Professional Documents

Culture Documents

ااىى

ااىى

Uploaded by

aymen telli0 ratings0% found this document useful (0 votes)

15 views2 pagesThe drilling fluid, also called drilling mud, is a mixture of liquids, gases, and solids that is circulated through the drill pipe and drill bit during drilling operations. It serves several important purposes:

- It carries cuttings from the drill bit up to the surface for analysis of the rock formations being drilled.

- It helps keep cuttings suspended when circulation is stopped to prevent them from settling and causing drilling problems.

- It cools and lubricates the drill bit to prevent excessive wear on moving parts.

The drilling fluid is carefully engineered to have a density high enough to counter abnormal formation pressures and prevent fluid from the formations from entering the wellbore but not so high as to damage

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe drilling fluid, also called drilling mud, is a mixture of liquids, gases, and solids that is circulated through the drill pipe and drill bit during drilling operations. It serves several important purposes:

- It carries cuttings from the drill bit up to the surface for analysis of the rock formations being drilled.

- It helps keep cuttings suspended when circulation is stopped to prevent them from settling and causing drilling problems.

- It cools and lubricates the drill bit to prevent excessive wear on moving parts.

The drilling fluid is carefully engineered to have a density high enough to counter abnormal formation pressures and prevent fluid from the formations from entering the wellbore but not so high as to damage

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views2 pagesااىى

ااىى

Uploaded by

aymen telliThe drilling fluid, also called drilling mud, is a mixture of liquids, gases, and solids that is circulated through the drill pipe and drill bit during drilling operations. It serves several important purposes:

- It carries cuttings from the drill bit up to the surface for analysis of the rock formations being drilled.

- It helps keep cuttings suspended when circulation is stopped to prevent them from settling and causing drilling problems.

- It cools and lubricates the drill bit to prevent excessive wear on moving parts.

The drilling fluid is carefully engineered to have a density high enough to counter abnormal formation pressures and prevent fluid from the formations from entering the wellbore but not so high as to damage

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

I.1.

1 Définition

The drilling fluid, also called drilling mud, is a system composed of

different liquid (water, oil) and / or gaseous (air or natural gas)

constituents containing in suspension other mineral and organic

additives (clays, polymers, surfactants, cuttings, cements, ...). The drilling

fluid was already presented in 1933 at the first World Petroleum

Congress, where it was the subject of five papers The first treatise on

drilling fluids was published in 1936 by Evans and Reid. In 1979, the

American Petroleum Institute (API) defined drilling fluid as a fluid in

continuous circulation throughout the drilling period, both in the borehole

and on the surface. The fluid is prepared in sludge tanks, it is injected

inside the rods to the tool from where it goes up into the ring finger,

loaded with the cuttings formed at the face. At the exit of the well, it

undergoes various treatments, sieving, dilution, addition of products, so

as to eliminate the excavated material transported and to readjust its

physico-chemical characteristics to their initial values. It was then reused

(Landriot, 1968)....

Ensure removal of cuttings from the bottom of the well to the surface by

the circulation of a viscous fluid in the annular space. This cuttings

provide geological information on the formations drilled.

Keep the cuttings in suspension when there is no circulation in order to

prevent sedimentation of cuttings which may lead to mecanical stuck,

this is possible thanks to the thixotropic nature of the fluid.

Cool and lubricate the bit to prevent rapid wear of moving metal parts.

Formation pressure monitoring

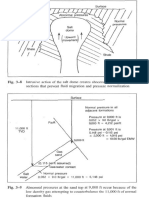

The formation pressure is the pressure of the fluid within the pore spaces of the formation

rock while the hydrostatic pressure is the total fluid pressure created by the weight of a

column of fluid acting on any given point in a well and it is mathematically represented

by equation 1 and 2. The fluid formation pressure must be kept and maintained at a level

that is sufficiently lower than the fluid hydrostatic pressure in order to prevent the inflow

of formation fluid into the well bore. Uncontrolled fluid formation pressure can result in

formation fracture, abnormal inflow of formation fluid into the wellbore (Kick) and an

uncontrolled kick will eventually lead to blow out [Rabia 1986]. One common method

of increasing the hydrostatic pressure is by increasing the drilling mud density. Drilling

muds are typically required to have moderately high densities that provides sufficient

hydrostatic pressure to prevent influx of formation fluids into the well bore, counter

abnormal formation pressure and to mechanically stabilize unstable formation.

Excessively high density can result in loss of circulation, damage to the drilled formation

and lower drilling rate.

