Professional Documents

Culture Documents

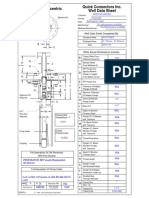

C-15 EX Mudline and Surface Wellhead - Casing Program

Uploaded by

BrunoPestanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C-15 EX Mudline and Surface Wellhead - Casing Program

Uploaded by

BrunoPestanaCopyright:

Available Formats

Proposal

Running Procedure

C-15 EX Mudline and

Surface Wellhead

30" x 20" x 13-3/8" x 9-5/8"

Casing Program

Surface Systems Publication

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 1

This document alone does not qualify an individual to Install/Run the Equipment. This document

is created and provided as a reference for Qualified Cameron Service Personnel and does not

cover all scenarios that may occur.

© 2008 Cameron International Corporation. All rights reserved. This material is the copyrighted work of Cameron

International Corporation and may not be reproduced, displayed, modified or distributed without the express prior written

permission of the copyright holder.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 2 Houston, Texas

Table of Contents

Mudline System Drawing ..................................................... 5

Mudline Bill of Materials ...................................................... 6

Wellhead System Drawing ................................................... 7

Wellhead Bill of Materials .................................................... 8

Stage 1 — 30" Conductor .................................................... 9

Install the Mudline Sub ........................................................................................... 9

Stage 2 — 20" Casing ........................................................ 10

Examine the 20" Running Tool ............................................................................. 10

Examine the 20" Hanger ...................................................................................... 10

Onshore Preparation ........................................................................................... 11

Offshore Preparation ........................................................................................... 11

Install the Hanger ................................................................................................. 12

Post-Operational Care ........................................................................................ 13

Annulus Washout ................................................................................................. 14

Contingency: Unable to Close Washports on 20" Running Tool or Test Fails ......... 15

Post-Operational Care ........................................................................................ 15

Install the Casing Head ........................................................................................ 16

Energize 'P' Seal ................................................................................................. 18

Test Between the P Seals .................................................................................... 18

Stage 3 — 13-3/8" Casing .................................................. 20

Test the BOP Stack ............................................................................................. 20

Run the Wear Bushing Before Drilling .................................................................. 21

Retrieve the Wear Bushing After Drilling .............................................................. 22

Examine the 13-3/8" Running Tool ....................................................................... 23

Examine the 13-3/8" Hanger ................................................................................ 24

Onshore Preparation ........................................................................................... 25

Offshore Preparation ........................................................................................... 25

Install the Hanger ................................................................................................. 26

Post-Operational Care ........................................................................................ 27

Annulus Washout ................................................................................................. 28

Contingency: Unable to Close Washports on 13-3/8" Running Tool or Test Fails ... 29

Post-Operational Care ........................................................................................ 29

Hang Off the Casing ............................................................................................ 30

Installing the Casing Spool ................................................................................... 32

Energize 'P' Seal ................................................................................................. 33

Test Between the Seals ....................................................................................... 33

Test the Connection ............................................................................................. 33

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 3

Stage 4 — 9-5/8" Casing .................................................... 34

Test the BOP Stack ............................................................................................. 34

Run the Wear Bushing Before Drilling .................................................................. 35

Retrieve the Wear Bushing After Drilling .............................................................. 36

Examine the 9-5/8" Running Tool ......................................................................... 37

Examine the 9-5/8" Hanger .................................................................................. 38

Onshore Preparation ........................................................................................... 39

Offshore Preparation ........................................................................................... 39

Clean Out the 13-3/8" Split Landing Ring Profile .................................................. 40

Install the Hanger ................................................................................................. 42

Post-Operational Care ........................................................................................ 43

Annulus Washout ................................................................................................. 44

Contingency: Unable to Close Washports on 9-5/8" Running Tool or Test Fails ..... 45

Post-Operational Care ........................................................................................ 45

Hang Off the Casing ............................................................................................ 46

Installing the Casing Spool ................................................................................... 48

Test Between the Seals ....................................................................................... 49

Test the Connection ............................................................................................. 49

System Drawing — Section 2 — Abandonment ............... 50

Stage 1 — Abandon the 9-5/8" Casing ............................. 51

Examine the T/A Cap Running Tool ...................................................................... 51

Examine the 9-5/8" T/A Cap ................................................................................ 51

Stage 2 — Abandon the 13-3/8" Casing ........................... 54

Examine the T/A Cap Running Tool ...................................................................... 54

Examine the 13-3/8" T/A Cap .............................................................................. 54

Stage 3 — Abandon the 20" Casing ................................. 57

Examine the T/A Cap Running Tool ...................................................................... 57

Examine the 20" Non Sealing Cap ...................................................................... 57

Stage 4 — Abandon the 30" Casing ................................. 60

Examine the 30" Trash Cover Running Tool .......................................................... 60

Examine the 30" Slip Over Trash Cover ............................................................... 60

Install the 30" Trash Cover ................................................................................... 61

Injection Gun Preperation .................................................. 62

Injection Gun Preparation .................................................................................... 62

Capacity Chart ..................................................................... 63

Load Chart ........................................................................... 64

Revision History .................................................................. 65

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 4 Houston, Texas

Mudline System Drawing

30" Casing

20" Casing

13-3/8" Casing

9-5/8" Casing RP030653

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 5

Mudline Bill of Materials

MUDLINE EQUIPMENT MUDLINE SERVICE TOOLS ABANDONMENT TOOLS

Item Qty Description Item Qty Description Item Qty Description

A1 1 Mudline Sub, C-15-EX, 30" x ST1 1 Running Tool, C-15-EX for AT1 1 T/A Cap Running Tool for 20",

1" buttweld prep top and 20" hanger, 20" buttress box 13-3/8" and 9-5/8" C-15-EX

bottom top T/A Caps

Part# 2182017-03 Part# 647434-01 Part#Y41166-02000231

A2 1 Mudline Hanger, C-15-EX, ST2 1 Running Tool, C-15-EX for AT2 1 20" T/A Cap, C-15-EX, Non-

20" with separate left hand 13-3/8" hanger, 13-3/8" but- Sealing

running and right hand tie- tress box top Part#2166654-01

back threads and 20" cas- Part# 2165950-01

AT3 1 13-3/8" T/A Cap, C-15-EX,

ing thread box bottom

Sealing

Part# 2181130-01 ST3 1 Running Tool, C-15-EX for

Part#Y41006-00001131

9-5/8" hanger, 9-5/8" Seal

A3 1 Mudline Hanger, C-15-EX, AT4 1 9-5/8" T/A Cap, C-15-EX,

Lock HC box top

13-3/8" with separte left hand Sealing

Part# 2165958-02

running and right hand tie- Part#Y41160-00001631

back threads and 13-3/8" ST4 1 Wash Tool with Wire Rope, AT5 1 30" Trash Cover Running

casing thread box bottom 13-3/8", C-15-EX Tool

Part# 2215920-03 Part# Y29444-00001601 Part# Y42150-31000011

AT6 1 30" Slip Over Trash Cover

A4 1 Mudline Hanger, C-15-EX, Part# Y41160-00001310

9-5/8" with separte left hand

running and right hand tie-

back threads and 9-5/8" cas-

ing thread box bottom

Part# 2166905-02

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 6 Houston, Texas

Wellhead System Drawing

30" Conductor

20" Casing

13-3/8" Csing

9-5/8" Csing

RP040986

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 7

Wellhead Bill of Materials

CASING HEAD ASSEMBLY COMPACT SPOOL ASSEMBLY SURFACE SERVICE TOOLS

Item Qty Description Item Qty Description Item Qty Description

B1 1 Casing Head, 20-3/4" 3M C1 1 Casing Spool, 'S-11' , 20-3/4" ST6 1 Test Plug, 20-3/4" 3M, 'W',

