Professional Documents

Culture Documents

IJMCE (Mac and Nelson)

Uploaded by

Mac Eteli DaviesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJMCE (Mac and Nelson)

Uploaded by

Mac Eteli DaviesCopyright:

Available Formats

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

MODELLING REVIEWED HYDRAULIC INDICES OF PERIWINKLE SHELL ASH

OCCASIONED BY VARIATIONS IN CALCINATION TEMPERATURE

Mac-Eteli H.D. and Nelson T.A

Department of Civil Engineering and Hydrology, Niger Delta University Wilberforce Island,

Nigeria

*Corresponding Author: happinessmac-eteli@ndu.edu.ng

Cite this article: ABSTRACT: Periwinkle shellfish can be found in abundance in

Mac-Eteli H.D., Nelson T.A. the Niger Delta's wetlands. Periwinkle shells are frequently piled

(2022), Modelling Reviewed in open fields and landfills, resulting in pollution and the

Hydraulic Indices of

Periwinkle Shell Ash

development of disease-carrying organisms. Attempts have been

Occasioned by Variations in made to employ periwinkle shell ash (PSA) as recycled materials

Calcination Temperature. in cement-based products in order to manage periwinkle shell by-

International Journal of

Mechanical and Civil

products, preserve natural resources, and minimize building

Engineering 5(1), 73-84. DOI: expenses. A better understanding of results obtained can be

10.52589/IJMCE-UAUFOF8L established using statistical tools in the analysis and modelling of

the trends established with respect to reviewed papers on the PSA

Manuscript History production parameters as well as the cement replacement level

Received: 26 Oct 2022

on the mechanical indices of concrete. This paper, therefore, uses

statistical templates to develop analyzed models for a more

Accepted: 18 Nov 2022

enhanced understanding of trends and patterns associated with

Published: 8 Dec 2022 PSA processing variables and cement replacement levels on the

compressive strength of concrete.

Copyright © 2022 The Author(s).

This is an Open Access article KEYWORDS: Hydraulicity indices, Cementation indices,

distributed under the terms of

Creative Commons Attribution-

Pozzolanicity, Calcination, Compressive strength.

NonCommercial-NoDerivatives

4.0 International (CC BY-NC-ND

4.0), which permits anyone to

share, use, reproduce and

redistribute in any medium,

provided the original author and

source are credited.

73 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

INTRODUCTION

Periwinkle is a mollusc shellfish whose shell is the by-product of removing the edible

component of the periwinkle shellfish. Fishing and fishery are the means to raising shellfish.

Winkles, abalones, and conchs account for about 2.8 percent of the 16 million tonnes of

mollusk shellfish produced by aquaculture each year worldwide (FAO, 2014 quoted in Yang

et al., 2016; FAO, 2016). The shell, which is a challenge for shellfish growers, merchants, and

consumers, is a concern in shellfish food production (Morris et al., 2018).

Periwinkle shell remnants are commonly piled in open fields and landfills, resulting in a foul

odour, ugly appearance, and the development of disease-carrying organisms. Periwinkle shell

dumps can be found in various Niger Delta towns and cities, including Port Harcourt, Uyo,

Calabar, Yenagoa, Warri, and Oron (Ohimain et al., 2009). Various approaches have been tried

to address the waste management issues related with periwinkle shell (Table 1). Some of the

periwinkle shell's potential applications necessitates additional processing steps such as

crushing and calcination (Eziefula et al., 2020). Periwinkle shells could be used in concrete and

other cement-based products like sandcrete and mortar as recycled resources.

The large volume of cement produced and consumed is due to the rapid development of the

construction industry. The most common type of cement available is Portland cement. Cement

is so important to humans that it is commercially manufactured in over 150 countries and

produced in excess of 3.5 billion metric tonnes per year (McLeod, 2005; UNEP Global

Environmental Alert Service, 2014).

Carbonate oxidation in the cement clinker manufacturing process accounted for about 5% to

8% of total global carbon dioxide (CO2) emissions (Olivier et al., 2016). CO2 and other

greenhouse gases released into the atmosphere are the primary cause of climate change, which

is today a critical global environmental issue. Partially replacing cement with supplementary

cementitious materials (SCMs) is one way to reduce CO2 emissions from the current cement

manufacturing process. These SCMs are by-products that are used in cement-based materials

as fillers or pozzolans. In the hardened condition, one of the most essential features of concrete

is its compressive strength. The resistance to compressive loads is the primary consideration in

the construction of concrete structures. Compressive strength is the quality criterion in

structural design (Umoh & Olusola, 2013; Neville, 2010).

