Professional Documents

Culture Documents

Blackmer Paint and Coatings Brochure

Uploaded by

arajamani78Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blackmer Paint and Coatings Brochure

Uploaded by

arajamani78Copyright:

Available Formats

Paint &

Coatings

■ Unloading

■ Transfer

■ Processing

■ Loading

Process Energy Transport Military • Marine

Paint & Coatings Blackmer Pumps are Designed

Transfer and Production to Help Paint & Coatings Producers:

Process Flow Solutions ■ Improve fluid flow efficiencies

■ Control costs through energy-efficient pump designs

Blackmer offers a comprehensive line of

flow solutions for the world’s most ■ Eliminate VOC emissions through seal integrity and seal-less, zero

critical Paint & Coatings production shaft-leak pump designs

missions – yours. ■ Ensure uptime performance - our self-priming, high suction pumps are ideal

Blackmer pumps move organic and for applications susceptible to solvent evaporation between batches and for resin

synthetic solvents and resins from transfer from transports or storage tanks even in cold weather

petrochemical and oleo chemical ■ Control quality by ensuring volumetric output consistency in mixing operations

processing facilities to transports that are

off-loaded, using Blackmer pumps into

aboveground or underground storage

tanks at paint & coatings facilities. From

the storage tanks, Blackmer transfer

pumps move the liquid ingredients to

sand mills or dispersion mixers and C Series “Seal-less” Eccentric Disc Pumps SNP Sliding Vane Pumps

between every phase of the water-borne Blackmer C-Series “sealless” eccentric disc The unbeatable suction and self-priming

or solvent-borne paint-making processes, pumps offer the industry’s most reliable capabilities of SNP/NP pumps make them ideal

prevention against leaks, VOC release and for high-efficiency offloading of resins and

including the filtration and finishing

product loss. The eccentric movement design makes solvents from transports and as transfer pumps from

phases to the transport loading and/or it highly energy efficient and capable of handling aboveground or underground storage tanks to mixers.

container filling applications within abrasives without damage to the pump. The design also SNP/NP pumps offer superior sealing, sustained high

paint & coatings plants. allows for constant flow rates at varying pressures and level performance and trouble-free operation. The

viscosities which eliminates metering and volumetric stainless-steel construction of the SNP makes it ideal

In paint & coatings production, nothing efficiency problems. The C-Series’ clean-in-place for handling clean, corrosive and non-corrosive liquids

beats a Blackmer for reliability, energy- flushing and cleaning without disassembly means at varying temperatures, pressures and viscosities.

efficiency, sealing integrity for controlling maximum production flexibility. Concerns about solvent

evaporation between batches are eliminated by the

VOCs and volumetric consistency when

C-Series’ excellent dry-run and self-priming capabilities.

transferring difficult-to-handle solvents, Its constant, no-pulsating flow and sealless design make

resins, additives, and finished products, it ideal for filtration applications.

such as:

SMVP Series “Seal-less” Sliding Vane Pumps

■ Solvent-borne paint & coatings

The stainless-steel SMVP pump series offers the

■ Water-borne paint & coatings energy-efficiency and life cycle advantages of

■ Petroleum mineral spirits sliding vane technology coupled with a sealless,

magnetic coupling to offer “zero shaft leakage” when

■ Benzol dealing with hard-to-seal hazardous liquids. The SMVP

■ Alcohols provides the best available technology for controlling

Abaque Peristaltic Hose Pump VOC releases from hazardous/toxic fluids, making it

■ Esters Designed specifically for harsh environments, ideal for use with solvents where leakage and VOC

■ Ketones the Abaque can move everything from viscous, release cannot be tolerated.

■ Acetone highly abrasive solutions to water without risk

of damage to the pump. Applications include thin, non-

■ Linseed, coconut and soybean oils lubricating fluids, corrosive materials and shear-sensitive

■ Alkyds materials. The Abaque‘s sealless design eliminates

leaks, contamination, VOC releases and wear problems

■ Acrylics associated with hard-to-seal products. Ideal for

■ Epoxies byproduct and waste transfer or where the potential

■ Polyurethanes accidental transfer of solid particles or heavy abrasives

may be possible. ML/HXL Series Sliding Vane Pumps

■ Thickeners/Rheology modifiers ML/MXL Series pumps are for high-capacity

■ Surfactants transfer, top and bottom loading, and unloading

of resins and solvents. They are ideal as resin

■ Biocides transfer pumps from transports and aboveground or

■ Defoamers underground storage tanks to mixers because of their

■ Co-Solvents unbeatable suction, self-priming and run dry capabilities.

