Professional Documents

Culture Documents

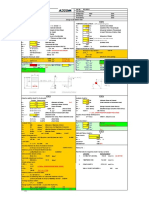

APCS-20A Hempel

Uploaded by

arjunmohananOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APCS-20A Hempel

Uploaded by

arjunmohananCopyright:

Available Formats

Product Data

HEMPADUR 15590

15590: BASE 15599: CURING AGENT 95100

Description: HEMPADUR 15590 is a two-component epoxy primer coating especially for use on surfaces exposed

to severe abrasion.

Recommended use: As a blast primer for heavy duty epoxy systems on submerged and non-submerged areas according to

specification.

Service temperature: Maximum, dry exposure only: 140°C/284°F

Certificates/Approvals:

Availability: Part of Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Shade nos/Colours: 56880 / Red.

Finish: Semi-gloss

Volume solids, %: 44 ± 1

Theoretical spreading rate: 11 m2/l [441.1 sq.ft./US gallon] - 40 micron/1.6 mils

Flash point: 26 °C [78.8 °F]

Specific gravity: 1.3 kg/litre [11 lbs/US gallon]

Surface-dry: 1 hour(s) 20°C/68°F

Through-dry: 3.5 hour(s) 20°C/68°F

Fully cured: 7 day(s) 20°C/68°F

VOC content: 499 g/l [4.1 lbs/US gallon]

Shelf life: 1 year for BASE and 3 years for CURING AGENT (stored in closed container) (25°C/77°F) from time of

production. Depending on storage conditions, mechanical stirring may be necessary before usage.

- The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

APPLICATION DETAILS:

Version, mixed product: 15590

Mixing ratio: BASE 15599: CURING AGENT 95100

15 : 4 by volume

Application method: Airless spray / Air spray

Thinner (max.vol.): 08450 (5%) / 08450 (15%)

Pot life: 2 hour(s) 20°C/68°F

Nozzle orifice: 0.017 - 0.019 "

Nozzle pressure: 150 bar [2175 psi]

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: HEMPEL'S TOOL CLEANER 99610

Indicated film thickness, dry: 40 micron [1.6 mils]

Indicated film thickness, wet: 100 micron [4 mils]

Overcoat interval, min: see REMARKS overleaf

Overcoat interval, max: see REMARKS overleaf

-

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Safety Data Sheets and follow all local or national safety regulations.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Date of issue: September 2017 Page: 1/2

Product Data

HEMPADUR 15590

SURFACE PREPARATION: New steel: Remove oil and grease etc. thoroughly with suitable detergent. Remove salts and other

contaminants by high pressure fresh water cleaning. Abrasive blasting to minimum Sa 2½ (ISO 8501-1:

2007) with a surface profile corresponding to Rugotest No. 3, N9a to N10, preferably BN9a to BN10,

Keane-Tator Comparator, 2.0 G/S or ISO Comparator, Medium (G). After blasting, clean the surface

carefully from abrasives and dust.

Repair and maintenance: Remove oil and grease etc. thoroughly with suitable detergent. Remove

salts and other contaminants by high pressure fresh water cleaning. On pit-corroded surfaces,

excessive amounts of salt residues may call for high pressure water jetting, wet abrasive blasting or,

alternatively, dry abrasive blasting, high pressure fresh water hosting, drying, and finally dry abrasive

blasting again.

APPLICATION CONDITIONS: Apply only on a dry and clean surface with a temperature above the dew point to avoid condensation.

Minimum temperature for application is 5°C/41°F, preferably above 10°C/50°F. Relative humidity

maximum 80 %, preferably below 60%.

The temperature of the paint itself should be: Between 15°C (59°F) and 25°C (77°F).

In confined spaces provide adequate ventilation during application and drying.

PRECEDING COAT: None.

SUBSEQUENT COAT: Recommended systems are: HEMPADUR MULTI-STRENGTH 35530, HEMPADUR MULTI-

STRENGTH 45751.

HEMPADUR 15590 can be used as a blast primer.

REMARKS:

Film thicknesses/thinning: May be specified in another film thickness than indicated depending on purpose and area of use. This

will alter spreading rate and may influence drying time and overcoating interval. Normal range dry is:

30-50 micron/1.2-2 mils.

Overcoating: Overcoating intervals related to later conditions of exposure: If the maximum overcoating interval is

exceeded, roughening of the surface is necessary to ensure intercoat adhesion.

Before overcoating after exposure in contaminated environment, clean the surface thoroughly with high

pressure fresh water hosing and allow drying.

A specification supersedes any guideline overcoat intervals indicated in the table.

Environment Atmospheric, medium

Surface temperature: 10°C (50°F) 20°C (68°F) 30°C (86°F)

Min Max Min Max Min Max

HEMPADUR 18 h 67½ d 8h 30 d 5h 20 d

Environment Immersion

HEMPADUR 18 h 67½ d 8h 30 d 5h 20 d

NR = Not Recommended, Ext. = Extended, m = minute(s), h = hour(s), d = day(s)

Overcoating note: The coating is to be applied in a dry film thickness as near as possible to the specified: 40 micron.