Cementation and hydraulic indexes are parameters mainly dependent on the oxide

compositions of silicon, aluminum, iron, magnesium and calcium. Figueiredo et al. (2016)

noted that silicon and aluminum oxides are the primary oxides responsible for the hydraulic

behavior of a material. In the discussion of their findings, they asserted that at higher

calcination temperatures, greater amounts of Alite (C3S) are produced.

Findings of Herbert et al. (2019) showed that Hydraulicity Index (HI) is directly proportional

to Cementation Index (CI) as well as compressive strength, on the condition that all samples

are prepared to have an approximate uniform fineness. This could explain the variation

observed in the findings of Figueiredo et al. (2016) in which NHL2-B had a better cementation

and Hydraulic Indexes when compared to NHL2-A, but was found to be lower in compressive

strength as the fineness of both samples was not defined.

74 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

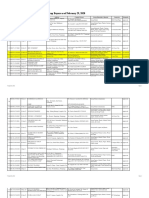

Table 1: Some applications of periwinkle shells in environmental management,

construction industry and economic advancement (Eziefula et al., 2020).

S/N Application Reference

1 Substitute coarse aggregate in Agbede and Manasseh (2009), Ohimain et al. (2009),

concrete Ekop et al. (2013), Ettu et al. (2013b), Osarenmwinda

construction and Awaro. (2009)

2 Supplementary cementitious Etuk et al. (2012), Olusola and Umoh (2012), Umoh and

material in Olusola (2012, 2013) and Etim et al. (2017)

cement-based construction

materials

3 Lime substitute in glass Malu and Bassey (2003)

manufacturing

4 Formulation of fish feed; Oribhabor and Ansa (2006)

livestock food

(calcium) supplement

5 Liming agent in soil stabilization Otoko and Cynthia (2014), Otoko and Welcome (2014)

and Nnochiri (2017)

6 Biofilter medium; treatment of Badmus et al. (2007), Badmus and Audu (2009),

wastewater Awokoya et al. (2016), Davies and Ogidiaka (2017) and

contaminated with heavy metals; Ugwuoha et al. (2017)

pH

buffering medium in aquaculture

7 Particle board production Abdullahi and Sara (2015)

8 Automotive brake pad Yawas et al. (2016) and Dan-asabe and Stephen (2018)

9 Pharmaceutical excipient Ugoeze and Chukwu (2015) and Ugoeze and Udeala

(2015)

10 Filling material for potholes in Ohimain et al. (2009)

pavements

11 Cleaning/cleansing agent Bob-Manuel (2012) and Ademolu et al. (2015)

12 Aesthetic and decorative Bob-Manuel (2012) and Soneye et al. (2016)

purposes;

ornamentals; bead making

75 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

Table 2: Relating hydraulicity index to the compressive strength of pozzolana concrete

(Herbert et al., 2019)

Pozzolan ID Calcination Temperature

Based on 28day curing age @30 500oC 600oC 700oC 750oC 800oC Ref OPC

Cem. replacement level

Ar - A Comp. Strength (Mpa) 41.1 45.7 45.7 47.4 47.8 58.4

Hydraulic Index -4.22 23.49 23.49 33.73 36.14

Ar - B Comp. Strength (Mpa) 42.0 43.1 49.8 48.1 48.2 58.4

Hydraulic Index 1.45 8.01 48.19 37.83 38.25

600oC 700oC 750oC 800oC 850oC 900oC Ref OPC

Ar - C Comp. Strength (Mpa) 40.07 41.0 43.6 43.9 41.3 43.0 59.9

Hydraulic Index -6.08 -4.42 9.94 11.82 -2.87 6.57

Ar - C Comp. Strength (Mpa) 40.3 41.4 46.5 56.8 48.8 43.3 59.9

Hydraulic Index -8.29 -2.21 25.97 82.87 38.67 8.29

Table 3: Oxide composition. Cementation and hydraulicity index (Figueiredo et. al.,

2016)

Oxide NHL – 2A NHL – 2B NHL – 2C

CaO 66.38 66.03 66.41

SiO2 7.80 9.35 4.85

Al2O3 1.63 0.38 0.12

MgO 2.37 0.44 1.19

Fe2O3 2.10 0.38 0.5

SO3 0.37 0.46 1.19

K2O 0.89 0.33 0.46

Na2O 0.31 0.49 0.49

TiO2 0.16 0.09 0.09

MnO 0.05 0.01 0.01

LOI 17.95 22.03 24.64

CI 0.36 0.40 0.21

HI 0.14 0.15 0.07

Table 2 illustrates the peculiar effect of calcination on the hydraulicity of pozzolans which

invariably affects compressive strength contribution of the pozzolan in concrete when used as

a supplementary cementitious material. Table 3 contributes by showing as a way of example

the correlation between the oxide composition of cementitious materials and their

hydraulicity/cementitious indices.

