry corrosion, wet corrosion and It is a group of processes wherein a feedstock material is heated

hot corrosion. and propelled as individual particles or droplets onto a surface.

Erosion is the removal of material from a surface by high velocity Sprayed particles impinge upon the surface, they cool and build

fluids containing solid particles, or small drops of liquid or gas. up, splat by splat, into a laminar structure forming the thermal

It is the progressive loss of original material from a solid surface spray coating. A detonation gun unit mainly consists of a doubled

due to mechanical interaction between that surface and a fluid, a walled barrel, a combustion chamber, a powder feeder, control

multi-component fluid of impinging liquid or solid particles. panels to regulate gas flows and gas operation. The set-up also

When two surfaces are in contact, wear occurs on both of them. includes an appropriate manipulator to hold the work piece and

Wear is the predominant factor that controls the life of any machine control its movements. A barrel is filled with a small amount of

part. Most worn parts don’t fail from a single mode of wear, but powder and an explosive oxygen-acetylene mixture. With the use

from a combination of modes, such as abrasion and erosion etc. of a spark plug, the mixture is ignited. After ignition, a detonation

Wear is a process of removal of material from one or both of wave accelerates and heats the entrained powder particles. Instead

two surfaces in solid state [1]. It occurs when solid surfaces of a continuous combustion process, it uses an intermittent series

are in sliding or rolling motion relative to each other. In well- of explosions to melt and propel the particles onto the substrate.

designed tribological systems, the removal of material is usually After each detonation, the barrel is purged with nitrogen. This step

a very slow process but it is very steady and continuous [2]. Wear is essential to remove all remaining “hot” powder particles from

related failure of machinery components counts as one of the the chamber; otherwise these can detonate the explosive mixture in

major reasons for inefficient working of machines in a variety of an irregular fashion. With this, one detonation cycle is completed.

engineering applications. The above procedure is repeated at a particular frequency until the

These wear and corrosion related problems can be minimized required thickness of coating is deposited. The process produces

mainly by following two methods [3]: noise levels that can exceed 140 decibels and requires special

• By using high cost wear resistant alloys/metals better than sound and explosion proof rooms. Depending upon the ratio of

the existing low cost ones. the combustion gases, the temperature of the hot gas stream can

• By improving the wear resistance of the existing metals and go up to 3890°C and the velocity of the shock wave can reach

alloys by applying certain modifications to the surface. 3500m/s. Depending on the required coating thickness and the

Serviceable engineering components not only rely on their bulk type of coating material the detonation spraying cycle can be

material properties but also on the design and characteristics of repeated at the rate of 1-10 shots per second.

their surface [4]. The behavior of a material is therefore greatly

dependent on the surface of a material, surface area in contact

and the environment under which the material must operate. The

surface of these components may require certain treatments (called

surface engineering) to enhance the surface characteristics. The

w w w. i j r m e t. c o m International Journal of Research in Mechanical Engineering & Technology 85

IJRMET Vol. 3, Issue 2, May - Oct 2013 ISSN : 2249-5762 (Online) | ISSN : 2249-5770 (Print)

B. Chemical Vapor Deposition (CVD)

It involves the dissociation and/or chemical reactions of gaseous

reactants in a activated (heat, light, plasma) environment, followed

by the formation of a stable solid product. The deposition involves

homogeneous gas phase reactions, which occur in the gas phase,

and/or heterogeneous chemical reactions which occur on/near the

vicinity of a heated surface leading to the formation of powders

or films, respectively.

Advantages of Chemical Vapor Deposition (CVD) method are:

• The capability of producing highly dense and pure

materials.

• Produces uniform films with good reproducibility and

adhesion at reasonably high deposition rates.

• CVD is a non-line-of-sight process with good throwing

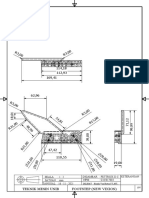

Fig. 1: Thermal Spray power. Therefore, it can be used to uniformly coat complex

shaped components and deposit films with good conformal

coverage.

• It has the ability to control crystal structure, surface morphology

and orientation of the CVD products by controlling the CVD

process parameters.

• Deposition rate can be adjusted readily.

