Professional Documents

Culture Documents

SCBA Safety Checks

Uploaded by

Akhil Raj BOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCBA Safety Checks

Uploaded by

Akhil Raj BCopyright:

Available Formats

D/109 SCBA CHECKS BEFORE USE

M.V AM GHENT 23-Jul-2019 Rev 0 Page 1 of 3

Action: Post

Note

Post this near each SCBA station.

Follow the below instructions each time prior donning the apparatus.

Carry out this test with another officer in assistance.

1. Equipment Inspection

Inspect the condition of following:

Harness straps / buckles / fittings.

Tubing for any cracks / cuts / damage.

Inhalation / exhalation valves,

Facemask / visor is clean, dry and clear.

Connect the facemask to cylinder airline.

Open cylinder valve and listen for ‘audible leaks’ (For Positive Pressure sets,

switch-off the positive pressure switch when checking).

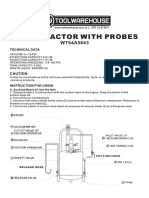

2. High Pressure Test

To check actual cylinder pressure and identify if any leakage:

Open the cylinder valve, and check that the bottle pressure is full.

Close the valve and observe the pressure gauge (Pressure must not drop by

more than 10 bars (or atm) in 1 minute).

3. Low Pressure Test

Check correct operation of the low-pressure audible warning whistle:

Gently depress the inhalation valve to drain the air slowly from the line whilst

observing the pressure gauge.

The audible warning whistle must sound when the gauge needle moves into

the ‘Red Sector’ . The ‘Red Sector’ is marked from 50 to 0 bar.

Re-open the cylinder valve. Whistle sound may also be heard momentarily as

gauge needle rises past the ‘Red Sector’.

4. Face Mask Seal Test

Check effective air-tightness of the seal between facemask and wearer’s face:

Don the facemask, tighten all straps uniformly and breathe normally.

Close the cylinder valve and continue breathing.

The whistle must sound as the air exhausts out.

When all the air is exhausted, the facemask must visibly collapse / be pulled

onto the wearer’s face when breathing in.

D/109 SCBA CHECKS BEFORE USE

M.V AM GHENT 23-Jul-2019 Rev 0 Page 2 of 3

5. Prior to Entering

If all the above tests are satisfactory, don the equipment, re-open cylinder

valve and be ready to proceed.

Wearer may not hear the audio warning whistle, hence at all times, monitor the

pressure gauge.

6. Working Duration

Working duration depends on the wearer and the amount of effort expended by the wearer.

As a rough rule, a trained wearer in fit condition and working reasonably hard will

consume about 40 Ltrs / minute.

An inexperienced wearer under similar conditions may well consume double this amount.

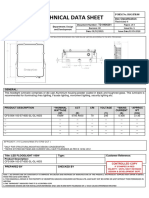

E.g.: A cylinder of 6 Ltrs, charged to 200 bars will hold 6 x 200 = 1200 Ltrs of air.

Cylinder Capacity (Ltr) 6

Working Pressure (Bar) 200

Quantity of Free Air in Cylinder (Ltr) 6 x 200= 1200

Average Consumption (Ltr / Minute) 40

Total Duration 1200 / 40 = 30 minutes

Safety Reserve* 10 minutes

Working Duration Final 30-10 = 20 minutes

* When hearing the low pressure whistle alarm, wearer must immediately evacuate the

space.

Volume of air contained in the cylinders shall be at least 1,200 Ltrs, or shall be capable of

functioning for at least 30 minutes.

All air cylinders for breathing apparatus shall be interchangeable.

For full details, refer to the maker’s instruction manual.

Each crewmember shall be able to wear the SCBA without assistance.

D/109 SCBA CHECKS BEFORE USE

M.V AM GHENT 23-Jul-2019 Rev 0 Page 3 of 3

You might also like

- Mindray Wato EX-65 Anaesthesia Machine - Service Manual-2Document50 pagesMindray Wato EX-65 Anaesthesia Machine - Service Manual-2Rene GonzalesNo ratings yet

- Cold Startup ProcedureDocument8 pagesCold Startup ProcedureRahul KurmiNo ratings yet

- User Manual: Model Number: FI-5N FI-5NK FI-5NV FI-5N-ST FI-5NK-ST FI-5NV-STDocument6 pagesUser Manual: Model Number: FI-5N FI-5NK FI-5NV FI-5N-ST FI-5NK-ST FI-5NV-STFelipe JaimesNo ratings yet