76 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

MATERIALS AND METHODS

The investigation primarily intends to fill the gap of the ideal temperature for optimum

hydraulicity of periwinkle shell ash as a partial cementitious material in concrete. Using oxide

composition findings from Etim et al. (2017), Etuk et al. (2012), Job et al. (2017), Nnochiri

(2017), Offiong and Akpan (2017), Umoh and Olusola (2012), and the equations for

hydraulicity as well as cementitious indices, resulting data were used as inputs in a surface

response methodological design from Design Expert analytical tool, to analyze and develop a

model for monitoring the hydraulic potentials of PSA in PSA cement blended concrete.

2.8SiO2 + 1.1Al 2 O3 + 0.7 Fe2O3

Cl =

CaO + 1.4MgO 1.0

SiO2 + Al2O33

Hl =

CaO 2.0

RESULTS AND DISCUSSION

Table 4: Hydraulic and cementation indices of PSA effected by variations in calcination

temperature

Reference Temp Weight of elemental oxide (%)

(oC) CaO SiO2 Al2O3 Fe2O3 MgO Na2O K2O CI HI

Etim et al. (2017) 1000 42.32 29.54 11.6 5.13 0.42 0.43 0.11 2.31 0.97

Nnochiri (2017) 1000 41.35 35.37 9.6 4.84 0.5 0.21 0.2 2.69 1.09

Offiong and 1000 46.39 30.8 10.84 5.58 0.73 0.27 0.27 2.15 0.90

Akpan (2017)

Average 1000.00 43.35 31.90 10.68 5.18 0.55 0.30 0.19 2.38 0.99

Etuk et al. (2012) 800 55.53 26.26 8.79 4.82 0.4 0.25 0.2 1.54 0.63

Job et al. (2017) 800 37.54 34.74 15.57 0.12 0 0 0.03 3.05 1.34

Offiong and 800 40.63 33.85 10.24 6.25 0.83 0.15 0.26 2.64 1.09

Akpan (2017)

Umoh and 800 40.84 33.84 10.2 6.02 0.48 0.24 0.14 2.65 1.08

Olusola (2012)

Average 800 43.64 32.17 11.20 4.30 0.43 0.16 0.16 2.47 1.03

Offiong and 600 38.62 23.32 9.62 5.01 0.36 0.24 0.13 2.03 0.85

Akpan (2017)

77 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

From the figure (Figure 1), it can be said that a quadratic trend exists between calcination

temperature and the hydraulicity of periwinkle shell ash as a cementing material. Whilst 800oC

appears to be optimal for hydraulicity index, 900oC appears to be more suitable for cementation

index. It can be observed, however, that no significant difference in hydraulicity index is

observed between 600oC and 1000oc

Figure 1: Effect of calcination temperature on the hydraulicity of periwinkle shell ash

Table 5: Input Data of calcination effect on PSA’s hydraulicity

Temp (oC) HI CI Temp HI CI

(oC)

25 -0.94338 -2.25465 550 0.7235 1.7616

100 -0.604 -1.4784 600 0.796 1.9716

150 -0.3965 -0.9984 650 0.8535 2.1516

200 -0.204 -0.5484 700 0.896 2.3016

250 -0.0265 -0.1284 750 0.9235 2.4216

300 0.136 0.2616 800 0.936 2.5116

350 0.2835 0.6216 850 0.9335 2.5716

400 0.416 0.9516 900 0.916 2.6016

450 0.5335 1.2516 950 0.8835 2.6016

500 0.636 1.5216 1000 0.836 2.5716

78 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

Table 6: Design variables and responses

Factor 1 Response 1 Response 2

Run A: Temperature Hydraulic Index Cementation Index

(oC)

1 500 0.636 1.5216

2 500 0.636 1.5216

3 1000 0.836 2.5716

4 25 -0.94338 -2.25465

5 250 -0.0265 -0.1284

6 1000 0.836 2.5716

7 500 0.636 1.5216

8 25 -0.94338 -2.25465

9 150 -0.3965 -0.9984

10 650 0.8535 2.1516

11 350 0.2835 0.6216

12 1000 0.836 2.5716

13 800 0.936 2.5116

Table 7: ANOVA for Response Surface Quadratic model for Hydraulic Index of PSA

Analysis of variance table [Partial sum of squares - Type III]

Sum of Mean F p-value

Source Squares df Square Value Prob > F

Model 5.59 2 2.79

A-Temperature 4.96 1 4.96

2

A 1.19 1 1.19

Residual 0.000 10 0.000

Lack of Fit 0.000 5 0.000

Pure Error 0.000 5 0.000

Cor Total 5.59 12

Table 8: Coefficient of Regression for Hydraulic Index model of PSA

Std. Dev. 0.000 R-Squared 1.0000

Mean 0.32 Adj R-Squared 1.0000

C.V. % 0.000 Pred R-Squared 1.0000

PRESS 1.929E-011 Adeq Precision

79 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

PSA Hydraulic Index (HI) = -1.06 + 0.0049T – 0.000003T2 𝐸𝑞. 3.0

From Tables 7 and 8, the model as analyzed is quadratic having a coefficient of regression of

1. This implies the formation of an arc resulting from variations in calcination temperature.

This arc is observed to have its crest around 800oC.