• Low deposition rate is favored for the growth of epitaxial

thin films for microelectronic applications. However, for the

deposition of thick protective coatings, a high deposition rate

is preferred and it can be greater than tens of mm per hour.

This is substantially exceeded only by techniques such as

plasma spraying.

C. Physical Vapor Decomposition (PVD)

It is based on separating atoms from surfaces and accumulating

(atomic or ionic) them to sub material surface to be coated, by

evaporating or sloping materials under vacuum. Coating material,

in PVD method, is transmitted to surface in atomic, molecular

or ionic form, obtaining it not chemically but physically from

solid, liquid and gas source. Chemical reactions can exist on

main material surface too colder than CVD coating (50500 °C);

however such a reaction formation is no necessary. It is more

interesting that PVD operation is performed in relatively lower

Fig. 2: General Thermal Spray Process temperatures. In addition, after completion of coating micro

structure and properties of main material are not affected. PVD

Advantages of detonation spray coating process are: Method is carried out by three methods called as evaporating,

• Low substrate temperature dispersion and ionic coating.

• Low cost of operation Advantages of Physical Vapour Decomposition (PVD) coatings

• Less gas consumption are:

• Less scrap • Covered material reaches very high surface hardness levels

• High bond strength (3000 – 4000 HV about 85 – 90 HRC) without loss of its

• Dense microstructure resistance and its abrasive resistance increases.

• As coating penetrates to main material, it adheres to perfectly

material and it is inseparable as result of being exposed to

thermal expansion or trauma.

• As thermal transmittance of coating is on low level, it can

move up to high speed (approximately 30 % speed and

penetration are obtained.). For this reason, work item surface

becomes smooth.

• Coefficient of friction on cutting edge decreases; lubricity

level increases and edge accumulations don’t exist in the

course of cutting.

• As coating thickness is between 2–15 μm, tolerances of

covered items are unchanged. Tools can be used without

necessity of an additional operation.

• As its color is different from tools, tools wearing can be

Fig. 3: Thermal Spray Applications easily definable.

86 International Journal of Research in Mechanical Engineering & Technology w w w. i j r m e t. c o m

ISSN : 2249-5762 (Online) | ISSN : 2249-5770 (Print) IJRMET Vol. 3, Issue 2, May - Oct 2013

Table 1: Characteristic of Coating Methods Singh et al (2003) investigated the NiCrAlY, Ni-20Cr, Ni3Al and

Thermal satellite-6 coatings on Fe-based super alloy at temperature 900

Characteristic CVD PVD ºC in the molten environment under cyclic conditions [5]. After

Spray

Low to Moderate to performing XRD, SEM/EDAX and EPMA, they found that all

Equipment Cost Moderate these coating showed better resistance to hot corrosion as compared

Moderate High

Low to Low to Moderate to to that of uncoated super alloy and NiCrAlY was found to be most

Operating Cost protective followed by Ni-20Cr coating. The Ni3Al coating was

Moderate Moderate High

Substrate Low to Moderate to also effective in decreasing the weight gain to about one third

Low as compared to uncoated super alloy. They further found that

Temperature Moderate High

satellite coating was least effective but still decreases the weight

Thick

50um-cm gain to about 60% that of uncoated super alloy. The formation of

Coating Thin –Thick Very Thin to oxides and spinels of Ni, Al, Cr or Co may be contributing to the

High

Thickness 0.1-mm Moderate development of hot corrosion resistance.

Coating

Rates Gulene & Kahraman (2002) examined that the abrasive wear rate

Moderate

can often be reduced by the application of hard materials [6]. The

Good Mechanical transition from low wear to high wear with increasing hardness

Very Good of the abrasive is very instructive and abrasive wear resistance of

Adherence Mechanical Bond

Chemical Bond flame sprayed coatings observed to be dependent on the chemical

Bond Very Good

Chemical Bond composition and characteristics of coating materials and coating

condition.