Flange top x 20" sliplock 3M flange x 13-5/8" 5M Flange 4-1/2" IF box top and bottom

bottom, w/ double 'P' Seal for top, two double 'P' Seals for Part#

20" OD Casing, with two 2-1/ 13-3/8" OD Casing, with two ST7 1 Wear Bushing Running Tool,

16" 5M studded side outlets 2-1/16" 5M SSO's for 20-3/4" WB, for type S&SL

Part# 2221349-01-01 Part# 162754-03-01-01 Bowl

B2 1 Gate Valve, manual, 2-1/16" C2 1 Valve Removal Plug, 1-1/2" Part#

5M, flanged Part# 014886-02 ST8 1 Wear Bushing, For type S&SL

Part# Bowl, 20-3/4" Nom., w/ j-slots

C3 1 Gate Valve, manual, FL,

Part#

B3 3 Ring Gasket, R-24 2-1/16" 5M, flanged

ST9 1 Test Plug, Type 'W', for S&SL

Part# Part# 141501-31-91-02

bowl, 13-5/8" Nom. 4-1/2" IF

B4 2 Companion Flange, 2-1/16" C4 3 Ring Gasket, RX-24 top and btm

5M x 2" line pipe Part# 702002-02-42 Part#

Part# 142362-01-03-03 ST10 1 Wear Bushing Running and

C5 2 Companion Flange, 2-1/16"

Retrieval Tool 13-5/8" WB for

B5 1 Bull Plug, solid, 2" line pipe 5M x 2" line pipe

type S&SL

Part# 006994-04 Part# 142362-01-03-02

Part#

B6 1 Bull Plug, tapped, 2" line pipe C6 2 Bull Plug, solid, 2" line pipe x ST11 1 Wear Bushing, 13-5/8" Nom.

x 1/2" npt 1/2" NPT For type S&SL w/ j-slots

Part# 007481-01 Part# 007481-01 Part#

B7 8 Stud, continuous thread, 7/8" C7 8 Stud, continuous thread, 7/8"

x 6" long, B7, plated x 6" long, B7, plated

Part# 702533-08-10-60 Part# 702533-08-10-60

B8 16 Nut, heavy hex, 7/8", 2H, C8 16 Nut, heavy hex, 7/8", 2H, plated

plated Part# 2709000-09-01

Part# 2709000-09-01

C9 1 Casing Hanger,type SB-3A,

B9 1 Ring Gasket, RX-74

13-5/8" x 9-5/8"

Part# 702002-07-42

Part#

B10 1 Casing Hanger,type SB-3A,

C10 1 Spool S-11, 13-5/8" 5M x 11"

20" x 13-3/8"

10M, w/2-1/16"M sso's, dbl

Part#

'T' seal bottom prep

Part#

C11 1 Ring Gasket, BX-160

Part#

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 8 Houston, Texas

Stage 1 — 30" Conductor

SAFETY NOTE: Always wear

30" C-15-EX Mudline Sub

proper PPE (Personal Protective

Equipment) such as safety shoes,

30.02"

safety glasses, hard hat, gloves, Maximum

etc. to handle and install equip-

ment.

11.00"

Install the Mudline Sub 18.00"

1. Examine the 30" Mudline Sub (Item

A1). Verify the following:

• bore is clean and free of debris 26.25"

Minimum

• weld preps are clean and un-

damaged

• casing threads are clean and RP020729

undamaged, if applicable

NOTE: Typically the Mudline Sub is

welded into a standard casing joint on-

shore. This casing joint may be a pin x 30" Conductor

box configuration. to Surface

2. Orient the Sub as illustrated.

3 Run the 30" casing as required.

4. At an appropriate location in the 30"

Mudline Sub

casing string, install the Sub in the

casing string.

NOTE: Typically the Mudline Sub is landed

approximately 50' ± 5' below the sea

floor.

5. Run the remaining 30" casing as

required.

6. Record the final setting depth of the

30" Conductor

Mudline Sub from the top of the

landing shoulder. RP020730

7. Cut the 30" conductor at an appro-

priate level and install the diverter

system.

8. Test as required.

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 9

Stage 2 — 20" Casing

Examine the 20" Running

20" C-15-EX Mudline Hanger

Tool Running Tool

1. Examine the 20" Mudline Hanger 20"

Running Tool (Item ST1). Verify the Casing Thread

following:

Test Port

• bore is clean and free of debris

• all threads are clean and un-

damaged O-Rings

• o-rings are properly installed 22.50"

and undamaged Washport

• washports are clean and un- 18.72" O-Ring

obstructed Minimum

NOTE: Typically the C-15-EX Mudline

Hanger Running Tool has a pup joint Left Hand

made up and Bakerlocked into the top of Running Thread

it onshore.

RP020731

2. Orient the Tool as illustrated.

Examine the 20" Hanger 20" C-15-EX Mudline Hanger

1. Examine the 20" Mudline Hanger Right Hand

(Item A2). Verify the following: Tieback Thread

• bore is clean and free of debris

• all threads are clean and un-

damaged

• landing shoulder is properly

installed, retained and undam-

aged Left Hand

Running Thread

NOTE: Typically the C-15-EX Mudline

Hanger has a pup joint made up into the

bottom of it onshore. 40.86"

2. Orient the Hanger as illustrated.

27.25" Fluted Landing

Maximum Shoulder

Retainer Wire

17.58" 20" Casing

Minimum Thread

RP020732

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 10 Houston, Texas

Stage 2 — 20" Casing

Onshore Preparation

1. Ensure the threads of both the Run- 20" Casing

ning Tool and Hanger are clean and Pup Joint

free of debris.

2. Wipe the o-ring and threads of the 20" Running

Running Tool with a light coat of Tool

seawater resistant grease.

WARNING: Do not use pipe dope or other

metal based compounds on the Hanger/

Running Tool connection.

3. Make up the Running Tool to the

Hanger by sliding the Running Tool

into the Hanger and rotating ap- 39.22"

proximately 5 turns to the left to a

Positive Stop.

20" Mudline

4. Pressure test the Tool/Hanger in- 49.41" Hanger

terface through the test port on the

Running Tool to 80% of the casing

burst.

WARNING: Do not exceed the working

pressure of the equipment as referenced

in the chart in the back of this manual.

Alternately, blanking caps may be in-

stalled to either end of the Assembly and

a full body test may be performed to 80%

of the casing burst pressure.

NOTE: When fully assembled the Hanger/

Tool assembly will be the same length

as a standard joint of casing or to cus- 20" Casing

tomer specifications. Pup Joint

5. Once a successful pressure test is

complete, replace the fitting in the RP020733

test port.

6. Place a single, permanent paint Offshore Preparation

mark across the Hanger/Tool inter-

face to ensure the Hanger and Tool 1. Inspect the entire assembly, prior to handling and verify the following:

are properly made up. • all threads are clean and undamaged

• paint mark across the Hanger/Tool interface is properly aligned

• thread protectors are properly installed and may be removed when

required

• all casing connections are properly made up

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 11

Stage 2 — 20" Casing

Install the Hanger

1. At the appropriate point in the cas- 20" Casing

ing string bring the assembly up the Pup Joint

V-door such that the box connection

is up.

2. Remove the thread protector from 20" Running

Tool

the box connection.

3. Carefully lift the assembly into the

vertical position on the rig floor.

NOTE: As the assembly is being lifted,

visually verify the paint mark is still prop-

erly aligned.

4. Remove the thread protector from

the pin connection.

5. Make up the connection to the cas-

ing in the rig floor to the thread

manufacturer's recommended op-

timum torque. 20" Mudline

Hanger

6. Release the casing from the floor

slips and lower the assembly to an

elevation comfortable for a final in-

spection.

NOTE: At this point, verify the paint mark

is still properly aligned. In the event the

paint mark has become misaligned dur-

ing handling or torquing, rotate the Run-

ning Tool to the right 3 turns to expose the

washports. Inspect the o-rings and re-

tighten the connection to between 4,500

and 5,000 ft lbs. The connection may be

retested if required through the test port

to 80% of the burst of the casing as

previously described.

