Professional Documents

Culture Documents

OMQUES2

Uploaded by

Sayan GangulyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OMQUES2

Uploaded by

Sayan GangulyCopyright:

Available Formats

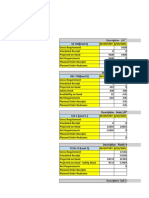

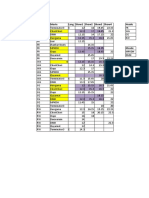

PRODUCT STRUCTURE DIAGRAM

BOM RK1-720

RK1-720

721A-12 IS-720(1)

BOM 34-720

34-720(1)

722-1(1) 721A-12(1) IS-720(1) 34-850(2)

722-1-000(1)

Description - 3/4" 720w/BV

INVENTOR 8/29/200 10-03- 10/31/200 11/28/200 01-02-

34-720(level 0) Y 5 2005 5 5 2006

Gross Requirement 5000 5000 5000 4000 4000

Scheduled Receipt 0 0 0 0 0

Projected on Hand 9600 4600 -400 0 0 0

Net Requirements -9600 0 400 5000 4000 4000

Planned Order Receipts 400 5000 4000 4000

Planned Order Realeases 400 5000 4000 4000

Description - Repair Kit,1/2"-1"720

INVENTOR 8/29/200 10-03- 10/31/200 11/28/200 01-02-

RK1-720(level 0) Y 5 2005 5 5 2006

Gross Requirement 517 662 578 650 858

Scheduled Receipt 0 0 0 0 0 0

Projected on Hand 482 0 0 0 0 0

Safety Stock 400 400 400 400 400 400

Availability on Hand 82 -435

Net Requirements -482 435 662 578 650 858

Planned Order Receipts 435 1062 978 1050 1258

Planned Order Realeases 435 1062 978 1050 1258

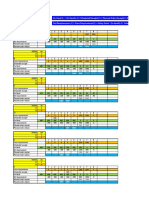

Description - Body 3/4",720 finished

INVENTOR 8/29/200 10-03- 10/31/200 11/28/200 01-02-

722-1 (Level 1 ) Y 5 2005 5 5 2006

Gross Requirement 400 5000 4000 4000

Scheduled Receipt 0 0 0 0 0 0

Projected on Hand 16650 16650 16250 11250 7250 3250

Net Requirements -16650 0 0 0 0 0

Planned Order Receipts

Planned Order Realeases 0 0 0 0 0

Description - Plastic Washer,1/2"

INVENTOR 8/29/200 10-03- 10/31/200 11/28/200 01-02-

721A-12 (Level 1) Y 5 2005 5 5 2006

Gross Requirement 11564 11552 14198 11188 10764

Scheduled Receipt 55000 0 0 0 0

Projected on Hand 18533 61969 50417 36219 25031 14267

Projected on Hand - Safety

Stock 9533 52969 41417 27219 16031 5267

Net Requirements 0 0 0 0 0

Planned Order Receipts

Planned Order Realeases

Description -Ball Valve 3/4"

INVENTOR 8/29/200 10-03- 10/31/200 11/28/200 01-02-

34-850 (Level1) Y 5 2005 5 5 2006

Gross Requirement 50 850 10050 8040 8040

Scheduled Receipt 0 0 0 0 0

Projected on Hand 10430 10380 9530 -520 0 0

Net Requirements -10430 0 0 520 8040 8040

Planned Order Receipts 11444 11444

Planned Order Realeases 11444 11444

Description -Instruction Sheet 720

IS720 (Level1) INVENTOR 8/29/200 10-03- 10/31/200 11/28/200 01-02-

Y 5 2005 5 5 2006

Gross Requirement 13235 13502 14478 11580 11758

Scheduled Receipt 49500 49500 54900 9000 12600

Projected on Hand 64372 100637 136635 177057 174477 175319

Projected on Hand-Safety

Stock 64345 100610 136608 177030 174450 175292

Net Requirements 0 0 0 0 0

Planned Order Receipts

Planned Order Realeases

Description - Body 3/4",720 raw

INVENTOR 8/29/200 10-03- 10/31/200 11/28/200 01-02-

722-1-000(Level 2) Y 5 2005 5 5 2006

Gross Requirement 0 0 4021 5409 4928

Scheduled Receipt 0 0 0 0 0

Projected on Hand 612 612 612 -3409 0 0

Net Requirements -612 3409 5409 4928

Planned Order Receipts 56413

Planned Order Realeases 56413

Recommended Changes:

1. As Gerpheide, I recommend addressing the issue of high inventory costs for Item 34-850 by reducing the

lead time in order to decrease the amount of inventory held. Inventory holding cost is also very high

because the lead time is of 2 months and hence the inventory bulk-up over time.

