Professional Documents

Culture Documents

Ariel JGM JGN JGP JGQ Manual

Uploaded by

KilienOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ariel JGM JGN JGP JGQ Manual

Uploaded by

KilienCopyright:

Available Formats

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

Table of Contents

General Safety for Reciprocating Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Lifting the Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Throw and Data Plate Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Other Ariel Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ariel Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ariel Technical and Service Schools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ariel Contact Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ariel Optional Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ariel Separately Purchased Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ariel Separately Purchased Tool Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Recommended Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Instrumentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Digital No-Flow Timer (DNFT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DNFT Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Programmable DNFTs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

DNFT Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting DNFT’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Proximity Switch A-18255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Proximity Switch Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting Proximity Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Initial Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Maintenance Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Monthly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Six-Month (4,000-Hour) Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

One-Year (8,000-Hour) Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Two-Year (16,000-Hour) Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Three-Year (24,000-Hour) Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Four-Year (32,000-Hour) Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Six-Year (48,000-Hour) Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Frame Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Oil Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Oil Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ARIEL CORPORATION | www.arielcorp.com 1

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

Oil Sampling Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Oil System Cleanliness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Frame Oil System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Oil Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Oil Pump & Regulating Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Oil Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Oil Temperature Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Oil Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Oil Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Compressor Pre-lube System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Compressor Pre-lube for CNG Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Auxiliary Frame Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Flushing to Change to a PAG Lubricant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Recommended Flushing Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Flushing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Flushing the Force Feed Lubrication System - Common Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Flushing the Force Feed Lubrication System - Independent Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Cylinder and Packing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Force Feed Lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pressure Relief. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Pump Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Priming the Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Pump Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pump Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Auto-Relief Valve (ARV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

ARV Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Force Feed Lube Blow-Out Fittings, Rupture Disks, and Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Distribution Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Distribution Block Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Divider Valve Bypass Pressure Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Balance Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Selecting Balance Valves and Pressure Gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Installing Balance Valves and Pressure Gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Adjustment of Balance Valves Fed by a Divider Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Adjustment of Balance Valves Fed by Primary/Secondary Divider Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Subsequent Compressor Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Force Feed System Design, Operating Parameters, and Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Common Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Independent Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Force Feed Lubrication Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Under/Over Lube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Cylinder Lubrication Paper Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Coolant System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Part Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Relieving Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ARIEL CORPORATION | www.arielcorp.com 2

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Depressurization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Positioning a Throw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Variable Volume Clearance Pocket (VVCP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

VVCP Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

VVCP Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

VVCP Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

VVCP Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

VVCP Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Compressor Valves - Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Required Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Valve Cap Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Valve Caps on Cast Iron Cylinders or High-Pressure Caps without Spring Energized Seals . . . . . . . . . . . . . . . . 81

Removal of Valve Cap with Spring Energized Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Valve Cap with Spring Energized Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Valve Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Valve Cap Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Installation of Valve Caps on Cast Iron Cylinders or High-Pressure Caps without Spring Energized Seals . . . 87

Installation of Valve Cap with Spring Energized Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Gas Containment Fastener Torque Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Piston and Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Piston Rod Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Piston and Rod Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Piston and Rod Manual Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Piston and Rod Manual Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Piston and Rod Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Piston Rod Runout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Piston Rings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Seal-Joint Piston Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Straight-Cut Chamfered Piston Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

High-Pressure Face-Cut Piston Rings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Three-Piece Piston Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Five-Piece Piston Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Wear Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Piston Rod Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Piston Rod Packing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Piston Rod Packing Reassembly and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Types of Piston Rod Packing Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

“P” Pressure Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

“PB1” Pressure Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

“UP” Pressure Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

“P1U” Pressure Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

“BTR” Single-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

“BD” Double-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Double "WAT" Double-Acting Seal Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

“AL” Double-Acting Seal Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

“BT” Single-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

“BTS” Single-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

“BTUU” Single-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

ARIEL CORPORATION | www.arielcorp.com 3

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

“CU” Single-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

“CUU” Single-Acting Seal Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

“RS3” Single-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

“DS” Double-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

“STU” Single-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

“CR” Single-Acting Seal Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

“RTV” Oil Wiper Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

“3RWS” Oil Wiper Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Crossheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Crosshead Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Crosshead Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Connecting Rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Connecting Rod Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Connecting Rod Bearing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Crank Pin Assessment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Connecting Rod Bearing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Connecting Rod Bushing Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Connecting Rod Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Connecting Rod Bearing Vertical Jack Clearance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Connecting Rod Thrust (Side) Clearance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Crankshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Main Bearing Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Main Bearing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Crankshaft Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Crankshaft Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Main Bearing Vertical Jack Clearance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Crankshaft Thrust (End) Clearance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Chain Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Chain and Sprocket Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Chain Idler Sprocket Replacement (Eccentric Adjustment Caps) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Lube Oil Pump Sprocket Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Force Feed Lubricator Chain Sprocket Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Crankshaft Chain Sprocket Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Chain Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Warranty Notification - Installation List Data and Start Up Check Lists for Reciprocating

Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Compressor Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Piston Rod Runout Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Ariel Fasteners and Torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Recommendations for Torque Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

JGM:P:N:Q Fastener Torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Measuring Head End Clearance for Forged Steel Tandem Cylinders with Concentric Valves . . . 161

ARIEL CORPORATION | www.arielcorp.com 4

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

Frame Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Opposed Throw - Reciprocating Weight Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Compressor Clearance, Oil, & Temperature Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Balance Valve Maintenance Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Hold-down Bolting to Resist Shaking Forces and Couples in Reciprocating Compressors. . . . . . . . . 172

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Soft Foot and Top Plane Flatness Checks for Proper Main Bearing Bore Alignment in Reciprocating

Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Soft Foot Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Top Plane Flatness Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Attachment of Wiring, Tubing, or Pipe Clamps to Ariel Compressor Cylinders . . . . . . . . . . . . . . . . . . . 177

Alternate Attachment Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

ARIEL CORPORATION | www.arielcorp.com 5

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

General Safety for Reciprocating Compressors

WARNING CAUTION

To reduce risk of injury or death, only trained personnel Noise generated by reciprocating machinery may

who have read and thoroughly understand the damage hearing. See Packager information for specific

appropriate Ariel Technical Manual and Packager recommendations. Wear hearing protection during

information should attempt any maintenance. compressor operation.