They are particularly useful in gravity-fed operations in

When it comes to optimizing flow ProVane® Motor Speed Vane Pumps cold weather.

performance, reducing costs and The ProVane® is designed for energy-efficient,

increasing profitability, the world’s most high fluid transfer and reliability in process

and blending applications. It is ideal for shear-

productive operations share a common

sensitive liquids and wide ranging viscosities while

demand – Better Get Blackmer. delivering consistent volumetric output to ensure

batch quality blending. ProVane® has exceptional

suction and self-priming capabilities for moving

TX Series Sliding Vane Pumps

solvents from underground tanks to mixers and is

capable of continuous duty operation for superior Fast, quiet and highly reliable, the TX Series is

uptime performance. a truck-mounted transfer pump specifically

designed for use on tank trucks and transports

ISO 9001 Certified for the transfer of solvents and resins.

Pump Technologies*

Processes

C-Series ✓ Peristaltic SMVP SNP/NP ProVane® ML/HXL TX/TXV X/GX

Resin Unloading ■ ■ ■ ■ ■

Solvent Unloading ■ ■ ■ ■ ■

Resin Loading to Mixer ■ ■ ■ ■ ■ ■

Solvent Transfer to Mixer ■ ■ ■ ■ ■ ■

Additives Transfer to Mixer ■ ■ ■ ■ ■

Product Transfer to Auxilliary Tank ■ ■ ■ ■

Product Transfer to Grinding/

■ ■ ■ ■ ■

Dispersion Tank

Transfer to Final Mixer/

■ ■ ■ ■ ■

Lengthening Tank

Transfer to Stocking Tank ■ ■ ■ ■

Transfer to Drums ■ ■ ■ ■

Transfer to Pails ■ ■ ■ ■

Transfer to Transports ■ ■ ■ ■

Transport & Delivery ■

Byproduct Waste ■

*Specific model choice is dependent on material compatibility/shaft seal required per specific fluid type.

✓Ideal for finished waterborne paint & coatings products.

Every Blackmer Product Comes With A Value-Added Extra:

Applications Engineering/Technical Support/Customer Care

When it comes to flow solutions, uptime, output, reliability and profitability are critical to every operation’s mission. To this

end, Blackmer knows that reliable, proven flow technologies are critically important, but we also know that this represents

only one part of the overall equation. The other, equally important part involves having trained, knowledgeable and

customer-focused staff, which is why we make substantial investments in our people. It is through their collaborative effort

with customers that the greatest achievements are realized.

■ Applications Engineers – experts in peace-of-mind assurance,

making sure your equipment is always right for the job

■ Market & Product Specialists – unparalleled technical knowledge,

on-site product training, troubleshooting, installation and

product-selection consultation, and total life cycle attention

■ Regional Sales Management – proven technicians with an

“above and beyond” commitment to every customer’s mission

■ Customer Care Specialists – action-oriented specialists

committed to making sure every order receives immediate at-

tention, is accurately processed and followed up, and to help-

ing keep your process flowing smoothly

When you put it all together, for mission critical flow solutions,

it’s easy to see why leading companies around the world have

one common demand … Better Get Blackmer.

Total Life Cycle Support

From the moment of initial contact and equipment selection through Regional Sales

every point of the product and application life cycle, Blackmer Manager

specializes in helping customers get the maximum value from their flow Customer Care

Market & Product

technology assets by providing total life cycle support.

Specialists

Manufacturing

Application Design

Engineer Engineer

www.blackmer.com

ATK-1402-001 (08/07) Process | Energy | Transport | Military • Marine

World Headquarters European Headquarters

1809 Century Avenue SW, Grand Rapids, MI 49503-1530 USA ZI Plaine des Isles, 2 rue des Caillottes, 89000 Auxerre, France

T 616.241.1611 F 616.241.3752 T +33.3.86.49.86.30 F +33.3.86.46.42.10

RECIPROCATING

SLIDING VANE ECCENTRIC CENTRIFUGAL PERISTALTIC ROTARY VANE SCREW

GAS

PUMPS DISC PUMPS PUMPS (HOSE) PUMPS COMPRESSORS COMPRESSORS

COMPRESSORS

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Power Press Operator TrainingDocument40 pagesPower Press Operator TrainingpandaprasadNo ratings yet

