Professional Documents

Culture Documents

BS 1139-2-1982, Metal Scaffolding

BS 1139-2-1982, Metal Scaffolding

Uploaded by

eko0 ratings0% found this document useful (0 votes)

52 views9 pagesOriginal Title

BS 1139-2-1982 , Metal Scaffolding

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

52 views9 pagesBS 1139-2-1982, Metal Scaffolding

BS 1139-2-1982, Metal Scaffolding

Uploaded by

ekoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

BSI BS*1139 PART#2 82 MM Ub24bL9 OO02b1S O i

i . BS 1139: Part 2: 1982

i voc eo.0s762094 60087089

‘ Briteh Standard station, Nopart

‘tts pbeton maybe photocopied

‘rotharnie repoduces without the

Broeparmiseln inwitng of

British Standard

Metal scaffolding

Part 2. Specification for couplers and fittings

for use in tubular scaffolding

Echafaudages métaliques

Parte 2. Raccords ot accouplements pour échafaudagestubulaltes ~ Spécification

Metaigerste

‘Tell 2. Verbindungssticke und Zubshdr fic Robrgeriste

British Standards Institution

A

BS 1139: Part 2: 1982

Contents

Poge

Inside front cover

Back cover

Foreword

Cooparating organizations

Specification

Scope

References

Definitions

Materials

Aluminium specification

Suitability of fittings

Fittings for close-jointed tubes

Design of fittings

3. Test on fittings

10. Right-angle couplers

11. Swivel couplers

12, Putlog couplers

18, Joint pins

“BSI BS¥L139°

PART*2 82 MM Lb24669 0002619 2 ml

Poge

14, Sleeve couplers

15, Reveal pin

16. Putlogs

17. Putlog ends

18, Base plates

19. Adjustable base plates

20. Detechable castors

21, Toe board clips

22. Finish

1. Test for distortion of right-angle coupler

2. Test for slip of right-angle coupler

3. Test for distortion of swivel coupler

4. Test for slip of swivel coupler

5. Rig for sip tests on putlog couplers

6. Test for bending putlog end

Compliance with a British Standard does not of itself confer immunity from legal obligations.

Foreword

‘This Part of this revision of BS 1139 has been prepared

under the direction of the Civil Engineering and Building

Structures Standards Committe.

“The requirements ofthis standard are not technically

changed from those in sections 3 and 6 of BS 1199 : 1964,

“The strength requirements are now quoted in SI units,

+o bring the standard into line with eurrent practice and

with the codes of practice in which reference is made to

fittings manufactured in accordance with BS 1139.

‘Tho motric values adopted are not the pracise conversion

from the imperial values but for all practical purposes may

be considered to be equivalent to the imperial values in

BS 1139: 1964.

Progress is being made towards the preparation of a full

revision of thase requirements, but it will be some time

before the final text becomes available. However, as the

major part of BS 1139 is now superseded by revised and

separately available Parts (see below) it was felt that it

would be helpful to users of BS 1139 to republish the

requirements for couplers and fittings in the new format

and with all duplicated text deleted. This edition of this

standard, therefore, supersedes sections three and six of

BS 1139 : 1964, The publication of this standard, however,

is only an interim measure, and this edition will itself be

superseded when the revised requirements have been

finalized.

‘The revision of BS 1139 : 1964 comprises the following

four Parts and on publication of Part 4, BS 1139 : 1964

will be withdrawn,

Part 1 Specification for tubes for use in seaffolding

Part 2 Specification for couplers and fittings for use in

tubular scaffolding

Part 3 Specification for prefabricated access and

working towers

Port 4 Specification for prefabricated steel split

and trestles

Further Parts will be added as the need arises.

ads

BSI BSx1135

PARTX2 62 MM 2624665 0002620 7 mm

BS 1139: Part 2: 1982

British Standard

Metal scaffolding

Part 2. Specification for couplers and fittings for use in tubular scaffolding

1. Scope

‘This British Standard specifies requirements for new steel

and aluminium alloy couplors and fitings for use with

scaffolding used as temporary structures on winich persons

work and which provide support for the plant and mate

Used in building, constructional, maintenance, repair and

demolition work,

2. References

‘The titles of the standards publications referred to in this

standard are listed on the inside back cover.