20" Casing

WARNING: Do not exceed the working

Pup Joint

pressure of the equipment as referenced

in the chart in the back of this manual.

RP020733

NOTE: It is recommended that no cen-

tralizers be run above the Tool/Hanger

assembly.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 12 Houston, Texas

Stage 2 — 20" Casing

7. Make up a joint of casing to the top

of the assembly to the thread manu- 20" Landing/Pup Joint

facturers recommended optimum

torque.

20" Running Tool

8. Release the assembly from the rig

floor and carefully lower it into the

well.

9. Run the remaining joints in a nor-

mal manner, measuring the casing

30" Conductor

as it is run in the hole. 39.32"

Above the Top of

10. At approximately 10 feet from the the 30" Mudline Sub

Landing Shoulder 20" Hanger

anticipated landing point, slow the

rate of descent and land the Hanger

on the 30" mudline sub.

11. Cement as required.

Mudline Sub

Post-Operational Care

1. If the 20" Running Tool is retrieved

from the well, clean the Tool with

fresh water and apply a liberal

amount of sea water resistant

grease. 30" Conductor

2. Replace the thread protector in the

box connection. 20" Casing/Pup Joint

3. Install the protector provided on the RP020734

running threads of the Tool.

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 13

Stage 2 — 20" Casing

Annulus Washout

1. Upon completion of cementing,

open the washports by rotating the

casing string 3 turns to the right.

20" Running Tool

During this operation, balance the

running string weight such that the

Running Tool is unloaded, the cas-

ing will rise approximately 3 inches.

Rotate Running

2. Pump sea water or drill fluid down Tool to the Right Washports

through the casing string until re- Exposed

turns are clear of cement. Continue

flushing the area 2 times that of the

mudline to surface annular volume

has been displaced. During this

process, maintain high pump rates

and a pressure of 400 to 500 psi.

3. Close the washports by rotating the

20" Hanger

casing string to the left 3 turns when

the torque builds up, continue ap-

plying torque smoothly to between

4,500 and 5,000 ft lbs. During this

operation, balance the running string RP020735

weight such that the Running Tool

is unloaded. The casing string will

descend 3 inches. If the casing

string starts to rise this means a

casing connection is backing out. In

this event carry out the contingency

plan detailed in this Stage.

4. Pressure test the casing string

through the cementing head to 80%

of casing burst pressure or as indi-

cated by the company representa-

tive.

WARNING: Do not exceed the working

pressure of the equipment as referenced

in the chart in the back of this manual.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 14 Houston, Texas

Stage 2 — 20" Casing

Contingency: Unable to

Close Washports on 20"

Running Tool or Test Fails

1. If the casing connections should

start backing out, rotate the casing

string to the right until the Running

20" Running Tool

Tool is released from the Hanger,

this will be a maximum of 5 turns.

(Mark the casing clearly prior to re- Rotate Running

Tool to the Right

covery). The running string should

be balanced during this operation

such that the Running Tool is un-

loaded.

2. Recover the Running Tool to the

surface visually inspect the seals,

sealing areas and threaded areas.

3. Replace the o-rings. Apply a light

coat of clean seawater resistant

20" Hanger

lubricant.

NOTE: Do Not apply Pipe Dope or other

metal based compounds to the Hanger/

Running Tool thread connection. RP020736

4. Rerun the Running Tool on the cas-

ing string torqued to the maximum Post-Operational Care

allowable torque.

1. If the 20" running Tool is retrieved from the well, clean the Tool with fresh water

5. When the Running Tool is 5 feet

and apply a liberal amount of sea water resistant grease.

from the Hanger top slow the rate of

descent and stab the Running Tool 2. Replace the thread protector in the box connection.

into the Hanger. (Watch the casing

mark carefully) 3. Install the protector provided on the running threads of the Tool.

6. Land the Running Tool into the

Hanger and rotate to the left, balanc-

ing the weight as the Running Tool

moves down such that it is unloaded.

It will take 5 turns to make up and will

descend 4 to 5 inches. Final torque

should be 5,000 ft lbs maximum.

7. Pressure test the casing string

through the cement head to 80% of

casing burst pressure, or as indi-

cated by the company representa-

tive.

WARNING: Do not exceed the working

pressure of the equipment as referenced

in the chart in the back of this manual.

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 15

Stage 2 — 20" Casing

Install the Casing Head

1/8" x 45° 3/16"

1. Run the conductor and casing as

required.

2. Determine the correct elevation for 3/8"

the Casing Head and cut conductor Final Cut

pipe as required. Ensure conductor

is level and the cut is smooth.

3. Rough cut the 20" casing approxi-

mately 30" above the top of the con-

ductor (or a minimum of 8" above

16.00" 20" Casing

the anticipated final cut height).

+ 1/8"

NOTE: Always physically measure the -0

bottom prep of the next component to be

installed prior to making the final casing 30" Conductor

cut.

4. Final cut the casing at 16" +.125" -

.000" above the top of the conductor.

Place a 3/8" x 3/16" bevel on the

casing stub and remove all burrs

and sharp edges.

NOTE: The ID edge of the casing may be RP040997

ground slightly to allow drill pipe and

casing collars to pass smoothly. Baseplate

5. Examine the Baseplate. Verify the Access Ports

following:

9.25" 7.25"

• all components are securely

welded

• is appropriate for the bottom of Centering Lugs

the Casing Head and the cas-

ing size

34.00"

RP040998

6. Slide the Baseplate over the 20"

casing stub until it lands on the

conductor.

NOTE: The centering lugs on the bottom

of the Baseplate will center the Base-

plate on the conductor and should fall in 6.75" Baseplate Landed

+ 1/8"

the ID of the conductor. -0

RP040999

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 16 Houston, Texas

Stage 2 — 20" Casing

SAFETY NOTE: Always wear proper PPE (Personal Protective Equipment) especially gloves to handle

and install the slip type casing hanger.

7. Examine the Sliplock Casing Head

(Item B1). Verify the following: S-11 Casing Head

• ring groove and seal areas are 20-3/4" 3M x 20" Sliplock

clean and undamaged

• Sliplock assembly is clean and

undamaged

• bore is clean and free of debris

• P seals are properly installed

and undamaged

27.78"

• all peripheral equipment is in- 33.06"

tact and undamaged 19.00"

• the baseplate is clean and un-

damaged P Seals

7.00"

Slip Segments

8. Orient the Casing Head with the

Sliplock connection down. Slip Bowl

9. Liberally Lubricate the ID of the P Slip Retainer

seals of the Casing Head and the Screws

Guide Pin

OD of the casing stub with light oil.

RP021168

WARNING: Excessive oil may prevent a

positive seal from forming.

10. Suspend the Casing Head above

the 20" casing stub, ensuring that it

is level and orienting the outlets to

be compatible with drilling equip-

ment.

NOTE: Orient the Baseplate so that the

holes in the OD allow access to the slip

retainer screws.

11. Carefully lower Head until it lands

on the base plate. Remove Slip

Retainer Screws

12. Remove the slip retaining screws

and allow the slip segments to settle

around the casing.

Slips Settle

Around Casing

RP021169

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 17

Stage 2 — 20" Casing

Energize 'P' Seal

Remove Pipe Plug

and Check Valve Remove Pipe Plug

1. Locate the two injection ports on the and Bleed and Inject Plastic

Casing Head for energizing the up-

per P seal.

2. Remove the pipe plug from both

ports.

3. Remove the check valve from one RP021171

port only. This port becomes the

bleeder port. The other port is the

injection port. 5. Reinstall the check valve and pipe 7. Once the packing pressure has sta-

plug into the bleeder port and con- bilized, carefully bleed off the pres-

4. Install the plastic packing injection tinue to inject packing not to exceed sure and remove the injection gun.

gun (with a pressure gauge) to the 80% of the collapse pressure of

injection port and inject packing until the casing. 8. Replace the pipe plug in the injec-

a constant stream comes from the tion port.

bleeder port. 6. Hold and monitor the injection pres-

sure until it has stabilized. 9. Repeat this procedure to energize

the lower P Seal.

