Professional Documents

Culture Documents

MSC Chemistry PSCT Unit 7.1

Uploaded by

Girish RoyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSC Chemistry PSCT Unit 7.1

Uploaded by

Girish RoyCopyright:

Available Formats

What is Scanning Electron Microscopy (SEM)

The scanning electron microscope (SEM) uses a focused beam of high-energy electrons

to generate a variety of signals at the surface of solid specimens. The signals that derive

from electron-sample interactions reveal information about the sample including

external morphology (texture), chemical composition, and crystalline structure and

orientation of materials making up the sample. In most applications, data are collected

over a selected area of the surface of the sample, and a 2-dimensional image is

generated that displays spatial variations in these properties. Areas ranging from

approximately 1 cm to 5 microns in width can be imaged in a scanning mode using

conventional SEM techniques (magnification ranging from 20X to approximately

30,000X, spatial resolution of 50 to 100 nm). The SEM is also capable of performing

analyses of selected point locations on the sample; this approach is especially useful in

qualitatively or semi-quantitatively determining chemical compositions (using EDS),

crystalline structure, and crystal orientations (using EBSD). The design and function of

the SEM is very similar to the EPMA and considerable overlap in capabilities exists

between the two instruments.

Fundamental Principles of Scanning Electron

Microscopy (SEM)

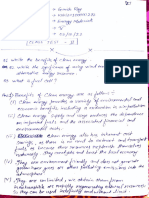

Accelerated electrons in an SEM carry significant amounts of kinetic energy, and this

energy is dissipated as a variety of signals produced by electron-sample

interactions when the incident electrons are decelerated in the solid sample. These

signals include secondary electrons (that produce SEM images), backscattered electrons

(BSE), diffracted backscattered electrons (EBSD that are used to determine crystal

structures and orientations of minerals), photons (characteristic X-rays that are used for

elemental analysis and continuum X-rays), visible light (cathodoluminescence--CL), and

heat. Secondary electrons and backscattered electrons are commonly used for imaging

samples: secondary electrons are most valuable for showing morphology and

topography on samples and backscattered electrons are most valuable for illustrating

contrasts in composition in multiphase samples (i.e. for rapid phase discrimination). X-

ray generation is produced by inelastic collisions of the incident electrons with electrons

in discrete ortitals (shells) of atoms in the sample. As the excited electrons return to

lower energy states, they yield X-rays that are of a fixed wavelength (that is related to

the difference in energy levels of electrons in different shells for a given element). Thus,

characteristic X-rays are produced for each element in a mineral that is "excited" by the

electron beam. SEM analysis is considered to be "non-destructive"; that is, x-rays

generated by electron interactions do not lead to volume loss of the sample, so it is

possible to analyze the same materials repeatedly.

Scanning Electron Microscopy (SEM)

Instrumentation - How Does It Work?

Essential components of all SEMs include the following:

Electron Source ("Gun")

Electron Lenses

Sample Stage

Detectors for all signals of interest

Display / Data output devices

Infrastructure Requirements:

o Power Supply

o Vacuum System

o Cooling system

o Vibration-free floor

o Room free of ambient magnetic and electric fields

SEMs always have at least one detector (usually a secondary electron detector), and

most have additional detectors. The specific capabilities of a particular instrument are

critically dependent on which detectors it accommodates.

Applications

The SEM is routinely used to generate high-resolution images of shapes of objects (SEI)

and to show spatial variations in chemical compositions: 1) acquiring elemental maps or

spot chemical analyses using EDS, 2)discrimination of phases based on mean atomic

number (commonly related to relative density) using BSE, and 3) compositional maps

based on differences in trace element "activitors" (typically transition metal and Rare

Earth elements) using CL. The SEM is also widely used to identify phases based on

qualitative chemical analysis and/or crystalline structure. Precise measurement of very

small features and objects down to 50 nm in size is also accomplished using the SEM.

Backscattered electron images (BSE) can be used for rapid discrimination of phases in

multiphase samples. SEMs equipped with diffracted backscattered electron detectors

(EBSD) can be used to examine micro fabric and crystallographic orientation in many

materials.

Strengths and Limitations of Scanning

Electron Microscopy (SEM)?