Prior to performing any maintenance activities:

• Always wear appropriate personal protection equip-

ment and follow your company safety and opera- CAUTION

tional procedures. Where applicable, compressor installation must

• Never tighten or loosen any fastener while the unit is conform to Zone 1 requirements. A Zone 1 environment

operating or pressurized. requires installation of proper intrinsically safe or

• Verify neither driver nor compressor can turn during equivalent protection to fulfill electrical requirements.

maintenance.

• Follow packager instructions to completely isolate

and vent the system; call the packager for assis- CAUTION

tance.

Hot gas temperatures (especially the cylinder

• Verify each compressor cylinder is relieved to atmo-

discharge), 190°F (88°C) oil, and high friction areas. Wear

spheric pressure. To relieve residual cylinder bore

proper protection. Shut down unit and allow to cool

pressure after blowdown, open the “Kiene” valves

before maintaining these areas.

on the indicator ports, if so equipped.

WARNING: RELEASED GAS MAY BE POISONOUS

AND/OR FLAMMABLE. CAUTION

Before resuming operation, purge the entire system with

the gas being compressed to avoid a potentially Suction or discharge valves installed in improper

explosive gas/air mixture in the system. A gas/air locations may result in severe personal injury and

mixture under pressure can explode and cause severe property damage.

injury or death.

CAUTION

If applicable, do not remove the pin from the crosshead

guide to compressor cylinder mounting face. It is there

When the symbol to the left appears to prevent installation of misapplied cylinders and avoid

personal injury.

on a compressor or control panel, consult the

appropriate Ariel Maintenance and Repair

Manual for specific information before Lifting the Compressor

proceeding. The Maintenance and Repair

Manual applies to current design and build; it

may not apply to equipment built prior to the CAUTION

date on the front cover and is subject to

When lifting a compressor with lifting lugs, use only

change without notice. For questions of Ariel-supplied lugs. Verify lugs are fastened with correct

compressor safety, operation, maintenance, grade cap screws, and properly tightened. Lifting cable

or repair, contact your packager or Ariel. spreaders are required perpendicular to the crankshaft

axis and the lift point. Verify crane capacity is adequate.

ARIEL CORPORATION | www.arielcorp.com 6

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – General Safety for Reciprocating Compressors 12/03/2022

• Determine compressor weight before lifting. more suitable for low temperatures per ASME

See the Ariel Performance Program for frame B18.15 and ASTM F541.

and cylinder weights. Also account for any • Use spreader bars or lifting beams for a

extra weight such as external and internal vertical pull on eyebolts or lifting lugs. Chains

flywheels, etc. or straps attached to eyebolts or lifting lugs

• Each compressor ships with an attached should be within 5 degrees of vertical. For

Compressor Lifting Information packet. Refer eyebolt load capacity rating or if pulling on an

to the Compressor Lifting Information docu- eyebolt in a direction other than along the

ment for each specific compressor frame threaded axis, consult ASME B18.15.

serial number. Ariel can provide the weight, • Verify lifting tackle, spreader bars, and crane

center of gravity, and lifting hook locations capacity are adequate, properly attached

for the compressor via the Ariel Performance and properly rigged for the load. Keep

software, or by contacting the Ariel Response compressor level when lifting and setting.

Center. Heavier cylinders and/or blank throws can

• If you are not experienced in lifting large significantly affect center of gravity.

compressors, Ariel recommends using quali-

fied professional riggers/movers.

• Ariel-supplied eyebolts (attached to cross-

head guides), brackets (attached to cylinder

nozzles) and lifting lugs (attached to frame

walls) are designed to lift the Ariel

compressor only, with no other equipment

such as bottles, skid, etc. Do not attempt to

lift the compressor when it is attached to the

skid, driver, or piping. Do not use these lifting

attachments on other equipment.

• On frames with lifting lugs, install lugs with

the proper Grade 8 cap screws and tighten to

the torque listed in the appropriate Ariel

Maintenance and Repair Manual or the Ariel

Torque App. If lifting lugs are already

installed, recheck bolt torque prior to lifting.

• For compressors with no lifting lugs, lift by

the eyebolts installed by Ariel at the cross-

head guides. Ariel-installed eyebolts are

locked in position with Loctite® thread locker

to help prevent turning.

• Verify eyebolts, brackets and lifting lugs are

free of any visual defects that could affect

serviceability. Remove and destroy all defec-

tive eyebolts, brackets, and lifting lugs. Use

only Ariel-supplied brackets and lifting lugs.

• Standard lifting lug and eyebolt materials can

fail when subject to shock loads at low

ambient temperatures. Follow ASME B18.15

guidelines. If necessary, eyebolts may be

replaced with forged eyebolts of materials

ARIEL CORPORATION | www.arielcorp.com 7

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

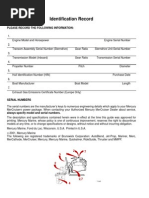

Throw and Data Plate Locations

When contacting Ariel with compressor machine. This data helps Ariel representatives

questions, know throw locations and answer quickly and accurately. Contact Ariel for

information on data plates fastened to the replacement if any data plates are missing.