Film formation of each coat has to be of good quality, free from defects such as pinholes and without

any dry spray.

Drying and curing conditions have to be according to APPLICATION CONDITIONS until full curing has

been obtained.

No kind of surface contamination must exist except loose dust, abrasives, loose dry-spray, which is

possible to remove by vacuum cleaning before overcoating.

The surface MUST be completely clean before overcoating. The coating is to be checked carefully and

should have no patchy, whitish, and/or greasy formation, which can hinder adhesion of the subsequent

coat.

Exudation of the curing agent causes the mentioned patchy, whitish, and/or greasy formation, which

will take place if the product is applied at low temperatures without proper induction time and/or if the

coating is exposed to water (rain, condensation) during drying and curing.

Overcoating intervals: Overcoating intervals: According to specification.

The stated minimum overcoating interval may be halved for areas not intended for water immersion.

Depending on actual local conditions, extended maximum overcoating interval may apply. Contact

HEMPEL for more information. If the maximum over coating interval is exceeded, roughening of the

surface is necessary to ensure intercoat adhesion. Before overcoating after exposure in contaminated

environment, clean the surface thoroughly by high pressure water cleaning and allow drying. The

product will resist a hosing down of the surface 8 hours after application at a steel temperature of

20°C/68°F.

Note: HEMPADUR 15590 For professional use only.

ISSUED BY: HEMPEL A/S 1559056880

X Move PDS Disclaimer to Second page

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet

represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions

of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed

in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said

GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Date of issue: September 2017 Page: 2/2

Product Data 1/2

HEMPEL’S EPOXY RESIN 05500

BASE 05509 with CURING AGENT 98500

Description: HEMPEL’S EPOXY RESIN 05500 is a solvent-free, two-component, high build polyamine

cured epoxy paint, which cures to a coating with excellent resistance to fresh water, sea

water, oil cargoes and to abrasion.

Recommended use: As resin for a coating system which, in combination with glassfibre mats ("hand lay-up"

system), is used for re-bottoming of steel storage tanks or for reinforcing the interior of

concrete storage tanks.

Service temperatures: Dry exposure: Maximum 120°C/248°F

In water service: Resists normal ambient temperatures

Wet service temperatures, other liquids: contact HEMPEL

Certificates/Approvals: Saudi Aramco approved product under Engineering Standard APCS-20A.

Certified by the Saudi Arabian Standards Organisation (SASO) for use in potable water.

Availability: Not included in Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Colours/Shade nos: Transparent/00000

Finish: Glossy

Volume solids, %: 100

Theoretical spreading rate: 2 m²/litre - 500 micron

81.5 sq.ft/US gallon - 20 mils

Flash point: > 100°C/212°F

Specific gravity: 1.1 kg/litre - 9.2 lbs/US gallon

Through dry: 24 (approx.) hours at 20°C/68°F

Fully cured: 7 days at 20°C/68°F

The physical constants stated are nominal data according to the HEMPEL Group's approved formulas. They are

subject to normal manufacturing tolerances and where stated, being standard deviation according to ISO 3534-1.

APPLICATION DETAILS:

Mixing ratio for 05500: Base 05509 : Curing agent 98500

1.8 : 1 by volume

Application method: Roller/brush (See separate APPLICATION INSTRUCTIONS)

Thinner (max.vol.): Do not dilute

Pot life: 4 hours (20°C/68°F)

Cleaning of tools: HEMPEL’S TOOL CLEANER 99610

Indicated film thickness, dry: 500 micron/20 mils (see REMARKS overleaf)

Indicated film thickness, wet: 500 micron/20 mils

Recoat interval, min: 24 hours (20°C/68°F)

Recoat interval, max: 3 days (20°C/68°F)

Safety: Handle with care. Before and during use, observe all safety labels on packaging and

paint containers, consult HEMPEL Material Safety Data Sheets and follow all local or

national safety regulations. Avoid inhalation, avoid contact with skin and eyes, and do

not swallow. Take precautions against possible risks of fire or explosions as well as

protection of the environment. Apply only in well ventilated areas.

Issued: January 2005 Page 1 of 2

HEMPEL

Product Data Sheet

2/2

HEMPEL’S EPOXY RESIN 05500

SURFACE Steel: Abrasive blasting to Sa 2½ or Sa 3, depending on the area of use.

PREPARATION: Surface profile corresponding to Rugotest No. 3 BN11, Keane-Tator Comparator 5.5 G/S, or ISO

Comparator, Coarse (G). Oil and grease must be removed with suitable detergent, salt and other

contaminants by (high pressure) fresh water cleaning prior to blasting. After blasting clean the

surface carefully from abrasives and dust. The blasted and cleaned surface may advantageously

be primed with HEMPADUR 15590.

