Professional Documents

Culture Documents

BS 1139-1-1982, Metal Scaffolding

BS 1139-1-1982, Metal Scaffolding

Uploaded by

eko0 ratings0% found this document useful (0 votes)

29 views8 pagesOriginal Title

BS 1139-1-1982 , Metal Scaffolding

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views8 pagesBS 1139-1-1982, Metal Scaffolding

BS 1139-1-1982, Metal Scaffolding

Uploaded by

ekoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

BSI _BS*2139 PART*L 82 M@ Lb246b9 0002609 T Me

pe 69.087.62-034 : 621.774

i BS 1139: Part 1: 1982

© British Standards Institution. No part

of this publication may be photocopied

Metal scaffolding

Part 1. Specification for tubes

for use in scaffolding

Echafaudages métalliques

Partie 1. Tubes pour échafaudages — Spécification

Metallgeriiste

Teil 1. Spezifikation fir Geriistrohre

British Standards Institution ~~

BSI BS*1139

BS 1139 : Part 1 : 1982

Contents

Page

Inside front cover

Back cover

Foreword

Cooperating organizations

‘Specification

Section one. General

1. Scope 1

2. References 1

Section two. Stoo! scaffold tubes

3, Method of manufacture

4, Materials

6, Dimensions and tolerances

6. Workmanship

7. Finish

8, Galvanizing

9. Idontification

Foreword

‘This Part of BS 1139 is one of a sories specifying

requirements for the design, construction and testing of

‘equipment for use in scaffolding and other temporary

structures. It specifies requirements for steel and aluminium

‘tubing of the type traditionally used in tubular scaffolding.

Recommendations for the design of tubular scaffolding

structures in aluminium and steel are given in BS 6973 and

BS 5974,

‘This standard was previously published as sections two and

five of BS 1139: 1964. However, open jointed steal

scaffold tube is not included in this revision. BS 1139 is,

‘now being published in separate Parts as follows and, on

"In course of preperation.

PARTS) 62 MM Lb24669 OO02610 & mm

Page

Section throe. Aluminium scaffold tubes

10. Method of manufacture 2

11, Materials 2

12. Dimensions and tolerances 2

13. Workmanship 2

14, Finish 2

16. Identification 2

‘Appendices

‘A. Bend test for steel scaffold tubes 3

B. Method of assessing the continuity of the zine

coating 3

C. Drift expanding tost for extruded aluminium

scaffold tubes 3

Tables

1. Dimensions and tolerances for welded and

seamless steel tubes 1

2, Dimensions and tolerances for aluminium tubes 2

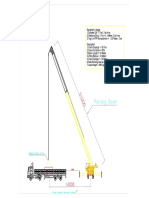

Figure

1. Arrangement of drift expanding test 3

publication of Parts 1 to 4, BS 1139 : 1964 will be

withdrawn.

Part 1 Specification for tubes for use in scaffolding

Part 2* Specification for couplers, fittings and

accessorias for uso in tubular scaffolding

Part 3" Specification for profabricated access and

working towers

Part 4 Specification for prefabricated steel splitheads

and trestles

Further Parts will be added as the need arises.

BSI BS*1139 PART#) 62 Mm

British Standard

Metal scaffolding

Part 1. Specification for tubes for use in scaffolding

Ub24bb9 000262) 8 mm

BS 1139 : Part 1; 1982

Section one. General

1. Scope

This British Standard spocifis requirements for the

material, dimensions and method of manufacture of welded

and seamless steel tubes and extruded aluminium tubes for

tse in scaffolding. It specifies one grade of material and

‘one range of dimensions for each.

‘Appendix A deseribes a bending test for steel scaffold tubes.

‘Appendix B describes a method for assossing the continulty

Of the zine coating on hot-dip galvanized stcl scaffold

tubes. Appendix C describes a drift expanding test for

extruded aluminium seaffold tubes

2, References

The titles of the standards publications referred to in this

standlard ere listed on the inside back cov

Section two. Steal scaffold tubes

3. Method of manufacture

‘Steel scaffold tubes shall be manufactured by a seamless or

‘welded process, When tested in accordance with

appendix A, a tube in its finished state shall show no sign

of fracture or failure,

NOTE. This test procodure should be considered as being part of a

‘ality control progremma and the frequancy of testing should be

‘uch af to encure adequate quality contr.