Figure 2: Model diagnostics for the hydraulic index of PSA

Figure 3: Modelled effect of calcination on the hydraulic index of PSA

80 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

Table 9: ANOVA for Response Surface Quadratic model for Cementation Index of PSA

ANOVA for Response Surface Linear model

Analysis of variance table [Partial sum of squares - Type III]

Sum of Mean F p-value

Source Squares df Square Value Prob > F

Model 33.57 1 33.57 77.26 < 0.0001 significant

A-Temperature 33.57 1 33.57 77.26 < 0.0001

Residual 4.78 11 0.43

Lack of Fit 4.78 6 0.80

Pure Error 0.000 5 0.000

Cor Total 38.34 12

Table 10: Coefficient of Regression for Cementation Index model of PSA

Std. Dev. 0.66 R-Squared 0.8754

Mean 0.92 Adj R-Squared 0.8640

C.V. % 71.83 Pred R-Squared 0.8172

PRESS 7.01 Adeq Precision 17.743

𝑃𝑆𝐴 𝐶𝑒𝑚𝑒𝑛𝑡𝑎𝑡𝑖𝑜𝑛 𝐼𝑛𝑑𝑒𝑥 (𝐶𝐼) = −1.525 + 0.0047𝑇 𝐸𝑞. 4.0

From Tables 9 and 10, the model can be said to be logically significant, having a confidence

interval (P- value) much greater than 95% as well as a predicted coefficient of regression of

0.8172. Other statistical indices such as the deviation about the mean, the coefficient of

variation, PRESS and adequate precision, collectively satisfy the logical arguments for a

statistically sound model. This can be said to be same for the model obtained for the Hydraulic

index of PSA as shown in equation 3.0.

81 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

Figure 4: Model diagnostics for Cementation index of PSA

Figure 5: Modelled effect of calcination on the cementation index of PSA

82 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

CONCLUSION

From the above investigation, the following sums up the research: Hydraulic index as well as

cementation index are indices of binders and pozzolans relating directly to their compressive

strength contribution in mortars and concretes. Similarly, both hydraulic and cementation

indices of periwinkle shell ash were observed to be of a quadratic nature under the influence of

varying calcination temperature with optimum results observed between 800 and 1000oC.

Finally, Hydraulic and cementation indices are components of the oxide composition of the

binder material, however, beyond compressive strength (which is favored directly with

increasing HI and CI), other stability factors such as concrete or mortars resistance to harsh

weather and chemical exposure conditions should be considered when choosing an optimum

temperature for calcination.

Declaration of competing interest

We undertake not to engage in any financial, commercial, legal, or professional dealings with

other organizations or the people we worked with that would have an impact on this research.

Credit authorship contribution statement

• Mac-Eteli, D. Happiness: Investigation, Writing - original draft.

• Nelson Tonbra Akari: Investigation, Writing - original draft.

REFERENCES

A.M. Neville, J.J. Brooks, Concrete Technology, second ed., Pearson Education, Essex, UK,

2010.

Agbede, O. I., & Manasseh, J. 2009. Suitability of periwinkle shell as partial replacement for

river gravel in concrete. Leonardo Electronic Journal of Practices and Technologies, 15,

pp.59-66.

Anieti-mfon E. I. and Benjamin R. E., (2016) ‘The Effect of Calcination Temperature on The

Chemical Composition of Oyster, Periwinkle and Snail Shell Ash’ International Journal

of Research in Engineering and Technology (IJRET): eISSN: 2319-1163 | pISSN:

2321-7308 (2016). Vol 5(8). pp 200-203

Attah, I. C., Etim, R. K., & Ekpo, D. U. (2018). Behaviour of periwinkle shell ash blended

cement concrete in sulphuric acid environment. Nigerian Journal of Technology, 37(2),

315-321.

E.I. Ohimain, S. Bassey, D.D.S. Bawo, Uses of sea shells for civil construction works in

coastal Bayelsa State, Nigeria: a waste management perspective, Res. J. Biol. Sci. 4 (9)

(2009) 1025–1031.

Etim, R. K., Attah, I. C. and Okon, B. B. “Assessment of Periwinkle Shell Ash Blended

Cement Concrete in Crude Oil Polluted Environment” FUW Trends in Science &

Technology Journal, Vol. 2 No. 2 pp. 879 – 885, 2017.