Concrete: Remove slip agent and other possible contaminants by emulsion cleaning followed by

high pressure hosing with fresh water. Remove scum layer and loose matter to a hard, rough and

uniform surface, preferably by abrasive blasting, possibly by other mechanical treatment, flame

cleaning or acid etching. Seal surface with suitable sealer, e.g. HEMPADUR SEALER 05990 (see

Product Data Sheet for 05990).

For further information in respect of surface preparation, reference is made to the separate

APPLICATION INSTRUCTIONS or Hempel's painting specification.

APPLICATION Use only where curing can proceed at temperatures above 10°C.

CONDITIONS: The temperature of the substrate and the paint itself should be above 15°C to secure proper

application properties.

Apply on a dry and clean surface with a temperature above the dew point to avoid condensation.

PRECEDING None, HEMPADUR SEALER 05990 or HEMPADUR 15590.

COAT:

SUBSEQUENT None or according to specification.

COAT:

REMARKS:

Weathering/service The natural tendency of epoxy coatings to chalk in outdoor exposure and to become more

temperatures: sensitive to mechanical damage and chemical exposure at elevated temperatures

is also reflected in this product.

Film thickness: May be specified in another film thickness than indicated, depending on purpose and area of use.

This will alter spreading rate and may influence drying time and recoating intervals.

Normal range dry is 300-600 micron/12-24 mils. Further reference is made to the separate

APPLICATION INSTRUCTIONS.

Recoating: If the maximum recoating interval is exceeded, roughening of the surface is necessary to ensure

intercoat adhesion.

Before recoating after exposure in a contaminated environment, clean surface thoroughly with high

pressure fresh water hosing and allow to dry.

Note: HEMPEL’S EPOXY RESIN 05500 is for professional use only.

ISSUED BY: HEMPEL PAINTS (SAUDI ARABIA) W.L.L. - 0550000000CS001

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” in the HEMPEL Book.

Data, specifications, directions and recommendations given in this data sheet represent only test results or

experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appro-

priateness under the actual conditions of any intended use of the Products herein must be determined exclu-

sively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF

SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed in writing. The Manufacturer and Seller

disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence,

except as expressed in said GENERAL CONDITIONS for all results, injury or direct or consequential losses or

damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Issued: January 2005 Page 2 of 2

Product Data Sheet

Product Data 1/1

HEMPEL’S GLASSFIBRE MAT 690SA

Description: HEMPEL'S GLASSFIBRE MAT 690SA is an emulsion bonded, glassfibre chopped strand

mat made from E-glass, with good surface bonding properties and a high strand

integrity.

Recommended use: As a glassfibre reinforcement for HEMPEL’S EPOXY RESIN 05500 tank linings, following

the “hand lay-up” method.

Availability: Not included in Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Weight: 450 gram/m² (BS 3496)

Moisture content: 0.5% (ISO 3344)

Loss on ignition: 4.8%

APPLICATION DETAILS: For information in regard to the application details, reference is made to HEMPEL’s

product data sheet for HEMPEL’S EPOXY RESIN 05500 and the relevant painting

specification. Contact HEMPEL for further advise.

Note: HEMPEL’S GLASSFIBRE MAT 690SA is for professional use only.

Safety: Handle with care. Before and during use, observe all safety labels on packaging and

paint containers, consult HEMPEL Material Safety Data Sheets and follow all local or

national safety regulations. Avoid inhalation, avoid contact with skin and eyes, and do

not swallow. Take precautions against possible risks of fire or explosions as well as

protection of the environment. Apply only in well ventilated areas.

ISSUED BY: HEMPEL PAINTS (SAUDI ARABIA) W.L.L. - 690SA

This Product Data Sheet supersedes those previously issued. For definition and scope, see explanatory notes to

applicable Product Data Sheets.

Data, specifications, directions and recommendations given in this data sheet represent only test results or experience

obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under

the actual conditions of any intended use of the Products herein must be determined exclusively by the Buyer and/or

User. The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF

SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed in writing. The Manufacturer and Seller disclaim, and

Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in

said GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of

the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Issued: January 2005 Page 1 of 1

HEMPEL

Product Data Sheet

Product Data 1/2

HEMPEL’S EPOXY RESIN 05500

BASE 05509 with CURING AGENT 98500

Description: HEMPEL’S EPOXY RESIN 05500 is a solvent-free, two-component, high build polyamine

cured epoxy paint, which cures to a coating with excellent resistance to fresh water, sea

water, oil cargoes and to abrasion.

Recommended use: As resin for a coating system which, in combination with glassfibre mats ("hand lay-up"

system), is used for re-bottoming of steel storage tanks or for reinforcing the interior of

concrete storage tanks.