Figure: Integral Guide Compressor Throw and Data Plate Locations - Typical

1 VVCP Dimension Plate 5 Mechanical Inspector Plate and 9 Force Feed Lubricator Data Plate

2 Rotation Direction Plate Frame Serial Number Stamp 10 Cylinder Serial Number, MAWP,

3 Compressor Data Plate 6 Cylinder Data Plate (see #10) and Hydrotest Stamp

4 VVCP Data Plate 7 Force Feed Lubricator Pump Data 11 VVCP Serial Number, MAWP, and

Plate Hydrotest Stamp

8 Oil Filter Change Instruction

Plate

ARIEL CORPORATION | www.arielcorp.com 8

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

Other Ariel Resources

Ariel Website • Packager Standards provide detailed

requirements and recommendations on the

Visit www.arielcorp.com to view and print the installation of an Ariel compressor.

latest documentation, such as: • Application Manual provides detailed infor-

• Customer Technical Bulletins (CTB’s) mation on the use of Ariel compressors in

provide important information on changes, different applications.

corrections, or additions to Ariel products or

services. Read these bulletins before oper- Ariel Technical and Service Schools

ating or servicing equipment.

• Engineering References (ER’s) provide stan- Ariel schedules several in-plant schools each

dard procedures and other useful informa- year, which include classroom and hands-on

tion for operation, maintenance, or repair of training. Ariel also sends representatives to

Ariel compressors or components. Read and provide customized training on location. Contact

follow these procedures for long and trouble- Ariel for details.

free service from your Ariel compressor.

• Maintenance and Repair Manuals provide

detailed maintenance and repair information Ariel Contact Information

on specific Ariel compressor models.

Contact Telephone Fax E-Mail

Ariel Response Center 888-397-7766 (toll-free USA & 740-397-1060 arc@arielcorp.com

Canada) or 740-397-3602

Ariel Parts Sales (International) 740-393-5054 parts@arielcorp.com

Order Entry 740-397-3856 -

Ariel World HQ 740-397-0311 740-397-3856 info@arielcorp.com

Technical Services fieldservice@arielcorp.

com

Ariel Response Center Technicians or Emergency Service. Calls are answered by

Switchboard Operators answer telephones voice mail.

during Ariel business hours, Eastern Time - USA 2. Leave a message: caller name and telephone

or after hours by voice mail. Contact an number, serial number of equipment in ques-

authorized distributor to purchase Ariel parts. tion (frame, cylinder, unloader), and a brief

Always provide Ariel equipment serial number(s) description of the emergency.

to order parts. The after-hours Telephone

3. Your voice mail routes to an on-call represen-

Emergency System works as follows:

tative who responds as soon as possible.

1. Follow automated instructions to Technical

Services Emergency Assistance or Parts

ARIEL CORPORATION | www.arielcorp.com 9

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

Tools

A variety of tools are required for safe and specifically designed for use on Ariel units. Clean

effective maintenance of Ariel compressors. all tools before use and verify full tool

Standard hand tools are readily purchased from engagement with the part being removed or

hardware stores or industrial supply companies. installed. If the Tool Kit is missing or if a single

Ariel makes certain special tools available where tool is missing, worn, or broken, call your

needed. distributor. Do not use worn or broken tools, or

substitutes for Ariel furnished tools. See Parts

Ariel Optional Tools List for individual tool part numbers.

Ariel offers an optional tool kit with every

compressor. For JGM:P:N:Q compressors, it

contains the tools shown below, which are

Figure: Optional Furnished Tools for JGM:P:N:Q Compressors

1 Tool Box

2 Main Bearing Removal Tool

3 Crank End Clearance Setting Tool

(included only for 2-3/4M, 3M, 2-3/4P-CE,

and 3-1/4P-CE class cylinders)

4 Piston Rod Entering Sleeve

5 3/8" Allen Wrench (2 provided)

6 5/16" Allen Wrench (3 provided)

7 1/4" Allen Wrench (3 provided)

8 3/16" Allen Wrench (5 provided)

9 5/32" Allen Wrench (5 provided)

10 9/64" Allen Wrench

11 1/8" Allen Wrench (10 provided)

12 3/32" Allen Wrench (10 provided)

13 Ariel Bore & Thread Gauge

14 Crank End Clearance Setting Tool

(included only for 2-1/4P-CE class cylin-

ders

15 3/4" Peg Wrench

16 2-Inch Open End Wrench

17 5/16" x 1/2" UNF Valve Tool

18 1/4" x 3/8" UNF Valve Tool

19 Piston Turning Tool for 9/16" socket

(included only for small tandem cylin-

ders)

20 Piston Nut Spanner

21 Ariel ER-63 Fastener Torque Chart (not

shown)

ARIEL CORPORATION | www.arielcorp.com 10

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Tools 12/03/2022

Ariel Separately Purchased Tools

Figure: Ariel Separately Purchased Tools for JGM:P:N:Q Compressors

1 Piston Rod Entering Sleeve (applies only

to cylinders with part number less than D-

4500 and bore size of 2-3/4", 3", or 3-3/8")

2 Force Feed Lubricator Bearing Housing

Spanner Wrench

3 Piston and Rod Clamping Fixture

4 Force Feed Lube Hand Purge Pump

Ariel Separately Purchased Tool Kits • 14-piece, 12-point socket set, 7/16” to

1. Ariel SAE Hand Measurement Tool Kit 1-1/4” with clip rail

• Extensions, 1-1/2”, 5”, and 10"

a. 0.0005 in. needle type dial indicator

• Drive adapters: 1/2” to 3/8" and 1/2”

b. 0.001 in. 1-inch travel dial indicator

to 3/4"

c. Magnet base for dial indicator

• 1-1/4” open end crow’s foot adapter

d. 3/8” drive calibrated torque wrench, 40 to

• 10-1/4” ratchet

200 in x lbs

• Speed handle

e. 3/8” drive calibrated torque wrench, 10 to

100 ft x lbs • Ball type universal joint

f. 1/2” drive calibrated torque wrench, 50 to • 18” breaker bar

250 ft x lbs • 1/2” and 5/8” hex key sockets

g. 3/4” drive calibrated torque wrench, 120 e. 3/4" square drive wrench set, including:

to 600 ft x lbs • 18-piece, 12-point socket set, 3/4” to

2”