Test Between the P Seals

1. Locate the test port on the Casing

Remove Fitting

Head and remove the fitting. and Inject Fluid

2. Install a test pump and inject fluid

not to exceed 80% of casing col-

lapse pressure.

Warning : Do Not over Pressurize!

RP021172

3. Hold and monitor pressure for fif-

teen minutes or as required by Drill-

ing Supervisor.

4. Once a satisfactory test is achieved,

remove the test pump, drain the oil,

and replace the fitting.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 18 Houston, Texas

Stage 2 — 20" Casing

5. Once all testing is complete, tighten

the nuts of the slip bowl in an alter-

nating cross pattern to 600 to 700 ft

lbs.

Tighten Nuts

Slip Bowl

Rises

RP021170

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 19

Stage 3 — 13-3/8" Casing

Test the BOP Stack 21-1/4" Type 'W' Test Plug

Immediately after making up the BOP stack and periodically

during the drilling of the hole for the next casing string, the BOP 4-1/2" IF

Box

stack (connections and rams) must be tested.

WQ Seal

1. Examine the Test Plug (Item ST6). Verify the following: Removed

• lower elastomer seal is in place and undamaged

• upper seal is removed

WQ Seal

• all threads are clean and undamaged

2. Orient the Tool with the pin connection down.

3. Make up a joint of drill pipe to the top of the Tool.

4-1/2" IF

4. Wipe the WQ seal of the Tool with a light coat of oil or PIN

grease. RP001141

5. Ensure the lockscrews of the Head are fully retracted from

the bore.

Landing Joint

NOTE: The Type W Test Plug does not require lockscrews to

energize the seal. Test Plug

6. Open the annulus valve of the Head.

7. Slowly lower the Test Plug through the BOP and riser until

it lands on the load shoulder in the Head.

8. Close the BOP rams on the drill pipe and test to 3,000 psi

maximum.

NOTE: In the event the Test Plug is to be installed in the drill

string, refer to the chart in the back of this manual for maximum

hanging loads for the desired test pressure. RP021173

9. Monitor the annulus valve for signs of pressure.

10. After a satisfactory test, close the annulus valve, release

the test pressure and open the rams.

11. Remove as much fluid from the BOP stack as possible

per rig procedure.

12. Retrieve the Test Plug slowly to avoid damage to the seal.

NOTE: It may be necessary to open the annulus valve when

starting to retrieve the Test Plug to relieve any vacuum that may

occur.

13. Clean, grease and store the Tool as required.

14. Repeat this procedure as required during drilling opera-

tions.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 20 Houston, Texas

Stage 3 — 13-3/8" Casing

WARNING: Always use a Wear Bushing while drilling to 20"

protect the load shoulder from damage by the drill bit or rotating Running Tool

drill pipe. The Wear Bushing must be retrieved prior to Lift Lug

installing a Test Plug or running the casing.

4-1/2"

Box

Run the Wear Bushing Before Drilling

1. Examine the Running Tool (item ST2). Verify the follow-

ing:

• bore is clean and free of debris

• threads are clean and undamaged

• lift lugs are properly installed 4-1/2"

Pin

2. Orient the Tool with the drill pipe box facing up.

20"

3. Make up a joint of drill pipe to the top of the Tool. Wear Bushing

4. Examine the Wear Bushing (Item ST3). Verify the follow-

ing:

• bore is clean and free of debris

• stop lugs are properly installed

19.00"

• J-slots are clean and free of debris

5. Lower the Tool into the Wear Bushing and rotate 1/4 turn

clockwise.

6. Ensure the lockscrews are fully retracted from the bore of

the Head.

7. Slowly lower the entire Tool/Wear Bushing Assembly RP001143

through the BOP until it lands on the load shoulder in the

Head.

Landing Joint

8. Run in both lockscrews 180° apart to hold the Wear

Running Tool

Bushing in place.

9. Disengage the Tool from the Wear Bushing by rotating the Run in Both

drill pipe counterclockwise 1/4 turn and lifting straight up. Lockscrews

10. Drill as required. Wear Bushing

RP021174

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 21

Stage 3 — 13-3/8" Casing

Retrieve the Wear Bushing

After Drilling Landing Joint

1. Make up the Running Tool to the drill Running Tool

pipe.

2. Slowly lower the Tool onto the Wear

Bushing. Retract Both

Lockscrews

3. Rotate the Tool clockwise until the

drill pipe drops approximately 2". Wear Bushing

This indicates the lugs have aligned

with the Wear Bushing slots.

4. Slack off all weight to make sure the

Tool is down and rotate it clockwise

1/4 turn to fully engage the lugs in

the Wear Bushing.

5. Fully retract the lockscrews from the

bore of the Head. RP021190

6. Slowly retrieve the Wear Bushing

and remove it and the Tool from the

drill string. Clean, grease and store

the Tool and Wear Bushing.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 22 Houston, Texas

Stage 3 — 13-3/8" Casing

Examine the 13-3/8"

Running Tool 13-3/8" C-15-EX Casing Hanger

Running Tool

1. Examine the 13-3/8" Mudline

13-3/8" Casing

Hanger Running Tool (Item ST2).

Thread

Verify the following:

• bore is clean and free of debris

• all threads are clean and un- 10.79"

Test Port

damaged 16.52"

Maximum Secondary Metal

• o-rings are properly installed Seal Area

and undamaged

O-Rings

• washports are clean and un-

obstructed

Washports

• secondary metal seal area is 30.50"

clean and undamaged

O-Ring

NOTE: Typically the C-15-EX Mudline 12.48"

Hanger Running Tool has a pup joint Minimum

made up and Bakerlocked into the top of

it onshore.

2. Orient the Tool as illustrated. Left Hand

Running Threads

RP020737

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 23

Stage 3 — 13-3/8" Casing

Examine the 13-3/8"

Hanger 13-3/8" C-15-EX Casing Hanger

1. Examine the 13-3/8" Mudline

Hanger (Item A3). Verify the follow-

ing:

Right Hand

• bore is clean and free of debris Tieback Thread

• all threads are clean and un-

damaged

• landing shoulder is properly

installed and undamaged Left hand

Running Thread

• split landing ring profile is clean

and free of debris

• metal tieback seal area is clean

and undamaged

18.51" Fluted Landing

NOTE: Typically the C-15-EX Mudline Maximum Shoulder

Hanger has a pup joint made up into the

bottom of it onshore. 50.59"

Metal Tieback

2. Orient the Hanger as illustrated. Seal Shoulder

65.00"

12.31"

Minimum

Split Landing

Ring Profile

13-3/8" Casing

Thread

RP020738

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 24 Houston, Texas

Stage 3 — 13-3/8" Casing

Onshore Preparation

13-3/8" Landing/Pup

1. Ensure the threads of both the Running Tool and Hanger Joint

are clean and free of debris.

2. Wipe the o-ring and threads of the Running Tool with a 13-3/8" Running Tool

light coat of seawater resistant grease.

WARNING: Do not use pipe dope or other metal based com-

pounds on the Hanger/Running Tool connection. 27.37"

3. Make up the Running Tool to the Hanger by sliding the

Running Tool into the Hanger and rotating the Tool to the

left 13 to 14 turns and torque to between 2,500 ft lbs.

4. Pressure test the Tool/Hanger interface through the test

port on the Running Tool to 80% of the casing burst.

13-3/8" Hanger

WARNING: Do not exceed the working pressure of the equip-

ment as referenced in the chart in the back of this manual. 75.82"

Alternately, blanking caps may be installed to either end of the

Assembly and a full body test may be performed to 80% of the

casing burst pressure.