4, Materials

4.1 General. The tube shall be manufactured from steel

complying with the requirements of 4.2 and 4.3.

4.2 Chemical composition (ladle analysis). The chemical

‘composition of the steel shall be as follows:

© 0,20% max.

Si 0.30 % max.

P 0.060% max.

S 0.060 % max.

4.3 Mechanical properties of the tube. The mechanical

properties of the tubes shall be as follows:

tensile strength (Ain) 340 N/mm? to 460 N/mm?

yield strenath (Ae) 210 N/mm? min,

elongation (A) on @ gauge

length, L, of 6.65V5,"

22 % min.

+8, i the original cross sbetional aea ofthe gauge

5, Dimensions and tolerances

‘The dimensions and tolerances for welded and seamless

stool tubes shall bo as given in table 1.

Table 1. Dimensions and tolerances for welded and

seamless steal tubes

Dimensions and mass

Outside diameter 48.3 mm

‘Thickness 4.0 mm

Nominal mate por u

length 4.37 kg/m

(48.3 mm x4 mm)

reduction 7.5 %

(Quantities of 150 m and

over +4 %

= 6.0mm

Length if specified exact

NOTE. The following values forthe properties of ste! scafotaing

tubes ofthe dimensions specified in table 1 are given fo

Information purposes only. Details of the maximum parmissble

stroses are glvan in BS 5973.

Symbol Value

Cross-sectional arse A 557 om?

Second moment of area

(momant of inertia), 1 138 emt

Elastic modulus Zz 5.70 em?

Faatius of gyeation , 187 em

6. Workmanship

‘A tube shall not deviate from a straight line by more then

1/600 of its length, measured at the centre of the length.

‘Tubes shall be free from cracks, surface flaws, laminations

and other detrimental defects, The ends shall be cut cleanly

and square with the axis of the tubs,

7. Finish

This standard does not specify that scaffold tubes need to

have a particulat surface finish but if galvanized tubes are

specified, the galvanizing shall comply with the require

ments of clause 8.

NOTE. 1s recommended that, if no other finish ie specified,

scaffold tubes should be varnished externally throughout their

lenath with the manufacturer's normal mil varnish

BSI BS*1139

BS 1139 : Part 1: 1982

8. Galvanizing

8.1. Quality of the zine. The zine used for galvanizing the

‘tubes shall comply with the requirements for grade Zn 4 as

speeified in BS 3436,

NOTE. BS 3436 spacifes the following maximum percentages af

Impurities for grade Zn 4: leod 1.35 %, cadmium 0.15 %, tn 0.02 %,

Iron 0.04 ¥. The permissible maximum total of lesd, cadmium, tn,

Iron and copper i 1.5 %

8.2 Appearance, When assessed visually, the coating shall

bbe uniform, adherent and without gaps in the layer of zinc.

When tested in accordance with appendix B, the coating

shall appear continuous and steel shall not be exposed at

any point,

NOTE. Tho moss of zine per unit ares should be not lets than

300 gin? this value applies ¥o both the internal and external

coatings.

“The mats of zine per unt area is not the subject of @ check. I is

‘ceapted thet because the hot-ip galvanizing proces is used, and

because of the dimensions of the tube, the mass por square mate it

‘nat normaly lass than the recommended minimum,

9. Identification

Any method of identification used shall not impair the

performance of the tube,

Section three. Aluminium scaffold tubes

10, Method of manufacture

Aluminium scaffold tubes shall be produced by extrusion,

e.g. by means of a process using a mandrel, a bridge die or

a porthole. When tested in accordance with appendix C,

2 tube in its finished state shall show no sign of an

unsound weld.

NOTE. A tube with fautty welding wil tnd to exhibit a stoight

Tino, rather than jagged, fracture at the position of the wold.

‘This test procedure should be considered as boing apart of a

quality contol programme and the frequency of testing should be

‘ch af fo ensure adequate quality contr.

11. Materials

11.1 Gonoral. The tube shall be manufactured from

aluminium complying with the requirements of 11.2

and 11.3.