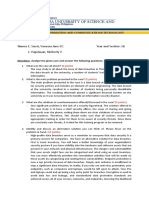

4 Sealing of permeable formation

During oil and gas drilling activities, the mud filtrate invades the porous and permeable

formation that is being drilled because the mud column pressure is higher than the

formation pressure and the filtrate invasion process continues until the solid components

of the mud form a thin low permeability filter cake on the wellbore wall that forms a seal

and thus prevents further invasion. Drilling mud system must be carefully formulated to

prevent the deposition of thick filter cake that unarguably cause tight holes, poor log

result quality, stuck pipe, lost circulation and potential damage to the formation [Anawe

and Folayan,2018a

You might also like

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Soil Erosion: The Greatest Challenge for Sustainable Soil ManagementFrom EverandSoil Erosion: The Greatest Challenge for Sustainable Soil ManagementNo ratings yet

- Hydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesFrom EverandHydraulic Fracturing Explained: Evaluation, Implementation, and ChallengesNo ratings yet

- Comparison of Jis and Din StandardsDocument14 pagesComparison of Jis and Din StandardsRaja Sunder50% (2)

- Inventory Optimization EbookDocument18 pagesInventory Optimization EbookDiego Cortez GranadosNo ratings yet

- Hidro FrackingDocument24 pagesHidro FrackingCalitoo IGNo ratings yet

- YR 7 Chapter 3 Notes - Shale Oil and FrackingDocument2 pagesYR 7 Chapter 3 Notes - Shale Oil and FrackingEldar SydneyNo ratings yet

- Hydraulic FracturingDocument50 pagesHydraulic FracturingjusrihNo ratings yet

- Chapter One 1.1 Hydraulic ExplorationDocument23 pagesChapter One 1.1 Hydraulic ExplorationNkem OkonkwoNo ratings yet

- Drilling FluidDocument9 pagesDrilling FluidJalaj DagarNo ratings yet

- English Work (1) 1Document17 pagesEnglish Work (1) 1Gizela MarcosNo ratings yet

- Well Control 1Document12 pagesWell Control 1mohamedNo ratings yet

- What Is Fracking?: Hydraulic FracturingDocument7 pagesWhat Is Fracking?: Hydraulic FracturingAnurag RoyNo ratings yet

- DRILLING FLUIDS HandoutDocument10 pagesDRILLING FLUIDS HandoutHans SamNo ratings yet

- Wastewater Management 050814Document6 pagesWastewater Management 050814downbuliaoNo ratings yet

- Drilling 1665432468Document7 pagesDrilling 1665432468yosifNo ratings yet

- Hydraulic Fracturing PDFDocument21 pagesHydraulic Fracturing PDFSarah HayesNo ratings yet

- Pore, Abnormal Formation and Fracture Pressure PredictionDocument16 pagesPore, Abnormal Formation and Fracture Pressure Predictiondion gunawanNo ratings yet

- PjTatano HydraulicFracturing TechnicalDefinitionDocument5 pagesPjTatano HydraulicFracturing TechnicalDefinitionPj TatanoNo ratings yet

- B Ing ArtikelDocument7 pagesB Ing ArtikelFauzan BasyithNo ratings yet

- Reservoir Normal Pressure Clay MudDocument6 pagesReservoir Normal Pressure Clay MudJohanes SiraitNo ratings yet

- Hydraulic FracturingDocument20 pagesHydraulic FracturingJuan David Gallego GomezNo ratings yet

- Contoh Soal SSC PerminyakanDocument6 pagesContoh Soal SSC PerminyakanEbelEdelEdelNo ratings yet

- Oil Well ControlDocument15 pagesOil Well ControlSunder Singh BishtNo ratings yet

- Hydraulic Fracturing Is The Propagation of Fractures in ADocument6 pagesHydraulic Fracturing Is The Propagation of Fractures in ASharmilaa Suresh KannanNo ratings yet

- Mud NotesDocument56 pagesMud Notesrainaldy sebastianNo ratings yet

- Mist Drilling: Soal-Soal PetroleagueDocument9 pagesMist Drilling: Soal-Soal PetroleagueHeri YantoNo ratings yet

- Chapter 4 - Formation PressureDocument69 pagesChapter 4 - Formation PressureMuhammad NursalamNo ratings yet

- Hydraulic Fracturing, Also Called Fracking, Fracing, Hydrofracking, Fraccing, Frac'ingDocument2 pagesHydraulic Fracturing, Also Called Fracking, Fracing, Hydrofracking, Fraccing, Frac'ingHSENo ratings yet