Service temperatures: Dry exposure: Maximum 120°C/248°F

In water service: Resists normal ambient temperatures

Wet service temperatures, other liquids: contact HEMPEL

Certificates/Approvals: Saudi Aramco approved product under Engineering Standard APCS-20A.

Certified by the Saudi Arabian Standards Organisation (SASO) for use in potable water.

Availability: Not included in Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Colours/Shade nos: Transparent/00000

Finish: Glossy

Volume solids, %: 100

Theoretical spreading rate: 2 m²/litre - 500 micron

81.5 sq.ft/US gallon - 20 mils

Flash point: > 100°C/212°F

Specific gravity: 1.1 kg/litre - 9.2 lbs/US gallon

Through dry: 24 (approx.) hours at 20°C/68°F

Fully cured: 7 days at 20°C/68°F

The physical constants stated are nominal data according to the HEMPEL Group's approved formulas. They are

subject to normal manufacturing tolerances and where stated, being standard deviation according to ISO 3534-1.

APPLICATION DETAILS:

Mixing ratio for 05500: Base 05509 : Curing agent 98500

1.8 : 1 by volume

Application method: Roller/brush (See separate APPLICATION INSTRUCTIONS)

Thinner (max.vol.): Do not dilute

Pot life: 4 hours (20°C/68°F)

Cleaning of tools: HEMPEL’S TOOL CLEANER 99610

Indicated film thickness, dry: 500 micron/20 mils (see REMARKS overleaf)

Indicated film thickness, wet: 500 micron/20 mils

Recoat interval, min: 24 hours (20°C/68°F)

Recoat interval, max: 3 days (20°C/68°F)

Safety: Handle with care. Before and during use, observe all safety labels on packaging and

paint containers, consult HEMPEL Material Safety Data Sheets and follow all local or

national safety regulations. Avoid inhalation, avoid contact with skin and eyes, and do

not swallow. Take precautions against possible risks of fire or explosions as well as

protection of the environment. Apply only in well ventilated areas.

Issued: January 2005 Page 1 of 2

HEMPEL

Product Data Sheet

2/2

HEMPEL’S EPOXY RESIN 05500

SURFACE Steel: Abrasive blasting to Sa 2½ or Sa 3, depending on the area of use.

PREPARATION: Surface profile corresponding to Rugotest No. 3 BN11, Keane-Tator Comparator 5.5 G/S, or ISO

Comparator, Coarse (G). Oil and grease must be removed with suitable detergent, salt and other

contaminants by (high pressure) fresh water cleaning prior to blasting. After blasting clean the

surface carefully from abrasives and dust. The blasted and cleaned surface may advantageously

be primed with HEMPADUR 15590.

Concrete: Remove slip agent and other possible contaminants by emulsion cleaning followed by

high pressure hosing with fresh water. Remove scum layer and loose matter to a hard, rough and

uniform surface, preferably by abrasive blasting, possibly by other mechanical treatment, flame

cleaning or acid etching. Seal surface with suitable sealer, e.g. HEMPADUR SEALER 05990 (see

Product Data Sheet for 05990).

For further information in respect of surface preparation, reference is made to the separate

APPLICATION INSTRUCTIONS or Hempel's painting specification.

APPLICATION Use only where curing can proceed at temperatures above 10°C.

CONDITIONS: The temperature of the substrate and the paint itself should be above 15°C to secure proper

application properties.

Apply on a dry and clean surface with a temperature above the dew point to avoid condensation.

PRECEDING None, HEMPADUR SEALER 05990 or HEMPADUR 15590.

COAT:

SUBSEQUENT None or according to specification.

COAT:

REMARKS:

Weathering/service The natural tendency of epoxy coatings to chalk in outdoor exposure and to become more

temperatures: sensitive to mechanical damage and chemical exposure at elevated temperatures

is also reflected in this product.

Film thickness: May be specified in another film thickness than indicated, depending on purpose and area of use.

This will alter spreading rate and may influence drying time and recoating intervals.

Normal range dry is 300-600 micron/12-24 mils. Further reference is made to the separate

APPLICATION INSTRUCTIONS.

Recoating: If the maximum recoating interval is exceeded, roughening of the surface is necessary to ensure

intercoat adhesion.

Before recoating after exposure in a contaminated environment, clean surface thoroughly with high

pressure fresh water hosing and allow to dry.

Note: HEMPEL’S EPOXY RESIN 05500 is for professional use only.

ISSUED BY: HEMPEL PAINTS (SAUDI ARABIA) W.L.L. - 0550000000CS001

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” in the HEMPEL Book.

Data, specifications, directions and recommendations given in this data sheet represent only test results or

experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appro-

priateness under the actual conditions of any intended use of the Products herein must be determined exclu-

sively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF

SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed in writing. The Manufacturer and Seller

disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence,

except as expressed in said GENERAL CONDITIONS for all results, injury or direct or consequential losses or

damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Issued: January 2005 Page 2 of 2

Product Data Sheet

Product Data

HEMPEL’S GLASSFIBRE

SURFACING TISSUE 691SA

Description: HEMPEL’S GLASSFIBRE SURFACING TISSUE 691SA is composed of staple glassfibre,

arranged in a fibrous veil-like pattern, held together by a polystyrene binder. It is used as a

backing to add strength to the gel coat and as a final layer to improve appearance.