11.2 Chemical composition. Tubes shall be extruded

aluminium tubes complying with the requirements for

alloy 6082-TF (formerly HE3O-TF) as specified in BS 1474,

NOTE. As thoso tubes are heat reatod, hast should not be applied

to thom by welding, flame cutting te, unlos this ie earied out

Under the controlled conditions recommended in CP 178

11.3 Mechanical properties. The mechanical properties of

the tubes shall be as follows

‘tensile strongth (Rx,)

yield strength (2)

(0.2 % proof stress)

clongation (A) on a gauge

length, Lo, of 60 mm

295 Nimm?* min.

255 N/mm? min.

7% min

“Aluminium Federation Ltd, Broadway Hous

PARTS) 62 MM 1624669 O002b12 7 mt

Calthorpe Road, Five Ways, Birmingham, 615 ITN.

2

12, Dimensions and tolerances

‘The dimensions and tolerances for aluminium tubes shall be

as given in table 2.

Table 2. Dimensions and tolerances for aluminium

tubes

Os mm

£0.56 mm

Single tube max.

reduction 7.5 %

‘Thickness 447 mm

Nominal mass per uni

length 1.667 kg/m

(48.30 mm x 4.47 mm)

Length if specified exact

NOTE. Tho following nominal value forthe propertios of

‘sluminium scaffeding tubes of the dimensions specified in table 2

{are given for Information purposes ony. Details of maximum

pormisibo stresses are given in 8S 5975,

Symbol Value

Croseasetional aroa A 6.15 em?

Second momant of. ' 149 om

Elastic modulus Zz 6.18 em?

Radius of gyration , 1.86 om

13, Workmanship

‘A tube shall not deviate from a straight line by more than

1/600 of its length, measured at the centre of the length.

‘Tubes shall be clean and free from detrimental defects.

“The ends shall be cut cleanly and square with the axis of

the tubo,

14, Finish

Tubes shall be mil finished, ie. without any surface

treatment,

NOTE, For all normal purposes no painting or other surface

‘reatmont is roquirod. Tubes likey to roma In contact with wet

acid oF elkalina materials, eg. damp coment of lime rendering, need

protection. Advice on suitable costing can be obtained from the

‘Aluminium Fedoration®

15, Identification

‘The method of identification used shall not impair the

performance of the tube.

Appendix A

Bend test for steel scaffold tubes

‘The tests shall be carried out by using a tube bending

‘machine and bending round a grooved former of the

specified radius. Welded tubes shall bo bont with the weld

‘at 90" to the position of maximum bend. The tubes shall

not be filled for this test.

(a) Ungatvanized tubes. When cold, bond the tube

‘through an angle of 180° round a former having a

radius at the bottom of the groove equal to six times

‘the outside diameter of the tube, When the tube is at

red heat, bend it through an angle of 180 ° round @

former having a radius equal to three times the outside

diameter of the tube. Check that no eracking has

occurred.

(b) Galvanized tubes. When cold, bend the tube

through an angle of 90° round a former having a radius

at the bottom of the groove equal to eight times the

‘outside diameter of the tube. Check that no cracking

hhas occurred.

Appendix B

Method of assessing the continuity of the zine

coating

B.1 Principle. The continuity of the zine coating is

checked by immersing a test piece in a standard copper

sulphate solution,

NOTE. This test only allows the continuity of the coating to bo

checked, and indications ofits thickness oF ant-corrosive qualities

should not be assumed trom i

B.2 Reagent

B.2.1 Copper sulphate pentahydrate solution

(CuSO, 6H, 0}, fresh, pure and with a density not

exceeding 1.17 giml at 20°C,

Prepare the solution by dissolving pure crystalline copper

sulphate pentahydrate in the proportion of approximately

930 g to 1 litre of distilled wator. Shake the solution with

{an excess of copper carbonate or copper hyclroxide (about

1g/ of solution) and filter or allow to stand before use.

Use a minimum volume of 1200 mi for each series of four

immersions,

B.3 Apparatus

B.3.1 Container, of a material that does not react with

‘copper sulphate solution and with internal dimensions

allowing a clearance of at least 26 mm batwoen the

containor and the test piece,

B.4 Test pieces. Test pieces shall be selected from freshly

galvanized new tubes and teken from current manufacture.

