Professional Documents

Culture Documents

Browning Belt Tension Gauge

Uploaded by

Jasperken2x0 ratings0% found this document useful (0 votes)

274 views2 pagesBrowning Belt Tension Gauge

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBrowning Belt Tension Gauge

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

274 views2 pagesBrowning Belt Tension Gauge

Uploaded by

Jasperken2xBrowning Belt Tension Gauge

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

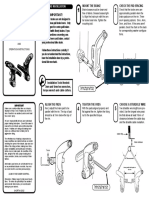

How to increase Belt Life BELT TENSIONING

INSTRUCTIONS

Keep sheaves

and belts clean.

Abrasive dust, rust, oil and acids

reduce service life.

Give drives elbow room.

Never let belts run against belt

guards or other obstructions. 1. Measure the belt span.

2. Calculate deflection

3. See tables below for correct deflection force.

Use large diameter 4. Apply force at right angles to the center of the span

This (see diagram below). The BROWNING® belt tension

sheaves and fewer belts. checker, shown at left, is ideal for this procedure.

You save money and increase 5. Check the tension at least twice during the first day

drive life. of operation, and periodically thereafter.

Not This Be sure DEFLECTION = BELT SPAN

— use the 64

Never force belts.

inexpensive

Move motor on adjustable base

so belts can go on easily. BROWNING® Belt

Tension Checker

See Form 5453

Eliminate slack.

for more detail.

Adjust motor and tighten belts in

position. Slack belts wear The capacity of the BROWNING® belt tension checker is 35

excessively, cause slippage and lbs. Other means of applying force must be used if force

deliver less power. requirement is greater than this.

Use matched belts. SHEAVE DIAM - INCHES

Matched belts run smoother and DEFLECTION FORCE - LBS.