Ettu L.O, Ajoku C.A, Nwachukwu K.C, Awodiji C.T.G, and Eziefula U.G. 2013b. Strength

variation of OPC-rice husk ash composites with percentage rice husk ash’ Int. Journal

of Applied Sciences and Engineering Research, Vol. 2, Issue 4, pp420-424.

83 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

International Journal of Mechanical and Civil Engineering

ISSN: 2689-940X

Volume 5, Issue 1, 2022 (pp. 73-84) www.abjournals.org

Etuk B. R., Etuk I. F., and Asuquo L.O., 2012. Feasibility of Using Sea Shells Ash as

Admixtures for Concrete. Journal of Environmental Science and Engineering A 1 pp

121-127

Etuk B. R., Etuk I. F., and Asuquo L.O., 2012. Feasibility of Using Sea Shells Ash as

Admixtures for Concrete. Journal of Environmental Science and Engineering A 1 pp

121-127

Eziefula, U. G., Ezeh, J. C., & Eziefula, B. I. (2018). Properties of seashell aggregate

concrete: A review. Construction and Building Materials, 192, 287-300.

Figueiredo, C., Lawrence, M., & Ball, R. J. (2016). Chemical and physical characterisation of

three NHL 2 binders and the relationship with the mortar properties. In REHABEND

2016, Euro-Americal Congress: Construction Pathology, Rehabilitation Technology

and Heritage Management. Santander Spain.

I.E. Ekop, O.A. Adenuga, A.A. Umoh, Strength characteristics of granitepachymelania aurita

shell concrete, Nigerian J. Agric. Food Environ. 9 (2) (2013) 9–14.

Job, O. F., Umoh, A. A. and Nsikak, S. C. “Engineering Properties of Sandcrete Blocks

Containing Periwinkle Shell Ash and Ordinary Portland cement”, International Journal

of Civil Engineering, vol. 1, no.1, pp, 18-24, 2009.

Neville, A. M. Properties of Concrete, 5th edition, New York: Pitman, 2000.

Olivier, J. G. J., Janssens-Maenhout, G., Muntean, M., and Peters, J. A. H. W.: Trends in

global CO2 emissions: 2016 report, PBL Netherlands Environmental Assessment

Agency; Ispra: European Commission, Joint Research Centre, The Hague.

Olusola, K. O. and Umoh, A. A. 2012 Strength Characteristics of Periwinkle Shell Ash

Blended Cement Concrete. International Journal of Architecture, Engineering and

Construction Vol. 1, No 4, pp 213- 220.

Osarenmwinda, J. O., & Awaro, A. O. (2009). The potential use of periwinkle shell as coarse

aggregate for concrete. In Advanced Materials Research (Vol. 62, pp. 39-43). Trans

Tech Publications Ltd.

Sumadi, S. R., Zakaria, R., Yahya, K., Haron, Z., Ahankoob, A., Khoshnava, S. M., &

Abdulrahman, A. S. (2012) Make Concrete as a Sustainable Material for the

Environment. APSEC-ICCER, pp 78 – 84.

Umoh, A. A., & Olusola, K. O. 2013. Performance of periwinkle shell ash blended cement

concrete exposed to magnesium sulphate. Civil Engineering Dimension, 15(2), 96-101.

Umoh,A. A. and Olusola, K. O. 2012. Compressive Strength and Static Modulus of Elasticity

of Periwinkle Shell Ash Blended Cement Concrete. International Journal of Sustainable

Construction Engineering & Technology Vol 3, Issue 2, pp45-55.

UNEP 2014. UNEP Global Environmental Alert Service: Sand, rarer than one thinks. Online

Source available on

http://unepineurope.org/index.php?option=com_content&view=article&id=86:unep-

global-environmental-alert-service-sand-rarer-than-one-thinks&catid=59. Last Visited

on 17/10/2021

84 Article DOI: 10.52589/IJMCE-UAUFOF8L

DOI URL: https://doi.org/10.52589/IJMCE-UAUFOF8L

You might also like

- RHA4Document35 pagesRHA4HelloNo ratings yet

- Ali Sarmah STOTENPaper2017Document10 pagesAli Sarmah STOTENPaper2017Terry McManamanNo ratings yet

- Journal of Cleaner ProductionDocument9 pagesJournal of Cleaner ProductionJITHIN BENNYNo ratings yet

- Case Studies in Construction MaterialsDocument13 pagesCase Studies in Construction MaterialsLusman SulaimanNo ratings yet

- Compatibility Issues of Flyash Based Cements With Nanomaterials Like Nano-SilicaDocument8 pagesCompatibility Issues of Flyash Based Cements With Nanomaterials Like Nano-SilicaansarNo ratings yet