NOTE: When fully assembled the Hanger/Tool assembly will

be the same length as a standard joint of casing or to customer

specifications.

5. Once a successful pressure test is complete, replace the

fitting in the test port, if applicable.

6. Place a single, permanent paint mark across the Hanger/

Tool interface to ensure the Hanger and Tool are properly

made up.

13-3/8" Casing/Pup

Offshore Preparation Joint

RP020739

1. Inspect the entire assembly, prior to handling and verify

the following:

• all threads are clean and undamaged

• paint mark across the Hanger/Tool interface is prop-

erly aligned

• thread protectors are properly installed and may be

removed when required

• all casing connections are properly made up

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 25

Stage 3 — 13-3/8" Casing

Install the Hanger

1. At the appropriate point in the casing string 13-3/8" Landing/Pup

bring the assembly up the V-door such that Joint

the box connection is up.

2. Remove the thread protector from the box

13-3/8" Running Tool

connection.

3. Carefully lift the assembly into the vertical

position on the rig floor.

NOTE: As the assembly is being lifted, visually

verify the paint mark is still properly aligned.

4. Remove the thread protector from the pin

connection.

5. Make up the connection to the casing in the

rig floor to the thread manufacturer's recom-

mended optimum torque.

6. Release the casing from the floor slips and

lower the assembly to an elevation comfort-

able for a final inspection.

13-3/8" Hanger

NOTE: At this point, verify the paint mark is still

properly aligned. In the event the paint mark has

become misaligned during handling or torquing,

rotate the Running Tool to the right 7 to 8 turns to

expose the washports. Inspect the o-rings and

retighten the connection. Final running torque

should be between 4,500 and 5,000 ft lbs. The

connection may be retested if required through

the test port to 80% of the burst of the casing as

previously described.

WARNING: Do not exceed the working pressure

of the equipment as referenced in the chart in the

back of this manual.

NOTE: It is recommended that no centralizers be

run above the Tool/Hanger assembly.

13-3/8" Casing/Pup

Joint

RP020739

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 26 Houston, Texas

Stage 3 — 13-3/8" Casing

7. Make up a joint of casing to the top

of the assembly to the thread manu-

facturers recommended optimum 13-3/8" Landing/Pup

torque. Joint

8. Release the assembly from the rig

floor and carefully lower it into the

well.

13-3/8" Running Tool

9. Run the remaining joints in a nor-

mal manner, measuring the casing

as it is run in the hole. 39.19"

Above the Top

10. At approximately 10 feet from the of the Mudline Sub

anticipated landing point, slow the Landing Shoulder 20" Hanger

rate of descent and land the Hanger

on the load shoulder in the 20"

Hanger.

11. Cement as required.

Post-Operational Care 13-3/8" Hanger

1. If the 13-3/8" Running Tool is re-

trieved from the well, clean the Tool

with fresh water and apply a liberal

amount of sea water resistant

grease.

2. Replace the thread protector in the

box connection.

3. Install the protector provided on the

running threads of the Tool.

13-3/8" Casing/Pup

Joint

RP020740

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 27

Stage 3 — 13-3/8" Casing

Annulus Washout

1. Upon completion of cementing,

open the washports by rotating the

casing string 7 to 8 turns to the right. 13-3/8" Landing/Pup

During this operation, balance the Joint

running string weight such that the

Running Tool is unloaded, the cas-

ing will rise approximately 2 inches.

2. Pump sea water or drill fluid down 13-3/8" Running Tool

through the casing string until re- Rotate Running

turns are clear of cement. Continue Tool to the Right

flushing the area 2 times that of the

mudline to surface annular volume

has been displaced. During this

process, maintain high pump rates

and a pressure of 400 to 500 psi.

3. Close the washports by rotating the

casing string to the left 7 to 8 turns

when the torque builds up, continue

applying torque smoothly. Final run-

ning torque should be between 13-3/8" Hanger

4,500 and 5,000 ft lbs. During this

operation, balance the running string

weight such that the Running Tool

is unloaded. The casing string will

descend 2 inches. If the casing

string starts to rise this means a

casing connection is backing out. In

this event carry out the contingency

plan detailed in this Stage.

4. Pressure test the casing string

through the cementing head to 80%

of casing burst pressure or as indi-

cated by the company representa-

tive.

RP020741

WARNING: Do not exceed the working

pressure of the equipment as referenced

in the chart in the back of this manual.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 28 Houston, Texas

Stage 3 — 13-3/8" Casing

Contingency: Unable to

Close Washports on 13-3/

8" Running Tool or Test

Fails

1. If the casing connections should

start backing out, rotate the casing

string to the right until the Running

Tool is released from the Hanger,

13-3/8" Landing/Pup

this will be a maximum of 14 turns.

Joint

(Mark the casing clearly prior to re-

covery). The running string should

be balanced during this operation

such that the Running Tool is un-

loaded. 13-3/8" Running Tool

Rotate Running

2. Recover the Running Tool to the Tool to the Right

surface visually inspect the seals,

sealing areas and threaded areas.

3. Replace the o-rings. Apply a light

coat of clean seawater resistant

lubricant.

NOTE: Do Not apply Pipe Dope or other

metal based compounds to the Hanger/

Running Tool thread connection.

4. Rerun the Running Tool on the cas- 13-3/8" Hanger

ing string torqued to the maximum

allowable torque.

5. When the Running Tool is 5 feet

from the Hanger top slow the rate of

descent and stab the Running Tool

into the Hanger. (Watch the casing

mark carefully)

6. Land the Running Tool into the

Hanger and rotate to the left, balanc-

ing the weight as the Running Tool

moves down such that it is unloaded.

It will take 13 to 14 turns to make up

and will descend 4 to 5 inches. Final

torque should be 5,000 ft lbs maxi- RP020742

mum.

7. Pressure test the casing string

through the cement head to 80% of Post-Operational Care

casing burst pressure, or as indi-

1. If the 13-3/8" running Tool is retrieved from the well, clean the Tool with fresh

cated by the company representa-

water and apply a liberal amount of sea water resistant grease.

tive.

2. Replace the thread protector in the box connection.

WARNING: Do not exceed the working 3. Install the protector provided on the running threads of the Tool.

pressure of the equipment as referenced

in the chart in the back of this manual.

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 29

Stage 3 — 13-3/8" Casing

SAFETY NOTE: Always wear proper PPE (Personal Protective Equipment) especially gloves to handle

and install the slip type casing hanger.

1. Reconfirm the Casing OD and grade.

Remove and clean loose scale from

Casing OD.

Casing Hanger 'SB-3A'

Packoff

2. Verify Slip Bowl taper is smooth,

clean with no corrosion and dam- Rubber

age free.

3. Disassembly of the Hanger to re-

orient the slips is not required.

Slip Retainer

4. Handles are not removed when

setting Slips.

Latch Screw

Screw

Hang Off the Casing Slips

1. Run the 13-3/8" casing and cement

as required. Guide Pin

WARNING: Ensure that the casing is

centralized. Hanger clearances are small RP970458

and centering must be accurate.

Casing Hanger

2. Drain the BOP and Casing Head

bowl through its side outlet. Leave Remove Slip

the valve open until the Casing Retaining

Hanger is set. Screws

3. There are two methods used to in-

stall the Casing Hanger: Support Boards

• from the rig floor through a full

opening BOP stack, provided

no casing collars are between

the rig floor and the Head

RP000575

• underneath the BOP stack, pro-

vided the well is safe and under

control. This option allows the 5. Remove the two latch screws and handles, separating the Hanger halves.

Hanger bowl to be inspected

and thoroughly washed prior to 6. Place two boards against the casing to support the Hanger.

the Hanger Installation.