Strengths

There is arguably no other instrument with the breadth of applications in the study of

solid materials that compares with the SEM. The SEM is critical in all fields that require

characterization of solid materials. While this contribution is most concerned with

geological applications, it is important to note that these applications are a very small

subset of the scientific and industrial applications that exist for this instrumentation.

Most SEM's are comparatively easy to operate, with user-friendly "intuitive" interfaces.

Many applications require minimal sample preparation. For many applications, data

acquisition is rapid (less than 5 minutes/image for SEI, BSE, spot EDS analyses.) Modern

SEMs generate data in digital formats, which are highly portable.

Limitations

Samples must be solid and they must fit into the microscope chamber. Maximum size in

horizontal dimensions is usually on the order of 10 cm, vertical dimensions are

generally much more limited and rarely exceed 40 mm. For most instruments samples

must be stable in a vacuum on the order of 10-5 - 10-6 torr. Samples likely to outgas at

low pressures (rocks saturated with hydrocarbons, "wet" samples such as coal, organic

materials or swelling clays, and samples likely to decrepitate at low pressure) are

unsuitable for examination in conventional SEM's. However, "low vacuum" and

"environmental" SEMs also exist, and many of these types of samples can be

successfully examined in these specialized instruments. EDS detectors on SEM's cannot

detect very light elements (H, He, and Li), and many instruments cannot detect elements

with atomic numbers less than 11 (Na). Most SEMs use a solid state x-ray detector

(EDS), and while these detectors are very fast and easy to utilize, they have relatively

poor energy resolution and sensitivity to elements present in low abundances when

compared to wavelength dispersive x-ray detectors (WDS) on most electron probe

microanalyzers (EPMA). An electrically conductive coating must be applied to electrically

insulating samples for study in conventional SEM's, unless the instrument is capable of

operation in a low vacuum mode.

User's Guide - Sample Collection and

Preparation

Sample preparation can be minimal or elaborate for SEM analysis, depending on the

nature of the samples and the data required. Minimal preparation includes acquisition

of a sample that will fit into the SEM chamber and some accommodation to prevent

charge build-up on electrically insulating samples. Most electrically insulating samples

are coated with a thin layer of conducting material, commonly carbon, gold, or some

other metal or alloy. The choice of material for conductive coatings depends on the data

to be acquired: carbon is most desirable if elemental analysis is a priority, while metal

coatings are most effective for high resolution electron imaging applications.

Alternatively, an electrically insulating sample can be examined without a conductive

coating in an instrument capable of "low vacuum" operation.

Data Collection, Results and Presentation

Representative SEM images of asbestiform minerals from the USGS Denver Microbeam

Laboratory

You might also like

- What Is Scanning Electron Microscopy (SEM)Document5 pagesWhat Is Scanning Electron Microscopy (SEM)mayheartNo ratings yet

- SEM Advantages and Applications in 40 CharactersDocument11 pagesSEM Advantages and Applications in 40 CharactersRizki Yuni PratiwiNo ratings yet

- Scanning Electron Microscopy (SEM) : Geochemical Instrumentation and AnalysisDocument10 pagesScanning Electron Microscopy (SEM) : Geochemical Instrumentation and AnalysisJOHNNYNo ratings yet

- Scanning Electron Microscopy (SEM)Document4 pagesScanning Electron Microscopy (SEM)Er Rachit ShahNo ratings yet

- Sandy Adel Ishaaq - Electron MicroscopeDocument4 pagesSandy Adel Ishaaq - Electron MicroscopeMohammed R.HusseinNo ratings yet

- Scanning Electron Microscopy (SEM) : Geochemical Instrumentation and AnalysisDocument11 pagesScanning Electron Microscopy (SEM) : Geochemical Instrumentation and AnalysiskrunalNo ratings yet

- What is SEM? Understanding Scanning Electron MicroscopyDocument6 pagesWhat is SEM? Understanding Scanning Electron MicroscopyAli Abbas Warwar AltaiNo ratings yet

- Scanning Electron MicroscopeDocument6 pagesScanning Electron MicroscopeRaza AliNo ratings yet

- Methods On Destructive TestingDocument6 pagesMethods On Destructive TestingNiño UretaNo ratings yet

- Scanning ElectronMicroscopy - VipulDocument5 pagesScanning ElectronMicroscopy - VipulsriyajambukarNo ratings yet

- Auger Electron SpectrosDocument8 pagesAuger Electron SpectrosROHITM RA1811002040067No ratings yet