- Application of Recycled Waste Materials For Highway Construction: Prospect and ChallengesDocument12 pagesApplication of Recycled Waste Materials For Highway Construction: Prospect and ChallengesArchibold KganyagoNo ratings yet

- Effect of Mix Ratio and Curing Water On The Compressive Strength of Oil Palm Shell (Ops) Aggregate ConcreteDocument88 pagesEffect of Mix Ratio and Curing Water On The Compressive Strength of Oil Palm Shell (Ops) Aggregate ConcreteSoma DeborahNo ratings yet

- Carbon CaptureDocument13 pagesCarbon Capturewaled officeNo ratings yet

- 2020 Application of Alkali-Activated Industrial Wastes For The Stabilisation of A Full-Scale (Sub) Base LayerDocument12 pages2020 Application of Alkali-Activated Industrial Wastes For The Stabilisation of A Full-Scale (Sub) Base LayerS R Kumar KonathalaNo ratings yet

- Application and Circular Economy Prospects of Palm Oil Waste ForDocument23 pagesApplication and Circular Economy Prospects of Palm Oil Waste Forskdumka1997No ratings yet

- Espuma A Partir de Vidrio PDFDocument8 pagesEspuma A Partir de Vidrio PDFYENIFER PLATA LOPEZNo ratings yet

- Waste CowdungandSawdustDocument7 pagesWaste CowdungandSawdustJanica GavinoNo ratings yet

- Aerogels For Water Treatment A ReviewDocument21 pagesAerogels For Water Treatment A ReviewVeronica HernandezNo ratings yet

- Utilization of Water Treatment Plant Sludge in Structural Ceramics BricksDocument7 pagesUtilization of Water Treatment Plant Sludge in Structural Ceramics BricksGabriel GodoyNo ratings yet

- Ye Et Al. - DoneDocument12 pagesYe Et Al. - DoneAyesha Ferdous MitaNo ratings yet

- Coal Combustion Residues Valorisation Research and DevelopmentDocument9 pagesCoal Combustion Residues Valorisation Research and DevelopmentValeriaSchiavoNo ratings yet

- Waste Management: Rahul Dandautiya, Ajit Pratap SinghDocument12 pagesWaste Management: Rahul Dandautiya, Ajit Pratap Singhjammy_titansNo ratings yet

- Goddey Proposal NdaDocument9 pagesGoddey Proposal Ndagoddey abahNo ratings yet

- Enhancing Asphalt Rheological Behavior andDocument12 pagesEnhancing Asphalt Rheological Behavior andDaríuNo ratings yet

- 3 BrazilDocument7 pages3 BrazilMD. ASIF UR RAHAMANNo ratings yet

- Recent Progress in Environmentally Friendly Geopolymers A ReviewDocument51 pagesRecent Progress in Environmentally Friendly Geopolymers A ReviewMsheer Hasan AliNo ratings yet

- Experimental Investigation On M25 & M30 Concrete With Construction & Demolition (C&D) WasteDocument15 pagesExperimental Investigation On M25 & M30 Concrete With Construction & Demolition (C&D) WasteIJRASETPublicationsNo ratings yet

- Review of Related LiteratureDocument4 pagesReview of Related Literatureparay.kimberlyNo ratings yet

- Hydrogen Gas Production From Waste Water 1670566516Document7 pagesHydrogen Gas Production From Waste Water 1670566516Ian PillayNo ratings yet

- Expensive Soil Stabilization by Using Eggshell PowderDocument8 pagesExpensive Soil Stabilization by Using Eggshell PowderInternational Journal of Innovative Science and Research Technology100% (1)

- 1 s2.0 S0048969718337586 MainextDocument13 pages1 s2.0 S0048969718337586 MainextLaura GarcíaNo ratings yet

- ThesisDocument62 pagesThesisWaquar TaiyebNo ratings yet

- An Investigation On Blast Furnace Stag As Fine Aggregate - 2016 - Journal of CLDocument11 pagesAn Investigation On Blast Furnace Stag As Fine Aggregate - 2016 - Journal of CLAdilson GonçalvesNo ratings yet

- Artigo 7 - Utilization of Drinking Water Treatment Sludge in Concrete Paving Blocks - Microstructural Analysis, Durability and Leaching PropertiesDocument9 pagesArtigo 7 - Utilization of Drinking Water Treatment Sludge in Concrete Paving Blocks - Microstructural Analysis, Durability and Leaching PropertiesJuscimara RodriguesNo ratings yet

- 1 s2.0 S0892687520300546 MainDocument18 pages1 s2.0 S0892687520300546 Mainnehakrishnab200527ceNo ratings yet

- Utilization of Fly Ash in Construction Industries For Environment ManagementDocument6 pagesUtilization of Fly Ash in Construction Industries For Environment ManagementSwanandNo ratings yet