‘They shall be 180 mm long and eut at least 25 mm from

‘tho ond of the tube. A single test piece shall bo used for

each series of four immersions.

B.5 Procedure. Degrease the tost piece using benzine,

trichlorethylene or other suitable organie solvent, then

ringo with distilled wator and wipe clean with cotton wool

or a clean cloth,

‘Subject each test piece to four successive total immersions

in the copper sulphate solution, each immersion lasting for

BSI BS*L)39 PART#L 82 MM Lb24bb9 0002633 1 mm

BS 1139 : Part 1: 1982

After each immersion, wash and scrub the test piece

under running water to remove the deposited copper, then

dry it. Carry out the immersion and washing operations

without interruption. Keop the solution at a temperature of

20: 2°C during the test and use a fresh solution for each

series of four immersions,

BG Analysis of results. After the final washing, the test

piece shall not show, at any point more than 25 mm from

either tube end, any adherent deposit of salmonred

coloured copper, indicating exposure of the steel,

When the zinc coating of the test pisce is considerably

oxidized, a copper deposit that cannot be removed by

sctubbing may be apparent. A drop of hydrochloric acid

solution (prepared by diluting 10 ml of hydrochloric aci

(d = 1.14) with 90 ml of distilled water) should be put on

tach of these areas. If no effervescence occurs, the deposit

of copper is on exposed steel and the test piece shall be

deemed not to comply with the requirements of this

standard, If, however, strong effervescence occurs, it is due

to the attack of the acid on the zinc which indicates that

the steel has not been exposed,

Appendix C

Drift expanding test for extruded aluminium

scaffold tubes

€.1 Principle. The end of a tube or test piace is expanded

Using a conical mandrel until it tears or splits.

The testis carried out at ambient temperature unless

otherwise specified.

C2 Apparatus

6.2.1 Polished stee! conical mandrel, of adequate hardness

and having a conical included angle of 30 °, 45° or 60°,

fee (5)

3)

Key

4. Outside a

2. Thicknoss of wall of tube oF test ple

23. Length of tet piece

4. Conieat angle of mandral

5. Meximum external dlamoter of end of expended tube

Figure 1. Arrangement of drift expanding test

BSI BS*1139 PART#) 82 MM 1624669 0002614 3 ml

BS 1139 : Part 1: 1982

C.3 Test piece. The test piece shall consist of a piece of

‘tube having a length equal to at least twice the external

diameter of the tubs. Both ends of the test piece shall be

plane and perpendicular to the axis of the tube. The test

piece shall be cleaned to remove any loose chips or dirt

from the inside surface.

NOTE. The end to be tested is normally rounded by filing

However test piace with edges that have not been rounded is

socoptabio provided thet the tst result i satistoatory,

24 Procedure, Lubricate the mandrel so that doesnot e

rotten vltion to the tube during the test, Fore the

conical andra under pressure nt the opan endl ofthe

tet pec, so that th ani ofthe cone concer with the

tn of tho tat lee, Continue eplyngprestre unt the

tbe taro sis

BSI BS¥4137 PART#) 82 MM 1624669 OOO2LIS § mw

Standards publications referred to

185 147 Wrought aluminium and aluminium says for general engineering purposes

8S.3493 ingot zine

8S 5973 Code of practice for access and working scaffolds and specol scaffold structures in steel

85.5974 “Code of practice for tomporalyinetalled suspended scaffolds end access equipment

CP 118 ——Thestructural use of aluminium

bars, extruded round tubes ond sections

* Referred to in the foreword only

BSI BS*1139

“This British Standard, having been propared under the direction of

the Chil Engineering nd Bullding Structures Standards Committe,

‘aos published under the authority of the Board of BSI and comes

Into effect on90 Apri 1982.

(© British Standords Institution, 1982

3 publthed, 6s BS 1138, November 1949

ion Novombor 1981

vision June 1964

Pere third revtion (Part 1) April 1982

SBN 0 680 12701 X

British Standards Institution

Incorporated by Royal Charter, BSI isthe independent national

body for th tion of British Standords. I isthe UK member

Of the International Organization for Standardization and UK

sponsor ofthe Britith National Committe of the Internationel

Electrotechnical Commision.