7. Wrap the Hanger around the casing and replace the latch screws and handles.

4. Examine the Casing Hanger (Item

B10). Verify the following: 8. Verify that the seal element is 1" thick and is not compressed beyond the OD

• the packoff rubber is in good of the Hanger. If it is, loosen the cap screws in the top of the Hanger. The seal

condition MUST NOT BE COMPRESSED prior to slacking off casing weight onto the

Hanger.

• all screws are in place and in-

tact

9. Loosen the slip retainer screws on the OD of the slip bowl one turn. These

• bore and threads are clean and screws hold the slips in the retracted position. The slips will NOT set unless

in good condition these screws are loosened before the Hanger is placed in the Head.

• slips are intact, clean, undam- 10. Grease the Casing Hanger body.

aged

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 30 Houston, Texas

Stage 3 — 13-3/8" Casing

11. Remove the support boards and

lower the hanger into the Casing

Rough Cut

Head bowl, using a cat-line to cen-

ter the casing, if necessary.

12. Pull tension on the casing to the

desired hanging weight (minimum

15,000 lbs to energize the packoff). 1/8" x 45° 3/16"

13. Slack off on the casing. A sharp Approximately

decrease on the weight indicator 24.00" 3/8"

will signify that the Hanger has taken

weight and is supporting the cas-

ing.

6.00" Final Cut

± 1/8"

WARNING: Because of the circumferen-

tial marks created on the slip bowl inside

diameter during the setting process; it is

not recommended to reset an 'SB' slip

assembly after weight has been ap-

plied. Prior to resetting the 'SB' slips they

should be sent to a Cameron facility for

evaluation and possible repair.

14. Rough cut the casing approximately

24" above the top of the Casing

Head and move the excess casing RP021175

and BOP out of the way.

NOTE: Always physically measure the

bottom prep of the next component to be

installed prior to making the final casing

cut.

15. Final cut the casing at 6" ± 1/8"

above the top of the Casing Head

flange. Place a 3/8" x 3/16" bevel on

the casing stub and remove all burrs

and sharp edges.

NOTE: The ID edge of the casing may be

ground slightly to allow drill pipe and

casing collars to pass smoothly.

16. Fill the void above the Casing Hanger

with clean oil to the top of the Casing

Head.

WARNING: DO NOT overfill the void. Oil

that becomes trapped under the ring

gasket will prevent formation of a good

seal.

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 31

Stage 3 — 13-3/8" Casing

Installing the Casing Spool Casing Spool 'S-11'

1. Examine the Casing Spool (Item 13-5/8" 5M x 20-3/4" 3M

C1). Verify the following:

• bore is clean and free of de-

bris

• all seal areas are clean and

undamaged

• P seals are properly installed

and undamaged

• all fittings and peripheral

equipment are intact and un-

damaged

2. Orient the Spool as illustrated.

'P' Seals

3. Wipe the ID of the P seal and the RP040989

OD of the casing stub with a light

oil.

WARNING: Excessive oil or grease may

prevent a good seal from forming.

4. Clean the mating ring grooves of

the Casing Head and Casing

Spool.

5. Install the RX-74 Ring Gasket (Item

B9) in the ring groove of the Head.

6. Orient the Casing Spool so the

outlets are in proper position and

carefully lower it over the casing

stub.

WARNING: Do not damage the P Seal or

its sealing ability will be impaired!

7. Make up the connection with the

Studs and Nuts tightening them in

an alternating cross pattern to the

torque referenced in the chart in the RP040990

back of this manual.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 32 Houston, Texas

Stage 3 — 13-3/8" Casing

5. Reinstall both fittings.

Energize 'P' Seal Remove Fittings Energize 'P' Seals Remove Fitting

and Bleed and Inject Plastic

1. Locate the two injection ports on the

Casing Head for energizing the up-

per P seal.

2. Remove the pipe plug from both

ports.

3. Remove the check valve from one

port only. This port becomes the RP040974

bleeder port. The other port is the

injection port. 5. Reinstall the check valve and pipe 7. Once the packing pressure has sta-

plug into the bleeder port and con- bilized, carefully bleed off the pres-

4. Install the plastic packing injection tinue to inject packing not to exceed sure and remove the injection gun.

gun (with a pressure gauge) to the 80% of the collapse pressure of

injection port and inject packing until the casing. 8. Replace the pipe plug in the injec-

a constant stream comes from the tion port.

bleeder port. 6. Hold and monitor the injection pres-

sure until it has stabilized. 9. Repeat this procedure to energize

the lower P Seal.

Test Between the Seals

1. Locate the two autoclave ports on

the Spool lower flange. Test Seals

Remove Pipe Plug

and Check Valve Remove Pipe Plug

2. Remove both fittings. and Inject Test Fluid and Check Valve

and Monitor

3. Install a test pump to the port for

testing between the P seals and

inject test fluid to either 3000 psi or

80% of casing collapse-whichever

is less. RP040987

4. Monitor the open flange test port for

6. Once a satisfactory test is achieved, carefully bleed off test pressure and

signs of leakage.

remove test pump.

5. Hold and monitor test pressure for

fifteen minutes or as required by NOTE: Do Not reinstall the fittings.

Drilling Supervisor.

Test the Connection

1. Install a test pump to the port for

testing the connection and inject Remove Pipe Plug Test Connection

test fluid to either 3000 psi or 80% and Check Valve

Remove Pipe Plug

and Monitor

of casing collapse-whichever is and Check Valve

and Inject Test Fluid

less.

2. Monitor the open port used to test

between the P seals.

3. Hold and monitor test pressure for RP040988

fifteen minutes or as required by

Drilling Supervisor. 4. Once a satisfactory test is achieved, carefully bleed off test pressure and

remove the test pump.

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 33

Stage 4 — 9-5/8" Casing

Test the BOP Stack

McEvoy Type W Test Plug

Immediately after making up the BOP stack and periodically

during the drilling of the hole for the next casing/tubing string,

the BOP stack (connections and rams) must be tested.

4-1/2"

1. Make up the BOP stack to the Head/Spool using a spare Box

ring gasket. 1/2" LP

Weephole

2. Examine the Test Plug (Item ST9). Verify the following:

Pipe Plug

• elastomer(s) seal is in place and undamaged

• all threads are clean and undamaged

• pipe plug is properly installed (if necessary)

3. Orient the Tool with the pin connection down. 'WQ' Seal

4. Make up a joint of drill pipe to the Tool.

5. Wipe the WQ seal of the Tool, with a light coat of oil or

grease.

6. Ensure the lockscrews, if applicable, of the Head/Spool

are fully retracted from the bore.

NOTE: The Type W Test Plug does not require lockscrews to

energize the seal.

7. Open the annulus valve of the Head/Spool. 4-1/2"

8. Slowly lower the Test Plug through the BOP and riser until Pin

RP001883

it lands on the load shoulder in the Head/Spool.

9. Close the BOP rams on the drill pipe and test to 5,000 psi

maximum. Landing Joint

NOTE: In the event the Test Plug is to be installed in the drill

string, refer to the chart in the back of this manual for maximum

hanging loads for the desired test pressure.

10. Monitor the annulus valve for signs of pressure.

11. After a satisfactory test, close the annulus valve, release

the test pressure and open the rams.

12. Remove as much fluid from the BOP stack as possible

per rig procedure. 11" Test Plug

13. Retrieve the Test Plug slowly to avoid damage to the seal.

RP001818

NOTE: It may be necessary to open the annulus valve when

starting to retrieve the Test Plug to relieve and vacuum that may

occur.