- Impact of Partial Substitution of Cement With Cow Dung Ash and Rice Husk Ash On Performance of ConcreteDocument8 pagesImpact of Partial Substitution of Cement With Cow Dung Ash and Rice Husk Ash On Performance of ConcreteIJRASETPublicationsNo ratings yet

- 52-Alum Sludge ReviewDocument46 pages52-Alum Sludge ReviewBinyam KebedeNo ratings yet

- Aloe VeraDocument10 pagesAloe VeraIrvany PetitNo ratings yet

- 1 s2.0 S0195925519301374 MainDocument11 pages1 s2.0 S0195925519301374 MainbeingatakmalNo ratings yet

- Nanotechnology in Oil and Gas PDFDocument11 pagesNanotechnology in Oil and Gas PDFKhaled HamidNo ratings yet

- Adegoke 2019 J. Phys. Conf. Ser. 1378 022058Document12 pagesAdegoke 2019 J. Phys. Conf. Ser. 1378 022058Camilo CórdobaNo ratings yet

- Mechanical Behaviour of Composite Produced With Quarry DustDocument10 pagesMechanical Behaviour of Composite Produced With Quarry DustMiggy YangNo ratings yet

- Bjet 8xwy2my31Document11 pagesBjet 8xwy2my31Neil Patrick PanganibanNo ratings yet

- Ajib 17 (Q3)Document11 pagesAjib 17 (Q3)NuriyahNo ratings yet

- Tracking Effective Measures For Closed Loop Recycling of Automobile Steel in ChinaDocument7 pagesTracking Effective Measures For Closed Loop Recycling of Automobile Steel in ChinaTasnim Binte Masud UrnishaNo ratings yet

- Recycling of Eggshell Powder and Wheat Straw Ash ADocument17 pagesRecycling of Eggshell Powder and Wheat Straw Ash Akarthiksupaariii0708No ratings yet

- OkonkwoDocument9 pagesOkonkwoSulaiman OluwapelumiNo ratings yet

- 1 s2.0 S2352710222010907 MainDocument20 pages1 s2.0 S2352710222010907 MainDoc Alcides SitoeNo ratings yet

- Reusing Plastic Waste in The ProductionDocument35 pagesReusing Plastic Waste in The ProductionChristian Philip TamioNo ratings yet

- Materials Today: Proceedings: Abdeliazim Mustafa Mohamed, Mohd Azreen Mohd Ariffin, Hichem Smaoui, Mohd Hanim OsmanDocument5 pagesMaterials Today: Proceedings: Abdeliazim Mustafa Mohamed, Mohd Azreen Mohd Ariffin, Hichem Smaoui, Mohd Hanim OsmanTuğçe VuralNo ratings yet

- A Comprehensive Review On The Use of Recycled Concrete AggregateDocument21 pagesA Comprehensive Review On The Use of Recycled Concrete Aggregateskdumka1997No ratings yet

- Saleh 2020Document10 pagesSaleh 2020samuelNo ratings yet

- Study On The Replacement of Construction & Demolition Waste Materials As Fine Aggregates in The Production of Low Strength ConcreteDocument8 pagesStudy On The Replacement of Construction & Demolition Waste Materials As Fine Aggregates in The Production of Low Strength ConcreteIJRASETPublications100% (1)

- Gautam-Saini-2020-Review-Use of Natural Coagulants For Industrial WastewateDocument26 pagesGautam-Saini-2020-Review-Use of Natural Coagulants For Industrial WastewatePastor MogollónNo ratings yet

- Cost Optimization of Geopolymer Concrete PavementDocument11 pagesCost Optimization of Geopolymer Concrete PavementIJRASETPublicationsNo ratings yet

- Nanocellulose For Oil and Gas Field Drilling and Cementing ApplicationDocument10 pagesNanocellulose For Oil and Gas Field Drilling and Cementing Applicationmajd899No ratings yet

- 5-Evaluation of Phase Formation and Physical-Mechanical Properties of Portland Cements Produced With Civil Construction WasteDocument10 pages5-Evaluation of Phase Formation and Physical-Mechanical Properties of Portland Cements Produced With Civil Construction WastequyNo ratings yet

- The Properties and Durability of Self-Leveling and Thixotropic Mortars With Recycled SandDocument27 pagesThe Properties and Durability of Self-Leveling and Thixotropic Mortars With Recycled SandMajd M. KhalilNo ratings yet

- Behavior of Kernelrazzo FloorDocument10 pagesBehavior of Kernelrazzo FloorAmin ZuraiqiNo ratings yet

- 787-Article Text-1196-1-10-20221121Document7 pages787-Article Text-1196-1-10-20221121Shanen CruzNo ratings yet