2. The inventory for items 1S720 and 722-1 is causing concern as the forecasted stock on hand is enough to

last for the next five months, but the regular monthly deliveries are substantial and contribute to an

accumulation of inventory. This results in rising inventory expenses, which were already high in the first

month. To address this issue, it is suggested to decrease the inventory levels and adjust the planned

deliveries/batch orders accordingly.

3. Item 722-1-000 & 721A-12 are also facing a problem with large lot order sizes which exceeds the gross

requirement by significant margin, leading to increased inventory holding costs. It is recommended to

reduce the lot order size significantly.

4. Adjust the lot order and safety stock based on the screening of defective items at the beginning of the

process.

You might also like

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Om Ques2Document4 pagesOm Ques2Sayan GangulyNo ratings yet

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- Final Reports On SapDocument57 pagesFinal Reports On SapJabranNo ratings yet

- Motion Control ReportFrom EverandMotion Control ReportRating: 4 out of 5 stars4/5 (1)

- SM T560 Eplis 11Document7 pagesSM T560 Eplis 11Becerropinto100% (2)

- XYZ Contractor Project 7081 Summary Coins Costs & Accruals 40,452 Overhead Subcontract Transfer Stats MaterialsDocument12 pagesXYZ Contractor Project 7081 Summary Coins Costs & Accruals 40,452 Overhead Subcontract Transfer Stats MaterialsOmar J. McWilliamsNo ratings yet

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- Electrical Part ListDocument12 pagesElectrical Part ListMarianoAnchávalNo ratings yet

- Arlington HOA 2011 BudgetDocument1 pageArlington HOA 2011 Budgetmhoover1No ratings yet

- P 4 RDocument1 pageP 4 RALONSO EUGENIO ENCINAS MAGALLANESNo ratings yet

- Equity Valuation: Models from Leading Investment BanksFrom EverandEquity Valuation: Models from Leading Investment BanksJan ViebigNo ratings yet

- 966C Pedido2Document1 page966C Pedido2Diego CatariNo ratings yet

- S7390 Electrical Part List PDFDocument6 pagesS7390 Electrical Part List PDFDaniel CekulNo ratings yet

- T210 Electrical Part List PDFDocument6 pagesT210 Electrical Part List PDFDaniel Cekul100% (1)

- Case The Super ProjectDocument6 pagesCase The Super ProjectpaulNo ratings yet

- Wiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsNo ratings yet

- 1 - 50-108 Me-Me-C Operation (D2378a)Document660 pages1 - 50-108 Me-Me-C Operation (D2378a)SimonaMauna100% (3)

- Yahoo Mail - Re - York Chiller YCIV Spare Parts PDFDocument1 pageYahoo Mail - Re - York Chiller YCIV Spare Parts PDFمحمد عليNo ratings yet

- Electrical Part List PDFDocument5 pagesElectrical Part List PDFMang OtosNo ratings yet

- S7500 Electrical Part List PDFDocument7 pagesS7500 Electrical Part List PDFDaniel CekulNo ratings yet

- Electrical Part ListDocument6 pagesElectrical Part ListSantana CellNo ratings yet

- Samsung Galaxy V G-313 Electrical Part ListDocument7 pagesSamsung Galaxy V G-313 Electrical Part Listahmad riza virsNo ratings yet

- Electrical Part ListDocument11 pagesElectrical Part ListAfuy ChinesNo ratings yet

- SM-J105M Eplis 11Document8 pagesSM-J105M Eplis 11bapak nakalNo ratings yet

- MAIN Electrical Parts List: Part Code Design Loc DescriptionDocument7 pagesMAIN Electrical Parts List: Part Code Design Loc DescriptionKEEMNo ratings yet

- EDRPDocument9 pagesEDRPMichell Inzunza RomoNo ratings yet

- SM GTP5210 PDFDocument55 pagesSM GTP5210 PDFKyrie AbayaNo ratings yet

- MAIN Electrical Parts List: Sec Code Desing LOC DescriptionDocument16 pagesMAIN Electrical Parts List: Sec Code Desing LOC DescriptionDaniel Zapata GrajalezNo ratings yet

- MAIN Electrical Parts List: Parts Code Design Loc Parts DescriptionDocument12 pagesMAIN Electrical Parts List: Parts Code Design Loc Parts DescriptionWilliam SequeraNo ratings yet

- MAN B W Engine AutomationDocument548 pagesMAN B W Engine Automationbartofit100% (2)

- Aditya Choudhury - Financial AccountingDocument21 pagesAditya Choudhury - Financial AccountingIsha KhakharNo ratings yet