2. Ariel SAE Hand Tool Kit

• Extensions, 3-1/2”, 8”, and 16”

a. 15-piece combination open/box end • Drive adapters: 3/4” to 1/2", 3/4” to 1",

wrench set, 5/16” to 1-1/4” and 1” to 3/4"

b. 8-piece slot and Phillips screwdriver set • 24” ratchet

c. 3/8" square drive wrench set, including: • 22” breaker bar

• 12-piece, 12-point socket set, 5/16” to f. Adjustable wrenches: 12" and 18"

1”

g. Dead blow semi-soft faced hammers: 3 lb.

• 7” ratchet and 6 lb

• Speed handle h. 3/4” x 36” pry bar

• Extensions, 1-1/2”, 3”, 6”, and 12” i. 12” long feeler gauge set

• Ball type universal joint j. 12” machinist scale with 0.01 in. incre-

• 3/8” to 1/2" drive adapter ments

• 1/4” hex key socket k. 13-piece Allen wrench set, 0.050 in. - 3/8”

• 8-1/2” breaker bar

d. 1/2" square drive wrench set, including:

ARIEL CORPORATION | www.arielcorp.com 11

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Tools 12/03/2022

Recommended Tools

Ariel compressor maintenance and repair

normally requires only Ariel furnished tools and

separately purchased tools and tool kits.

However, Ariel also recommends purchasing the

additional tools below. Contact Ariel for

questions about tools for Ariel units.

1. 12-point box end torque adapter extension

wrench set

2. Tape measure

3. Flashlight

4. Small mirror on a flexible extension rod

5. Small magnet on a flexible extension rod

6. Electric and/or pneumatic drill

7. Twist drill set

8. Torque multiplier

ARIEL CORPORATION | www.arielcorp.com 12

JGM-JGN-JGP-JGQ Maintenance & Repair Manual 12/03/2022

Instrumentation

Several optional instruments can aid in the

operation of an Ariel compressor. Through the

CAUTION

data they provide, some instruments can help

decrease maintenance costs and downtime, and DO NOT drill holes in cylinders or other pressure

containing components for any purpose. Pressure

help diagnose lubrication and other types of containing components include cylinders, valve caps,

problems. The use of “alarm” instead of cylinder heads, unloaders, gas passage caps, and

“shutdown” for any minimum instrumentation flanges.See "Attachment of Wiring, Tubing, or Pipe

Clamps to Ariel Compressor Cylinders".

requirement may result in equipment damage.

NOTE: Ariel recommends the use of shipboard or CAUTION

armored cabling as opposed to wiring in conduit to Any arc welding on the skid and/or associated

minimize nuisance shutdowns due to wire chafing equipment and piping can permanently damage solid-

and shorts. Cable in cable trays also facilitates main- state electronic equipment. Welding can cause

tenance access. immediate failure or reduce electronic equipment life

and void the warranty. To protect electronic equipment

prior to any arc welding (including repair welding),

disconnect all electrical connections including ground,

and remove batteries, or completely remove the

electronic equipment from the compressor.

It is good practice to attach the welding ground clamp as

close as possible to the area where the welding will

occur and to use the lowest practical welder output

setting. Welding must not cause a current flow across

any compressor bearing surface, including but not

limited to crankshaft and crosshead bearing surfaces.

Table: Required Instrumentation Summary

INSTRUMENT SUPPLIER SETTING/REQUIREMENT

Frame Oil System (see "Frame Oil System Components")

Oil Pressure Packager

- Start Permissive with Pre-lube Pump 30 psig (2.1 barg) for 2 minutes

- Run Permissive 45 psig (3.1 barg) within 10 seconds of start

- Alarm 50 psig (3.4 barg)

- Shutdown 45 psig (3.1 barg)

Oil Filter Differential Ariel Change at 10 psi (0.7 bar) or 6 months of operation, whichever

occurs first.

Oil Temperature Packager

- Minimum, to start-up or to load See "Viscosity" for max. oil viscosity based on frame size.

- Minimum, operating 150°F (66°C)

- Maximum, shutdown 190°F (88°C)

ARIEL CORPORATION | www.arielcorp.com 13

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

INSTRUMENT SUPPLIER SETTING/REQUIREMENT

Crankcase Level Packager 1/2 to 2/3 sight glass level

- Low Level Shutdown 1/4 sight glass level

Packing Case Temp. Ariel Optional

- Alarm +20°F (11°C) above normal

- Shutdown +30°F (17°C) above normal

Packing Case Vent Packager Optional

- Vent Flow Alarm 2 - 4 scfm (per throw)

- Vent Flow Shutdown > 4 scfm (per throw)

Scrubber Liquid Level Packager

- High Liquid Level Control

- High Liquid Level Shutdown

Gas Conditions Packager

- Inlet Temperature Indicator, each cylinder

- Inlet Pressure Indicator, each stage

- Discharge Pressure Indicator, each stage

- Discharge Temperature Indicator, each cylinder, each nozzle on dual nozzle cylinders

- High Discharge Temperature Shutdown, each 10% above normala (Not to exceed the maximum temperatures

cylinder below)

- Lubricated Cylinders 350°F (177°C)

- Non-Lube/PRC Cylinders 325°F (163°C)

- Hydrogen Rich > 50% < 0.41 Specific Gravity 300°F (149°C)

- Air Not to exceed autoignition temperature of cylinder lubricant at

discharge pressure

- Relief Valve Setting above normal operating • Up to 150: 15 psig (1.0 barg)

pressure (not to exceed MAWP) • to 2500: 10%

• to 3500: 8%

• to 5000: 6%

• Over 5000: As agreed

• See "Relief Valves" in the Packager Standards Manual.