Recommended use: As a surfacing tissue for HEMPEL’S glassfibre reinforced tank linings; HEMPEL’S EPOXY

RESIN 05500 and HEMPADUR SPRAYFIBRE 35890.

Used as surfacing tissue in Saudi Aramco Engineering Standard APCS 20B.

Availability: Not included in Group Assortment. Local availability subject to confirmation.

Physical constants:

Nominal thickness: 0.3 mm

Nominal density: 30 gram/m2

Application details: For information in regard to the application details, reference is made to HEMPEL’s product

data sheet of HEMPEL’S EPOXY RESIN 05500 or HEMPADUR SPRAYFIBRE 35890 and the

relevant painting specification. Contact HEMPEL for further advise.

Safety: Handle with care. Before and during use, observe all safety labels on packaging and

paint containers, consult Hempel Material Safety Data Sheets and follow all local

or national safety regulations.

Note: HEMPEL’S GLASSFIBRE SURFACING TISSUE 691SA is for professional use only.

Issued by: HEMPEL PAINTS (SAUDI ARABIA) W.L.L. – 691SA

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet

represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions

of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL’s GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed

in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said

GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Issued: October 2016 Page: 1/1

Product Data 1/2

HEMPEL’S EPOXY RESIN 05500

BASE 05509 with CURING AGENT 98500

Description: HEMPEL’S EPOXY RESIN 05500 is a solvent-free, two-component, high build polyamine

cured epoxy paint, which cures to a coating with excellent resistance to fresh water, sea

water, oil cargoes and to abrasion.

Recommended use: As resin for a coating system which, in combination with glassfibre mats ("hand lay-up"

system), is used for re-bottoming of steel storage tanks or for reinforcing the interior of

concrete storage tanks.

Service temperatures: Dry exposure: Maximum 120°C/248°F

In water service: Resists normal ambient temperatures

Wet service temperatures, other liquids: contact HEMPEL

Certificates/Approvals: Saudi Aramco approved product under Engineering Standard APCS-20A.

Certified by the Saudi Arabian Standards Organisation (SASO) for use in potable water.

Availability: Not included in Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Colours/Shade nos: Transparent/00000

Finish: Glossy

Volume solids, %: 100

Theoretical spreading rate: 2 m²/litre - 500 micron

81.5 sq.ft/US gallon - 20 mils

Flash point: > 100°C/212°F

Specific gravity: 1.1 kg/litre - 9.2 lbs/US gallon

Through dry: 24 (approx.) hours at 20°C/68°F

Fully cured: 7 days at 20°C/68°F

The physical constants stated are nominal data according to the HEMPEL Group's approved formulas. They are

subject to normal manufacturing tolerances and where stated, being standard deviation according to ISO 3534-1.

APPLICATION DETAILS:

Mixing ratio for 05500: Base 05509 : Curing agent 98500

1.8 : 1 by volume

Application method: Roller/brush (See separate APPLICATION INSTRUCTIONS)

Thinner (max.vol.): Do not dilute

Pot life: 4 hours (20°C/68°F)

Cleaning of tools: HEMPEL’S TOOL CLEANER 99610

Indicated film thickness, dry: 500 micron/20 mils (see REMARKS overleaf)

Indicated film thickness, wet: 500 micron/20 mils

Recoat interval, min: 24 hours (20°C/68°F)

Recoat interval, max: 3 days (20°C/68°F)

Safety: Handle with care. Before and during use, observe all safety labels on packaging and

paint containers, consult HEMPEL Material Safety Data Sheets and follow all local or

national safety regulations. Avoid inhalation, avoid contact with skin and eyes, and do

not swallow. Take precautions against possible risks of fire or explosions as well as

protection of the environment. Apply only in well ventilated areas.

Issued: January 2005 Page 1 of 2

HEMPEL

Product Data Sheet

2/2

HEMPEL’S EPOXY RESIN 05500

SURFACE Steel: Abrasive blasting to Sa 2½ or Sa 3, depending on the area of use.

PREPARATION: Surface profile corresponding to Rugotest No. 3 BN11, Keane-Tator Comparator 5.5 G/S, or ISO

Comparator, Coarse (G). Oil and grease must be removed with suitable detergent, salt and other

contaminants by (high pressure) fresh water cleaning prior to blasting. After blasting clean the

surface carefully from abrasives and dust. The blasted and cleaned surface may advantageously

be primed with HEMPADUR 15590.