- 1 s2.0 S0959652622045309 MainDocument17 pages1 s2.0 S0959652622045309 MainLaura MjkNo ratings yet

- Recycling Cupola Slag in Concrete As Partial Replacement of Fine Aggregate For Sustainable ConstructionDocument13 pagesRecycling Cupola Slag in Concrete As Partial Replacement of Fine Aggregate For Sustainable ConstructionIJRASETPublicationsNo ratings yet

- Installation Instructions W10436749 RevC PDFDocument36 pagesInstallation Instructions W10436749 RevC PDFCarlos Alberto VentreNo ratings yet

- Bidding Form Santos 1Document8 pagesBidding Form Santos 1Eldrianne Louie OponNo ratings yet

- Example BOQDocument11 pagesExample BOQmitchbutterworth65No ratings yet

- A World of Composite Technologies BrochureDocument15 pagesA World of Composite Technologies Brochurethorsten_kasterNo ratings yet

- ASTM453Document1 pageASTM453EderNo ratings yet

- IC - Concrete Works - Surveying & Setting-Out, Excavation & FormworkDocument2 pagesIC - Concrete Works - Surveying & Setting-Out, Excavation & FormworkNaison StanleyNo ratings yet

- Thermal and Mechanical Properties of Fiber Reinforced High Performance SCC at Elevated Temperatures - Khaliq, Kodur PDFDocument11 pagesThermal and Mechanical Properties of Fiber Reinforced High Performance SCC at Elevated Temperatures - Khaliq, Kodur PDFMauricio GarcíaNo ratings yet

- Astm 6061-6082-6005 Comparativa ExcelDocument1 pageAstm 6061-6082-6005 Comparativa Exceljuan rodriguezNo ratings yet

- Extrusion Dies Design PDFDocument9 pagesExtrusion Dies Design PDFR.SeetharamaiahNo ratings yet

- Ssej File No.2Document1 pageSsej File No.2muthu kumarNo ratings yet

- Moisture Methods Plastic EN PDFDocument24 pagesMoisture Methods Plastic EN PDFAttef BedaweNo ratings yet

- Steelworkers Face Challenges All Around: Local 2958's Rex Ambrose Talks About Haynes, Union Issues and Buying AmericanDocument8 pagesSteelworkers Face Challenges All Around: Local 2958's Rex Ambrose Talks About Haynes, Union Issues and Buying AmericantrturnerjrNo ratings yet

- KLINGERDocument4 pagesKLINGERJalal AlbadriNo ratings yet

- List of CDC Accreditated Scrap Buyers As of February 29, 2020Document10 pagesList of CDC Accreditated Scrap Buyers As of February 29, 2020Jnb CreativeNo ratings yet

- Section 034501 - Miscellaneous Architectural Precast ConcreteDocument6 pagesSection 034501 - Miscellaneous Architectural Precast ConcreteWENDING HUNo ratings yet

- June 2018 API RP 577 Practice QuestionsDocument4 pagesJune 2018 API RP 577 Practice QuestionsMahmoud Alwasif100% (2)

- Use of Corrugated Metal Pipe For Tunnels-ContechDocument8 pagesUse of Corrugated Metal Pipe For Tunnels-ContechRenanNo ratings yet

- BS - FF SlabDocument7 pagesBS - FF SlabAnonymous YDwBCtsNo ratings yet

- Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument39 pagesCode of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresIshor ThapaNo ratings yet

- Desin Teplets and Cost Analysis (Best)Document102 pagesDesin Teplets and Cost Analysis (Best)SolomonNo ratings yet

- BS en 1759-1 2004Document78 pagesBS en 1759-1 2004AlexandreinspetorNo ratings yet

- MS 4062 Rev A 2008Document6 pagesMS 4062 Rev A 2008Bartek HajaNo ratings yet

- MetalWork - Baileigh 2016Document126 pagesMetalWork - Baileigh 2016Peter DavidsonNo ratings yet

- Bomba de Lodos Listado de PartesDocument59 pagesBomba de Lodos Listado de Partesjesus alfonso fragozo calderonNo ratings yet

- G30-97 (Reapproved 2015) PDFDocument7 pagesG30-97 (Reapproved 2015) PDFHadi HowaidaNo ratings yet

- Roofing Code of Practice PDFDocument379 pagesRoofing Code of Practice PDFAlejandro Segura Pereira100% (1)

- Curtain WallDocument18 pagesCurtain WallTushar JainNo ratings yet

- Method Statement: Sika Carbodur® SystemDocument16 pagesMethod Statement: Sika Carbodur® SystemIki HendroNo ratings yet

- Repair Rate Report ExampleDocument5 pagesRepair Rate Report ExampleDarryl007No ratings yet

- With World Class Quality: GasketsDocument12 pagesWith World Class Quality: GasketsblahblahNo ratings yet