IV. Some Studies Related to Surface Coatings Gitanjali et al (2000) reported that by controlling the various

Current research on surface coating focuses on using various process parameters (air /fuel ratio, temperature, pressure, etc.)

coating methods, parameters, different base materials and materials of boiler and gas turbines were also useful to some extent in

to be coated. combating oil ash corrosion [7]. The low excess of combustion

Lozano D.E., Mercado-Solis R.D. (2009) evaluated wear air can control hot temperature of boilers to some extent. As a

performance of the new hypereutectic Al-Si-Cu alloy using Pin- matter of fact excess of oxygen promotes formation of SO3 and

on-disc tribometer [1]. Modern engine blocks use grey iron liners V2O5 (melting point 675ºC) instead of lower oxides V2O3-V2O4

from the engine bore; however a new hypereutectic Al alloy was (melting point 2000ºC). The industrial practice generally does not

developed to eliminate grey iron liners from engine block. Wear allow operating with low excess of combustion air, consequently

evaluation was carried out at different loading conditions, various the use of additives turns out to be the only effective means to

sliding speeds and various sliding distances under lubricated and prevent corrosion at elevated temperatures.

un-lubricated conditions. Wilson S., Alps A.T. (1998) performed dry sliding wear experiments

Bobzin K., Lugscheider E. (2007) examined magnetron sputtered using TiN coatings on AISI M2 high-speed steel substrate [8]. Wear

three (Cr 1-x Alx) N coatings on their tribological characteristics rates, coefficients of friction, and temperatures of were measured

with different aluminum contents (x = 0; 0.23; 1) .The tests were as a function of load. Three wear regimes were identified; transfer

performed on BoD tribometer. The ceramics Al2O3 and Si3N4 and build up of oxidized pin debris on the coating (20N), increased

were used as counterpart materials [2]. The counterpart wear for polishing damage and brittle spallation failure of the TiN (50-

Al2O3 was less than for Si3N4. On the contrary the highest wear 100N), a sharp transition to plastic deformation microploughing of

rates of coated samples were measured for Al2O3. With regard to TiN (>100N) which coincided with critical steady state temperature

coatings, Cr 0.77 Al 0.23 N showed the lowest wear rates in all of 160 degrees. Softening of TiN above this temperature leads to

cases, though the friction coefficient of Cr 0.77 Al 0.23 N against rapid wear and exposure of substrate material.

Si3N4 was the highest.

Shaffer S.J., Rogers M. J. (2007) assessed the tribological V. Conclusion

performance of a variety of coatings under un-lubricated sliding Surface coating improves the life of the worn out component

conditions [3]. Coatings types investigated include: TiCN, PTFE and reduces the cost of replacement. It reduces downtime by

filled resin-bonded coatings, electro less nickel- cobalt alloy extending the service life and hence few shutdowns are required

coatings, ferritic nitro-carburizing treatment etc. Substrate included to replace them. The purpose of surface technology is to produce

medium carbon steel, D2 tool steel and 6061-T6 aluminum. The functionally effective surfaces. A wide range of coatings can

tests were run using a cylinder-on-flat geometry with self-mated improve the corrosion, erosion and wear resistance of materials.

coatings in both reciprocating and unidirectional conditions. These The various commercially viable coating techniques are thermal

tests ranked the tribological performance of the coatings using both spraying, Chemical Vapor Deposition (CVD) and Physical Vapor

coefficient of friction and wear coefficient. The best performing Deposition (PVD) methods.

samples were tested up to total sliding distance of 3.6 km.

Sidhu et al (2003) studied and concluded that the thermal VI. Acknowledgement

sprayed Ni3Al coatings on boiler tube steels was very effective The authors would like to thank the referees of AMMT-2013

in decreasing corrosion rate in air and molten salt at 900ºC in case for their valuable suggestions and comments for modifying the

of ASTM-SA210 grade A1 steel and ASTM-SA-213-T11 type of contents of this paper.

steel whereas coating was least effective for ASTM-SA-213-T22

steel [4]. They further proposed that uncoated ASTM-SA-213-T22 References

steel showed very poor resistance to hot corrosion in molten salt [1] Bhushan, B., Gupta, B. K.,“Handbook of Tribology: Material

environment with spalling of oxide scale. Coating and Surface Treatments”, McGraw-Hill, New York,

1991.

w w w. i j r m e t. c o m International Journal of Research in Mechanical Engineering & Technology 87

IJRMET Vol. 3, Issue 2, May - Oct 2013 ISSN : 2249-5762 (Online) | ISSN : 2249-5770 (Print)

[2] Archard, J. F.,“Wear Theory and Mechanisms”, Wear Contro

Handbook, ed. M. B. Peterson and W. O. Winer, pp. 35-80, Vineet Shibe received his B.E. degree

ASME, New York, 1980. in Mechanical Engg. from S.L.I.E.T.,

[3] Singh, H., Grewal, M., Sekhon, H., Rao, R.,“Sliding Wear Longowal, India in 2000, the M.E.

