Professional Documents

Culture Documents

Steel MFG

Steel MFG

Uploaded by

Vaibhav Shah0 ratings0% found this document useful (0 votes)

5 views2 pagesOriginal Title

Steel mfg

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesSteel MFG

Steel MFG

Uploaded by

Vaibhav ShahCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

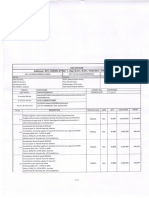

CLAUSE NO.

TECHNICAL SPECIFICATIONS

1.0

representative. The test report along with the recommendations shall be obtained

from the laboratories without delay and submitted to Employer.

Based on the schedule of work agreed with the Employer and the approved FOP,

the Contractor shall prepare a schedule of tests and submit them to the Employer

and organize to carry out the tests as scheduled / agreed

PURCHASE AND SERVICE

" All Structural steel and Reinforcement steel supply if in the scope of the

contractor shall be procured from Main Steel Producers enlisted by NTPC from

time to time. Currently, Main Steel Producers enlisted by NTPC are SAIL, JSW

Steel Ltd, Jindal Steel & Power, Tata steel Ltd, (for Reinforcement steel/TMT

bars), RINL (for long products/Rolled sections and Reinforcement steeVTMT

bars), Essar Steel India Ltd. (for Flat products/ Steel Plates), Electrosteel ste!

Ltd. (for Reinforcement stee/TMT bars) and Monnet Ispat and Energy Ltd. (for

long products/Rolled sections and Reinforcement = stee//TMT bars).

Subsequently, if any new Main Steel Producer/s are enlisted, they may also be

considered for procurement during execution of the contract if proposed by the

Contractor.

In case of non-availability of certain steel section/s i.e, Angle smaller than

100x100x10 mm, MS flats, rounds, square bars and chequered plate from

primary steel producers, an option is given to the Main contractor to source these

sections directly from SAIL Conversion/Wet Leasing agent subject to the

conditions given at point no, A) below:

A) Approval conditions for procurement of structural stee| sections through SAIL

Conversion/Wet Leasing agent:

1. Main Contractor to ensure continuity of BIS license of the manufacturer for the

sections being manufactured for NTPC supply.

2. Billets shall be procured from NTPC approved Main Stee! Producers. Proper

records for traceability from raw material to final product shall be maintained

3. 100% chemical analysis of the raw material (Billets) shall be carried out as per

IS: 2830. Testing of one sample per 40 MT for each type of section or part

thereof shall be carried out as per IS: 2062 on finished product.

4. Each lot of delivery of finished product shall be accompanied with co-relatable

Manufacturer's Test Certificate (MTC). MTC of finished sections shall be

correlated with original MTC for Billets received from Main Steel Producer and

Manufacturer Test Report of chemical analysis of Billets mentioned at point no.3.

MTC of finished sections shall include the reference of MTC for Billets from Main

Steel Producer.

5. NTPC will have access to carry out the surveillance checks for in-process

stage

6. In case of any defects are seen in the material, Main Contractor will replace

the material without any cost implication to NTPC.

In case of non-availability of certain size/s of steel tubes conforming to IS:1161

and Hollow (square and rectangular) steel sections conforming to IS: 4923 from

primary steel producers, the same may be sourced from BIS approved sources

having valid BIS license subject to the conditions given at point no. B) below:

DEVELOPMENT OF 6 MW SOLAR PV TECHNICAL SPECIFICATION E2 PAGE

PROJECT AT KAWAS IN GUJARAT BID DOC, NO: RE-CS-5732-004(R3)-9 4 38

CLAUSE NO.

TECHNICAL SPECIFICATIONS

2.0

3.0

B) Approval conditions for procurement of Steel tubes conforming to IS: 1161

and Hollow (square and rectangular) steel sections conforming to IS: 4923 from

BIS approved sources:

1. Main Contractor to ensure continuity of BIS license of the manufacturer for the

sections being manufactured for NTPC supply.

2. Raw materials shall be procured from NTPC approved Main Stee! Producers.

3. 100% chemical analysis of the raw material (steel) shall be carried out as per

IS: 228. Testing of samples of steel tubes and hollow sections from each lot shall

be carried out as per IS: 1161 & IS: 4923 respectively on finished product.