Copyright

‘Users of British Stendards ae reminded thet copyright subsists in

all BSI publications, No part ofthis publication may be reproduced

in any form without th prior parmision in writing of BS. This

{doesnt preclude the free uso, n the course of Implementing the

stencard, of necaory dtals such as symbols and size, type or

>!

PARTS] 62 MM 1624669 OO02b2b 7 Mil

BS 1139: Part 1: 1982

‘grade designations. Enquties by post should be addressed to the

Publteations Manager, British Standard Institution, Linford Wood,

Hilton Keynes M14 GLE, The numbar for tolephone enquiries is

(01-897 8901 ond for telex 23238,

Contract requirements

{A British Standard doss not purport to include all the necessery

provisions of contract Usere of British Standards are responsible

for their corrct application,

Revision of British Standards

Btish Standacds are revised, when necessary, by the fsue either

Of amendments or of rvieed editions. It is important that uses of

British Standards should ascertain that thay ae in possesion of

fest amendments or editions. Information on all BSI

tons isin the BS Yearbook, supplemented each month by

[BSI News which I available to subscribing members of the

Institution and gives detals of now publications, revisions,

tmendments and withdravin stondarde. Any parson who, wien

tmoking use of e Brith Stondard, encounters en inaccureey or

Ambiguity, fe requested to notify BSI without delay in order that

the mattor mey be investigated and appropriate action taken,

“The following BSI references relat to the work on this standard:

ference CSB/46 Draft for eommant 81/12468 DC

Cooperating organizations

“The Civil Engineering and Building Structures Standards Committee,

Under whoee direction this British Standard wes prepered, consists

‘of representatives from tho following

‘Aluminium Federation

‘Association of Consulting Engineers

Briek Development Association

British Precast Concrete Federation Ltd.

British Steal Corporation

‘Beith Steal Industry

‘Cament and Concrete Association

Conerate Society Limited

‘Consumer Standards Advisory Committs of BSI

‘Gonvontion of Scottish Local Authorities

County Surveyor's Society

*Deperttnant of the Environment (Building Research Establishment)

Departmant of the Environment (Housing and Construction}

‘Department ef the Environment (PSA)

‘Departmont of the Environment (Weter Engineering Division

Vnotuding Water Data Unit)

Departmant of Transport

+ Federation of Chl Engineering Contractors

‘Health and Safety Executive

*inetitution of Cll Engineers

Amendments issued since publication

*inattution of Municipal Engineers

Intitution of Public Heath Engineers

“institution of Structural Engineers

Institution of Water Engineers and Scientists

London Transport Exocut

Ministry of Agriculture

‘National Federation of Building Trades Employers

National Water Council

oval Institute of British Architects

Scottish Development Department

‘Timber Ressarch and Development Association

“Trades Union Congress

“The organizations marked with an asterisk in the above list, together

‘withthe allowing, wera clrctly represented on the Technical

‘Committe entrusted withthe preparation of this British Stanserd

‘Association of Consulting Scientists

Confederation of British Industry

Construction Health and Safety Group

Construction Industry Training Boara

Eloctriity Supply Industry in England and Wales

Incorporated Association of Architects and Surveyors

National Association of Sesffolcing Contractors

Prefebricated Aluminium Seaffolaing Manufacturers’ Assocation

Amd, No. Date of Issue | Text affected

Lued:6ELL Sa

e@ 786

British Standards Institution - 2 Park Street London W1A 28S - Telephone 01-629 9000 . Telex 266933

8908-3—1k-8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 01 Layout Crane FixxxxDocument1 page01 Layout Crane FixxxxekoNo ratings yet

- Cover OutnerDocument1 pageCover OutnerekoNo ratings yet

- Spek KomputerDocument1 pageSpek KomputerekoNo ratings yet

- BS 1139-4-1990, Metal ScaffoldingDocument12 pagesBS 1139-4-1990, Metal Scaffoldingeko100% (1)

- BS 1139-2-1982, Metal ScaffoldingDocument9 pagesBS 1139-2-1982, Metal ScaffoldingekoNo ratings yet