14. Clean, grease and store the Tool as required.

15. Repeat this procedure as required during drilling opera-

tions.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 34 Houston, Texas

Stage 4 — 9-5/8" Casing

WARNING: Always use a Wear Bushing while drilling to McEvoy Wear Bushing

protect the load shoulder from damage by the drill bit or rotating Running Tool

Set Screw

drill pipe. The Wear Bushing must be retrieved prior to 4-1/2" IF

installing a Test Plug or running the casing. Box

Run the Wear Bushing Before Drilling

Lift Lug

1. Examine the Running Tool (Item ST10). Verify the follow-

ing:

• bore is clean and free of debris

• threads are clean and undamaged

• lift lugs are properly installed

2. Orient the Tool with the drill pipe box facing up.

3. Make up a joint of drill pipe to the top of the Tool. 4-1/2" IF J-Slot

Pin

4. Examine the Wear Bushing (Item ST11). Verify the follow- McEvoy Wear Bushing Stop Lug

ing:

• bore is clean and free of debris Optional

O-Ring

• stop lugs are properly installed

• J-slots are clean and free of debris

• o-ring, if required, is properly installed and undam-

aged

5. Lower the Tool into the Wear Bushing and rotate 1/4 turn

clockwise.

6. Ensure the lockscrews, if applicable, are fully retracted

from the bore of the Head/Spool.

7. Wipe the o-ring of the Wear Bushing, if applicable, with a

RP001869

light coat of oil or grease.

8. Slowly lower the entire Tool/Wear Bushing Assembly

Landing Joint

through the BOP until it lands on the load shoulder in the

Head/Spool.

BOP Stack

9. Run in two lockscrews, if applicable, 180° apart to hold the

Wear Bushing in place.

Run in

Lockscrews

10. Disengage the Tool from the Wear Bushing by rotating the

drill pipe counterclockwise 1/4 turn and lifting straight up.

Wear Bushing

11. Drill as required.

Running Tool

RP001820

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 35

Stage 4 — 9-5/8" Casing

Retrieve the Wear Bushing

Landing Joint

After Drilling

O-Ring Removed

1. Make up the Running Tool to the drill from Wear Bushing

pipe. when Lockscrews

are Used

2. Slowly lower the Tool onto the Wear

Bushing. Retract

Lockscrews

3. Rotate the Tool clockwise until the

drill pipe drops approximately 2".

This indicates the lugs have aligned Wear Bushing

with the Wear Bushing slots.

4. Slack off all weight to make sure the

Running Tool

Tool is down and rotate it clockwise

1/4 turn to fully engage the lugs in RP001882

the Wear Bushing.

5. Retract the lockscrews, if applicable.

6. Slowly retrieve the Wear Bushing

and remove it and the Tool from the

drill string. Clean, grease and store

the Tool and Wear Bushing.

NOTE: McEvoy Wear Bushing Running

Tools and Wear Bushings, using lift lugs

and J-slots, are all of the same basic

configuration and are all run in the same

fashion, depending on the whether the

Head/Spool is equipped with lockscrews

or not.

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 36 Houston, Texas

Stage 4 — 9-5/8" Casing

Examine the 9-5/8"

Running Tool 9-5/8" C-15-EX Casing Hanger

1. Examine the 9-5/8" Mudline Hanger Running Tool

Running Tool (Item ST3). Verify the

following: 13-3/8" Casing

• bore is clean and free of debris

Thread

• all threads are clean and un-

damaged

• o-rings are properly installed 10.56" Test Port

and undamaged

• washports are clean and un-

Secondary Metal

obstructed 12.15" Seal Area

Maximum

• secondary metal seal area is O-Rings

clean and undamaged

NOTE: Typically the C-15-EX Mudline Washports

Hanger Running Tool has a pup joint

30.31"

made up and Bakerlocked into the top of

it onshore.

O-Ring

2. Orient the Tool as illustrated. 8.80"

Minimum

Left Hand

Running Threads

RP020743

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 37

Stage 4 — 9-5/8" Casing

Examine the 9-5/8" Hanger

1. Examine the 9-5/8" Mudline Hanger

(Item A4). Verify the following:

9-5/8" C-15-EX Casing Hanger

• bore is clean and free of debris Seal Area

• all threads are clean and un-

damaged

• split landing ring is properly

installed, retained and undam- Right Hand

aged Tieback Threads

• split landing ring area is clean

and free of debris Left Hand

• metal tieback seal area is clean

Running Threads

and undamaged

NOTE: Typically the C-15-EX Mudline

12.23"

Metal Seal Area

Hanger has a pup joint made up and for Tieback Tool

Bakerlocked into the bottom of it on- Maximum

50.12"

shore.

Load Ring

2. Orient the Hanger as illustrated.

8.80"

Minimum Split Landing Ring

9-5/8" Casing Thread

RP030159

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 38 Houston, Texas

Stage 4 — 9-5/8" Casing

Onshore Preparation

1. Ensure the threads of both the Running

9-5/8" Landing/Pup

Tool and Hanger are clean and free of

Joint

debris.

2. Wipe the o-ring and threads of the Run-

ning Tool with a light coat of seawater 9-5/8" Running Tool

resistant grease.

WARNING: Do not use pipe dope or other metal

based compounds on the Hanger/Running

Tool connection.

9-5/8" Hanger

3. Make up the Running Tool to the Hanger

by sliding the Running Tool into the Hanger

and Rotating the Tool to the left 13 to 14

turns and torque to between 2,500 ft lbs.

4. Pressure test the Tool/Hanger interface

through the test port on the Running Tool

to 80% of the casing burst.

60.76"

WARNING: Do not exceed the working pres-

sure of the equipment as referenced in the

chart in the back of this manual.

Alternately, blanking caps may be installed to

either end of the Assembly and a full body test

may be performed to 80% of the casing burst

pressure.

NOTE: When fully assembled the Hanger/Tool

assembly will be the same length as a stan-

dard joint of casing or to customer specifica-

tions.

5. Once a successful pressure test is com-

plete, replace the fitting in the test port, if 9-5/8" Casing

applicable.

6. Place a single, permanent paint mark RP030160

across the Hanger/Tool interface to en-

sure the Hanger and Tool are properly

made up. Offshore Preparation

1. Inspect the entire assembly, prior to handling and verify the following:

• all threads are clean and undamaged

• paint mark across the Hanger/Tool interface is properly aligned

• thread protectors are properly installed and may be removed when

required

• all casing connections are properly made up

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 39

Stage 4 — 9-5/8" Casing

Clean Out the 13-3/8" Split Landing Ring

Profile 13-3/8" Clean Out Tool

1. Examine the Clean Out Tool (Item ST4). Verify the follow-

ing:

• threads are clean and undamaged 4-1/2" IF

• bore is clean and free of debris Box

• washports are clean and unobstructed

• wire rope scrapers are of adequate length

2. Orient the Tool as illustrated.

Washports

108.00"

Wire Rope

12.00" Scrapers

14.38"

RP941643

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 40 Houston, Texas

Stage 4 — 9-5/8" Casing

3. Make up a landing joint to the top of the Tool.

4. Lower the Tool into the well and spot it at the expected

Hanger landing profile.

5. Pump through the drill pipe while rotating the Tool to clean

out the profile and casing up to (5) five feet on either side 13-3/8" Running Tool

of the expected landing profile.

6. Once the profile is thoroughly cleaned, retrieve the Tool to

the rig floor.

7. Clean the Tool with fresh water and coat it liberally with a

sea-water resistant grease.

13-3/8" Hanger

13-3/8" Clean

Out Tool

Wire Rope Scrapers

13-3/8" Casing/Pup

Joint

RP020787

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 41

Stage 4 — 9-5/8" Casing

Install the Hanger

1. At the appropriate point in the casing string bring the

assembly up the V-door such that the box connection is 9-5/8" Landing/Pup

up. Joint

2. Remove the thread protector from the box connection.

9-5/8" Running Tool

3. Carefully lift the assembly into the vertical position on the

rig floor.

NOTE: As the assembly is being lifted, visually verify the paint

mark is still properly aligned.

4. Remove the thread protector from the pin connection.

5. Make up the connection to the casing in the rig floor to the 9-5/8" Hanger

thread manufacturer's recommended optimum torque.