Performance of High-Velocity-Oxy-Fuel Spray Al2O3/TiO2 degree in CAD/CAM & Robotics

and Cr2O3 Coatings”, Vol. 222, 2008, pp. 601-610. from Thapar University, Patiala,

[4] Stokes, J.,“Theory and Application of the High Velocity India in 2004 and is a Ph.D. Research

Oxy-Fuel (HVOF) Thermal Spray Process”, Dublin City Scholar, Discipline of Mechanical

University, 2008. Engg., Punjab Technical University,

[5] Halling, J., “Introduction: Recent Development in Surface Jalandhar, India. He was a lecturer in

Coating and Modification Processes”, MEP, London, the Department of Mechanical Engg.,

1985. RIMT-Institute of Engg. & Technology,

[6] Arulmani R., Pandey, S.,“Surfacing Applications: A Review”, Mandigobindgarh in 2004 & 2005. He

National Workshop on Welding Technology, April 25-26, is an Assistant Professor, since August

S.L.I.E.T., Longowal, pp. 233-238, 2003. 2005, B.H.S.B.I.E.T. (Estb. by Govt. of Punjab), Lehragaga, Distt.

[7] Lozano D.E., Mercado-Solis R.D.,“Tribological Behaviour Sangrur, India. His research interests include Computer Aided

of Cast Hypereutectic Al-Si-Cu alloy Subjected to Sliding Designing, Computer Aided Manufacturing, Robotics and Surface

Wear”, Journal of Wear, Vol. 26, 2009, pp. 545-549. Engineering. At present, he is engaged in studying the surface

[8] Bobzin K., Lugscheider E.,“Wear Behaviour of Cr 1-x Al modification techniques such as hardfacing & surface coatings

x N PVD Coatings in Dry Running Conditions”, Journal of for combating wear on boiler components in Coal fired power

Wear, Vol. 263, 2007, pp. 1274-1280. plants.

[9] Shaffer S.J., Rogers M. J.,“Tribological Performance of

various coatings in Unlubricated Sliding for Use in Small

Arms Action Components-A Case Study”, Journal of Wear,

Vol. 263, 2007, pp. 1281-1290.

[10] Sidhu B.S., Parkash S.,“Evaluation of Corrosion Behavior

of Plasma Sprayed Ni3Al Coating on Steel in Oxidation and

Molten Salt Environment at 900ºC”, Surface and Coating

Technology, Vol. 166, No. 1-3, 2003, pp. 89-100.

[11] Singh H., Puri D., Parkash S.,“Some Studies on Hot Corrosion

Performance of Plasma Sprayed Coatings on a Fe-based

Super Alloy”, Surface and Coating Technology, Vol. 192,

2003, pp. 27-38.

[12] Gulene, Kahraman,“Wear Behavior of Bulldozer Rollers

Welded Using a Submerged Arc Welding Process”, Journal

of Materials and Design, Vol. 24, 2003, pp. 537-542.

[13] Gitanjali, Parkash S.,“Review on Effect of Additives on

Hot Corrosion”, NACE International, Vol. 1, 2000, pp. 174-

182.

[14] Wilson S., Alps A.T.,“TiN Coating Wear Mechanisms in

Dry Sliding Contact Against High Speed Steel”, Journal of

Surface & Coatings Technology, Vol. 108-109, 1998, pp.

369-376.