- ABSC 2452 Blast MachineDocument8 pagesABSC 2452 Blast MachineMehman NasibovNo ratings yet

- Eebd THH15 ManualDocument9 pagesEebd THH15 Manualaswin ajayNo ratings yet

- SC100V ManualDocument22 pagesSC100V ManualPeter OberauerNo ratings yet

- SopDocument8 pagesSopSean PassinoNo ratings yet

- Air CompressorDocument12 pagesAir CompressorVenkat PavanNo ratings yet

- Cyclone CompressorDocument4 pagesCyclone CompressorElton HodgesNo ratings yet

- Professional Anesthesia Handbook - Sharn PDFDocument78 pagesProfessional Anesthesia Handbook - Sharn PDFvicmanNo ratings yet

- LP301A LP600 4000 InstDocument1 pageLP301A LP600 4000 InstSERVICIOS ESPECIALIZADOS EN LUBRICACIÓNNo ratings yet

- Training Report On Self Contained Breathing ApparatusDocument4 pagesTraining Report On Self Contained Breathing ApparatusHiren MahetaNo ratings yet

- 5.1.2 Two-Stage High Pressure Industrial Air CompresorsDocument124 pages5.1.2 Two-Stage High Pressure Industrial Air CompresorsPablo Andres Espin MartinNo ratings yet

- SCBA GuideDocument20 pagesSCBA Guidemohamed_sahnoun_enisNo ratings yet

- The Proper Way To Ohm A Single Phase Compressor PDFDocument3 pagesThe Proper Way To Ohm A Single Phase Compressor PDFslipargolokNo ratings yet

- Compressed Air AwarenessDocument7 pagesCompressed Air Awarenessasimnaqvi2003No ratings yet

- Manual Compresor Hydrovan 501Document64 pagesManual Compresor Hydrovan 501MARIA GONZALEZNo ratings yet

- Aspirador Quirurgico - Tomas PDFDocument6 pagesAspirador Quirurgico - Tomas PDFMario O.No ratings yet

- Drain ValveDocument1 pageDrain ValveJose MontielNo ratings yet

- Emergency EquipmentDocument8 pagesEmergency Equipmentafsar019No ratings yet

- Roscoe NEB RITE4 ManualDocument33 pagesRoscoe NEB RITE4 ManualCristina Tovar OspinaNo ratings yet

- D500 Air Compressor Instruction ManualDocument2 pagesD500 Air Compressor Instruction ManualEddie RedfearnNo ratings yet

- AC PROV OPERATION & MAINTENANCE-rev2.compressedDocument2 pagesAC PROV OPERATION & MAINTENANCE-rev2.compressedMuhammed RiazNo ratings yet

- Manual Toku TPB 90Document9 pagesManual Toku TPB 90Toño Rodriguez LopezNo ratings yet

- Model: Air Concrete BreakerDocument12 pagesModel: Air Concrete BreakerING MANTENIMIENTO CONINTEL S.ANo ratings yet

- 100C Air Compressor Kit Safety and Installation GuideDocument8 pages100C Air Compressor Kit Safety and Installation GuideRubenNo ratings yet

- WFK3000 Series Precautions(0.2MB)Document4 pagesWFK3000 Series Precautions(0.2MB)Ryuzaki GamingNo ratings yet

- 637 W. Main Street, Worthington, PA 16262-0129 Phone: 724-297-3416 Fax: 724-297-5189 Url: E-MailDocument15 pages637 W. Main Street, Worthington, PA 16262-0129 Phone: 724-297-3416 Fax: 724-297-5189 Url: E-MailRubenn54No ratings yet

- Steam Trap TesterDocument4 pagesSteam Trap TesterISMAEL RAMIREZNo ratings yet

- TPB90 ManualDocument8 pagesTPB90 ManualAmaury LeonNo ratings yet

- Unior 1561 Pistol PneumaticDocument4 pagesUnior 1561 Pistol PneumaticVladimir ArsicNo ratings yet

- M-137-2_inst. Manual for Deck Air Compressor_part 4 of 4Document25 pagesM-137-2_inst. Manual for Deck Air Compressor_part 4 of 4Laston Aron DsouzaNo ratings yet

- Owner's Manual for 3-Gallon 1.5 HP Air CompressorDocument11 pagesOwner's Manual for 3-Gallon 1.5 HP Air CompressorSIVARAMANJAGANATHANNo ratings yet

- Dräger Aerotest Alpha Instruction ManualDocument14 pagesDräger Aerotest Alpha Instruction ManualChacho GuzmanNo ratings yet