6. Release the casing from the floor slips and lower the

assembly to an elevation comfortable for a final inspec-

tion.

NOTE: At this point, verify the paint mark is still properly aligned.

In the event the paint mark has become misaligned during

handling or torquing, rotate the Running Tool to the right 7 to

8 turns to expose the washports. Inspect the o-rings and

retighten the connection to between 4,500 and 5,000 ft lbs.

The connection may be retested if required through the test

port to 80% of the burst of the casing as previously described.

WARNING: Do not exceed the working pressure of the equip-

ment as referenced in the chart in the back of this manual.

NOTE: It is recommended that no centralizers be run above the

Tool/Hanger assembly.

9-5/8" Casing

RP030161

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 42 Houston, Texas

Stage 4 — 9-5/8" Casing

7. Make up a joint of casing to the top

of the assembly to the thread manu-

facturers recommended optimum 13-3/8" Landing/Pup

torque. Joint

9-5/8" Landing/Pup

8. Release the assembly from the rig Joint

floor and carefully lower it into the

well. 13-3/8" Running Tool

9. Run the remaining joints in a nor-

mal manner, measuring the casing

as it is run in the hole.

10. At approximately 10 feet from the

anticipated landing point, slow the

rate of descent.

11. Lower the 9-5/8" Hanger through

the 13-3/8" Hanger until the split 4.39"

Above the Top

landing ring on the 9-5/8" Hanger

of the 30" Mudline 13-3/8" Hanger

identifies and engages the internal Sub Landing Shoulder

profile in the 13-3/8" Hanger. 9-5/8" Running Tool

12. Continue to lower the 9-5/8 Hanger

an additional 3" until the full string

weight is suspended.

20" Casing/Pup Joint

NOTE: In the event the split landing ring

on the 9-5/8" Hanger does not engage 9-5/8" Hanger

the profile in the 13-3/8" Hanger, retrieve

the 9-5/8" above the 13-3/8" Hanger and

lower it through the split landing ring

profile in the 13-3/8" Hanger again at a

slower rate of descent.

13. Cement as required.

Post-Operational Care

1. If the 9-5/8" Running Tool is re-

trieved from the well, clean the Tool

13-3/8" Casing/Pup

with fresh water and apply a liberal Joint

amount of sea water resistant

grease.

9-5/8" Casing

2. Replace the thread protector in the

box connection. RP030162

3. Install the protector provided on the

running threads of the Tool.

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 43

Stage 4 — 9-5/8" Casing

Annulus Washout

1. Upon completion of cementing,

open the washports by rotating the

casing string 7 to 8 turns to the right.

During this operation, balance the

running string weight such that the

Running Tool is unloaded, the cas-

ing will rise approximately 4 to 5

inches.

2. Pump sea water or drill fluid down

through the casing string until re-

turns are clear of cement. Continue

flushing the area 2 times that of the

mudline to surface annular volume

has been displaced. During this

process, maintain high pump rates 9-5/8" Running Tool

and a pressure of 400 to 500 psi.

3. Close the washports by rotating the

casing string to the left 7 to 8 turns

when the torque builds up, continue

applying torque smoothly to between

4,500 and 5,000 ft lbs. During this

operation, balance the running string Washports Exposed

weight such that the Running Tool Rotate Running

is unloaded. The casing string will Tool to the Right

descend 4 to 5 inches. If the casing

string starts to rise this means a

casing connection is backing out. In

this event carry out the contingency

plan detailed in this Stage.

4. Pressure test the casing string 9-5/8" Hanger

through the cementing head to 80%

of casing burst pressure or as indi-

cated by the company representa-

tive.

WARNING: Do not exceed the working

pressure of the equipment as referenced

in the chart in the back of this manual.

RP030163

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program

Page 44 Houston, Texas

Stage 4 — 9-5/8" Casing

Contingency: Unable to Close Washports

on 9-5/8" Running Tool or Test Fails

1. If the casing connections should start backing out, rotate 9-5/8" Running Tool

the casing string to the right until the Running Tool is

released from the Hanger, this will be a maximum of 14

turns. (Mark the casing clearly prior to recovery). The

running string should be balanced during this operation

such that the Running Tool is unloaded.

2. Recover the Running Tool to the surface visually inspect

the seals, sealing areas and threaded areas.

3. Replace the o-rings. Apply a light coat of clean seawater

resistant lubricant.

NOTE: Do Not apply Pipe Dope or other metal based com-

pounds to the Hanger/Running Tool thread connection.

4. Rerun the Running Tool on the casing string torqued to Rotate Running

the maximum allowable torque. Tool to the Right

5. When the Running Tool is 5 feet from the Hanger top slow

the rate of descent and stab the Running Tool into the

Hanger. (Watch the casing mark carefully)

9-5/8" Hanger

6. Land the Running Tool into the Hanger and rotate to the

left, balancing the weight as the Running Tool moves

down such that it is unloaded. It will take 13 to 14 turns

to make up and will descend 4 to 5 inches. Final torque

should be between 4,500 and 5,000 ft lbs.

7. Pressure test the casing string through the cement head

to 80% of casing burst pressure, or as indicated by the

company representative.

WARNING: Do not exceed the working pressure of the equip-

RP030164

ment as referenced in the chart in the back of this manual.

Post-Operational Care

1. If the 9-5/8" running Tool is retrieved from the well, clean

the Tool with fresh water and apply a liberal amount of sea

water resistant grease.

2. Replace the thread protector in the box connection.

3. Install the protector provided on the running threads of the

Tool.

C-15-EX Mudline and Surface Wellhead RP-001473

30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program Draft

Houston, Texas Page 45

Stage 4 — 9-5/8" Casing

SAFETY NOTE: Always wear proper PPE (Personal Protective Equipment) especially gloves to handle

and install the slip type casing hanger.

1. Reconfirm the Casing OD and grade.

Remove and clean loose scale from Casing Hanger 'SB-3A'

Casing OD.

Packoff

2. Verify Slip Bowl taper is smooth, Rubber

clean with no corrosion and dam-

age free.

3. Disassembly of the Hanger to re-

orient the slips is not required.

Slip Retainer

4. Handles are not removed when Latch Screw

setting Slips.

Screw

Hang Off the Casing Slips

1. Run the 9-5/8" casing and cement

as required.

Guide Pin

WARNING: Ensure that the casing is RP970458

centralized. Hanger clearances are small

and centering must be accurate.

2. Drain the BOP and Casing Head Casing Hanger

bowl through its side outlet. Leave

the valve open until the Casing Remove Slip

Hanger is set. Retaining

Screws

3. There are two methods used to in-

stall the Casing Hanger:

Support Boards

• from the rig floor through a full

opening BOP stack, provided

no casing collars are between

the rig floor and the Head

.

• underneath the BOP stack, pro- RP000575

vided the well is safe and under

control. This option allows the

5. Remove the two latch screws and handles, separating the Hanger halves.

Hanger bowl to be inspected

and thoroughly washed prior to 6. Place two boards against the casing to support the Hanger.

the Hanger Installation.

4. Examine the Casing Hanger (Item 7. Wrap the Hanger around the casing and replace the latch screws and handles.

C9). Verify the following:

8. Verify that the seal element is 1" thick and is not compressed beyond the OD

• the packoff rubber is in good of the Hanger. If it is, loosen the cap screws in the top of the Hanger. The seal

condition MUST NOT BE COMPRESSED prior to slacking off casing weight onto the

• all screws are in place and in- Hanger.

tact 9. Remove the slip retainer screws on the OD of the slip bowl. These screws hold

• bore and threads are clean and the slips in the retracted position. The slips will NOT set unless these screws

in good condition are removed before the Hanger is placed in the Head.

• slips are intact, clean, undam- 10. Grease the Casing Hanger body.

aged

RP-001473 C-15-EX Mudline and Surface Wellhead

Draft 30" x 20" x 13-3/8" x 9-5/8" 5M Casing Program