Concrete: Remove slip agent and other possible contaminants by emulsion cleaning followed by

high pressure hosing with fresh water. Remove scum layer and loose matter to a hard, rough and

uniform surface, preferably by abrasive blasting, possibly by other mechanical treatment, flame

cleaning or acid etching. Seal surface with suitable sealer, e.g. HEMPADUR SEALER 05990 (see

Product Data Sheet for 05990).

For further information in respect of surface preparation, reference is made to the separate

APPLICATION INSTRUCTIONS or Hempel's painting specification.

APPLICATION Use only where curing can proceed at temperatures above 10°C.

CONDITIONS: The temperature of the substrate and the paint itself should be above 15°C to secure proper

application properties.

Apply on a dry and clean surface with a temperature above the dew point to avoid condensation.

PRECEDING None, HEMPADUR SEALER 05990 or HEMPADUR 15590.

COAT:

SUBSEQUENT None or according to specification.

COAT:

REMARKS:

Weathering/service The natural tendency of epoxy coatings to chalk in outdoor exposure and to become more

temperatures: sensitive to mechanical damage and chemical exposure at elevated temperatures

is also reflected in this product.

Film thickness: May be specified in another film thickness than indicated, depending on purpose and area of use.

This will alter spreading rate and may influence drying time and recoating intervals.

Normal range dry is 300-600 micron/12-24 mils. Further reference is made to the separate

APPLICATION INSTRUCTIONS.

Recoating: If the maximum recoating interval is exceeded, roughening of the surface is necessary to ensure

intercoat adhesion.

Before recoating after exposure in a contaminated environment, clean surface thoroughly with high

pressure fresh water hosing and allow to dry.

Note: HEMPEL’S EPOXY RESIN 05500 is for professional use only.

ISSUED BY: HEMPEL PAINTS (SAUDI ARABIA) W.L.L. - 0550000000CS001

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” in the HEMPEL Book.

Data, specifications, directions and recommendations given in this data sheet represent only test results or

experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appro-

priateness under the actual conditions of any intended use of the Products herein must be determined exclu-

sively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF

SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed in writing. The Manufacturer and Seller

disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence,

except as expressed in said GENERAL CONDITIONS for all results, injury or direct or consequential losses or

damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Issued: January 2005 Page 2 of 2

Product Data Sheet

You might also like

- Pds Hempadur 15590 En-GbDocument2 pagesPds Hempadur 15590 En-Gbyasararafat12010No ratings yet

- HempelDocument2 pagesHempelAnuar SalehNo ratings yet

- Hempaline Prepare 130Document2 pagesHempaline Prepare 130CRISTIAN SILVIU IANUCNo ratings yet

- PDS Hempadur Fast Dry 15560 en-GBDocument2 pagesPDS Hempadur Fast Dry 15560 en-GBErwin MalmsteinNo ratings yet

- MS GF 35870 en-GBDocument2 pagesMS GF 35870 en-GBLinnie McleodNo ratings yet

- HEMPADUR ZINC 15360 15360 en-GB PDFDocument2 pagesHEMPADUR ZINC 15360 15360 en-GB PDFErwin MalmsteinNo ratings yet

- PDS Hempadur Multi-Strength 35842 en-GBDocument2 pagesPDS Hempadur Multi-Strength 35842 en-GBIfrahimNo ratings yet

- HEMPADUR PRIMER 15300 Product Data SheetDocument3 pagesHEMPADUR PRIMER 15300 Product Data SheetvitharvanNo ratings yet

- High-Zinc Epoxy Primer Product DataDocument2 pagesHigh-Zinc Epoxy Primer Product DatasizmaruNo ratings yet

- Pds Hempadur 35900 En-GbDocument2 pagesPds Hempadur 35900 En-Gbluisbarrios104No ratings yet

- PDS Hempatex Hi-Build 46330 en-GBDocument2 pagesPDS Hempatex Hi-Build 46330 en-GBSARAVANANo ratings yet

- HEMPADUR MULTI-STRENGTH GF 35870 Product Data SheetDocument3 pagesHEMPADUR MULTI-STRENGTH GF 35870 Product Data SheetAnuar SalehNo ratings yet

- HEMPADUR 47182 47182 en-GB PDFDocument3 pagesHEMPADUR 47182 47182 en-GB PDFwilfran villegasNo ratings yet

- PDS en-GB 45751Document2 pagesPDS en-GB 45751Anuar SalehNo ratings yet

- Hempadur 15553 two-component epoxy primerDocument2 pagesHempadur 15553 two-component epoxy primerachusanachuNo ratings yet

- Hempadur 15553Document2 pagesHempadur 15553EngTamerNo ratings yet

- Shopprimer Product Data SheetDocument2 pagesShopprimer Product Data SheetErikas Abepa100% (1)

- Hempadur Avantguard 550Document2 pagesHempadur Avantguard 550Anuar SalehNo ratings yet

- PDS Hempaprime Multi 500 Summer en-GBDocument2 pagesPDS Hempaprime Multi 500 Summer en-GBFreddyNo ratings yet