- Principios de La MEBDocument27 pagesPrincipios de La MEBFernando Iván MedinaNo ratings yet

- Imaging MicrosDocument17 pagesImaging MicrosSiddhartha SharmaNo ratings yet

- Resume Dry Practical 2Document6 pagesResume Dry Practical 2Dharmapadmi KasilaniNo ratings yet

- MEL-416 Lab Report On OM &SEMDocument7 pagesMEL-416 Lab Report On OM &SEMAjay VermaNo ratings yet

- Research Paper On Electron MicroscopeDocument4 pagesResearch Paper On Electron Microscopecakwn75t100% (1)

- Fundamental Principles of Scanning Electron Microscopy (SEM)Document4 pagesFundamental Principles of Scanning Electron Microscopy (SEM)hebesuji7No ratings yet

- How SEMs Produce High-Resolution Images of SamplesDocument7 pagesHow SEMs Produce High-Resolution Images of SampleszzaanNo ratings yet

- EDX (Phy Final Project)Document10 pagesEDX (Phy Final Project)Vines 747No ratings yet

- Material Characterization - Lecture 4Document18 pagesMaterial Characterization - Lecture 4Nilesh BondreNo ratings yet

- Advantages:: DisadvantagesDocument10 pagesAdvantages:: DisadvantagesZahir Rayhan JhonNo ratings yet

- SEM and TEM MicroscopesDocument20 pagesSEM and TEM MicroscopesAmira Mohamed AbdullahNo ratings yet

- Sem-Tem-XrdDocument32 pagesSem-Tem-Xrdaditya raajNo ratings yet

- SEM and TEM NotesDocument7 pagesSEM and TEM NotesVarshini Rajkumar100% (4)

- Analytical Methods MSE528: Chemical Analysis Structural Analysis Physical PropertiesDocument76 pagesAnalytical Methods MSE528: Chemical Analysis Structural Analysis Physical PropertiesCLPHtheoryNo ratings yet

- Lecture 9 Image Analysis Techniques for Macro to Nano ScalesDocument33 pagesLecture 9 Image Analysis Techniques for Macro to Nano ScalesRachit GoyalNo ratings yet

- Materials ChracterisationDocument62 pagesMaterials ChracterisationAbdul MajidNo ratings yet

- SEM and TEM NotesDocument8 pagesSEM and TEM NotesBayikati PavaniNo ratings yet

- SEM - EDS - Scanning Electron Microscopy With X-Ray MicroanalysisDocument2 pagesSEM - EDS - Scanning Electron Microscopy With X-Ray MicroanalysisSableen Singh100% (1)

- Material S. Presentation 1Document77 pagesMaterial S. Presentation 1Dagmawi HailuNo ratings yet

- SEM and EDS Analysis in IndustryDocument11 pagesSEM and EDS Analysis in IndustryUfuk AKKAŞOĞLUNo ratings yet

- TEM Electron Microscope GuideDocument4 pagesTEM Electron Microscope GuidePASUPULETI ANILNo ratings yet

- Scanning Electron MicroscopDocument21 pagesScanning Electron Microscopabhishek ranaNo ratings yet

- 10 AndrewsDocument6 pages10 AndrewsJuan Carlos Gonzalez LNo ratings yet

- EDX (Energy Dispersive X-Ray Analysis)Document9 pagesEDX (Energy Dispersive X-Ray Analysis)shirley rajNo ratings yet

- Electron Probe MicroDocument7 pagesElectron Probe MicroimrankhanNo ratings yet

- Experiment 2-1Document15 pagesExperiment 2-12000jepthaNo ratings yet

- Sem Lab Record)Document5 pagesSem Lab Record)Koustav GhoshNo ratings yet

- New Microsoft Office Word DocumentDocument159 pagesNew Microsoft Office Word Documenttapa_415027No ratings yet

- (Scanning Electron Microscopy) : Assignment-IiDocument11 pages(Scanning Electron Microscopy) : Assignment-IiDilli KrishnaNo ratings yet

- Unit 4Document20 pagesUnit 4Parth PatelNo ratings yet

- Sem, Tem, XRD, AfmDocument3 pagesSem, Tem, XRD, AfmHari GovindNo ratings yet

- Water ManagementDocument30 pagesWater Managementvarshithgr27No ratings yet

- Electron Probe X-Ray Microanalysis: Microscopy - Biomedical ApplicationsDocument15 pagesElectron Probe X-Ray Microanalysis: Microscopy - Biomedical ApplicationsJuan CogolludoNo ratings yet