Belt Deflection Force

last longer because the load is

Super Gripnotch

evenly distributed. Never replace Smallest Gripbelts Belts

Belt and and

just part of a set of belts. Sheave RPM

Cross Unnotched Notched

Diameter Range

Section Gripbands Gripbands

Range

Avoid belt idlers. Used

Belt

New

Belt

Used

Belt

New

Belt

Belt idlers decrease belt life! 1000-2500 3.7 5.5 4.1 6.1

3.0 - 3.6

Always maintain proper tension 2501-4000 2.8 4.2 3.4 5.0

1000-2500 4.5 6.8 5.0 7.4

through motor adjustment. A,AX 3.8 - 4.8 2501-4000 3.8 5.7 4.3 6.4

1000-2500 5.4 8.0 5.7 8.4

5.0 - 7.0 2501-4000 4.7 7.0 5.1 7.6

Mount belts straight. 3.4 - 4.2 860-2500 - - 4.9 7.2

2501-4000 - - 4.2 6.2

Shafts must be parallel and 860-2500 5.3 7.9 7.1 10.5

B,BX 4.4 - 5.6

sheave grooves in alignment to 2501-4000 4.5 6.7 6.1 9.1

prevent unnecessary belt wear. 860-2500 6.3 9.4 8.5 12.6

5.8 - 8.6 2501-4000 6.0 8.9 7.3 10.9

500-1740 11.5 17.0 14.7 21.8

7.0 - 9.0 1741-3000 9.4 13.8 11.9 17.5

C,CX

Don’t overload. 9.5 - 16.0 500-1740 14.1 21.0 15.9 23.5

1741-3000 12.5 18.5 14.6 21.6

An overloaded belt drive is like a 200-850 24.9 37.0 - -

12.0 - 16.0

one-ton truck with a two-ton 851-1500 21.2 31.3 - -

D

load — both are sure to break 200-850 30.4 45.2 - -

18.0 - 20.0 851-1500 25.6 38.0 - -

down. Always use ample capacity. 1000-2500 - - 3.3 4.9

2.2 - 2.4 2501-4000 - - 2.9 4.3

1000-2500 3.6 5.1 4.2 6.2

3V,3VX 2.65 - 3.65 2501-4000 3.0 4.4 3.8 5.6

1000-2500 4.9 7.3 5.3 7.9

4.12 - 6.90 2501-4000 4.4 6.6 4.9 7.3

500-1749 - - 10.2 15.2

4.4 - 6.7 1750-3000 - - 8.8 13.2

3001-4000 - - 5.6 8.5

5V,5VX 500-1740 12.7 18.9 14.8 22.1

7.1 - 10.9 1741-3000 11.2 16.7 13.7 20.1

500-1740 15.5 23.4 17.1 25.5

11.8 - 16.0 1741-3000 14.6 21.8 16.8 25.0

200-850 33.0 49.3 - -

12.5 - 17.0

© Emerson Power Transmission Manufacturing, L.P. 1998, 1999. 8V

851-1500 26.8 39.9 - -

200-850 39.6 59.2 - -

All Rights Reserved. 18.0 - 22.4 851-1500 35.3 52.7 - -

Do Not

These BROWNING Gripbelts

are accurately machine matched Install

BROWNING Matched Belts provide a true running drive and longer

service life. You can depend on them because they are matched un-

der tension — that is, while in the sheave grooves, in motion, under

the same conditions encountered during operation. These

Fill in the information below —

detach and tie to machine or file for handy reference

when belts need to be replaced. Matched

These BROWNING BELTS

were installed:

Date

Belts

Machine

Description

Factory

Location

Until

Gripbelt

Size

Number

of Belts

You

Reorder From:

Read

This

Form 8082-C 7/30/99

Printed in U.S.A. Browning

© Emerson Power Transmission Manufacturing, L.P. 1998, 1999. Emerson Power Transmission

All Rights Reserved. ® MAYSVILLE, KY 41056

You might also like

- 303 - 1 Power Transmission Equipment Course PreviewDocument19 pages303 - 1 Power Transmission Equipment Course PreviewAnonymous q9eCZHMuS0% (2)

- DODGE V Belt IOM PDFDocument8 pagesDODGE V Belt IOM PDFSupervisorNo ratings yet

- Belt Tension Checker Instruction Sheet PDFDocument2 pagesBelt Tension Checker Instruction Sheet PDFhectorNo ratings yet

- Shorty 4 InstallDocument2 pagesShorty 4 Installoli garkiNo ratings yet

- ME2121-2 Lab ReportDocument14 pagesME2121-2 Lab ReportZu Jian LeeNo ratings yet

- Manual de Servicio CX330 PDFDocument623 pagesManual de Servicio CX330 PDFandrea83% (6)

- P&ID Symbols For EngineerDocument2 pagesP&ID Symbols For EngineerVarun PatelNo ratings yet

- Belt Tension IngDocument2 pagesBelt Tension Ingmallick099No ratings yet

- 106.5 - BeltsDocument10 pages106.5 - BeltsHassan GDOURANo ratings yet

- BANDO-Belt TensionDocument1 pageBANDO-Belt TensionTeerachai PruksapitakulNo ratings yet

- V-Belt Drives 0905Document3 pagesV-Belt Drives 0905FV AllanNo ratings yet

- ACS SCBA Fit Poster ANZ PA LogoDocument1 pageACS SCBA Fit Poster ANZ PA LogopgsvarnaNo ratings yet

- Fenner Belt Tension Pen Data Sheet PDFDocument2 pagesFenner Belt Tension Pen Data Sheet PDFSadi KutkutNo ratings yet

- Torque Team V-Belt: Installation GuideDocument2 pagesTorque Team V-Belt: Installation GuideMary Huaylla ANo ratings yet

- Variable Speed Cog-Belt - pdf-1Document4 pagesVariable Speed Cog-Belt - pdf-1Daniel VilchesNo ratings yet

- Fenner 471 Friction Belt Installation Guide by CBC AustraliaDocument2 pagesFenner 471 Friction Belt Installation Guide by CBC AustraliaFanir ZNo ratings yet

- Methods of Power TransmissionDocument6 pagesMethods of Power Transmissionirka kaNo ratings yet

- The Gap Should Be The Same On Both Sides of The RimDocument2 pagesThe Gap Should Be The Same On Both Sides of The RimGeorge UrdeaNo ratings yet

- Steep Angle Conveyors Brochure 2015 - WEBDocument4 pagesSteep Angle Conveyors Brochure 2015 - WEBDug1as GreyNo ratings yet

- V-Belt Troubleshooting-1Document1 pageV-Belt Troubleshooting-1IR MA Al AzharNo ratings yet

- Fabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionDocument16 pagesFabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionAbdul Kani Ahamed MNo ratings yet

- Belt Tension Gauge InstructionsDocument2 pagesBelt Tension Gauge InstructionsTodor HuklevNo ratings yet

- Fault Possible Cause Remedy: 4.3 Bale Thrower Faults and RemedyDocument34 pagesFault Possible Cause Remedy: 4.3 Bale Thrower Faults and RemedyEugenio ChipreNo ratings yet