- Oil Wells and Drilling TheoryDocument13 pagesOil Wells and Drilling TheoryAyanami ReiNo ratings yet

- 2 IntroductionDocument45 pages2 IntroductionAmany AymanNo ratings yet

- PDFDocument25 pagesPDFDani S ManikNo ratings yet

- Oil Recovery (Oil Production) ProcessDocument7 pagesOil Recovery (Oil Production) ProcessLathifa Rahma AstutiNo ratings yet

- Pressure Regimes Drilling Process Formation Evaluation 1645995935Document34 pagesPressure Regimes Drilling Process Formation Evaluation 1645995935Muhammad Husein MahfudzNo ratings yet

- Hydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydrofracking) IsDocument1 pageHydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydrofracking) IsAnonymous QM0NLqZONo ratings yet

- Hydraulic FracturingDocument17 pagesHydraulic FracturingGeroldo 'Rollie' L. QuerijeroNo ratings yet

- Enhanced Oil Recovery - EOR-1Document16 pagesEnhanced Oil Recovery - EOR-1seb359No ratings yet

- Fluidos Neumaticos de PerforacionDocument12 pagesFluidos Neumaticos de PerforaciondollyNo ratings yet

- FlotationDocument40 pagesFlotationAhmed Mohamed RedaNo ratings yet

- Hydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydr Ofracking) Is ADocument2 pagesHydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydr Ofracking) Is AAnonymous QM0NLqZONo ratings yet

- 55 - Formation FracturingDocument12 pages55 - Formation Fracturingrizal tri susiloNo ratings yet

- Water: As A Drilling Fluid in Production Zone of Geothermal WellsDocument4 pagesWater: As A Drilling Fluid in Production Zone of Geothermal WellsSuci Nur HidayahNo ratings yet

- Some Hydraulic Fracturing ExampleDocument5 pagesSome Hydraulic Fracturing ExampleLeonNo ratings yet

- Pore, Abnormal Formation and Fracture Pressure Prediction: F. Khoshnaw, P. Jaf & S. FarkhaDocument15 pagesPore, Abnormal Formation and Fracture Pressure Prediction: F. Khoshnaw, P. Jaf & S. FarkhaC9c mNo ratings yet

- C631217 Bentonite Test PDFDocument6 pagesC631217 Bentonite Test PDFsunitkghosh1No ratings yet

- Chapter 1 - Introduction To Reservoir EngineeringDocument17 pagesChapter 1 - Introduction To Reservoir Engineeringmdkhan1100% (1)

- 589 PDFDocument10 pages589 PDFRezaNo ratings yet

- Project Report 2013Document45 pagesProject Report 2013Bhupendrapal SinghNo ratings yet

- Drilling Fluid - Wikipedia, The Free EncyclopediaDocument9 pagesDrilling Fluid - Wikipedia, The Free EncyclopediasomsubhraNo ratings yet

- Introduction To Oil and Gas Mock Marking GuidesDocument6 pagesIntroduction To Oil and Gas Mock Marking Guidesboris yeltinNo ratings yet

- High Temprature and High Pressure 2Document16 pagesHigh Temprature and High Pressure 2Sushmita SatiNo ratings yet

- Determination of PH Value in Mud FluidDocument18 pagesDetermination of PH Value in Mud Fluidn oNo ratings yet

- Candice Palmer, Zbigniew Sito : Air Products and ChemicalsDocument8 pagesCandice Palmer, Zbigniew Sito : Air Products and ChemicalsNightNo ratings yet

- BlowoutDocument14 pagesBlowoutNelson TorresNo ratings yet

- Methods Used For Shale Gas Extraction: Shale Exploration and ProductionDocument5 pagesMethods Used For Shale Gas Extraction: Shale Exploration and ProductionRichard ObinnaNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Water-Based Chemicals and Technology for Drilling, Completion, and Workover FluidsFrom EverandWater-Based Chemicals and Technology for Drilling, Completion, and Workover FluidsRating: 3.5 out of 5 stars3.5/5 (3)

- New Perspectives on Deep-water Sandstones: Origin, Recognition, Initiation, and Reservoir QualityFrom EverandNew Perspectives on Deep-water Sandstones: Origin, Recognition, Initiation, and Reservoir QualityNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Multiphase Flow Metering: Principles and ApplicationsFrom EverandMultiphase Flow Metering: Principles and ApplicationsRating: 2.5 out of 5 stars2.5/5 (2)

