Professional Documents

Culture Documents

Flyabout Oz1505 Article

Flyabout Oz1505 Article

Uploaded by

coucou foufou0 ratings0% found this document useful (0 votes)

19 views4 pagesOriginal Title

Flyabout_oz1505_article

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views4 pagesFlyabout Oz1505 Article

Flyabout Oz1505 Article

Uploaded by

coucou foufouCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

MODEL AIRPLANE

News

vay

FLYABOUT

by ELBERT J. WEATHERS

Build this flying scale model

which has the proportions to

make it a real performer

HERE is a well designed pre-war American

lightplane that lends itself admirably to

‘model building, It was in the seme category

as the 40 hp Piper Cub, being of the same

General dimensions and performance. ‘The

Flyabout had ample room for two people and

puppy—so stated Aircraft Mechanics, the

manufacturer. Two powerplants were avail~

able: the Continental Ad0 of 38 hp, and the

Szekely of 45 hp, as reproduced’ on this

model. A few specifications covering the

Szekely powered type are:

‘Wingspan 37 ft. 9 in,

‘Wing loading, COIIIBr ibs. per sq. ft

Net "Weight 590_ Tbs

Climb rate 700 ft per min,

Overall. length 21 ft, Tin

Power loading. 218 ibs. per sq. ft

Service Ceiling. 13,000 ft

Cruising speed. <.2.1.1..175 meh

High Speed. 93 meh

‘The scale of the model is 1/20 full size.

All balsa used should be of firm texture un-

less otherwise specified.

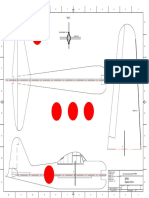

FUSELAGE—Begin by making the two

side frames (shaded on drawing) Use 1/16"

Sa. and 1/16" x 3/82" for these. 1/16" 1/8"

dHbck is required for front portion of the

iower Tonserons. Assemble the two frames

in the Usual way, first installing the cross

braces under the wing position. Notice that a

few of the upper crossbraces, of 1/8" sq.

balsa’ (between nose and rear of cabin), are

Sct low to allow passage of the rubber motor.

When the fuselage frame. is, completed to

this point, cut out the required formers from

1/52!"sheet balsa. Cement ench in their Te

spective pons: The 1/52" x 1/10" string=

rs should now be put in the note as well

the single stringer which runs along the cen=

ter on the bottom

‘Cover these areas with 1/64" sheet balsa,

using three separate pieces in covering the

Bottom as shoven. After cutting the rear rubs

Ber hoole bulkhead to: shape, bend the Tear

rubber motor hook from Ne. 18

nd insert in the bulkhead, following, with

the placing of the unit in the fuselage frame

st rear-as shown,

‘The nose block, of medium-hard balsa, is

made next. Its simply cut t0 shape, Dian

land ‘side views, and. the resting corners

founded off Before cementing it againct the

fuselage frame, drill’ hole for the propeller

shaft to accommodate No. 15 piano wire, The

front bearing isa dural aircraft type rivet,

dnilled for the same wire (running Bt), and

Sinks in the nose block’ with cement ina

counter-drilied hole

‘The dummy Szekely engine can now be

made and cemented in piace. Exch of the

three cylinder units are identics, being built

‘up with smail bits of balsa, Wrsp each with

Wire or thread to represent the cooling fins.

The exhaust. stacks and tappet gear are

merely. lengths of balta dowel assembled

‘with cement. The two valve springs on each

(ert 'to page 83)

23

Flyabout

(Continued from page 23)

cylinder head can be made by wrapping

fine wire on a nail, The. twin-igntion.

sparkplugs on the forward side of each

Gylinder head. are small pieces of belse

‘The cylinder units are cemented on the

nose block as shown on drawings at 12)

degrees apart, Carve the instrument panel

block from soft balsa and cement in post-

tion as the next step.

Te, complete the fuselage, cut from

Ye heat balan the nie Segre See

lared which extend along te eetsse

ides cementing then dice nee

focation a shown on fate Als roe

the lane wie fall si of Wo. 8 whe op

the Rielage aon aking ceo god

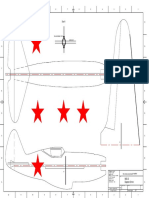

WING—The wing is reletively simple

to build. Cut the 18 required ribs from

| SOL-Whets the best] |

way to hatch bigger

|| profits frgm a

| fhe model

business

We are especially proud of our December record that

showed over 92% of our customers’ orders were

mediately. For our dealers,

T-S!

serviced promptly an

this prompiness spells P-R-O-

We are first to SHOW, STOCK and SHIP new items.