3. Definitions

For the purpotes of this British Standard, the following

|

Fixed scaffold tube

foact as a guide

BSI BS*L139 PART#2 82 MM Lb24b69 OO02b23 4 am

BS 1139 : Part 2: 1982

tube or reveal pin and the abutment faces. No permanent

set, distortion, or other damage shall occur which would

render tho tubs or reveal pin unsorviceable for furthe

use in scaffolding,

16. Putlogs

A putlog shall either be constructed from tube complying

BS 1139 : Part 1 or be so designed and constructed as

to provide at least equivalent resistance to bending,

shear and deflection. (See also note 1 to clause 17)

‘A fitting, other than a putlog coupler, provided for

connecting a putlog toa tube shall comply with clause 12

for putlog couplers

17. Putlog ends

A putlog end shall have an even bearing surface at least

76 rm long and at least 60 mm wide, measured from the

end of the tube.

Putlog ends shall be considered to be subject to bending,

bearing or shear stresses only and shall not be required to

‘transmit axial pulls or thrusts.

Detachable putlog ends shall be provided with means of

securing them to the putlog without risk of being

accidentally disconnected.

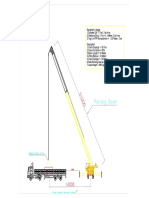

‘A putlog end, when attached to or forming part of @ putlog

and supported only within 38 mm of its extremity,

as shown in figure 6, shall be capable of supporting without

permanent set, a maximum distributed load of 4.4 kN over

a span of 1.2m.

[NOTE 1. As sluminium scaffold tube it heataeated, heat should

‘ot be applied to them by weding, lamecutting, et, unless

‘arred out under the controlled conctions of CP 118since this

‘may otherwise greatly impar the mechanical proportcs

NOTE 2, Where sluminium scaffold tubos sre required to be

flattgned at one end to form putlog ends this work should bo

carried out betore the tubes ae subjected to their final treatment.

It's recommended that putiogs with fattened ends be ebtained

reacy-made from the tubs manuectrers, exeent where adequate

heattrostmont facilities are aval

“ae

co

if =

1220

\N

Al aimensions are in millimetres

igure 6. Test for bending putlog end

18. Base plates

A base plate shall have @ flat surface not less than 232 om*

in area, concentric with the axis of the shank, to which it

shall be securely attached, The upper surface of the plate

shall provide a smooth and even bearing for the end of a

tube satisfying the requiremonts of this standard and be

such 98 not to damage or distort‘the tube under load.

“The shank shallzbe not less than 60 mm long, and shall be @

loose fit to allow the insertion of the full depth of the

shank inside the tube. :

A base plate, if of mild steal, shall be not less than 4.78 mm

thick. If of other steels they shall have a thickness sufficient

‘to provide an equal strength. Aluminium base plates shall

be not less than 6.35 mm thick.

{f provided with holes they shall be 6.35 mm diameter,

situated diametrically opposite each other ata distance of

not less than 50 mm from the centre of the plate, and not

less than 19 mm from the edge of the plate

19. Adjustable base plates

‘An adjustable base plate shall satisfy the requirements of

Clause 18 relating to the bearing surface and clause 15,

relating to the means for height adjustment.

When extended to its maximum working position the shank.

shall be capable of supporting a load of 69.7 KN without

distortion. In applying this test the base plate shall be

placed on a smooth horizontal surface and the load applied

‘through the seating on which the scaffold tube normally

rests. At the upper end the shank shall net be held in

position or restrained in direction,

20. Detachable castors

Detachable castors shall be designed and constructed to

provide adequate strength, rigidity and bearing surfaces for

‘their purpose.

All castors shall be clearly marked with the safe working

load they are designed to withstand, Such load shall be

vertically applied on the castors when stationary on an even,

and level surface.

‘The shank or socket of all castors shall be not less than

‘50 mm long, provided the design allows for an adequate

transfer of the loed from the tube to the shank. Means

shall be provided to prevent the caster unit falling out of

the tube when its wheel is not under load.

The diameter of castor wheels shall be not ess than

127 mm, When tyres are fitted they shall be of adequate

section and securely fixed to the wheel centres.