Cyl. Rod Load Protection Packager

High Vibration Shutdown Packager As close to a normal level as practical. See "Vibration

Protection" in the Packager Standards Manual.

Over Speed Packager 10% over rated speed for shutdown

a Example: Normal Discharge Temp. = 270°F; Shutdown Setting = 270 x 1.1 = 297°F.

ARIEL CORPORATION | www.arielcorp.com 14

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

Notes 7. Install all safety shutdowns, controls, instru-

1. Install the compressor frame low lube oil mentation, ignition systems, electrical

pressure shutdown set to stop the unit if oil devices, and high temperature piping (gas

pressure downstream of the filter falls below discharge and engine exhaust) in accordance

45 psig (3.1 barg). Compressor operation for with good engineering practice and appli-

only a few seconds without oil pressure cable codes for the area classification at the

causes major damage. Normal oil pressure is end user location. Ensure compatibility of all

about 60 psig (4.1 barg) at full rated speed systems for area classification.

and normal operating temperature. The low 8. If packing vent temperature is monitored,

oil pressure shutdown must activate after oil confirm alarm and shutdown set points

pressure exceeds 45 psig (3.1 barg) at start- through vent flow rates.

up. Ariel provides a 1/4 inch tubing fitting to

connect the low lube oil pressure shutdown

and ties a tag to this connection before each

Digital No-Flow Timer (DNFT)

compressor ships. Do not operate the

compressor for prolonged periods at less

CAUTION

than 50 psig (3.4 barg) oil pressure.

2. Automated pre-lube systems require a start Any arc welding on the skid and/or associated

equipment and piping can permanently damage solid-

permissive to sense minimum required pres- state electronic equipment. Welding can cause

sure/time at oil gallery inlet.See “Compressor immediate failure or reduce electronic equipment life

Pre-lube System”. Unit must shut down if the and void the warranty. To protect electronic equipment

prior to any arc welding (including repair welding),

system fails to achieve 45 psig (3.1 barg) oil disconnect all electrical connections including ground,

pressure within 10 seconds after crankshaft and remove batteries, or completely remove the

starts to turn. electronic equipment from the compressor.

It is good practice to attach the welding ground clamp as

3. Mount overhead lube oil supply tanks high close as possible to the area where the welding will

occur and to use the lowest practical welder output

enough to provide oil flow to the level control setting. Welding must not cause a current flow across

at all ambient temperatures. any compressor bearing surface, including but not

limited to crankshaft and crosshead bearing surfaces.

4. On multi-nozzle cylinders, Ariel strongly

recommends a temperature device in both A DNFT is a totally enclosed electronic device,

discharge nozzles. combining the latest technology in

5. Install the high lube oil inlet temperature microprocessor and transistor components to

shutdown at the filter inlet connection. detect slow-flow and no-flow of divider block

lubrication systems. The DNFT uses an oscillating

6. At a minimum, install one vibration shut- crystal to accurately monitor the lubrication

down.Mount vibration device near the top of system cycle time to enable precision timed

the frame with the sensitive axis parallel to shutdown capability. The magnet assembly and

the piston rod axis. control housing mount directly to a divider valve.

Lubricant flow through a divider valve assembly

forces the piston to cycle back and forth causing

a lateral movement of the DNFT magnet linked to

ARIEL CORPORATION | www.arielcorp.com 15

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

the piston. The DNFT microprocessor monitors

piston movement and resets the timer, lights the

light emitting diode (LED), and allows the unit to

continue operation, indicating one complete

cycle of the lubrication system. If the

microprocessor fails to receive this cycle within a

predetermined time, a shutdown occurs. The

DNFT automatically resets the alarm circuit when

normal divider valve operation resumes.

DNFTs utilize an LED to indicate each cycle of the

divider valve, which allows easy adjustment and

monitoring of lubrication rates. Programmable

models display total pints, cycle time of divider

valve, total cycles of divider valve, or pints per

day pump flow rate on a liquid crystal display and

operators can adjust alarm time from 20 to 255

seconds.

ARIEL CORPORATION | www.arielcorp.com 16

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

DNFT Installation remove magnet housing. Do not remove

magnet, spring, or spacer from magnet

Figure: Typical DNFT Magnet Assemblies housing.

2. Remove piston enclosure plug from the end

of desired divider valve. The DNFT installs on

any of the divider valves of the divider block.

The DNFT requires the correct magnet

assembly to match the divider valve

manufacturer.

NOTE: Do not install a DNFT on Lincoln divider valves

with cycle indicator pins.

3. If applicable, verify O-ring or metal gasket is

in place on magnet housing. Thread magnet

housing into the end of the divider valve.

Torque to 15 lbs x ft (20 N•m) maximum.

4. Slide DNFT all the way onto hex of magnet

housing. Torque Allen set screws on the hex

1 Trabon Style O-ring Seal 7/16-20 of magnet housing to 25 lbs x inch, (2.8 N•m)

2 Trabon Metal Gasket Seal 7/16-20 (1994 or earlier) maximum.

3 Lincoln O-Ring Seal 7/16-20 Extended Nose 5. The LED on the DNFT indicates each divider

valve cycle to allow lubricator pump

Figure: Typical DNFT Installation adjustment for Ariel recommended cycle

time and oil consumption. If the LED fails to

blink during compressor operation or by

manually pumping oil into the divider valve,

then the DNFT requires adjustment.