88 International Journal of Research in Mechanical Engineering & Technology w w w. i j r m e t. c o m

View publication stats

You might also like

- A Review On Thermal Spray Coating ProcessesDocument8 pagesA Review On Thermal Spray Coating ProcessesThanhluan Nguyen100% (1)

- Best Practices For Solid Sulphur Handling Dust Mitigation and Control PDFDocument25 pagesBest Practices For Solid Sulphur Handling Dust Mitigation and Control PDFpanoram bou20No ratings yet

- Hydrolyzable Chloride Content of Liquid Epoxy Resins: Standard Test Methods ForDocument3 pagesHydrolyzable Chloride Content of Liquid Epoxy Resins: Standard Test Methods Foralienz1988newNo ratings yet

- Review of Surface Modification Techniques to Enhance Erosion ResistanceDocument5 pagesReview of Surface Modification Techniques to Enhance Erosion ResistanceSandesh SandyNo ratings yet

- A Review of Surface Modification Techniques in Enhancing The Erosion Resistance of Engineering Components 1Document5 pagesA Review of Surface Modification Techniques in Enhancing The Erosion Resistance of Engineering Components 1Sandesh SandyNo ratings yet

- Vapour deposition reviewDocument4 pagesVapour deposition reviewNABIL HUSSAINNo ratings yet

- A Review Paper On Vapour Deposition Coating: Vishakha S. Pahade, Pankaj S. Chavan, Vaishali P. BaisaneDocument4 pagesA Review Paper On Vapour Deposition Coating: Vishakha S. Pahade, Pankaj S. Chavan, Vaishali P. BaisaneerpublicationNo ratings yet

- Control of Gas Nitriding ProcessDocument9 pagesControl of Gas Nitriding ProcessKevin ThomasNo ratings yet

- A Review On Detonation Gun Sprayed Coatings: Lakhwinder Singh, Vikas Chawla, J.S. GrewalDocument23 pagesA Review On Detonation Gun Sprayed Coatings: Lakhwinder Singh, Vikas Chawla, J.S. GrewalAntonio DíazNo ratings yet

- Abrasive Wear Maps For High Velocity Oxy Fuel (Hvof) Sprayed Wc-12Co and CR 3 C 2 25nicr CoatingsDocument17 pagesAbrasive Wear Maps For High Velocity Oxy Fuel (Hvof) Sprayed Wc-12Co and CR 3 C 2 25nicr Coatingsjotas254No ratings yet

- PVD and CVD Coatings For The Metal Forming IndustryDocument14 pagesPVD and CVD Coatings For The Metal Forming IndustrymeqalomanNo ratings yet

- CH 4 New Coating Material PDFDocument21 pagesCH 4 New Coating Material PDFmaheshnagarkarNo ratings yet

- ASE 02 FundamentalDocument62 pagesASE 02 FundamentalsriNo ratings yet

- Characterisation and Corrosion-Erosion Behaviour of Carbide Based Thermal Spray CoatingsDocument17 pagesCharacterisation and Corrosion-Erosion Behaviour of Carbide Based Thermal Spray CoatingsSharath RNo ratings yet

- Experimental Studies On Slurry Based Thermal Barrier CoatingsDocument6 pagesExperimental Studies On Slurry Based Thermal Barrier CoatingsMusharaf AbbasNo ratings yet

- TBTS2013-2065: Development of New Abradable/Abrasive Sealing Systems For Clearance Control in Gas TurbinesDocument10 pagesTBTS2013-2065: Development of New Abradable/Abrasive Sealing Systems For Clearance Control in Gas TurbinesJames CookNo ratings yet

- A Review Tribological Analysis of Cast Iron by Advanced CoatingDocument6 pagesA Review Tribological Analysis of Cast Iron by Advanced CoatingEditor IJTSRDNo ratings yet

- Metals 12 00138Document18 pagesMetals 12 00138SenTTrox RoxNo ratings yet

- Crystals 12 00298 v2Document19 pagesCrystals 12 00298 v2JulioNo ratings yet

- 1-s2.0-S2214785321024937-mainDocument12 pages1-s2.0-S2214785321024937-mainsunanNo ratings yet

- Improving The Efficiency of Thermochemical Processes With Shot PeeningDocument9 pagesImproving The Efficiency of Thermochemical Processes With Shot PeeningFatih Hayati ÇakırNo ratings yet

- Worksheet6 20MT30048Document7 pagesWorksheet6 20MT30048gaming channelNo ratings yet

- 140 Ijmperdjun2019140Document10 pages140 Ijmperdjun2019140TJPRC PublicationsNo ratings yet