- kx80 Página 148Document1 pagekx80 Página 148PabloNo ratings yet

- Technical Guideline: Ammeraal BeltechDocument2 pagesTechnical Guideline: Ammeraal Beltechbrad209No ratings yet

- Why Does Belt Tension Matter?: Why It Matters and How It Affects Belt LifeDocument2 pagesWhy Does Belt Tension Matter?: Why It Matters and How It Affects Belt LifeMinh AnhNo ratings yet

- Fenner Wedge & V-Belt Tensioning Instructions PDFDocument2 pagesFenner Wedge & V-Belt Tensioning Instructions PDFAlejandro Rosette88% (8)

- 5603 Front Derailer ServiceDocument1 page5603 Front Derailer ServiceMichaelRMilaniNo ratings yet

- Carlisle PowerWedgeCogBelt SellSheet 06071611Document2 pagesCarlisle PowerWedgeCogBelt SellSheet 06071611Fada RayNo ratings yet

- W412 EnUS 412 SelectFstrINS 110716Document2 pagesW412 EnUS 412 SelectFstrINS 110716Mary Antoinette C. MadoloraNo ratings yet

- General Information: Chain SlingsDocument5 pagesGeneral Information: Chain SlingsEtibar AliyevNo ratings yet

- Pulley Alignment ProceduDocument9 pagesPulley Alignment ProceduJosh Watts100% (2)

- Common Seam Quality DefectsDocument6 pagesCommon Seam Quality Defectskernchia100% (2)

- StarTracker ENG COMPRESSEDDocument3 pagesStarTracker ENG COMPRESSEDNiko SwandanaNo ratings yet

- Belt DriveDocument34 pagesBelt DriveGaurav Kumar GuptaNo ratings yet

- Ben SinglesizeDocument20 pagesBen SinglesizeZuhaib AhmadNo ratings yet

- 01 Belt DriveDocument54 pages01 Belt DrivessNo ratings yet

- 305-Fms Recommendation Machine Design enDocument20 pages305-Fms Recommendation Machine Design envhbernaltNo ratings yet

- Recommendations For Machine Design: ContentDocument20 pagesRecommendations For Machine Design: ContentEmerson FerreiraNo ratings yet

- Belt GuideDocument1 pageBelt GuideJulwenNo ratings yet

- Broch Offshore Sling Aug2013 WebDocument6 pagesBroch Offshore Sling Aug2013 WebDavid Wise-MannNo ratings yet

- Msi Belt Scale: Application GuidelinesDocument19 pagesMsi Belt Scale: Application GuidelinesJulisa LombardoNo ratings yet

- Bandas Industriales DAYCO PDFDocument70 pagesBandas Industriales DAYCO PDFdidi_carolaNo ratings yet

- ME 7 - Activity 8Document3 pagesME 7 - Activity 8Rygen Faye Del RosarioNo ratings yet

- Belt Routing GuideDocument87 pagesBelt Routing GuideBYRONGOSNo ratings yet

- Recommendations For Machine Design: Siegling TransilonDocument20 pagesRecommendations For Machine Design: Siegling Transilondesky nguyenNo ratings yet

- WC150XP: 16 Gauge 1" Wide Crown StaplerDocument2 pagesWC150XP: 16 Gauge 1" Wide Crown StaplerDmitry DanilovNo ratings yet

- Maintenance Notes: Ensure That Roller Chains Are Properly TensionedDocument8 pagesMaintenance Notes: Ensure That Roller Chains Are Properly TensionedBülent BulutNo ratings yet

- Vbelt Cog Belt BeltingDocument16 pagesVbelt Cog Belt BeltingmarranNo ratings yet

- Vbelt Cog Belt BeltingDocument16 pagesVbelt Cog Belt BeltingFREDDY YAJAMINNo ratings yet

- PuleyDocument9 pagesPuleynicolasNo ratings yet

- RefrigeraçãoDocument6 pagesRefrigeraçãoozeas Vilela de moraisNo ratings yet

- Electric Chainsaw: Instruction ManualDocument10 pagesElectric Chainsaw: Instruction Manualshabab_14No ratings yet

- Belt Weighing WT10 - en - Kap04 PDFDocument60 pagesBelt Weighing WT10 - en - Kap04 PDFomarNo ratings yet

- Belt Weighing WT10 - en - Kap04 PDFDocument60 pagesBelt Weighing WT10 - en - Kap04 PDFomarNo ratings yet