6. The divider valve must cycle during DNFT

adjustment. To cycle, either run the

compressor or manually pump oil through

the distribution block with a purge pump.

7. To adjust, slide DNFT all the way onto hex of

magnet housing. Tighten Allen set screws to

1 Divider Valve Piston 25 lbs x inch (2.8 N•m) maximum. A blinking

2 Magnet LED indicates correct adjustment. If the LED

3 Magnet Housing fails to blink with divider valve cycling, slide

4 Set Screws (2) DNFT back on the hex of the magnet housing

5 LED

in 1/16" increments until it does.

6 Control Housing 8. Make all conduits and connections

7 Wire Leads appropriate for area classification. Insulate

8 O-Ring unused wires from the ground, other wires,

9 Divider Valve and the case. Support conduit and fittings to

10 Piston Enclosure Plug avoid bending the magnet housing.

1. Loosen the Allen set screws on the DNFT and

ARIEL CORPORATION | www.arielcorp.com 17

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

9. After DNFT installation and before

compressor start-up, purge all air from the

divider block lubrication system with a purge

pump.

NOTE: When installing multiple DNFTs, wire each to a

separate alarm circuit of the control panel, annunci-

ator, or PLC to simplify lubrication system and DNFT

troubleshooting. Always secure the green ground

wire to "earth ground" in the control panel. Do not

ground to electrical conduit or skid. Improper

grounding can result in unreliable monitor operation.

Figure: A-10754 Programmable DNFT Wiring Connections for Unit in Operation

Figure: A-10753 and A-10772 DNFT Wiring Connections for Unit in Operation

Figure: A-20513 24 VDC Programmable DNFT Wiring Connections for Unit in Operation

ARIEL CORPORATION | www.arielcorp.com 18

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

Figure: A-20514 24 VDC DNFT Wiring Connections for Unit in Operation

Programmable DNFTs

Figure: Typical Programmable DNFT CAUTION

Program DNFT before installing it on a divider valve. DO

NOT insert programming magnet into 1/8” recessed

opening while the compressor is operating; it causes the

DNFT to shut down the compressor. Programming

modes cannot be changed while the compressor is

operating. To program a DNFT, first remove it from the

divider valve.

To program:

1. Insert the programming magnet into the 1/8"

1 Magnet

recessed opening on the face of the DNFT.

2 Magnet Housing The current programming mode (1, 2, 3, or 4)

3 Allen Set Screws immediately displays on the LCD followed by

4 LED "0" 2 seconds later. "0" indicates the current

5 Control Housing mode is ready for programming.

6 LCD

2. If the desired programming mode does not

7 1/8" recessed opening for programming magnet

display, remove and re-insert the

8 Wire Leads programming magnet into the recessed

9 Programming Magnet opening until it does. Leave the programming

Programmable DNFTs come with a small liquid magnet in the recessed opening when the

crystal display (LCD) screen to display total desired programming mode displays.

divider valve cycles (Mode 1), cycle time of 3. Select one of the programming modes below:

divider valve in seconds (Mode 2), total pints of a. Mode 1 - LCD displays total divider

oil used (Mode 3), or pump flow rate in pints per valve cycles; program alarm time.

day (Mode 4). Operators can also adjust alarm • To set alarm time, press and release

time in Mode 1. the spring-loaded magnet assembly

until the desired alarm time in

seconds displays on the LCD. Set

alarm time from a minimum of 20

ARIEL CORPORATION | www.arielcorp.com 19

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

seconds to a maximum of 255 magnet into the recessed opening, selects

seconds. If not set, the device defaults Mode 1 or Mode 3, and presses the spring-

to 120 seconds. loaded magnet assembly. This action resets the

unit to zero and allows entry of a new value.

• Remove programming magnet. DNFT

displays total divider valve cycles if NOTE: Power interruption to the DNFT requires

left in this mode and alarm time is reprogramming Mode 1 and Mode 3.

now set.

b. Mode 2 - LCD displays the cycle time of

the divider valve in seconds. DNFT Battery Replacement

• Remove programming magnet when

Mode 2 displays. LCD counts each Figure: Typical Digital No-Flow Timer Switch

divider valve cycle in seconds, (DNFT)

counting up from zero until the

divider valve completes one full cycle.

When divider valve completes one full

cycle, the LCD resets to zero and

repeats the count until another cycle

is completed. The LED blinks in all

modes to indicate each divider valve

cycle. This blink enables the operator

to set pump flow rate.

c. Mode 3 - LCD displays total pints used;

program divider valve total.

• To set divider valve total, add the sizes 1 Magnet Housing

of the divider valve sections on which 2 Magnet

the DNFT will be installed. Example: 3 O-Ring

24 + 24 + 24 = 72. 4 Control Housing

• Press and release the spring-loaded 5 Polarized Connector

magnet until the divider valve total 6 Field Replaceable Battery

displays on the LCD. Maximum value: 7 1/2" Pipe Plug

120. If not set, device defaults to zero 8 #22 AWG 18" (0.46 m) Leads

and prevents Mode 4 flow rate display. 9 Spring

• Remove programming magnet. The 10 Spacer

DNFT displays total pints on the LCD if 11 Allen Set Screws

left in this mode.

d. Mode 4 - LCD displays pump flow rate in The DNFT operates on a field-replaceable lithium

pints per day. battery that should last six to ten years. If the

• Remove programming magnet with battery voltage drops below 2.5 VDC, the DNFT

Mode 4 displays. LCD displays pump shuts down and the compressor cannot be

flow rate in pints per day based upon restarted until the battery is replaced.

the divider valve total set in Mode 3.

Mode 4 requires a minimum 4 second

cycle time.