- Thermal Barrier Coatings-A State of The Art Review: Jayant Gopal Thakare Chandan Pandey M. M. Mahapatra R. S. MulikDocument22 pagesThermal Barrier Coatings-A State of The Art Review: Jayant Gopal Thakare Chandan Pandey M. M. Mahapatra R. S. MulikwaleedsikandryNo ratings yet

- Laser CladdingDocument9 pagesLaser Claddingavadh87No ratings yet

- Additive Manufacturing: Full Length ArticleDocument8 pagesAdditive Manufacturing: Full Length ArticleMo YakoutNo ratings yet

- Review of Hard Turning and Hard Milling: ArticleDocument7 pagesReview of Hard Turning and Hard Milling: ArticleĐạt Phan ThànhNo ratings yet

- J Ceramint 2020 04 168Document77 pagesJ Ceramint 2020 04 168zeNo ratings yet

- Fire Side Erosion-Corrosion Protection of Boiler Tubes by Nanostructured CoatingsDocument16 pagesFire Side Erosion-Corrosion Protection of Boiler Tubes by Nanostructured CoatingsThanhluan NguyenNo ratings yet

- Influence of Sequential Surface Treatment Processes On Tribological Performance of Vanadis 6 Cold Work Tool SteelDocument12 pagesInfluence of Sequential Surface Treatment Processes On Tribological Performance of Vanadis 6 Cold Work Tool SteelNaresh PoppathiNo ratings yet

- 45IJMPERDJUN201945Document10 pages45IJMPERDJUN201945TJPRC PublicationsNo ratings yet

- Plasma Nitriding Improves Corrosion Resistance of Gun PartsDocument4 pagesPlasma Nitriding Improves Corrosion Resistance of Gun Partssr_rd5No ratings yet

- Ijresm V2 I8 21Document3 pagesIjresm V2 I8 21Melord RoneNo ratings yet

- Thermal Arc Spray Overview: IOP Conference Series Materials Science and Engineering June 2013Document12 pagesThermal Arc Spray Overview: IOP Conference Series Materials Science and Engineering June 2013novernandoNo ratings yet

- Jan Jun-5Document14 pagesJan Jun-5sreeiitm09No ratings yet

- Wear Characteristics of Adis A Comprehensive Review On Mechanisms and Effective ParametersDocument12 pagesWear Characteristics of Adis A Comprehensive Review On Mechanisms and Effective ParametersBiruk YifruNo ratings yet

- wetgrindingfabricationIJETAE_0312_04Document8 pageswetgrindingfabricationIJETAE_0312_04Thanh An NguyễnNo ratings yet

- The Influence of Surface Treatment of PVD Coating On Its Quality and Wear ResistantDocument12 pagesThe Influence of Surface Treatment of PVD Coating On Its Quality and Wear ResistantMaryam AlizadehNo ratings yet

- Fundamental Aspects of Surface Engineering: A Review: Maha S. HirmazDocument5 pagesFundamental Aspects of Surface Engineering: A Review: Maha S. HirmazRahul PatelNo ratings yet

- Modelling of Destructive Ability of Water-Ice-Jet While Machine Processing of Machine ElementsDocument4 pagesModelling of Destructive Ability of Water-Ice-Jet While Machine Processing of Machine ElementsGaby AlvarezNo ratings yet

- Tribological and Corrosion Behavior of Hvof Sprayed Wc-Co, Nicrbsi and CR C - Nicr Coatings and Analysis Using Design of ExperimentsDocument12 pagesTribological and Corrosion Behavior of Hvof Sprayed Wc-Co, Nicrbsi and CR C - Nicr Coatings and Analysis Using Design of ExperimentsMislav TeskeraNo ratings yet

- Hardfacing or HardsurfacingDocument15 pagesHardfacing or HardsurfacingAchu BalachandranNo ratings yet

- Fretting Corrosion of Lubricated Tin Plated ContactsDocument10 pagesFretting Corrosion of Lubricated Tin Plated ContactsJulio De la RosaNo ratings yet

- Ijebea15 240Document5 pagesIjebea15 240anushreeNo ratings yet

- On Design and Tribological Behaviour of Laser Textured SurfacesDocument7 pagesOn Design and Tribological Behaviour of Laser Textured SurfacesSaood AliNo ratings yet

