Professional Documents

Culture Documents

Instituto Alemão de Normalização-Din 10268

Instituto Alemão de Normalização-Din 10268

Uploaded by

Helder Vieira0 ratings0% found this document useful (0 votes)

8 views3 pagesDIN 10268

Original Title

INSTITUTO ALEMÃO DE NORMALIZAÇÃO-DIN 10268

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDIN 10268

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesInstituto Alemão de Normalização-Din 10268

Instituto Alemão de Normalização-Din 10268

Uploaded by

Helder VieiraDIN 10268

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

D

INA DEPRANIITI ;

PROIBIDO REP RODUZIR en ga EN tozes:z013-42

0 462471 Impresso: 26/08/2014)

2.730/0017-71 (Ped

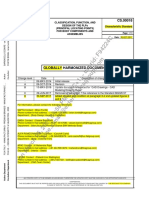

csN

COMPANHIA SIDERURGICA NACIONAL

Exemplar para uso exc!

Table 1 — Ladle analysis chemical composition

c si

steel | ste! | max ina

name | number

% %

[aeaor [ram [oor | 0s |

[eer os [oe | 07

HC220Y 03 09

02201 05 06

C2208 05 07

Ho260Y

H02601

HC2608

03 16

08 12

05 1,0

05

HC260A

C3001

HC3008

HC3OOLA

> These additional elements may be used Individually or in combination where they appear in the definition of the

steel within the composition limits indicated. Vanagium and boron may also be added. However, the sum of the

Contents of these four dispersoidal elements shall not exceed 0,22 %

» For all interstitial free (Y) grades, Nb may be added allematively or in combination with Ti. For all grades containing

"in its designation, Ti can be Substituted by Nb or B.

5.4 Mechanical properties

‘The products shall comply with the requirements for transverse test pieces given in Table 2. By agreement, they

may be delivered as suitable for making a particular part; in this case a maximum percentage of scrap may be

‘agreed and acceptance on the basis of mechanical properties is not applicable.

The mechanical properties given in Table 2 and Table 3 are valid for a period of at least 6 months from the date on

which the products are made available.

By agreement, special formabilty criteria can be defined between producer and purchaser.

DIN EN 10268:2013-12

EN 10268:2006+A1:2013 (E)

Table 2— Mechanical properties of transverse test pieces

0.2% proof

strength *

Rena

trans. MPa

Increase in|

roof

strength

after

heating

Tensile

strength

Elongation

Asai.

Plastic

strain ratio

Plastic

strain ratio

Strain

hardening

exponent

= T0922

5 1.0395

8 He220v J 1.0925 340-420

2 [THcz201] 1.0346 300-380

3 [pHez208_| 7.0306 320-400

8 HC260V_ 380-440,

2 Crczeor 320-400

= [rc2e08 360-440

& HC260LA. 350-430

Hos00|_| 1.0447 | 300-350 340440 30

& — Pics00s [71.0444 300-360 390-480] 26

& — [Heso0La | 7.0789] 300-380 380-480 | 23

5 HCS40LA [1.0548 [340-420 410-510,

= [ressota [1.0550] 380-480 “40-500 | 19]

3 Pacazota [1.0556] 420-520] 470-600

& — [ieasota 460-560 510-660,

g Hcso0La [1.0573 | 500-620 550-710,

8 [NOTE 1MPa=1Nmm?

Z| tthe yea swengt is pronounced, the valuos apply othe lower yield point Ra.

S| Forthicknessos » 1.2mm spacial agreements shall be mado

& — [© when he thickness Isls than or equal 100.7 mm and grater than 0.5 mm, the mininum valve for elongation is dood by

5 | untsFra ices ess than orcas! 96m, be minum ve eco by uns,

[4 Theminimum vaues fr (ran. and n (rans) only apply o products of thickness equal oor greater han 0,5 mm

S | & For products with thickness over 2mm the minimum r(trans.) valu is reduced by 02.

g

2

Exemplar para vs

PROIBIDO REPRODUZIR

ze

- OSN -33.042.730/0017-71 (Pe

Exemplar para uso exclusivo - COMPANHIA SIDERURGICA NACIONA\

DIN EN 10268:2013-12

EN 10268:2006+A1:2013 (E)

For the LA grades it may be agreed that the requirements given in Table 3 for longitudinal test pieces shall apply

instead of those for transverse test pieces.

B

Table 3 — Mechanical prope!

(ies of longitudinal test pieces

Tank proot | Tosa arergth | Eongeton

Swot name Sea number oe e ¢

Rp0,2 Rm ABO

lon. MPa long. MPa he

i

Tea Teo 70310 0a 600 mm

a

‘The products are supplied with one of the surface qualities A or B as defined in EN 10130 except for LA grades for

which only surface quality A applies.

5.5.2.2 Products of rolled width < 600 mm.

‘The requirements of EN 10139 apply.

5.5.3. Surface finish

5.5.3.1 Products of rolled width > 600 mm.

‘The requirements of EN 10130 apply.

5.5.3.2 Products of rolled width < 600 mm.

‘The requirements of EN 10139 apply.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Norma Fiat-Geometric Dimensioning and Tolerancing Practices-Cs.00019Document25 pagesNorma Fiat-Geometric Dimensioning and Tolerancing Practices-Cs.00019Helder VieiraNo ratings yet

- NORMA FIAT-CLASSIFICATION, FUNCTION, AND DESIGN OF THE PLPs-CS.00018Document13 pagesNORMA FIAT-CLASSIFICATION, FUNCTION, AND DESIGN OF THE PLPs-CS.00018Helder VieiraNo ratings yet

- Norma Fiat-Marking of Manufacture Date-0.00013Document7 pagesNorma Fiat-Marking of Manufacture Date-0.00013Helder VieiraNo ratings yet

- Instituto Alemão de Normalização-Din 10149-2Document15 pagesInstituto Alemão de Normalização-Din 10149-2Helder VieiraNo ratings yet