Dealers, Write Us Your Weeds

KRAMER BROTHERS

Er Mole}

Ler eet ae

The Mel Anderson Mfg. Co. announces the pro=

Auction of the Anderson SPITEIRE

STineyeotetandina Occ (61 'elnes ich) fomirvoee

engine for Uscontrol and free flight, designed by

SIE Alesse former Versa net lead fee octon

ofmadith Ercnehetaren

Mel Anderson pledges to the model industry the

finest quolity engines in modal aircraft. history

MEL ANDERSON MFG. CO., INC.

1819 THIRD AVE., LOS ANGELES 6, CALIF.

41/32" sheet balsa. Notch each one for the

MODEL AIRPLANE NEWS = Aprit, 1947

LIST of ENLARGED

WYLAM

MASTERPLANS

available in size 14x20 inches

per page — which is twice the

size published in MODEL AIR-

PLANE NEWS.

35c per enlarged page

Please order by number

For-3

14

PldeD' Gen. Arr

P-400 Layout

bak

08-01 Mitsubishi BETTY

2:22 MARYLAND Gen Are

4:22 MARYLAND Leyout

Sa CATALINA

‘here’ Lancaster t

Aas HELLoIveR

85176 FLYING FORTRESS Gen.Ar.

B-17G FLYING FORTRESS Loyout

6.29" SUPER FORTRESS. Gen.Art.

8-29 SUPER FORTRESS Layout

P61 BLACK WIDOW. Gen.

3-260 MARAUDER ‘Gen Arr

B-26D MARAUDER Loyeut

Sta Layout

P-59A AIRCOMET Gen.A.

1-26 INVADER Gen-Are

KINGCOBRA” Ges.Arr.

DA_KING COBRA Leyout

C37 Boeing. Gen.Arr

3. Layout

Xp-54 SWOOSE GOOSE Gen.Are.

XP-67 ‘MeDonnel.- Gen-he

HISPANO-SUIZA. Engine. Gon. Ar. ln

HISPANO-SUIZA Details

C-54 SKYMASTER Ge

SKYMASTER Layout

ngements Port

Fesel, Scart Ring. Details

Send order and remittance (at 35¢ per

enlarged page) to:

lan Dept.

MODEL AIRPLANE NEWS

551 Fifth Ave, New York 17, N.Y.

86

two main spars. The leading edge is a

length of 1/8" x 1/4” stock, sanded to

proper crossection later. Instead of build~

Ing the wing in one piece, each half is

constructed separately, both being joined

later with a cemented butt joint, Select

good hard stock for the spars. ‘The front

fone, in two sections of course, is 1/16" x

5/16" balsa. The rear spar is 1/16” x 3/16”.

As will be noted, two false spars are

included, each pair’ being the length of

the silerons. Cut the forward pair from

3/32" x 5/16” material, and the rear set

from 3/32" x 3/16" balsa, The trailing

edge is 1/16” x 3/16" stock;

the ribs. ‘To build 2 wing half, slide the

necessary ribs on the spars in’ their ap~

proximate positions. Pin the two spars to

the working surface followed by the trail-

Ing ‘edge. Raise all ‘three members on

blocks the necessary distance from the

‘workbench surface as required. The ribs

are then placed in their correct locations

and cemented,

At the fuselage end of each wing panel

there are two spar sections between the

first two ribs, each the depth of the air-

foil section in their respective locations.

Install these, then cementing the over-

head window in place (010" celluloid),

| following the contour of the ribs. Now

cement the leading edge against the ribs,

sanding it to section shown when dry,

Nex: cut a pair of wingtips from 1/32”

sheet balsa and install. Each aileron is

installed with soft copper or iron wire as

shown. Put 1/2” dihedral in each wing

panel (at tip) by eutting the leading and

trailing edges where indicated, after wing

frame has become a one-piece unit. Use

cement and reinforcing balsa blocks to

securely fasten the material which has |

‘been partially cut through.