- Development of An Erosion Testing Machine 06Document34 pagesDevelopment of An Erosion Testing Machine 06Omprakash ManharNo ratings yet

- 33 Fabrication of Pin On Disc Wear Testing Rig PDFDocument4 pages33 Fabrication of Pin On Disc Wear Testing Rig PDFEditor IJTSRDNo ratings yet

- Metals: High Velocity Oxygen Liquid-Fuel (HVOLF) Spraying of WC-Based Coatings For Transport Industrial ApplicationsDocument21 pagesMetals: High Velocity Oxygen Liquid-Fuel (HVOLF) Spraying of WC-Based Coatings For Transport Industrial Applicationssuresh_501No ratings yet

- Thermal Barrier Coatings-A State of The Art Review: Jayant Gopal Thakare Chandan Pandey M. M. Mahapatra R. S. MulikDocument22 pagesThermal Barrier Coatings-A State of The Art Review: Jayant Gopal Thakare Chandan Pandey M. M. Mahapatra R. S. MulikSon NguyenNo ratings yet

- SURFACE ENGINEERING TECHNIQUESDocument21 pagesSURFACE ENGINEERING TECHNIQUESPalak Naik100% (1)

- Advanced Surface Finishing Processes: A Comprehensive Review & Future Research DirectionsDocument44 pagesAdvanced Surface Finishing Processes: A Comprehensive Review & Future Research DirectionsKaran PatelNo ratings yet

- Aircraft Structural Integrity Ass 2 ViksDocument12 pagesAircraft Structural Integrity Ass 2 ViksJohirul Rumen100% (1)

- Review On Mechanism and Process of Surface Polishing Using LasersDocument21 pagesReview On Mechanism and Process of Surface Polishing Using LasersViệt TrầnNo ratings yet

- ICAET T3 14 522dwdDocument3 pagesICAET T3 14 522dwdkarthik RNo ratings yet

- Lubrication of Dry Sliding Metallic Contacts by Chemically Prepared Functionalized Graphitic NanoparticlesDocument18 pagesLubrication of Dry Sliding Metallic Contacts by Chemically Prepared Functionalized Graphitic Nanoparticlesmylover huNo ratings yet

- Applied Surface Science Advances: P.N. Belkin, S.A. Kusmanov, E.V. ParfenovDocument30 pagesApplied Surface Science Advances: P.N. Belkin, S.A. Kusmanov, E.V. ParfenovKaren AnnNo ratings yet

- Materials 15 05633 v2Document40 pagesMaterials 15 05633 v2Nadia ArrousseNo ratings yet

- Ijmet 07 05 010Document7 pagesIjmet 07 05 010hadi ebrahimfathNo ratings yet

- Effect of Abrasive Particle Size On Friction and Wear Behaviour of HVOFDocument20 pagesEffect of Abrasive Particle Size On Friction and Wear Behaviour of HVOFMouna KallelNo ratings yet

- Surface EngineeringDocument8 pagesSurface Engineeringبلسم محمود شاكرNo ratings yet

- Microwave Cladding of Inconel-625 On Mild Steel Substrate For Corrosion ProtectionDocument10 pagesMicrowave Cladding of Inconel-625 On Mild Steel Substrate For Corrosion ProtectionMUHAMMED FAISALNo ratings yet

- Footstep 2DDocument1 pageFootstep 2DRey TmNo ratings yet

- Raga ClearDocument4 pagesRaga ClearRey TmNo ratings yet

- Kinematic Model of A Stick Insect As An Example of A Six-Legged Walking SystemDocument16 pagesKinematic Model of A Stick Insect As An Example of A Six-Legged Walking SystemRey TmNo ratings yet

- Skala: Satuan: Tanggal: Digambar: NPM: Dilihat: Keterangan Raga Karisma Alam G1C017017 DR - Eng Hendra, ST - MT 1: 1 MM 15-03-2018 Mancal FT UnibDocument1 pageSkala: Satuan: Tanggal: Digambar: NPM: Dilihat: Keterangan Raga Karisma Alam G1C017017 DR - Eng Hendra, ST - MT 1: 1 MM 15-03-2018 Mancal FT UnibRey TmNo ratings yet