The eccentricity of the centre line of the wheel relative ta

the axis of swivel shall not excued 64 mm,

‘When requested by the purchaser castors shall be provided

with an effective wheel brake that cannot be accidentally

released,

21. Toe board clips

Toe board clips shall be suitably designed and constructed

for the attachment of toe boards to tubular members and

shal prevent accidental displacement of the boards. When

in position they shall not project sufficiently from the

surface of the board to cause a person to trip.

22, Finish

Fittings shall be supplied untreated, unless otherwise

specified.

NOTE 1. For normal purpoos aluminium requltes no printing oF

thor surface treaumant. Cre should bo taken, However, Yo avold

Brotonged contact with moterias such ar domp lm or wat cement,

Unless sulsble protective paint i apie,

NOTE 2.1 fittings aro stamped with @ motl die the stamping

should be earied out in such a manner as not ta impair the

iconcy ofthe fing.

BSI

BSxL139 PART*2 62 MM Lb24b69 OO02b24 & Mm

Publications referred to

as 12

as ore

BS 970

8S 1199

8s 1449

Bs 1472

8S 1473

a 1490

88 4360

88 6973,

op ita

Mathade for tonite teeing of metals

Black bots, screws and nuts

‘irought stele in the form of blooms il

Mota scatfolging

Part 1 Specification for tubas for use in seatflding

Stoel plate, sheet and strip

Wrought sluminium end aluminium alloys for genera angingsring purposss ~forgine stock and forgings

‘Specification for wrought aluminium and aluminium alloys for genaral engineering purposes —

rat, belt and ser stack eg

1s, bare and forgings

‘Specifiestion for aluminium ane aluminium alloy ingots and castings

Specification for weldeble swuctura steels

(Goce af practice for sccess and working eeffolds and speci seffold structures in stet

‘The structural vee of aluminium

For information about BSI services relating to thi party certification to suitable British Standard product specications, schemes

{or the registration of firms of assessed capability, testing end inspection facilities and Technical Help to Exporters, please contact

the Director, Quality Assurance Division, BSI, Maylands Avenue, Hemel Hempstead, Herts HP2 480. Tel Hemel Hempstead 3111.

| BST BS*1L35 PARTH2 82 WM Ub24LLT OOD2L25 8 MM BS 1139: Part2: 1982

‘This Bruch Standacd, having been prepared under the dtection of

the Chl Engineering and Suing Structures Standards Commitoe,

‘was published under the authority of the Board of BSI and comes

(o'offect on 30 September 1982.

‘©brtih Standards Institution, 1982

First published, a& BS 1198, Novernber 1943

First revision November 1961

Second revision June 1964

Part thied revision (Part 2) September 1962

SBN 0 680 12804 0

British Standards intitution

Incorporated by Royal Charter, 8S is the Independent nations

body fr the preparation of British Standerds ts the UK member

ofthe International Organization for Standardization and UK

‘sponsor ofthe British National Committe ofthe International

Eletrotechniel Commission

Copyright

Users of British Stonderds are reminded thet copyright subst in

‘1 BSI publiations. No port ofthis publication may be reproduces

in any form without the prior permission in writing of BSI

“This dots not prelude the fre ta, inthe cause of loplementing

the standard, of necessary detall such a symbols and sie, tye oF

trode designtions. Enquiries shouldbe addrested to the

Publications Manager, 101 Pentonville ld, Landon Ni 9ND

(Telephone 01-837 8801; Telex 75218)

Contract requirements

‘A British Standard does not purport to include all dhe necessary

provisions of contract. Uses of British Standerds are responsible

for their correct epaeation.