- PDS Hempadur Multi-Strength 45753 en-GBDocument2 pagesPDS Hempadur Multi-Strength 45753 en-GBJosip LasanNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- PDS en-GB 16490Document2 pagesPDS en-GB 16490Anuar SalehNo ratings yet

- PDS HEMPATHANE FAST DRY 55750 en-GBDocument2 pagesPDS HEMPATHANE FAST DRY 55750 en-GBEli KhawNo ratings yet

- PDS Hempaprime Multi 500 Winter en-GBDocument2 pagesPDS Hempaprime Multi 500 Winter en-GBFreddyNo ratings yet

- HEMPADUR MULTI-STRENGTH 35530 BlackDocument2 pagesHEMPADUR MULTI-STRENGTH 35530 BlackRuby Faith EspinosaNo ratings yet

- Pds Hempadur 85671Document2 pagesPds Hempadur 85671Namta GeorgeNo ratings yet

- Protect industrial surfaces with HEMPADUR 85671Document2 pagesProtect industrial surfaces with HEMPADUR 85671EkoAndriAntoNo ratings yet

- Product Data: Hempadur Multi-Strength 35530Document2 pagesProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarNo ratings yet

- Hempel - S Zinc Primer 16490Document2 pagesHempel - S Zinc Primer 16490Haryanto RNo ratings yet

- PDS Hempadur Mio 47950Document2 pagesPDS Hempadur Mio 47950VIKAS DAHIYA0% (2)

- PDS Hempel's Speed-Dry Primer 13770 en-GBDocument2 pagesPDS Hempel's Speed-Dry Primer 13770 en-GBSaul Antayhua0% (1)

- Hempadur Fast Dry 17410 En-GbDocument2 pagesHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaNo ratings yet

- Pds Hempel's Shopprimer e 15275 En-GbDocument2 pagesPds Hempel's Shopprimer e 15275 En-GbErwin MalmsteinNo ratings yet

- Pds Hempadur 85671 En-GbDocument2 pagesPds Hempadur 85671 En-GbPrabath Nilan GunasekaraNo ratings yet

- Product Data Sheet for HEMPADUR 85671 Epoxy CoatingDocument3 pagesProduct Data Sheet for HEMPADUR 85671 Epoxy CoatingvitharvanNo ratings yet

- HEMPATEX HI-BUILD 46410 Product Data SheetDocument2 pagesHEMPATEX HI-BUILD 46410 Product Data SheetMohamed ChelfatNo ratings yet

- Hempadur Zinc 17340 17340Document2 pagesHempadur Zinc 17340 17340Sachin NambiarNo ratings yet

- PDS Hempadur Hi-Build 45200 en-GBDocument2 pagesPDS Hempadur Hi-Build 45200 en-GBvitharvanNo ratings yet

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 pagesHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- Hempalin Enamel 52140Document2 pagesHempalin Enamel 52140EngTamerNo ratings yet

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDocument2 pagesHempel'S Vinyl Ester GF 35910: Description: Recommended UseSurendra KumarNo ratings yet

- Hempaprime Multi 500 Summer 45950Document3 pagesHempaprime Multi 500 Summer 45950omar alkarabliehNo ratings yet

- PDS HEMPADUR 85671 en-GB PDFDocument2 pagesPDS HEMPADUR 85671 en-GB PDFMohamed Farhan B PositiveNo ratings yet

- HEMPEL'S VINYL ESTER GF 35910 Product Data SheetDocument2 pagesHEMPEL'S VINYL ESTER GF 35910 Product Data SheetEngTamerNo ratings yet

- PDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBDocument2 pagesPDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBEli KhawNo ratings yet

- Product Data: HEMPADUR 85671Document2 pagesProduct Data: HEMPADUR 85671EngTamerNo ratings yet

- HEMPADUR SPEED-DRY ZP 500 Product Data SheetDocument3 pagesHEMPADUR SPEED-DRY ZP 500 Product Data SheetDHANOOPNo ratings yet

- Protect Tanks and Pipelines with HEMPADUR 85671Document2 pagesProtect Tanks and Pipelines with HEMPADUR 85671faisalfaiNo ratings yet

- PDS Hempalin Primer 12050 en-GBDocument2 pagesPDS Hempalin Primer 12050 en-GBErwin MalmsteinNo ratings yet

- PDS Hempadur 35560 en-GBDocument2 pagesPDS Hempadur 35560 en-GBErwin MalmsteinNo ratings yet

- Hempathane Hs 55610 55610 En-GbDocument2 pagesHempathane Hs 55610 55610 En-GbfaizalNo ratings yet

- 15553Document2 pages15553danish100% (1)

- Product Data: Hempel'S 15asgDocument2 pagesProduct Data: Hempel'S 15asgwahyu0% (1)

- PDS HEMPADUR 47183 en-USDocument2 pagesPDS HEMPADUR 47183 en-USFreddy Carl Fredricksen0% (1)