- Armor CalculationDocument11 pagesArmor CalculationRey TmNo ratings yet

- Wedge Belts Veco 200 Dynam System: ST - API - ISO 4184 - DIN 7753 - BS 3790Document2 pagesWedge Belts Veco 200 Dynam System: ST - API - ISO 4184 - DIN 7753 - BS 3790Alexandre GelsiNo ratings yet

- Sunon Dp203at 2122LBT - GN.155 (A12003480g-00) - 1Document9 pagesSunon Dp203at 2122LBT - GN.155 (A12003480g-00) - 1German DANo ratings yet

- Theory Questions Part 2 DCS1Document5 pagesTheory Questions Part 2 DCS1KEN ADAMSNo ratings yet

- 7 Plumbing Max FajardopdfDocument175 pages7 Plumbing Max FajardopdfEmere James P. TagoonNo ratings yet

- PLED Lecture: Polymer Light-Emitting Diode BasicsDocument21 pagesPLED Lecture: Polymer Light-Emitting Diode BasicsAlok KushwahaNo ratings yet

- Strategic TechnologiesDocument556 pagesStrategic TechnologiesMajmaah_Univ_PublicNo ratings yet

- Mechanical HandbookDocument124 pagesMechanical Handbookgugaskarthik50% (2)

- The Thermal Expansion Characteristic of Stainless Steel Weld Metal PDFDocument9 pagesThe Thermal Expansion Characteristic of Stainless Steel Weld Metal PDFAchmad Nur HusainiNo ratings yet

- Chemical CharacterisationDocument66 pagesChemical Characterisationvenkatakrishna chalapaathiNo ratings yet

- Dynasylan BSM 40%Document3 pagesDynasylan BSM 40%Francois-No ratings yet

- Techno-Economic Assessment About Sebacic AcidDocument3 pagesTechno-Economic Assessment About Sebacic AcidIntratec SolutionsNo ratings yet

- Silicon Native OxideDocument11 pagesSilicon Native OxideAshwin ChockalingamNo ratings yet

- Astm D2257 PDFDocument5 pagesAstm D2257 PDF郭哲宏No ratings yet

- DesignDocument123 pagesDesignJay PatelNo ratings yet

- Integrated Solid Waste ManagementDocument4 pagesIntegrated Solid Waste ManagementsonaliNo ratings yet

- Nautical Knoweldge - 1 - Cable-Rope Wire & ChainDocument30 pagesNautical Knoweldge - 1 - Cable-Rope Wire & ChainKostyantinBondarenkoNo ratings yet

- MDOT Pile Welding QCPDocument8 pagesMDOT Pile Welding QCPvelmurug_balaNo ratings yet

- ETABS 18.1.0 License Column Section DesignDocument1 pageETABS 18.1.0 License Column Section DesignVHAMNo ratings yet

- Module 1 - Introduction To ChemistryDocument10 pagesModule 1 - Introduction To ChemistryJhun Lerry TayanNo ratings yet

- Metallurgical Evaluation of The Wemco SuperCellDocument25 pagesMetallurgical Evaluation of The Wemco SuperCellmochechoNo ratings yet

- ID 4083 PresentationDocument17 pagesID 4083 PresentationNgIa MaStaNo ratings yet

- ADVANCEDBeam ManualCompositeDocument28 pagesADVANCEDBeam ManualCompositeAmir ShaikNo ratings yet

- C I & C C: Omplex ONS Oordination OmpoundsDocument2 pagesC I & C C: Omplex ONS Oordination OmpoundsAL-AMEENNo ratings yet

- SELF HEALING OF CONCRETE Pranayyy2Document21 pagesSELF HEALING OF CONCRETE Pranayyy2Kalyan Reddy AnuguNo ratings yet

- ISI 7272 Labour OutputDocument9 pagesISI 7272 Labour Outputniraj rai100% (2)

- Lead Free Series 35 Quick-Connect Valves Specification SheetDocument4 pagesLead Free Series 35 Quick-Connect Valves Specification SheetWattsNo ratings yet

- SikaProof A BrochureDocument12 pagesSikaProof A BrochureMod ApkNo ratings yet