4, Each lot of delivery of finished product shall be accompanied with co-relatable

Manufacturer's Test Certificate (MTC).

5. NTPC will have access to carry out the surveillance checks for in-process

stage

6. In case of any defects are seen in the material, Main Contractor will replace

the material without any cost implication to NTPC.

The specific methodology to be followed for procurement of Structural Steel and

Reinforcement Bars through conversion route/BIS approved sources route shall

be subject to approval by NTPC in advance.

For Module Mounting Structures, Structural steel shall be procured from

mutually agreed suppliers.”

The other conditions are covered in the chapter ‘GTR’.

FIELD QUALITY PLAN

Well before the start of the work, the contractor shall prepare and submit the

Field Quality Plans (FQP) on the format No. QS-01-QAI-P-09/F2-R1, and obtain

approval of NTPC, which shall detail out for all the works, EQUIPMENT,

services, quality practices and procedures etc in line with the requirement of the

technical specifications to be followed by the contractor at site. This FQP shall

cover for all the items / activities covered in the contract / schedule of items

required, right from material procurement to completion of the work at site. An

Indicative Field Quality Plan for civil works is enclosed at Annexure — Il

(Indicative FOP for civil and structural steel works).

GENERAL QA REQUIREMENTS

The contractor shall ensure that the works, BOls and services under the scope of

contract whether manufactured or performed within contractor's works or at his

sub-contractor's premises or at the NTPC's site or at any other place of work are

in accordance with the NTPC technical specification, applicable standards /

codes, approved drawings / data sheets / quality plans and BOQ. All the works,

BOls and services shall be carried out as per the best prevalent engineering

practices and to the directions of the Engineer.

Lists of Items requiring Quality Plan and Sub-Supplier Approval has been

attached at Annexure-IIl

DEVELOPMENT OF 56 MW SOLAR PV TECHNICAL SPECIFICATION PAGE

PROJECT AT KAWAS IN GUJARAT BID DOC, NO: RE-CS-5732-004(R3)-9 39

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Terminaiton Kit SpecificaitonDocument5 pagesTerminaiton Kit SpecificaitonVaibhav ShahNo ratings yet

- Switch DiDocument3 pagesSwitch DiVaibhav ShahNo ratings yet

- Tandem Isolator DrawingDocument1 pageTandem Isolator DrawingVaibhav ShahNo ratings yet

- FQP ErecdtionDocument10 pagesFQP ErecdtionVaibhav ShahNo ratings yet

- Column Rebar Design - NTPCDocument7 pagesColumn Rebar Design - NTPCVaibhav ShahNo ratings yet

- R3-Civil RA 04Document1 pageR3-Civil RA 04Vaibhav ShahNo ratings yet

- Cable 2nd LotDocument5 pagesCable 2nd LotVaibhav ShahNo ratings yet

- Einv1 - FDN BoltsDocument1 pageEinv1 - FDN BoltsVaibhav ShahNo ratings yet

- Einv1 RA 02 03 04Document6 pagesEinv1 RA 02 03 04Vaibhav ShahNo ratings yet

- Einv - VSL-SUP-02 - 31-05-2021 - GS FlatsDocument3 pagesEinv - VSL-SUP-02 - 31-05-2021 - GS FlatsVaibhav ShahNo ratings yet

- Einv - VSL-SUP-01 - 31-05-2021 - Foundation BoltsDocument3 pagesEinv - VSL-SUP-01 - 31-05-2021 - Foundation BoltsVaibhav ShahNo ratings yet

- Revised E InvoiceDocument2 pagesRevised E InvoiceVaibhav ShahNo ratings yet

- Einv2 - GS FlatsDocument1 pageEinv2 - GS FlatsVaibhav ShahNo ratings yet

- Credit Note InvoiceDocument2 pagesCredit Note InvoiceVaibhav ShahNo ratings yet

- Invoice - July 21Document8 pagesInvoice - July 21Vaibhav ShahNo ratings yet

- Illumination SpecificationDocument7 pagesIllumination SpecificationVaibhav ShahNo ratings yet

- QuestionsDocument1 pageQuestionsVaibhav ShahNo ratings yet

- Ups CRSDocument1 pageUps CRSVaibhav ShahNo ratings yet