- Motivation 1Document29 pagesMotivation 1arajamani78No ratings yet

- Lesson Plan TemplateDocument1 pageLesson Plan Templatearajamani78No ratings yet

- TPM 8 PillarsDocument6 pagesTPM 8 Pillarsarajamani78No ratings yet

- Skill Matrix For ChemistsDocument4 pagesSkill Matrix For Chemistsarajamani78No ratings yet

- 5s 7 Housekeeping Wastes Kanban 1233776462169799 2 PDFDocument26 pages5s 7 Housekeeping Wastes Kanban 1233776462169799 2 PDFMario Alberto Hernandez HerreraNo ratings yet

- Building Standards HandbookDocument170 pagesBuilding Standards Handbookarajamani78No ratings yet

- 5s 7 Housekeeping Wastes Kanban 1233776462169799 2 PDFDocument26 pages5s 7 Housekeeping Wastes Kanban 1233776462169799 2 PDFMario Alberto Hernandez HerreraNo ratings yet

- GM 750Document40 pagesGM 750arajamani78No ratings yet

- Powder MixingDocument1 pagePowder Mixingarajamani78No ratings yet

- Is 3043 1987Document95 pagesIs 3043 1987suresh kumarNo ratings yet

- Fall Protection ProceduresDocument14 pagesFall Protection Proceduresarajamani78No ratings yet

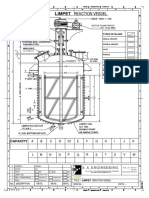

- Limpet Reaction Vessel PDFDocument1 pageLimpet Reaction Vessel PDFarajamani78No ratings yet

- Asian Paints LTD UPDocument14 pagesAsian Paints LTD UParajamani78No ratings yet

- Limpet Coil Reactor VesselDocument1 pageLimpet Coil Reactor Vesselarajamani78100% (1)

- Test Paper-For Paint Plant OperatorDocument1 pageTest Paper-For Paint Plant Operatorarajamani78No ratings yet

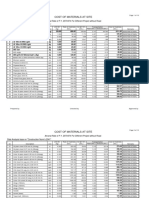

- DimensionsDocument4 pagesDimensionsarajamani78No ratings yet

- Plant Engineers Guide To Agitation Design and FundamentalsDocument33 pagesPlant Engineers Guide To Agitation Design and FundamentalsMark MacIntyre100% (1)

- Fire Safety Training: Presented by Environmental Safety Services, Division of Public Safety, Georgia Southern UniversityDocument36 pagesFire Safety Training: Presented by Environmental Safety Services, Division of Public Safety, Georgia Southern Universityarajamani78No ratings yet

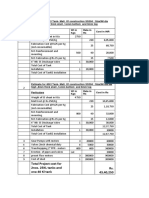

- Ss Tank EstimateDocument1 pageSs Tank Estimatearajamani78No ratings yet

- Bearing Housing PDFDocument1 pageBearing Housing PDFarajamani78No ratings yet

- API70 Spec PDFDocument1 pageAPI70 Spec PDFarajamani78No ratings yet

- Estimate For 25 KL TankDocument1 pageEstimate For 25 KL Tankarajamani78No ratings yet

- Total Project Cost For 2nos. 25KL Tanks and One 40 KL Tank Rs. 43,40,250Document1 pageTotal Project Cost For 2nos. 25KL Tanks and One 40 KL Tank Rs. 43,40,250arajamani78No ratings yet

- 26 Health Benefits of Cinnamon - Cinnamon VogueDocument5 pages26 Health Benefits of Cinnamon - Cinnamon Voguearajamani78No ratings yet

- Air DryersDocument85 pagesAir Dryersarajamani78No ratings yet

- Rs. 4,340,250 Total Project Cost For 2nos. 25KL Tanks and One 40 KL TankDocument1 pageRs. 4,340,250 Total Project Cost For 2nos. 25KL Tanks and One 40 KL Tankarajamani78No ratings yet

- Air DryersDocument85 pagesAir Dryersarajamani78No ratings yet

- Resin Pipeline CalibrationDocument1 pageResin Pipeline Calibrationarajamani78No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 16 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Document33 pagesChapter 16 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Falah Ud Din SheryarNo ratings yet