- CHEM F323 - Scanning Electron Microscope (SEM) PDFDocument23 pagesCHEM F323 - Scanning Electron Microscope (SEM) PDFAbhishek GaurNo ratings yet

- Construction Working and Use of Tunneling Microscope N Their AdvantageDocument19 pagesConstruction Working and Use of Tunneling Microscope N Their AdvantageAman Khera100% (1)

- Tranmission Electron MicrosDocument8 pagesTranmission Electron MicrosRizki Yuni PratiwiNo ratings yet

- NL - 10.2 Edx & SaxsDocument8 pagesNL - 10.2 Edx & SaxsAnanya BiswasNo ratings yet

- Characterization of Nanomaterials Using XRD and Electron MicroscopyDocument12 pagesCharacterization of Nanomaterials Using XRD and Electron MicroscopyWasan ShakirNo ratings yet

- 2012 SEM in Modern Dentistry ResearchDocument6 pages2012 SEM in Modern Dentistry ResearchPablo ForlamNo ratings yet

- Lecture 3 Conventional-MicroscopeDocument45 pagesLecture 3 Conventional-Microscopearul1987No ratings yet

- Fundamental Principles of X-Ray Fluorescence (XRF) : Interactions Between Electron Beams and X-Rays SEM EDS XRD WDSDocument24 pagesFundamental Principles of X-Ray Fluorescence (XRF) : Interactions Between Electron Beams and X-Rays SEM EDS XRD WDSsalimshahzad31No ratings yet

- HRTEMDocument5 pagesHRTEMRajathi YadavNo ratings yet

- What Is A SEMDocument5 pagesWhat Is A SEMVivek BelaNo ratings yet

- SEM LectureDocument7 pagesSEM Lectureabdul rehman khanNo ratings yet

- Laser Metrology in Fluid Mechanics: Granulometry, Temperature and Concentration MeasurementsFrom EverandLaser Metrology in Fluid Mechanics: Granulometry, Temperature and Concentration MeasurementsNo ratings yet

- Mechanical topicsDocument4 pagesMechanical topicsGirish RoyNo ratings yet

- 06479G Sample BuyNowDocument10 pages06479G Sample BuyNowGirish RoyNo ratings yet

- Lect 25Document6 pagesLect 25Girish RoyNo ratings yet

- Adobe Scan Apr 11, 2023Document11 pagesAdobe Scan Apr 11, 2023Girish RoyNo ratings yet

- Lect 5Document9 pagesLect 5Girish RoyNo ratings yet

- Lect 8Document6 pagesLect 8Girish RoyNo ratings yet

- Lect 24Document4 pagesLect 24Girish RoyNo ratings yet

- Lect 20Document7 pagesLect 20Girish RoyNo ratings yet

- Lect 15Document13 pagesLect 15Girish RoyNo ratings yet

- Lect 22Document7 pagesLect 22Girish RoyNo ratings yet

- Lect 14Document5 pagesLect 14Girish RoyNo ratings yet

- Lect 23Document6 pagesLect 23Girish RoyNo ratings yet

- Magnetostatics: The Divergence and Curl of BDocument6 pagesMagnetostatics: The Divergence and Curl of BGirish RoyNo ratings yet

- Metalurgija 2014 SBDocument5 pagesMetalurgija 2014 SBGirish RoyNo ratings yet

- Ipr EventDocument1 pageIpr EventGirish RoyNo ratings yet

- Semester7 Question PapersDocument5 pagesSemester7 Question PapersGirish RoyNo ratings yet

- Methods For Determining Oxygen Overvoltage and Anode Poisoning Over Time at Iron-Group Metals Under High Current Densities in Alkaline Water ElectrolysisDocument4 pagesMethods For Determining Oxygen Overvoltage and Anode Poisoning Over Time at Iron-Group Metals Under High Current Densities in Alkaline Water ElectrolysisAJER JOURNALNo ratings yet

- Work Text INGE09: Understanding The SelfDocument24 pagesWork Text INGE09: Understanding The SelfFrancis Dave MabborangNo ratings yet