The DNFT stores all programmed information

until the operator inserts the programming

ARIEL CORPORATION | www.arielcorp.com 20

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

10. Programmable DNFTs require

reprogramming of the alarm time (Mode 1)

CAUTION and divider valve total (Mode 3) after a power

Do not open a DNFT in an explosive gas atmosphere. interruption. See the programming section of

this document.

1. Shut down the compressor. 11. To verify DNFT operation, pre-lube the

2. Disconnect DNFT wiring. system and check for LED blink.

3. Use 1/8 inch Allen wrench to loosen Allen set Troubleshooting DNFT’s

screws and remove control housing to a safe

atmosphere.

NOTE: When installing multiple DNFTs, wire each to a

4. Use 3/8 inch ratchet wrench to remove pipe separate alarm circuit of the control panel, annunci-

plug. ator, or PLC to simplify lubrication system and DNFT

5. Remove the battery and disconnect from the troubleshooting. See ER-105.3.1 for DNFT bench test

polarized connector. procedures.

6. Test battery. The voltage should read 3.6

VDC. Problem:

7. Connect the new battery to the polarized • LED does not blink and control panel indi-

connector. cates lube no-flow. (see also Erratic Shut-

down)

8. Insert the new battery and reinstall the pipe

• ARV bypasses or rupture disk bursts and

plug. Apply Teflon tape to plug threads and

divider valve seizes after DNFT installation.

torque to 25 ft x lb (34 N•m).

• Erratic shutdown or LED blink.

9. Place DNFT control housing on the magnet

housing in its original position and tighten set

screws. Reattach wiring and conduit.

Troubleshooting: DNFT Lube No-Flow

Problem

LED does not blink and control panel indicates lube no-flow. (see also Erratic Shutdown)

Possible Cause 2. Either pump clean oil through lubrication

system with a purge pump or run the

Improperly adjusted DNFT.

compressor to cycle the divider valve.

Solution 3. If necessary, slide DNFT back in 1/16“

increments until LED blinks with each

1. Loosen set screws, slide DNFT all the way divider valve cycle.

onto hex of magnet housing and torque to

25 lbs x inch (2.8 N•m) max.

(Do not over tighten).

ARIEL CORPORATION | www.arielcorp.com 21

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

Possible Cause Possible Cause

Broken spring or magnet in magnet housing. Bent magnet housing.

Solution Solution

1. Loosen set screws, remove DNFT from 1. Loosen set screws, remove DNFT from

magnet housing. magnet housing.

2. Remove magnet housing from divider 2. Check for damaged or bent magnet

valve. housing.

3. Remove magnet, spring, and spacer and 3. Remove magnet assembly from divider

check for damage. valve.

4. Replace damaged components. 4. Replace magnet housing, magnet, spring,

and spacer.

5. Re-install magnet housing on divider valve

and DNFT on magnet housing. 5. Re-install new magnet housing on divider

valve and DNFT on magnet housing.

6. If necessary, adjust DNFT, check for LED

blink. 6. If necessary, adjust DNFT, check for LED

blink.

7. Purge air from system with purge pump.

7. Purge air from system with purge pump.

Possible Cause

Low battery voltage.

Solution

1. Remove battery from DNFT and test it.

2. Replace battery with a factory

recommended replacement lithium battery

if voltage is below 2.5 VDC.

Troubleshooting: DNFT ARV Bypasses

Problem

ARV bypasses or rupture disk bursts and divider valve seizes after DNFT installation.

Possible Cause 2. Check for correct magnet housing for

divider valve manufacturer.

Wrong magnet housing installed on divider

valve. 3. Remove and replace with correct magnet

housing.

Solution 4. Re-install DNFT on new magnet housing.

1. Loosen set screws and remove DNFT from

magnet housing.

ARIEL CORPORATION | www.arielcorp.com 22

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

5. If necessary adjust DNFT, check for LED 2. If needed, install pressure gauge to monitor

blink. lubrication system operation:

6. Purge air from system with purge pump. a. Loosen outlet plugs in front of valve

blocks.

Possible Cause b. Purge lubrication system with a purge

pump until clean, clear, air-free oil flows

Air or debris in divider valve assembly. from plugs.

c. Loosen, but do not remove, each piston

Solution

enclosure plug individually to purge air

1. Check system pressure to verify oil flows to from behind piston. To ensure proper

divider valves. lube system operation, all tubing and

components MUST be filled with oil and

free of air before start-up.

d. Tighten all divider valve plugs.

e. Adjust proximity switch.

Troubleshooting: DNFT Erratic Shutdown

Problem

Erratic shutdown or LED blink.

Possible Cause Normally Open

Faulty wiring from DNFT to control panel or air 1. Attach ohmmeter to orange wires; insulate

in system (see air in system). violet wires from each other.

2. Should read 10Ω or less in alarm.

Solution

Normally Closed

Part numbers: A-10753, A-10772, and A-

1. Attach ohmmeter to orange wires.

20513

2. Short violet wires together.

Normally Open

3. Should read open loop in alarm.

1. Attach ohmmeter to red wires.

2. Should read 10MΩ in operation and less than

Possible Cause

10Ω in alarm.

Faulty lube pump.

Normally Closed

1. Attach ohmmeter to orange wires. Solution

2. Should read less than 10Ω in operation and 1. Check system pressure to verify oil flows to

open loop in alarm. pump and divider valves. If needed, install

pressure gauge to monitor lubrication

Part number: A-10754, and A-20514 system operation.

ARIEL CORPORATION | www.arielcorp.com 23

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

2. Check gauge to verify pump builds The time for the proximity switch to repeat a

sufficient pressure to inject oil into cylinder. contact transition (ex. from open to closed) is

Do not remove tubing from check valve and known as the cycle time of the divider valve

pump oil to atmosphere to check oil flow assembly. The proximity switch must work with a

into cylinder.