- David Lawrence CVDocument32 pagesDavid Lawrence CVM.Awais AkhterNo ratings yet

- Assignment in English Plus Core 11 Full CircleDocument76 pagesAssignment in English Plus Core 11 Full CircleRitu Maan68% (38)

- SaponificationDocument2 pagesSaponificationK.SaravananNo ratings yet

- Growth, Stagnation or Decline? Agfficulturalproductm'Iy in British IndiaDocument290 pagesGrowth, Stagnation or Decline? Agfficulturalproductm'Iy in British IndiaHarshadeep BiswasNo ratings yet

- Global Resort List by Country (38 charactersDocument51 pagesGlobal Resort List by Country (38 charactersMaulik ShahNo ratings yet

- Maha VairocanaDocument8 pagesMaha VairocanaDavid Moerler100% (3)

- Friends of Hursley School: Late Summer NewsletterDocument6 pagesFriends of Hursley School: Late Summer Newsletterapi-25947758No ratings yet

- Ic M802 UDocument79 pagesIc M802 Uharis_fikriNo ratings yet

- Rental Range Powered by YANMAR Diesel GeneratorDocument6 pagesRental Range Powered by YANMAR Diesel GeneratorJonathan CastilloNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument21 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsnonzero15No ratings yet

- Enzyme ActivityDocument3 pagesEnzyme ActivityNabindra Ruwali100% (2)

- CH 2.2: Separable Equations: X F DX DyDocument9 pagesCH 2.2: Separable Equations: X F DX DyPFENo ratings yet

- 07 - Structural Organisation in AnimalsDocument31 pages07 - Structural Organisation in AnimalsKamala Kannan XANo ratings yet

- Interfacial Phenomena in Pharmaceutical FormulationDocument21 pagesInterfacial Phenomena in Pharmaceutical FormulationNickson DrabeNo ratings yet

- M/S Majumder Construction: Valuation Statement of PropertyDocument3 pagesM/S Majumder Construction: Valuation Statement of PropertyManoj MajumderNo ratings yet

- Regulation 1 Regulation 2 Regulation 3 Regulation 4 Regulation 5 Regulation 6 Regulation 7 Regulation 8 Regulation 9 AppendixDocument10 pagesRegulation 1 Regulation 2 Regulation 3 Regulation 4 Regulation 5 Regulation 6 Regulation 7 Regulation 8 Regulation 9 AppendixAnonymous 7gJ9alpNo ratings yet

- Browning Belt Tension GaugeDocument2 pagesBrowning Belt Tension GaugeJasperken2xNo ratings yet

- HymssheetDocument4 pagesHymssheettoby_wardmanNo ratings yet

- Rate Analysis-Norms 1Document10 pagesRate Analysis-Norms 1yamanta_rajNo ratings yet

- Miniaturized 90 Degree Hybrid Coupler Using High Dielectric Substrate For QPSK Modulator PDFDocument4 pagesMiniaturized 90 Degree Hybrid Coupler Using High Dielectric Substrate For QPSK Modulator PDFDenis CarlosNo ratings yet

- IRIScan Book Executive 3 PDFDocument86 pagesIRIScan Book Executive 3 PDFssamplingNo ratings yet

- Chapter 3Document58 pagesChapter 3hasanNo ratings yet

- Ex 2013 1 (Recurrent)Document30 pagesEx 2013 1 (Recurrent)alh basharNo ratings yet

- Care of Unconscious Nursing LessonDocument7 pagesCare of Unconscious Nursing LessonYendrembam Taruni90% (10)

- Buckling TestDocument11 pagesBuckling Testsharusli100% (1)

- 2024 Drik Panchang Telugu Calendar v1.0.1Document25 pages2024 Drik Panchang Telugu Calendar v1.0.1Sreekara GsNo ratings yet

- Guía de Instalación y Programación: Sistema de Seguridad de 32 ZonasDocument68 pagesGuía de Instalación y Programación: Sistema de Seguridad de 32 ZonasfernanfivNo ratings yet

- Philips HD5 enDocument5 pagesPhilips HD5 enmohamed boufasNo ratings yet

- ct62010 2013Document165 pagesct62010 2013Amit Poddar100% (2)