- The Fifth Meeting and the Termination of CSAGI: Annals of The International Geophysical Year, Vol. 10From EverandThe Fifth Meeting and the Termination of CSAGI: Annals of The International Geophysical Year, Vol. 10M. NicoletNo ratings yet

- Pingaping, Maricel Beed 3B EL ED 134 Yubos, Cherry AnnDocument2 pagesPingaping, Maricel Beed 3B EL ED 134 Yubos, Cherry AnnPingaping, Maricel B.No ratings yet

- Python CurriculumDocument3 pagesPython CurriculumUjwal TickooNo ratings yet

- Data Science Practical No 09Document8 pagesData Science Practical No 09Satyavan MestryNo ratings yet

- Mo 12134Document21 pagesMo 12134MohamedAyoubNo ratings yet

- NCP Impaired ComfortDocument2 pagesNCP Impaired ComfortGia P. de VeyraNo ratings yet

- Combined Cycle Nandi Pur Power PlantDocument57 pagesCombined Cycle Nandi Pur Power PlantHassan FarazNo ratings yet

- Man Pack Jammer - PKI Electronic Intelligence GMBH GermanyDocument1 pageMan Pack Jammer - PKI Electronic Intelligence GMBH Germanyashwin tripathiNo ratings yet

- Visual Foxpro Excel Question PaperDocument1 pageVisual Foxpro Excel Question PaperSukanta PalNo ratings yet

- MTB Q1W4Document10 pagesMTB Q1W4BERWYN JAKE LAZONo ratings yet

- Mint 4 PDFDocument16 pagesMint 4 PDFgst userNo ratings yet

- Module 3 - CommunicationDocument58 pagesModule 3 - CommunicationMishal UbaidullahNo ratings yet

- Lactobacillus Pneumococcus Plasmodium: MCQ Unit 6Document4 pagesLactobacillus Pneumococcus Plasmodium: MCQ Unit 6Anand100% (1)

- Quiz 3 SolutionDocument6 pagesQuiz 3 SolutionZuhoor UddinNo ratings yet

- SurfaceDocument20 pagesSurfaceHernandez CitlalyNo ratings yet

- Effectiveness of Digital Music Platforms ' Social Media Interaction On Advertising Trust Using Cognitive AspectsDocument16 pagesEffectiveness of Digital Music Platforms ' Social Media Interaction On Advertising Trust Using Cognitive Aspectsceria Pro 02No ratings yet

- Electromegnetics Field Theory - KEE301 PDFDocument1 pageElectromegnetics Field Theory - KEE301 PDFTomer ThakurNo ratings yet

- G&C - Monolithic Refractories PDFDocument8 pagesG&C - Monolithic Refractories PDFWalmansilalahiNo ratings yet

- Lecture 3 - Process Management (Concurrency-Mutual Exclusion, Synchronization Concurrency Problems)Document67 pagesLecture 3 - Process Management (Concurrency-Mutual Exclusion, Synchronization Concurrency Problems)samwel sittaNo ratings yet

- Design of Retaining WallDocument35 pagesDesign of Retaining WalluviNo ratings yet

- Book 1Document5 pagesBook 1Mas Hamzah FansuriNo ratings yet

- Voices UpperIntermediate Wordlist 1Document45 pagesVoices UpperIntermediate Wordlist 1Olga ChervonenkoNo ratings yet

- Activity 2 IASbDocument3 pagesActivity 2 IASbVanessa SawitNo ratings yet

- Muranga Ees 201 Tut 1Document3 pagesMuranga Ees 201 Tut 1jonathan otienoNo ratings yet

- Generalphysics q1 Mod1 KDoctolero-1Document28 pagesGeneralphysics q1 Mod1 KDoctolero-1Mary Christine DamianNo ratings yet

- Design of Pressure Vessel by Group 4Document46 pagesDesign of Pressure Vessel by Group 4anteneh tesfayeNo ratings yet

- @janhavi Saywan Resume-1Document2 pages@janhavi Saywan Resume-1Debi Das SarkarNo ratings yet

- Atlantic Pilot Atlas (Including The Caribbean & Mediterranean) - James Clarke PDFDocument81 pagesAtlantic Pilot Atlas (Including The Caribbean & Mediterranean) - James Clarke PDFEzequiel Juarez BenítezNo ratings yet

- Extended Enterprise Architecture Maturity Model Guide v2Document8 pagesExtended Enterprise Architecture Maturity Model Guide v2amunoz81No ratings yet