- Exam Gestion Financier Ratt 2018 Prof MESK - Faculté HASSAN 2 CASABLANCADocument1 pageExam Gestion Financier Ratt 2018 Prof MESK - Faculté HASSAN 2 CASABLANCAAbdoNo ratings yet

- MAIN Electrical Parts List: FirmwareDocument14 pagesMAIN Electrical Parts List: FirmwareServi-vent MorenoNo ratings yet

- MAIN Electrical Parts List: FirmwareDocument8 pagesMAIN Electrical Parts List: FirmwareServi-vent MorenoNo ratings yet

- MAIN Electrical Parts List: Sec-Code Design LOC DescriptionDocument13 pagesMAIN Electrical Parts List: Sec-Code Design LOC DescriptionHenry TamayoNo ratings yet

- MAIN Electrical Parts List: FirmwareDocument9 pagesMAIN Electrical Parts List: FirmwareServi-vent MorenoNo ratings yet

- MAIN Electrical Parts List: SEC Code Design LOC DescriptionDocument6 pagesMAIN Electrical Parts List: SEC Code Design LOC DescriptionEsterlin SueroNo ratings yet

- Electrical Part ListDocument20 pagesElectrical Part ListKevinNo ratings yet

- 05 51 10 DVI 10000 001hard Landing N Excee Vle, VloDocument22 pages05 51 10 DVI 10000 001hard Landing N Excee Vle, VloAnonymous 0HKLkFIPsYNo ratings yet

- Electrical Part List PDFDocument15 pagesElectrical Part List PDFsafi alsafiNo ratings yet

- Rasgas Company LTD Offshore Expansion Project: Train 4 (WH No.5)Document1 pageRasgas Company LTD Offshore Expansion Project: Train 4 (WH No.5)MarkyNo ratings yet

- Summary Status Report Prs'92Document5 pagesSummary Status Report Prs'92Joshua Edward LaqueNo ratings yet

- I9060 Electrical Part List PDFDocument5 pagesI9060 Electrical Part List PDFDaniel CekulNo ratings yet

- Line Account Entered: Debit Entered: Credit DescriptionDocument7 pagesLine Account Entered: Debit Entered: Credit Descriptionsohaibmuzaffar007No ratings yet

- Fol Haws Catering Service Exercise-1Document16 pagesFol Haws Catering Service Exercise-1Guiana WacasNo ratings yet

- SM-J106B DS Eplis 11 PDFDocument7 pagesSM-J106B DS Eplis 11 PDFMariangela RondonNo ratings yet

- SM N900 Eplis 11Document11 pagesSM N900 Eplis 11SERVER CELL MackzuryNo ratings yet

- MAIN Electrical Parts List: Design Loc Parts Code DescriptionDocument13 pagesMAIN Electrical Parts List: Design Loc Parts Code DescriptionADRYNo ratings yet

- Sm-A510fd Eplis 11Document11 pagesSm-A510fd Eplis 11ekoNo ratings yet

- MAIN Electrical Parts List: Sec-Code Design LOC DescriptionDocument13 pagesMAIN Electrical Parts List: Sec-Code Design LOC DescriptionHenry Tamayo0% (1)

- MRP SheetsDocument2 pagesMRP SheetsAiman DarwishNo ratings yet

- MAIN Electrical Parts List: Sec-Code Design LOC DescriptionDocument9 pagesMAIN Electrical Parts List: Sec-Code Design LOC DescriptionMaster RolandNo ratings yet

- Electrical Part List PDFDocument8 pagesElectrical Part List PDFKevin ZambranoNo ratings yet

- Di 51-54Document1 pageDi 51-54Sayan GangulyNo ratings yet

- Book NameDocument2 pagesBook NameSayan GangulyNo ratings yet

- SamDocument6 pagesSamSayan GangulyNo ratings yet

- Sam 1Document56 pagesSam 1Sayan GangulyNo ratings yet

- MultiplexMovies Session6 DataDocument7 pagesMultiplexMovies Session6 DataSayan GangulyNo ratings yet

- Data Session 3Document5 pagesData Session 3Sayan GangulyNo ratings yet

- Data - Location of Fair Price ShopsDocument5 pagesData - Location of Fair Price ShopsSayan GangulyNo ratings yet

- Session 2Document5 pagesSession 2Sayan GangulyNo ratings yet

- Assignment 03Document14 pagesAssignment 03Sayan GangulyNo ratings yet

- Data Session4Document3 pagesData Session4Sayan GangulyNo ratings yet

- Data Session 9Document9 pagesData Session 9Sayan GangulyNo ratings yet