- Towards Innovative Community Building: DLSU Holds Henry Sy, Sr. Hall GroundbreakingDocument2 pagesTowards Innovative Community Building: DLSU Holds Henry Sy, Sr. Hall GroundbreakingCarl ChiangNo ratings yet

- (D-301) General Requirement in Equipment Installation - Rev.4 PDFDocument11 pages(D-301) General Requirement in Equipment Installation - Rev.4 PDFmihir_jha2No ratings yet

- Lesson Plan Sir MarcosDocument7 pagesLesson Plan Sir MarcosJhon AgustinNo ratings yet

- Costallocationvideolectureslides 000XADocument12 pagesCostallocationvideolectureslides 000XAWOw Wong100% (1)

- Check List Valve PDFDocument2 pagesCheck List Valve PDFikan100% (1)

- Oil & Gas Rig Roles Functions ProcessesDocument5 pagesOil & Gas Rig Roles Functions ProcessesAnant Ramdial100% (1)

- Autonomy Necessity and Love by Harry FrankfurtDocument14 pagesAutonomy Necessity and Love by Harry FrankfurtjamesdigNo ratings yet

- Improving Performance With Goals、Feedback、Reward、and Positive ReinforcementDocument15 pagesImproving Performance With Goals、Feedback、Reward、and Positive ReinforcementMichelle HuwaeNo ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- StuffIt Deluxe Users GuideDocument100 pagesStuffIt Deluxe Users Guidesergio vieiraNo ratings yet

- Medical Imaging - Seminar Topics Project Ideas On Computer ...Document52 pagesMedical Imaging - Seminar Topics Project Ideas On Computer ...Andabi JoshuaNo ratings yet

- Aristotle's virtue theory - Become virtuous through habitDocument4 pagesAristotle's virtue theory - Become virtuous through habitWiljan Jay AbellonNo ratings yet

- Narrative Report On Catch Up Friday ReadingDocument2 pagesNarrative Report On Catch Up Friday ReadingNova Mae AgraviadorNo ratings yet

- Distributed Oracle EAM - A White PaperDocument38 pagesDistributed Oracle EAM - A White PaperrpgudlaNo ratings yet

- John Constantine Rouge Loner Primordial Orphan Paranormal DetectiveDocument4 pagesJohn Constantine Rouge Loner Primordial Orphan Paranormal DetectiveMirko PrćićNo ratings yet

- .Design and Development of Motorized Multipurpose MachineDocument3 pages.Design and Development of Motorized Multipurpose MachineANKITA MORENo ratings yet

- AN2061 Application Note: EEPROM Emulation With ST10F2xxDocument15 pagesAN2061 Application Note: EEPROM Emulation With ST10F2xxleuchimed mouhNo ratings yet

- Schmitt Trigger FinalDocument4 pagesSchmitt Trigger Finalsidd14feb92No ratings yet

- PreviewpdfDocument68 pagesPreviewpdfwong alusNo ratings yet

- Microorganisms Friend or Foe Part-5Document28 pagesMicroorganisms Friend or Foe Part-5rajesh duaNo ratings yet

- Lesson Plan Nº1Document7 pagesLesson Plan Nº1Veronica OrpiNo ratings yet

- Free Fall ExperimentDocument31 pagesFree Fall ExperimentLeerzejPuntoNo ratings yet

- Ici-Ultratech Build Beautiful Award For Homes: Indian Concrete InstituteDocument6 pagesIci-Ultratech Build Beautiful Award For Homes: Indian Concrete InstituteRavi NairNo ratings yet

- Four Golden RuleDocument6 pagesFour Golden RulerundyudaNo ratings yet

- Property Law Supp 2016Document6 pagesProperty Law Supp 2016Tefo TshukuduNo ratings yet

- PROPOSED ARFF BUILDINGDocument27 pagesPROPOSED ARFF BUILDINGDale Bryan S DalmacioNo ratings yet

- Cause and Effect Diagram for Iron in ProductDocument2 pagesCause and Effect Diagram for Iron in ProductHungNo ratings yet

- The Future of Power Systems: Challenges, Trends, and Upcoming ParadigmsDocument16 pagesThe Future of Power Systems: Challenges, Trends, and Upcoming ParadigmsAndres ZuñigaNo ratings yet

- Product+Catalogue+2021+New+Final PreviewDocument34 pagesProduct+Catalogue+2021+New+Final Previewsanizam79No ratings yet