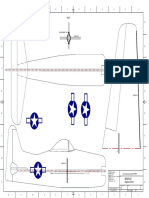

TTAIL, SURFACES—The empennage is

of simple construction yet ragged in serv=

fee, Fin and rudder spars are 1/10" x

3/82" balsa, while the sibs are merely

S/n6” aq. stip balsa, All diagonal cross

Bracing ie of 1/2" ag, bomb. To form

fhe edges, use No. 18 sluminum wire, bent

“foveprrect outline with the fingers a3 eis

‘worked sround from one end to the other

Finw#lly, connect the fin and rudder with

the sie hinge wire used for the ailerons

The stabilizer 1s of the same. general

construction asthe vertical empennage

Selena of 4/30" x 99" tock for al

S/AG" sq. balsa, and 1/32" sq, bamboo 1s

again used for crossbracing.'To complete

connect the elevator to the horizontal

Sabilizer with the wire hinges

LANDING GEAR~This unit is of bam~

boo construction. In building it, use 3/04”

x /16” bamboo, sanded to approximate

streamlined section, Where each strut is

cemented to the fuselage, use cement

freely to, effect good unions. Proceed to

cement the three struts together at the

axle after the fuselage attachment. To

complete it, make two aries from No. 15

piano wire’as shown on plate 2, Where

attached, they are to be bent in a “U”

shape and then wrapped with thread and

cemented. The 3/4” diameter wheels, of

{he air-wheel type, can be purchased

from any model supply house, or turn

from balsa if desired. Hold ‘wheels on

with a small drop of solder.

PROPELLER & MISC. STRUTS—Carve

the propeller from medium-hard balsa.

First blank it out as. shown on plate 1

After it has been carefully sanded to

{goed finish, upon completion of the cary=

jag of the blades, dill = hole through the

to accommodate the No. 15 piano

MODEL AIRPLANE NEWS

notch it for |

ST ing

sed to mate model fying

WF IT WILL RUN, A SP

ore fon, more they SINT. Standart

tasters, Weavy fr. motors. Tro. blade

abort lone delve, 4.00; 3 blade models,

Bit. White for folder. Order ara dealer or diese

STREED ELECTRIC CO.

215 Harmon Face,

JET PROPULSION

IT WILL START IT

*# * Be one of the first to build a real

‘Tusbo-Jet Model Engine. Single-stage

‘centrifugal compressor and turbine. A.

real engine, easily made with ordinary

home workshop equipment.

Complete plans for con-

struction...design formulas

and curves for checking

performance and testing.

‘THE ROTOJET CO. Department 12

BOX 187+ LOS ANGELES 25» CALITORNIA

HELPFUL BOOKS

FOR MODELERS

(See page 60)

| JOYCE REPLACEABLE BLADE PROPELLER

‘A JOYCE PRODUCT

tie design gives utmost thrust per

horsepower expended." Expertly molded in

ivory or black plastic, Joyce props have

‘nue pitch and perfec! aerodynamic balancs

Each package. contains three replaceable

blades {equal to 2 propeller), 2 aluminum

ing dlvce ond 1 aluminum bushing:

‘8!prop $1 10"prop$1.30 11"'prop $1.45

Individval blades orereplaceable at low cost:

B"blade 30¢ 10"blode 40e 11"blo«

JOYCE PRODUCTS, INC.

‘ioneosr srepin vs erahetce et

tear

wire shaft, which is inserted in the pro-

peller later,

‘The main wing struts are made from

1/16" x 1/8” hard bales, each being

sanded to a streamlired crossection. The

small inner brace struts between the main

struts and wing are made from 1/32" x

1/16” bamboo. Notice that a diagonal drag

strut of the same size bamboo is included

in the group (see dotted line across side

window of cabin—side view of fuselage

on plate 1). The brace struts for each side

of the stabilizer are also made from 1/32”

x 1/16" bagaboo. All struts, now ready to

install, are Inid aside until covering is

completed.

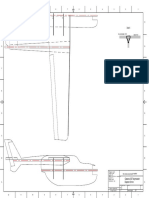

COVERING & ASSEMBLY — Colored

tissue should be used to cover the model.

Begin with the fuselage, which. should

first have installed. the side cabin win-

dows, cut from 010" shst celluloid tis

suggested that the fuselage be a dar

color, using lighter ‘contrasting color

for ‘wing and empennage. Proceed to

cover the wing and tail surfaces in the

usual manner. Now give the paper its

primary tautness by spraying with water,

following with a light coat of clear dope,

‘The assembly may now be started. First

aint the interior structure of the cabin,

with a selected colored dope, including

the instrument panel block. ‘Also paint

the engine at this time, giving it two coats

of glossy black dope. Cement the wing in

is core postion on he fuselage Cutfive

of No, 12 piano wire which forms

the windshield frame between nose upper

cowl and wing leading edge. One is in the

center, ‘while the remaining four” are

grouped in two sets as shown, Make and

Install the dummy balsa ges tank cap on

its 1/32" sheet balsa base. Determine the

Windshield template, using paper. After

getting it to correct guiline (fiat develop-

ment), make the windshield itself from

M10" sheet celluloid. To install it, first

coment it to the center brace, using pins

at upper cowl and wing leading edge tem=

Porarily, and work each half around to

the fuselage sides, cementing ‘well and

pins until dey.