- Tourniquet User Manual 2012 PDFDocument10 pagesTourniquet User Manual 2012 PDFphuongo2No ratings yet

- FH3 EL FHT ManualDocument2 pagesFH3 EL FHT ManualRubi WantoNo ratings yet

- Pressure TestingDocument27 pagesPressure Testingsaie_1No ratings yet

- Air Compressor: 3-Gallon 1.5 HP (Max Developed) 1 HP Running Oil LubricatedDocument20 pagesAir Compressor: 3-Gallon 1.5 HP (Max Developed) 1 HP Running Oil LubricatedJL AlexanderNo ratings yet

- Installation & Maintenance Instructions: Series F210Document3 pagesInstallation & Maintenance Instructions: Series F210Mar SolNo ratings yet

- Udor Kappa 30Document6 pagesUdor Kappa 30DanutNo ratings yet

- AP-20 - Manual COLOR INGLESDocument16 pagesAP-20 - Manual COLOR INGLESCOVESANo ratings yet

- Huayan TH15B Instruction Manual1Document9 pagesHuayan TH15B Instruction Manual1truryNo ratings yet

- Operations-And Maintenance Instructions For FansDocument16 pagesOperations-And Maintenance Instructions For Fanskeyur1109No ratings yet

- SCBA RefillingDocument8 pagesSCBA RefillingTammanurRaviNo ratings yet

- Compresora Ingersoll Rand 2475n75p Owners ManualDocument34 pagesCompresora Ingersoll Rand 2475n75p Owners ManualDaysi TitoNo ratings yet

- Compresora Ingersoll Rand 2475n75p Owners ManualDocument34 pagesCompresora Ingersoll Rand 2475n75p Owners ManualDaysi TitoNo ratings yet

- Manual Operacion Aas 100 SeriesDocument104 pagesManual Operacion Aas 100 Seriesdéborah_rosalesNo ratings yet

- 03.SOP For Air CompressorDocument4 pages03.SOP For Air CompressorThangella Vijayaramaraju100% (2)

- Longfian Scitech Jay 20 4.0 Oxygen Concentrator - User and Service ManualDocument24 pagesLongfian Scitech Jay 20 4.0 Oxygen Concentrator - User and Service ManualThomas BohlmannNo ratings yet

- 360-0027-01rD AP20S ManualDocument16 pages360-0027-01rD AP20S ManualetchegarayfNo ratings yet

- Full Bore Emerg Unloading Valve O&m - 02-24-2011Document9 pagesFull Bore Emerg Unloading Valve O&m - 02-24-2011Enrique AssmannNo ratings yet

- Operating Instructions: Model E3Document10 pagesOperating Instructions: Model E3Mauricio CGNo ratings yet

- Meritor Wabco Ss1200 Ss1800 Air Dryers Tp97101Document2 pagesMeritor Wabco Ss1200 Ss1800 Air Dryers Tp97101james100% (2)

- Kongskilde Suc 500 Blower ManualDocument44 pagesKongskilde Suc 500 Blower Manualarun kumarNo ratings yet

- XH18200(2.0ata)xiaoDocument7 pagesXH18200(2.0ata)xiaomlawler626No ratings yet

- OIL EXTRACTOR TECHNICAL DATA AND INSTRUCTIONSDocument2 pagesOIL EXTRACTOR TECHNICAL DATA AND INSTRUCTIONSApoelistas ApoelistasNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- D-114 VDR Data Recovery InstructionsDocument1 pageD-114 VDR Data Recovery InstructionsAkhil Raj BNo ratings yet

- D-111 Bridge Control Manoeuvering Console InstructionsDocument2 pagesD-111 Bridge Control Manoeuvering Console InstructionsAkhil Raj BNo ratings yet

- D-115 Paper Chart and Publication Management System Back-Up InstructionsDocument2 pagesD-115 Paper Chart and Publication Management System Back-Up InstructionsAkhil Raj BNo ratings yet

- International Regulations For The Prevention of Collisions at SeaDocument89 pagesInternational Regulations For The Prevention of Collisions at SeaAkhil Raj BNo ratings yet

- D-116 Procedure For Updating Uploading Charts On Ecdis SystemDocument3 pagesD-116 Procedure For Updating Uploading Charts On Ecdis SystemAkhil Raj BNo ratings yet

- Bridge Watchkeeping GuideDocument133 pagesBridge Watchkeeping GuideAkhil Raj B100% (5)

- Ecdis NotesDocument7 pagesEcdis NotesAkhil Raj B100% (3)

- Kushal M BrochureDocument2 pagesKushal M BrochureKangkan Kishore DasNo ratings yet

- Internal Freewheels FZ : With Ball Bearing PropertiesDocument6 pagesInternal Freewheels FZ : With Ball Bearing Propertiesmohammed kareemNo ratings yet

- Crystal Radio Project (For ISC)Document5 pagesCrystal Radio Project (For ISC)Nabhoneel Majumdar100% (1)

- Inverter High Wall Unit: 42QHA/38QHADocument2 pagesInverter High Wall Unit: 42QHA/38QHADennis Clyde AcantiladoNo ratings yet

- Vision Dvsdta SeriesDocument93 pagesVision Dvsdta SeriesEverton FernandesNo ratings yet

- 12 KV Outdoor Type Ring Main UnitDocument10 pages12 KV Outdoor Type Ring Main Unitzeeshan SiddiquiNo ratings yet

- Premier 816 Installation Manual - Iss 06Document83 pagesPremier 816 Installation Manual - Iss 06Esa Valtteri Vehviläinen50% (2)

- Manual Fisher 655Document16 pagesManual Fisher 655Francisco EspinozaNo ratings yet

- CFS 504 100 57 60D SL GL NSG - CLF500173 A2Document3 pagesCFS 504 100 57 60D SL GL NSG - CLF500173 A2ganesangNo ratings yet

- Yokes Y6 Y7 Y8Document4 pagesYokes Y6 Y7 Y8KuKu FunNo ratings yet

- 12 ControlDocument18 pages12 ControlTuệNguyễnNo ratings yet

- Ferroli Manual - Instalare - RLA IP - 200Document68 pagesFerroli Manual - Instalare - RLA IP - 200gereseNo ratings yet

- BOA Haz Area Equipment InspectionDocument41 pagesBOA Haz Area Equipment InspectionAmiruddin Abdul RahimNo ratings yet

- Expt No: 1 Mode Characteristics of Reflex Klystron 1.1 ObjectiveDocument6 pagesExpt No: 1 Mode Characteristics of Reflex Klystron 1.1 ObjectivePriya DarshuNo ratings yet

- High Performance Ride-On, Manageable Like A Walk-Behind: Scrubber-Dryer LineDocument4 pagesHigh Performance Ride-On, Manageable Like A Walk-Behind: Scrubber-Dryer Linemamun mamunNo ratings yet

- Hyd System - Part 1 Single Lift Pump ( - A - Batt. Comp.) (25,1.0,35,1.6, RR) (02.0-14.0-011)Document6 pagesHyd System - Part 1 Single Lift Pump ( - A - Batt. Comp.) (25,1.0,35,1.6, RR) (02.0-14.0-011)rorroscNo ratings yet

- Instruction Manual KPC - TMDocument22 pagesInstruction Manual KPC - TMNguyen AnNo ratings yet

- 100W Audio Amplifier: General DescriptionDocument6 pages100W Audio Amplifier: General DescriptionJhody FajriNo ratings yet

- Mpu 6050Document54 pagesMpu 6050Vladimir DjuricNo ratings yet

- Configure Hall Effect Thumbwheel OptionsDocument4 pagesConfigure Hall Effect Thumbwheel OptionsJuan ContrerasNo ratings yet

- Brass Safety Valves FK 46.13 (10) GB: Primary CharacteristicsDocument4 pagesBrass Safety Valves FK 46.13 (10) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- PMC Hydraulics - Hoses - Fittings - Catalogue - 2019 - 01 - EN - v2Document159 pagesPMC Hydraulics - Hoses - Fittings - Catalogue - 2019 - 01 - EN - v2Bouslimi SouhaibNo ratings yet

- Electricity QuestionsDocument24 pagesElectricity QuestionsNorKamilahMakhtarNo ratings yet

- Special CablesDocument115 pagesSpecial Cablesjav071No ratings yet

- Electric Motor and GeneratorDocument6 pagesElectric Motor and GeneratorJesell JeanNo ratings yet

- An Analysis DC-Machine Commutation: JapanDocument9 pagesAn Analysis DC-Machine Commutation: JapanDanang AjiNo ratings yet

- PotentiometerDocument12 pagesPotentiometerkarthikeyan19470% (1)

- Amx 13SM1Document2 pagesAmx 13SM1LatwPIATNo ratings yet

- Electric Motor Cooling Systems GuideDocument6 pagesElectric Motor Cooling Systems GuideHữu Thịnh ĐỗNo ratings yet

- CP CO EsDocument45 pagesCP CO EsFranklin Solano0% (1)