PLC or some other counter/timer device to

3. Replace pump. produce a shutdown. See "Instrumentation" in

the Ariel Packager Standards for interpretation of

Possible Cause proximity switch pulse output.

Overtightened divider valves

Solution

1. Step-torque divider valves to 75 lb x in (8.5

N•m) to the backplate.

Proximity Switch A-18255

CAUTION

Any arc welding on the skid and/or associated

equipment and piping can permanently damage solid-

state electronic equipment. Welding can cause

immediate failure or reduce electronic equipment life

and void the warranty. To protect electronic equipment

prior to any arc welding (including repair welding),

disconnect all electrical connections including ground,

and remove batteries, or completely remove the

electronic equipment from the compressor.

It is good practice to attach the welding ground clamp as

close as possible to the area where the welding will

occur and to use the lowest practical welder output

setting. Welding must not cause a current flow across

any compressor bearing surface, including but not

limited to crankshaft and crosshead bearing surfaces.

A proximity switch installs into a divider valve in

place of a piston end plug and can be used to

actuate any device. It consists of a reed switch

and a magnet. When installed, the magnet rests

against the divider valve piston and parallel to

the reed switch. With every divider valve cycle,

the piston moves the magnet, which opens and

closes the reed switch contacts.

ARIEL CORPORATION | www.arielcorp.com 24

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

Proximity Switch Installation Figure: Typical Proximity Switch Installation

Figure: Typical Magnet Assemblies

1 Divider Valve Piston

2 Magnet

3 Magnet Housing

4 Allen Set Screw (2)

5 Spacer

1 Trabon Style O-ring Seal 7/16-20

6 Spring

2 Trabon Metal Gasket Seal 7/16-20 (1994 or earlier)

7 Switch Housing

3 Lincoln O-Ring Seal 7/16-20 Extended Nose

8 Wire Leads (yellow)

9 Ground Wire (green)

10 O-Ring

11 Divider Valve

12 Piston End Plug

1. Loosen the Allen set screws on the proximity

switch housing and remove magnet housing.

Do not remove magnet, spring, or spacer

from magnet housing.

2. Remove piston enclosure plug from end of

desired divider valve. The proximity switch

installs on any of the divider valves of the

divider block. The proximity switch requires

the correct magnet assembly to match the

divider valve manufacturer.

NOTE: Do not install a proximity switch on Lincoln

divider valves with cycle indicator pins.

3. If applicable, verify O-ring or metal gasket is

in place on magnet housing. Thread magnet

housing into end of divider valve. Torque to

15 lbs x ft maximum.

ARIEL CORPORATION | www.arielcorp.com 25

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

4. Slide proximity switch all the way onto hex of 8. Make all conduit and connections

magnet housing. Torque Allen set screws on appropriate for area classification. Support

hex of magnet housing to 25 lbs x inch, conduit and fittings to avoid bending the

maximum. magnet housing.

5. Connect an ohm meter across the two yellow 9. After proximity switch installation and before

switch leads exiting the proximity switch compressor start-up, purge all air from

housing. divider block lubrication system with a purge

6. The divider valve must cycle during proximity pump.

switch adjustment. To cycle it, either run the NOTE: When installing multiple proximity switches,

compressor or manually pump oil through wire each to a separate alarm circuit of the control

the distribution block with a purge pump. panel, annunciator, or PLC to simplify lubrication

7. To adjust, slide proximity switch all the way system and proximity switch troubleshooting. Always

onto hex of magnet housing. Tighten Allen set secure green ground wire to "earth ground" in the

screws to 25 lbs x inch maximum. The ohm control panel. Do not ground to electrical conduit.

meter showing the switch changing state as Improper grounding can result in unreliable monitor

the divider valve cycles indicates correct operation.

adjustment. If the switch state fails to

change, slide proximity switch back on the

hex of the magnet housing in 1/16"

increments until it does.

Figure: A-18255 Proximity Switch Wiring Connections for Unit in Operation

Troubleshooting Proximity Switches • Switch does not cycle and control panel indi-

cates lube no-flow. (also see Erratic Opera-

NOTE: When installing multiple proximity switches, tion)

wire each to a separate circuit in the control panel, • ARV bypasses or rupture disk bursts and

annunciator, or PLC to simplify lubrication system divider valve seizes after proximity switch

and proximity switch troubleshooting. installation.

• Erratic Operation.

Problem:

ARIEL CORPORATION | www.arielcorp.com 26

JGM-JGN-JGP-JGQ Maintenance & Repair Manual – Instrumentation 12/03/2022

Troubleshooting: Proximity Switches Lube No-Flow

Problem

Switch does not cycle and control panel indicates lube no-flow. (see also Erratic Operation)

Possible Cause 4. Re-install magnet housing on divider valve

and proximity switch on magnet housing.

Improperly adjusted proximity switch.

5. If necessary, adjust proximity switch and

Solution test switch functionality.

1. Loosen set screws, slide proximity switch 6. Purge air from system with purge pump.

all the way onto hex of magnet housing and

torque to 25 lbs x inch max. (Do not over Possible Cause

tighten).

Bent magnet housing.

2. Either pump clean oil through lubrication

system with a purge pump or run the Solution

compressor to cycle the divider valve.

1. Loosen set screws, remove proximity

3. If necessary, slide proximity switch back in

switch from magnet housing.

1/16“ increments until the switch

opens/closes with each divider valve cycle. 2. Check for damaged or bent magnet

housing.

Possible Cause 3. Remove magnet assembly from divider

valve.

Broken spring or magnet in magnet housing.