- BetsDocument18 pagesBetskahandawalaNo ratings yet

- Effective Use of Gauges and Measuring InstrumentsDocument31 pagesEffective Use of Gauges and Measuring Instrumentsaizaz65No ratings yet

- INA 0045 enDocument2 pagesINA 0045 enOTAVIO RobertoNo ratings yet

- Denim Seam Quality DefectsDocument6 pagesDenim Seam Quality Defectsapi-26494555No ratings yet

- Belt Scale Handbookaa 180626111648 PDFDocument29 pagesBelt Scale Handbookaa 180626111648 PDFrbounaNo ratings yet

- Viper MKII Selection Guide 1020 V1Document7 pagesViper MKII Selection Guide 1020 V1po truongNo ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingNo ratings yet

- Class Code Description Revision: Numerical Index of Inspection CodesDocument8 pagesClass Code Description Revision: Numerical Index of Inspection CodesRaheleh JavidNo ratings yet

- 3225 HARDOX 450 Prilog OcjenDocument6 pages3225 HARDOX 450 Prilog OcjenGoran SpasojevicNo ratings yet

- Synchronous Motor Operation and ControlDocument2 pagesSynchronous Motor Operation and ControlHéctor AlmodovarNo ratings yet

- Daihatsu - 5DK-20 - Instruction Manual Aux. Engine DK-20 (Maintenance)Document173 pagesDaihatsu - 5DK-20 - Instruction Manual Aux. Engine DK-20 (Maintenance)andriy.b1979No ratings yet

- Is 1893 1984Document83 pagesIs 1893 1984rcdk2No ratings yet

- Allweiler NTT Series DimensionsDocument2 pagesAllweiler NTT Series Dimensionskrisorn100% (1)

- Astm A105Document5 pagesAstm A105Ali ArsalanNo ratings yet

- Application Guide - Aerospace Sealants PDFDocument4 pagesApplication Guide - Aerospace Sealants PDFRiki NurzamanNo ratings yet

- Dominar 400 Spare Parts CatalogueDocument82 pagesDominar 400 Spare Parts CatalogueAkshayaNo ratings yet

- Tensile Calculation PDFDocument2 pagesTensile Calculation PDFWendimagen Meshesha FantaNo ratings yet

- Outdoor UnitsDocument47 pagesOutdoor UnitsSayeed AnwarNo ratings yet

- Tapered Pipe Threads PDFDocument1 pageTapered Pipe Threads PDFMoises GarciaNo ratings yet

- 2016-1 Breno Ventorim de TassisDocument49 pages2016-1 Breno Ventorim de TassisMedhn AbrahaNo ratings yet

- Stability Analysis of Steel Storage Rack StructuresDocument6 pagesStability Analysis of Steel Storage Rack StructurescoolkaisyNo ratings yet

- SKF Explorer ACBB 10572 en TCM 12-32273Document8 pagesSKF Explorer ACBB 10572 en TCM 12-32273ankitsarvaiyaNo ratings yet

- PID Rotary Dryer PDFDocument6 pagesPID Rotary Dryer PDFLêNhậtMinhNo ratings yet

- F DampersDocument17 pagesF Dampersbaba onuNo ratings yet

- Techdoc - Print - Page (Manual Armado CAT 785) PDFDocument347 pagesTechdoc - Print - Page (Manual Armado CAT 785) PDFhualae67% (3)

- ItemsDocument204 pagesItemsfattaninaveed786100% (1)

- Engineering Design Guideline-Relief Valves - Rev 02Document30 pagesEngineering Design Guideline-Relief Valves - Rev 02Pilar Ruiz RamirezNo ratings yet

- Ibong Tiririt Pipe 1Document75 pagesIbong Tiririt Pipe 1Mc LesterNo ratings yet

- Hydraulic Showvls Cat 6090 Fs PDFDocument8 pagesHydraulic Showvls Cat 6090 Fs PDFGlory LightNo ratings yet

- OrganizedDocument34 pagesOrganizedMochammad Su'udNo ratings yet

- KTG ThermodynamicsDocument36 pagesKTG ThermodynamicsSatyajit ManeNo ratings yet

- 00 Catalogue Update UK PDFDocument7 pages00 Catalogue Update UK PDFhepcomotionNo ratings yet

- Precision Meters: User ManualDocument24 pagesPrecision Meters: User ManualJuan Flores GraweNo ratings yet

- Aab Acv Cooling SystDocument35 pagesAab Acv Cooling SystAgusto C'estimo100% (1)