- Hempathane Topcoat Product DataDocument2 pagesHempathane Topcoat Product DataQA QCNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 5 Nov 2023rfi Request CoatingDocument1 page5 Nov 2023rfi Request CoatingarjunmohananNo ratings yet

- 5 Nov 2023rfi Request CoatingDocument1 page5 Nov 2023rfi Request CoatingarjunmohananNo ratings yet

- APCS-26T HempelDocument5 pagesAPCS-26T HempelarjunmohananNo ratings yet

- APCS-26 HempelDocument4 pagesAPCS-26 HempelarjunmohananNo ratings yet

- APCS-20B HempelDocument3 pagesAPCS-20B HempelarjunmohananNo ratings yet

- Hempadur 45070 Product Data SheetDocument3 pagesHempadur 45070 Product Data Sheetarjunmohanan50% (2)

- Properties of Oilfield WatersDocument7 pagesProperties of Oilfield WatersMaisam AbbasNo ratings yet

- PDFDocument11 pagesPDFchandro57No ratings yet

- Setting Up A PCR LaboratoryDocument11 pagesSetting Up A PCR LaboratoryMet RizalNo ratings yet

- NLAM - National Library of Ayurved MedicineDocument2 pagesNLAM - National Library of Ayurved MedicineJack LeeNo ratings yet

- Installation of Ceramic Tile in Swimming PoolsDocument5 pagesInstallation of Ceramic Tile in Swimming PoolsTenaw AlamirewNo ratings yet

- Deep Drawing Process: A Brief Overview: September 2015Document6 pagesDeep Drawing Process: A Brief Overview: September 2015novkovic1984No ratings yet

- Pub Role Additives v4 LODocument20 pagesPub Role Additives v4 LOTudor RatiuNo ratings yet

- I Jet R Milk Adult RationDocument6 pagesI Jet R Milk Adult Rationmr cmfNo ratings yet

- Methods For Chemical Analysis of Steels: Indian StandardDocument5 pagesMethods For Chemical Analysis of Steels: Indian StandardGopalMahantaNo ratings yet

- Basic Plant Processes (Laboratory)Document70 pagesBasic Plant Processes (Laboratory)anon_228573261No ratings yet

- Method for Determining Thermo-Flow Parameters for Steam BoilersDocument8 pagesMethod for Determining Thermo-Flow Parameters for Steam BoilersElena RadanNo ratings yet

- Lecture 1Document37 pagesLecture 1Alberto GallottiniNo ratings yet

- Dr. Fixit Piditop 333 Concrete Floor HardenerDocument3 pagesDr. Fixit Piditop 333 Concrete Floor Hardenerhunky11No ratings yet

- LAB REPORT Buffer and PH ExperimentDocument19 pagesLAB REPORT Buffer and PH ExperimentFelix YeboahNo ratings yet

- Salinity Quantab FinalDocument1 pageSalinity Quantab FinalAytaç KesginNo ratings yet

- March 2019 (v2) MS - Paper 5 CIE Biology A-LevelDocument8 pagesMarch 2019 (v2) MS - Paper 5 CIE Biology A-Leveleric sivaneshNo ratings yet

- TinDocument16 pagesTinzidaaanNo ratings yet

- Subjective and Objective Questions With Answers of Chemical Equilibrium For PracticeDocument21 pagesSubjective and Objective Questions With Answers of Chemical Equilibrium For PracticehappyNo ratings yet

- Poisson's Ratio (Lab2)Document4 pagesPoisson's Ratio (Lab2)Brandon J. HowardNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument17 pagesSafety Data Sheet: Section 1. IdentificationGibbs PerNo ratings yet

- Basic Energy Concepts and First Law of ThermodynamicsDocument2 pagesBasic Energy Concepts and First Law of ThermodynamicsGeorge Isaac McQuiles100% (1)

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Direct Determination of Phosphite in Fertilizers by Amperometric TitrationDocument3 pagesDirect Determination of Phosphite in Fertilizers by Amperometric TitrationKarol Astrid Landines BarraganNo ratings yet

- Ce6603 Scad MSMDocument141 pagesCe6603 Scad MSMSasmita SahooNo ratings yet

- Water SupplyDocument37 pagesWater SupplyGTS100% (1)

- Inspector Technical QCDocument117 pagesInspector Technical QCESAVENo ratings yet

- Flow BatteryDocument10 pagesFlow BatteryFatima AgNo ratings yet

- Gas Metal Arc Welding Consumables for High Tensile SteelDocument5 pagesGas Metal Arc Welding Consumables for High Tensile Steelkhoi nguyenvanNo ratings yet

- Nomenclature Practice ChemistryDocument6 pagesNomenclature Practice ChemistryScott Wheeler100% (2)

- MSDS Colafax PmeDocument2 pagesMSDS Colafax Pmemndmatt100% (2)