Proceed with the assembly by next in-

stalling all’ the. wing struts’ previously

made. Cement the horizontal stabilizer in

position in the slot provided. The stabi-

Iizer struts (one is on each underside of

the stab.) can now be cemented in posl-

tion, The vertical fin and rudder assembly

ug,nem cemented ot top of fuselage

taking care that it lines up correctly. wi

the horizontal stabilizer. The thread brac~

ing on the tail, also the dummy elevator

‘and rudder control cabies, should now be

cemented in place. Use gray thread for

these. Each should be strung as taut as

possible, being pinned’ in place under

fension ‘until cement is dry

‘Next paint the wing and tail struts with

a properly colored dope to match. yout

Paper color scheme. he propeller shaft

with hook bent in i is now slid forward

from rear side of the nose block through

the block and propeller. Insert two small

brass washers between the two. in this

operation. Bend the shaft over and sink it

in the propeller hub, using cement

BALANCING AND FLYING—First

glide the model after ascertaining that it

is in approximate balance. Bend the ele-

ators down slightly to compensate for a

slight stall. Should it require more nose

weight than the elevators can counteract

for, cement a small piece of solder on

rear side of the nove Block. When gliding

properly, install 2 to 4 strands of 1/8" flat

rubber, giving the propeller a few turns

only for a trial flight. I satisfactory, pro:

ceed to wind it to capacity,

MODEL AIRPLANE NEWS « Api

tt

Redtead

A powerful performer in all events,

the McCoy RED HEAD is prec:-

* sion built for record-making racing

‘on land, water and in the air. $35

Sensational for U-control racing

A

The McCoy RED HEAD, JR. is

the husky “litle brother” of the

RED HEAD “60,” built to the

same standards of quality and de-

sign. For U-control, free fight

and precision flying............$25

PRODUCTS COMPANY

Erte reo

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Alco Sport Oz12232 ArticleDocument1 pageAlco Sport Oz12232 Articlecoucou foufouNo ratings yet

- Gregor Oz2005 ArticleDocument2 pagesGregor Oz2005 Articlecoucou foufouNo ratings yet

- Flyabout Oz1505Document3 pagesFlyabout Oz1505coucou foufouNo ratings yet

- Alert Oz12473 ArticleDocument1 pageAlert Oz12473 Articlecoucou foufouNo ratings yet

- AMA BETA Bernoulli-02Document5 pagesAMA BETA Bernoulli-02coucou foufouNo ratings yet

- FK8 Oz1681 ArticleDocument3 pagesFK8 Oz1681 Articlecoucou foufouNo ratings yet

- All American Pan-Am Plane Oz8518 ArticleDocument2 pagesAll American Pan-Am Plane Oz8518 Articlecoucou foufouNo ratings yet

- P 51 DdepronDocument10 pagesP 51 Ddeproncoucou foufouNo ratings yet

- NnChuck Cessna 172Document1 pageNnChuck Cessna 172coucou foufouNo ratings yet

- ZerodepronDocument10 pagesZerodeproncoucou foufouNo ratings yet

- Guillow Arrow Oz1467Document2 pagesGuillow Arrow Oz1467coucou foufouNo ratings yet

- Junkeref 112 DepronDocument10 pagesJunkeref 112 Deproncoucou foufouNo ratings yet

- Mig 3Document10 pagesMig 3coucou foufouNo ratings yet

- BearcatdepronDocument10 pagesBearcatdeproncoucou foufouNo ratings yet

- HellcatdepronDocument10 pagesHellcatdeproncoucou foufouNo ratings yet

- p40 DepronDocument10 pagesp40 Deproncoucou foufouNo ratings yet

- Impression de La Page EntièreDocument8 pagesImpression de La Page Entièrecoucou foufouNo ratings yet

- Cessna 337 DepronDocument10 pagesCessna 337 Deproncoucou foufouNo ratings yet

- FW 190 DepronDocument10 pagesFW 190 Deproncoucou foufouNo ratings yet

- Laird LC-DE Speedwing Oz1522Document1 pageLaird LC-DE Speedwing Oz1522coucou foufouNo ratings yet

- HELICE ElasticDocument10 pagesHELICE Elasticcoucou foufouNo ratings yet

- Albsperber Oz13269 Parts List enDocument1 pageAlbsperber Oz13269 Parts List encoucou foufouNo ratings yet