Revision of British Standards

British Standards are revised, wlan nscesory, by he ine thor

lof amendments or of revised eation. His important that usars of

British Standards should ascertain that they ae in possession of

the latest amondmantsoreition. Information on all St

publication sin the 25 Yearbook, supplemented each month by «

BSI New which i available to subscribing members of the

Institution nd gives datas of new publications, evisions,

mendients an withdrawn standards. Any parson who, when

‘making use of 2 Britsh Standard, encounters an inaceuracy oF

ambiguity is equested to aotily BSI without delay im order that

the matter may be investigated and epprapriate action taken,

“The following BSI referances relat to the work on this standecd:

‘Commitee refeence C38/46, Draft announced In BS) Nowe

‘Api 1982

Cooperating organizations

‘Tho Chil Enginsering end Building Structures Standards Committe,

under whose ceetion this British Standord was prepared, consists

‘of representatives from the folowing

"Aluminium Federation

‘Association of Coneulting Ensinere

Brick Development Assocation

British Preeare Concrete Federation Ltd

‘British Stoel Corporation

“British Steet Industry

‘Cornent and Concrete Assocation

‘Concrete Society Limited

Consumer Standards Advisory Committee of BSI

CConvontion of Scottish Local Authoritie

(County Surveyor’ Society

"Department of the Environment (Building Research Estabiehment)

Department of the Enviranment (Housing and Cansteustion)

*Departmant of the Environment (PSA

Department ofthe Environment (Water Engineering Division

Tluding Water Data Unit)

Department of Transport

‘Federation of Gill Engineering Contractors

‘Heaith and Safety Executive

*fgitution of Gill Enginesre

MTostitution of Municipal Engineert

Institution of Pubte Heath Engineers

netittion af Structural Enginebrs

Institution of Water Engiosers nd Selanne

London Transport Executive

Ministry of Agriculture, Fishel snd Food

‘National Federation of Building Trades Employers

National Weter Counc!

Fooya lstitute of Sritish Architoote

Scottish Development Department

‘Timber Research and Development Atsocetion

‘Trader Union Congress

‘The organizations marked with an astrisk in the above list, together

with the following, wera dractlyropresntad on the Technicel

Cornmittee entrusted withthe preperation ofthis British Standard

‘Assocation of Consulting Scientists

CConfedaration of British Industry

Construction Health and Safety Group

Construction Industry Training Board

Electricity Supply Industry in England and Wee

Incorporated Assocation of Architects and Surveyors

‘National Asoeation of Scaffolding Contractors

Prafabricated Aluminium Seaffoding Manufacturers Assocation

@

a

Amendments issued since publication =

2

Amd. No. Date of sue | Text affocted 6

2

:

a

nN

2

@

a - — S

British Standards Institution . 2 Park Street London W1A 28S - Telephone 01-629 9000 - Telex 266933 *

8209-3-1.54-8

csa/46

BSI BS*139 PART*2 82 MM Lb24bb9 OOO2b2b T mm

AMD 5533

0 Amendment No. 1

} published and effective from 28 August 1987

] to BS 1139 : Part 2 : 1982

Metal scaffolding

Part 2. Specification for couplers and fittings

for use in tubular scaffolding

Revised text

AMD 5523 Contents

August 1987 Delete the existing title against clause 6 and substitute ‘Aluminium specifica

aM 5533 Clause 5. Tensile strength of aluminium

‘August 1987

Delete the existing title and substitute ‘Aluminium specication’

At the beginning of line 1 insert the new heading ‘5.1 Tensile strength’

[At the end of the existing text insert the following

"B.2 Castings. Cast components formed by sand or gravity

casting shall comply with LM 25TF or LM 28787 of

BS 1490.

5,3. Hinge pins, Hinge pins in aluminium shall eomply with

6082.TF of BS 1473."

Amo 6533, Publications referred to

‘August 1987

Insert the following publications after the entry for BS 1472,

‘85 1473 Spociicetion for wrought aluminium and aluminium alloys for general engineering purposes

ret, bole and serew stock

'BS 1480 Speciation for sluminium and aluminium alloy Ingote and cssting’

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 01 Layout Crane FixxxxDocument1 page01 Layout Crane FixxxxekoNo ratings yet

- Cover OutnerDocument1 pageCover OutnerekoNo ratings yet

- Spek KomputerDocument1 pageSpek KomputerekoNo ratings yet

- BS 1139-4-1990, Metal ScaffoldingDocument12 pagesBS 1139-4-1990, Metal Scaffoldingeko100% (1)

- BS 1139-1-1982, Metal ScaffoldingDocument8 pagesBS 1139-1-1982, Metal ScaffoldingekoNo ratings yet