0% found this document useful (0 votes)

3K views9 pagesSubcontracting Scrap Return Process

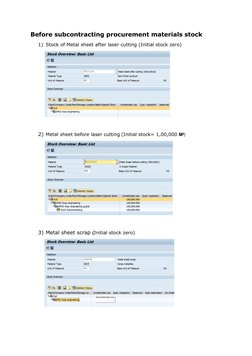

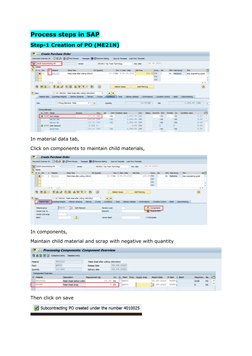

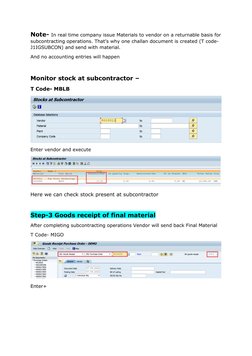

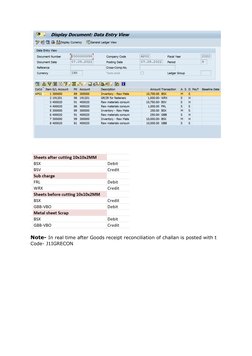

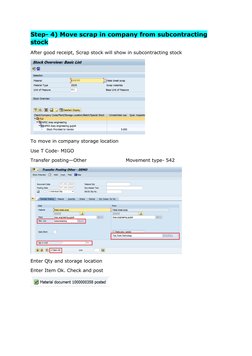

This document describes the scrap return process in subcontracting procurement in SAP. It discusses how a company can send raw materials to a subcontractor to perform operations, and the subcontractor will return the finished goods along with any scrap produced. It outlines the key steps in SAP for creating a purchase order, issuing goods to the subcontractor, receiving the finished goods back along with scrap, and moving the scrap into the company's storage location. It also discusses how to monitor stock at the subcontractor and view the accounting entries for the goods receipt.

Uploaded by

Sahil JadhavCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

3K views9 pagesSubcontracting Scrap Return Process

This document describes the scrap return process in subcontracting procurement in SAP. It discusses how a company can send raw materials to a subcontractor to perform operations, and the subcontractor will return the finished goods along with any scrap produced. It outlines the key steps in SAP for creating a purchase order, issuing goods to the subcontractor, receiving the finished goods back along with scrap, and moving the scrap into the company's storage location. It also discusses how to monitor stock at the subcontractor and view the accounting entries for the goods receipt.

Uploaded by

Sahil JadhavCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd