Professional Documents

Culture Documents

Belimo NR24A-MP Datasheet En-Gb

Uploaded by

COSTIN NESTIANOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Belimo NR24A-MP Datasheet En-Gb

Uploaded by

COSTIN NESTIANCopyright:

Available Formats

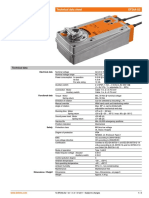

Technical data sheet NR24A-MP

Communicative rotary actuator for ball valves

• Torque motor 10 Nm

• Nominal voltage AC/DC 24 V

• Control modulating, communicative 2...10 V

variable

• Position feedback 2...10 V variable

• Conversion of sensor signals

• Communication via Belimo MP-Bus

Technical data

Electrical data Nominal voltage AC/DC 24 V

Nominal voltage frequency 50/60 Hz

Nominal voltage range AC 19.2...28.8 V / DC 21.6...28.8 V

Power consumption in operation 3.5 W

Power consumption in rest position 1.2 W

Power consumption for wire sizing 6 VA

Connection supply / control Cable 1 m, 4 x 0.75 mm²

Parallel operation Yes (note the performance data)

Data bus communication Communicative control MP-Bus

Number of nodes MP-Bus max. 8

Functional data Torque motor 10 Nm

Operating range Y 2...10 V

Input Impedance 100 kΩ

Operating range Y variable Start point 0.5...30 V

End point 2.5...32 V

Options positioning signal Open/close

3-point (AC only)

Modulating (DC 0...32 V)

Position feedback U 2...10 V

Position feedback U note Max. 0.5 mA

Position feedback U variable Start point 0.5...8 V

End point 2.5...10 V

Position accuracy ±5%

Manual override with push-button, can be locked

Running time motor 90 s / 90°

Running time motor variable 45...170 s

Adaptation setting range manual (automatic on first power-up)

Adaptation setting range variable No action

Adaptation when switched on

Adaptation after pushing the gear

disengagement button

Override control MAX (maximum position) = 100%

MIN (minimum position) = 0%

ZS (intermediate position, AC only) = 50%

Override control variable MAX = (MIN + 33%)...100%

MIN = 0%...(MAX – 33%)

ZS = MIN...MAX

Sound power level, motor 45 dB(A)

Position indication Mechanically, pluggable

Safety data Protection class IEC/EN III, Safety Extra-Low Voltage (SELV)

www.belimo.com NR24A-MP • en-gb • 2022-03-08 • Subject to change 1/7

Technical data sheet NR24A-MP

Safety data Power source UL Class 2 Supply

Degree of protection IEC/EN IP54

Degree of protection NEMA/UL NEMA 2

Enclosure UL Enclosure Type 2

EMC CE according to 2014/30/EU

Certification IEC/EN IEC/EN 60730-1 and IEC/EN 60730-2-14

Certification UL cULus according to UL60730-1A, UL60730-2-14

and CAN/CSA E60730-1

The UL marking on the actuator depends on

the production site, the device is UL-compliant

in any case

Mode of operation Type 1

Rated impulse voltage supply / control 0.8 kV

Pollution degree 3

Ambient temperature -30...50°C

Storage temperature -40...80°C

Ambient humidity Max. 95% RH, non-condensing

Servicing maintenance-free

Weight Weight 0.76 kg

Safety notes

• This device has been designed for use in stationary heating, ventilation and air-conditioning

systems and must not be used outside the specified field of application, especially in aircraft or

in any other airborne means of transport.

• Outdoor application: only possible in case that no (sea) water, snow, ice, insolation or

aggressive gases interfere directly with the device and that it is ensured that the ambient

conditions remain within the thresholds according to the data sheet at any time.

• Only authorised specialists may carry out installation. All applicable legal or institutional

installation regulations must be complied during installation.

• The switch for changing the direction of rotation may only be operated by authorised

specialists. The direction of rotation must not in particular be reversed in a frost protection

circuit.

• The device may only be opened at the manufacturer's site. It does not contain any parts that

can be replaced or repaired by the user.

• Cables must not be removed from the device.

• The device contains electrical and electronic components and must not be disposed of as

household refuse. All locally valid regulations and requirements must be observed.

Product features

Mode of operation Conventional operation:

The actuator is connected with a standard modulating signal of 0...10 V and drives to the

position defined by the control signal. Measuring voltage U serves for the electrical display of

the valve position 0.5...100% and as control signal for other actuators.

Operation on Bus:

The actuator receives its digital positioning signal from the higher level controller via the MP-

Bus and drives to the position defined. Connection U serves as communication interface and

does not supply an analogue measuring voltage.

Converter for sensors Connection option for a sensor (passive or active sensor or switching contact). The MP actuator

serves as an analogue/digital converter for the transmission of the sensor signal via MP-Bus to

the higher level system.

Parametrisable actuators The factory settings cover the most common applications. Single parameters can be modified

with the Belimo Service Tools MFT-P or ZTH EU.

www.belimo.com NR24A-MP • en-gb • 2022-03-08 • Subject to change 2/7

Technical data sheet NR24A-MP

Simple direct mounting Straightforward direct mounting on the ball valve with only one central screw. The assembly

tool is integrated in the plug-in position indication. The mounting orientation in relation to the

ball valve can be selected in 90° steps.

Manual override Manual override with push-button possible (the gear is disengaged for as long as the button is

pressed or remains locked).

Adjustable angle of rotation Adjustable angle of rotation with mechanical end stops.

High functional reliability The actuator is overload protected, requires no limit switches and automatically stops when the

end stop is reached.

Home position The first time the supply voltage is switched on, i.e. at the time of commissioning, the actuator

carries out an adaptation, which is when the operating range and position feedback adjust

themselves to the mechanical setting range.

The actuator then moves into the position defined by the positioning signal.

Factory setting: Y2 (counter-clockwise rotation).

Adaptation and synchronisation An adaptation can be triggered manually by pressing the "Adaptation" button or with the PC-

Tool. Both mechanical end stops are detected during the adaptation (entire setting range).

Automatic synchronisation after pressing the gearbox disengagement button is configured. The

synchronisation is in the home position (0%).

The actuator then moves into the position defined by the positioning signal.

A range of settings can be adapted using the PC-Tool (see MFT-P documentation)

Accessories

Gateways Description Type

Gateway MP zu BACnet MS/TP UK24BAC

Gateway MP to Modbus RTU UK24MOD

Electrical accessories Description Type

Auxiliary switch 1 x SPDT add-on S1A

Auxiliary switch 2 x SPDT add-on S2A

Feedback potentiometer 140 Ω add-on P140A

Feedback potentiometer 200 Ω add-on P200A

Feedback potentiometer 500 Ω add-on P500A

Feedback potentiometer 1 kΩ add-on P1000A

Feedback potentiometer 2.8 kΩ add-on P2800A

Feedback potentiometer 5 kΩ add-on P5000A

Feedback potentiometer 10 kΩ add-on P10000A

MP-Bus power supply for MP actuators ZN230-24MP

Service tools Description Type

Service Tool, with ZIP-USB function, for parametrisable and ZTH EU

communicative Belimo actuators, VAV controller and HVAC performance

devices

Belimo PC-Tool, Software for adjustments and diagnostics MFT-P

Adapter for Service-Tool ZTH MFT-C

Connection cable 5 m, A: RJ11 6/4 ZTH EU, B: 6-pin for connection to ZK1-GEN

service socket

Connection cable 5 m, A: RJ11 6/4 ZTH EU, B: free wire end for connection ZK2-GEN

to MP/PP terminal

Electrical installation

Supply from isolating transformer.

Parallel connection of other actuators possible. Observe the performance data.

Direction of rotation switch is covered. Factory setting: Direction of rotation Y2.

www.belimo.com NR24A-MP • en-gb • 2022-03-08 • Subject to change 3/7

Technical data sheet NR24A-MP

Wiring diagrams

AC/DC 24 V, modulating Operation on the MP-Bus

Cable colours: Cable colours:

1 = black 1 = black

2 = red 2 = red

3 = white 3 = white

5 = orange 5 = orange

Connection of active sensors Connection of external switching contact

A) additional MP-Bus nodes

A) additional MP-Bus nodes (max. 8)

(max. 8) • Switching current 16 mA @ 24

• Supply AC/DC 24 V V

• Output signal DC 0...10 V • Start point of the operating

(max. DC 0...32 V) range must be parametrised on

• Resolution 30 mV the MP actuator as ≥ 0.5 V

Connection of passive sensors

A) additional MP-Bus nodes

(max. 8)

1) Depending on the type

2) Resolution 1 Ohm

Compensation of the measured

value is recommended

Functions

Functions when operated on MP-Bus

Connection on the MP-Bus MP-Bus Network topology

There are no restrictions for the

network topology (star, ring,

tree or mixed forms are

permitted).

Supply and communication in

one and the same 3-wire cable

• no shielding or twisting

necessary

A) additional MP-Bus nodes • no terminating resistors

(max. 8) required

www.belimo.com NR24A-MP • en-gb • 2022-03-08 • Subject to change 4/7

Technical data sheet NR24A-MP

Functions with basic values (conventional mode)

Override control with AC 24 V with relay contacts Override control with AC 24 V with rotary switch

Control remotely 0...100% with Minimum limit with positioner SG..

positioner SG..

Follow-up control (position-dependent) Control with 4...20 mA via external resistor

Caution:

The operating range must be set

to DC 2...10 V.

The 500 Ω resistor converts the

4...20 mA current signal to a

voltage signal DC 2...10 V

Functional check

Procedure

1. Connect 24 V to connections 1

and 2

2. Disconnect connection 3:

– with direction of rotation Y1:

Actuator rotates to the left

– with direction of rotation Y2

Actuator rotates to the right

3. Short-circuit connections 2

and 3:

– Actuator runs in opposite

direction

www.belimo.com NR24A-MP • en-gb • 2022-03-08 • Subject to change 5/7

Technical data sheet NR24A-MP

Functions with specific parameters (parametrisation necessary)

Override control and limiting with AC 24 V with relay contacts Override control and limiting with AC 24 V with rotary switch

1) Caution: This function is only

guaranteed if the start point of

the operating range is defined

as min. 0.5 V.

Control open/close Control 3-point with AC 24 V

Operating controls and indicators

1 Direction of rotation switch

Switch over: Direction of rotation changes

2 Push-button and LED display green

Off: No power supply or malfunction

On: In operation

Press Triggers angle of rotation adaptation, followed by standard mode

button:

3 Push-button and LED display yellow

Off: Standard mode

On: Adaptation or synchronisation process active

Flickering: MP-Bus communication active

Flashing: Request for addressing from MP client

Press button: Confirmation of the addressing

4 Gear disengagement button

Press button: Gear disengages, motor stops, manual override possible

Release button: Gear engages, standard mode

5 Service plug

For connecting parametrisation and service tools

Check power supply connection

2 Off and 3 On Possible wiring error in power supply

www.belimo.com NR24A-MP • en-gb • 2022-03-08 • Subject to change 6/7

Technical data sheet NR24A-MP

Service

Service tools connection The actuator can be parametrised by ZTH EU via the service socket.

For an extended parametrisation the PC tool can be connected.

Connection ZTH EU / PC-Tool

Dimensions

Further documentation

• Overview MP Cooperation Partners

• Tool connections

• Introduction to MP-Bus Technology

• The complete product range for water applications

• Data sheets for ball valves

• Installation instructions for actuators and/or ball valves

• General notes for project planning

www.belimo.com NR24A-MP • en-gb • 2022-03-08 • Subject to change 7/7

You might also like

- Diesel PowertrainDocument284 pagesDiesel PowertrainCOSTIN NESTIANNo ratings yet

- Home Made Colloidal Silver Generator PDFDocument22 pagesHome Made Colloidal Silver Generator PDFscriberoneNo ratings yet

- Amateur Radio Transceiver Performance TestingDocument101 pagesAmateur Radio Transceiver Performance TestingThe Mini Company MiniPartsNo ratings yet

- Magnetic Particle Testing (Level I Level IIDocument145 pagesMagnetic Particle Testing (Level I Level IIChandresh100% (4)

- 8.3 Electromagnetic InductionDocument117 pages8.3 Electromagnetic InductionPAKK20622 CHARLENE LIONG YAN TINGNo ratings yet

- Ef24a SRDocument4 pagesEf24a SRTrunghieu LeNo ratings yet

- Belimo AFRX24-MFT N4 Datasheet En-UsDocument3 pagesBelimo AFRX24-MFT N4 Datasheet En-UsEdmond AndresNo ratings yet

- Technical Data Sheet SF24A-SRDocument5 pagesTechnical Data Sheet SF24A-SRbabs bobNo ratings yet

- Belimo LM24A-SR Datasheet En-GbDocument3 pagesBelimo LM24A-SR Datasheet En-GbRendi MulyadiNo ratings yet

- Technical Data Sheet LM24A-SRDocument3 pagesTechnical Data Sheet LM24A-SRUmen AryanNo ratings yet

- LM 230Document4 pagesLM 230wmqelmen8978No ratings yet

- Sf24a SRDocument3 pagesSf24a SRTrunghieu LeNo ratings yet

- Nf24a SRDocument3 pagesNf24a SRTrunghieu LeNo ratings yet

- Belimo BF24-TN Datasheet En-GbDocument5 pagesBelimo BF24-TN Datasheet En-GbjacquesgelderblomNo ratings yet

- Belimo BF24 Datasheet En-GbDocument4 pagesBelimo BF24 Datasheet En-GbsvirkomartinkoNo ratings yet

- Belimo SM24A-SR Datasheet En-GbDocument3 pagesBelimo SM24A-SR Datasheet En-GbAfonso ReisNo ratings yet

- Belimo LM24A-SX Datasheet En-GbDocument4 pagesBelimo LM24A-SX Datasheet En-GbHaj SmaNo ratings yet

- Technical Data Sheet EF24A-S2Document7 pagesTechnical Data Sheet EF24A-S2Bradley WillmothNo ratings yet

- SRF24A-SR EN DatasheetDocument3 pagesSRF24A-SR EN DatasheetParagNo ratings yet

- Technical Data Sheet LF24-SRDocument3 pagesTechnical Data Sheet LF24-SRJNo ratings yet

- Belimo EF24A-S2 Datasheet En-Gb PDFDocument4 pagesBelimo EF24A-S2 Datasheet En-Gb PDFSTEFANALINLUCIANNo ratings yet

- Belimo - BFL24-T - Datasheet - En-Gb - dAMPER CORTA FOGODocument5 pagesBelimo - BFL24-T - Datasheet - En-Gb - dAMPER CORTA FOGOraphaelNo ratings yet

- Belimo NV24-MFT - T Datasheet En-GbDocument5 pagesBelimo NV24-MFT - T Datasheet En-GbAndrzej KrzyżanowskiNo ratings yet

- Technical Data Sheet SY4U230-MF-TDocument6 pagesTechnical Data Sheet SY4U230-MF-TKyle LanNo ratings yet

- SF24A-S2 Datasheet En-Gb PDFDocument4 pagesSF24A-S2 Datasheet En-Gb PDFDragoi CristiNo ratings yet

- Technical Data Sheet LMX24-SRDocument3 pagesTechnical Data Sheet LMX24-SRMauricio CalzadaNo ratings yet

- Technical Data Sheet SY6U230-MF-TDocument6 pagesTechnical Data Sheet SY6U230-MF-TKyle LanNo ratings yet

- Belimo SF24A-SR Datasheet En-GbDocument4 pagesBelimo SF24A-SR Datasheet En-GbbadslayerNo ratings yet

- Uvc 102, 103: Dynamic Flow Control System With 2-Way or 3-Way Valve and Energy Monitoring, EvalvecoDocument11 pagesUvc 102, 103: Dynamic Flow Control System With 2-Way or 3-Way Valve and Energy Monitoring, EvalvecoClaudio ScacciatelliNo ratings yet

- Belimo BF24-TN-ST Datasheet En-GbDocument5 pagesBelimo BF24-TN-ST Datasheet En-GbBram DelaneyNo ratings yet

- EP..F+MP Datasheet en-APDocument10 pagesEP..F+MP Datasheet en-APLandz GanzonNo ratings yet

- InteliSys NTC Hybrid DatasheetDocument4 pagesInteliSys NTC Hybrid DatasheetfernandoNo ratings yet

- Valvula de Control Proporcional de Aceite Datos Tecnicos B PDFDocument5 pagesValvula de Control Proporcional de Aceite Datos Tecnicos B PDFMoreno NuevoNo ratings yet

- Belimo - NF24A-S2 - Datasheet - En-Gb WEBDocument4 pagesBelimo - NF24A-S2 - Datasheet - En-Gb WEBRaghwendra RaghavNo ratings yet

- IG NTC BB Datasheet - 1Document4 pagesIG NTC BB Datasheet - 1Tiên Lê Trần MỹNo ratings yet

- IG NT BB DatasheetDocument4 pagesIG NT BB DatasheetWilliam Will Controle WoodwardNo ratings yet

- MHPED Voltage Controls For HEM Working Sections 20: FieldDocument1 pageMHPED Voltage Controls For HEM Working Sections 20: FieldShaikh mahamad SharifNo ratings yet

- Inteligennt GC DatasheetDocument4 pagesInteligennt GC DatasheetٍJordan SportNo ratings yet

- Nfa S2Document5 pagesNfa S2Trunghieu LeNo ratings yet

- Smart Iii: ComputerDocument2 pagesSmart Iii: ComputerfaikNo ratings yet

- Actuator Three Way ValveDocument5 pagesActuator Three Way ValveRadwan AL TrougNo ratings yet

- Wpa-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Document7 pagesWpa-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Sathish J EceNo ratings yet

- Mamgeneral Documentsdatasheetsen Gbbelimo LV24A SR TPC Datasheet en GB PDFDocument4 pagesMamgeneral Documentsdatasheetsen Gbbelimo LV24A SR TPC Datasheet en GB PDFGeorgeNo ratings yet

- IG-NTC DatasheetDocument4 pagesIG-NTC DatasheetsNo ratings yet

- Belimo BFL24-T Datasheet En-GbDocument4 pagesBelimo BFL24-T Datasheet En-GbIonut Viorel TudorNo ratings yet

- InteliSys Gas DatasheetDocument4 pagesInteliSys Gas Datasheetchao wangNo ratings yet

- Huawei Sun2000 60KTL M0Document2 pagesHuawei Sun2000 60KTL M0Tashin WongprasertsiriNo ratings yet

- Technical Data Sheet GM24A-SRDocument3 pagesTechnical Data Sheet GM24A-SRheni01 MehrezNo ratings yet

- Sensor Balluf Ultrasonido 5mtsDocument3 pagesSensor Balluf Ultrasonido 5mtsMaikel OchoaNo ratings yet

- Balluf 8mts PDFDocument2 pagesBalluf 8mts PDFMaikel OchoaNo ratings yet

- Intelidrive Lite DatasheetDocument4 pagesIntelidrive Lite DatasheetArnoud NegraoNo ratings yet

- InteliSys Gas DatasheetDocument4 pagesInteliSys Gas DatasheetMaylen RivasNo ratings yet

- Intelimains NTC Basebox DatasheetDocument4 pagesIntelimains NTC Basebox DatasheetEnny ClocielNo ratings yet

- Technical Data Sheet Damper Actuator TMC24A-SRDocument4 pagesTechnical Data Sheet Damper Actuator TMC24A-SRdbricchiNo ratings yet

- Gma Sei̇emensDocument7 pagesGma Sei̇emensİbrahim UzunNo ratings yet

- Gm24a SRDocument2 pagesGm24a SRcharif.akouryNo ratings yet

- InteliDrive Lite FPC Datasheet - 4Document4 pagesInteliDrive Lite FPC Datasheet - 4widiNo ratings yet

- DB 1283 GBDocument4 pagesDB 1283 GBSentirse HndNo ratings yet

- InteliSysNTC BaseBox Datasheet - 1Document4 pagesInteliSysNTC BaseBox Datasheet - 1曾浩然No ratings yet

- Air Damper Actuators GMA..1 - enDocument6 pagesAir Damper Actuators GMA..1 - enlucemiro2009No ratings yet

- Datasheet: Inteligen NTC BaseboxDocument4 pagesDatasheet: Inteligen NTC BaseboxsantoNo ratings yet

- Belimo AFX24-SR-S N4 Datasheet En-UsDocument5 pagesBelimo AFX24-SR-S N4 Datasheet En-Usraul sajamaNo ratings yet

- Proportional Amplifier PV: For The Control of A Proportional SolenoidDocument8 pagesProportional Amplifier PV: For The Control of A Proportional SolenoidIvan BeljinNo ratings yet

- ChassisDocument74 pagesChassisCOSTIN NESTIANNo ratings yet

- Magnetic Drill MachineDocument7 pagesMagnetic Drill MachineCOSTIN NESTIANNo ratings yet

- MRCM CatalogueDocument8 pagesMRCM CatalogueCOSTIN NESTIANNo ratings yet

- Department of Education: Worksheet - Tle 10Document3 pagesDepartment of Education: Worksheet - Tle 10Maria Christina ManzanoNo ratings yet

- 8.0.1. Installation Guide Flatpack PRSB 9kW48VDC 1 (1) .3m OCabFan Rev 3 PDFDocument25 pages8.0.1. Installation Guide Flatpack PRSB 9kW48VDC 1 (1) .3m OCabFan Rev 3 PDFLuis Fernando Vargas MarihuanNo ratings yet

- Nemamgi: Motors AND GeneratorsDocument669 pagesNemamgi: Motors AND GeneratorsLuis DanielNo ratings yet

- Elettrovalvole DPHIDPHEDPHERDocument8 pagesElettrovalvole DPHIDPHEDPHERJoao Victor SilveiraNo ratings yet

- Solis-100KDocument2 pagesSolis-100KThohaku Abdul HadiNo ratings yet

- 9 TransformerDocument7 pages9 TransformerMThana BalanNo ratings yet

- CMA9 MOTOR DRIVE ManualDocument29 pagesCMA9 MOTOR DRIVE ManualAshraf NazifNo ratings yet

- Mark VIeDocument11 pagesMark VIebobyNo ratings yet

- Isolation Transformer Downstream of A UPS Causes Catastrophic DamageDocument15 pagesIsolation Transformer Downstream of A UPS Causes Catastrophic DamagePudeti RaghusreenivasNo ratings yet

- Frequency Approval EU en 301 489-1,-3 UMRR-11 Type 44 - CCDocument89 pagesFrequency Approval EU en 301 489-1,-3 UMRR-11 Type 44 - CCMA GonzalezNo ratings yet

- Catalog Code - Master Led Factory Sealed Luminaires Appleton en Us 7436896Document15 pagesCatalog Code - Master Led Factory Sealed Luminaires Appleton en Us 7436896Samuel VelizNo ratings yet

- Name: . Date: .. Each Question Has Only One Correct Answer! Please Enter Your Answers On The Answer SheetDocument9 pagesName: . Date: .. Each Question Has Only One Correct Answer! Please Enter Your Answers On The Answer SheetKarthikeyan GanesanNo ratings yet

- 33XR ManualDocument20 pages33XR ManualAbubacker SiddiqNo ratings yet

- Proposal For A New Undergraduate Degree Program: B. Eng. in Sustainable and Renewable Energy EngineeringDocument24 pagesProposal For A New Undergraduate Degree Program: B. Eng. in Sustainable and Renewable Energy EngineeringbinnyNo ratings yet

- 12) Universalmotor2Document7 pages12) Universalmotor2Vinod Kumar KadakalNo ratings yet

- Sony HCD Shake7 Ver1.2 PDFDocument92 pagesSony HCD Shake7 Ver1.2 PDFJoseLuisRuiz100% (2)

- CHP 14 TopicviseDocument9 pagesCHP 14 TopicviseSyed Mairaj Ul HaqNo ratings yet

- Dr. M. Syed Jamil Asghar: Paper Published: 101Document6 pagesDr. M. Syed Jamil Asghar: Paper Published: 101HarshitNo ratings yet

- Velocloud Edge: Product DatasheetDocument4 pagesVelocloud Edge: Product Datasheeteomba12No ratings yet

- Final Draft Spec SPN TC 63 2006Document18 pagesFinal Draft Spec SPN TC 63 2006Pandey ShaileshNo ratings yet

- User Manual V30S V20S V10S (En)Document28 pagesUser Manual V30S V20S V10S (En)wilson100% (1)

- Countis-E43-E44 Instruction-Manual 2020-06 547981a en PDFDocument34 pagesCountis-E43-E44 Instruction-Manual 2020-06 547981a en PDFBudhi HermawanNo ratings yet

- Kapitel 12 G OnlineDocument17 pagesKapitel 12 G OnlineJuan TamezNo ratings yet

- GW - MS G3 - Datasheet-EN - Catálogo InversorDocument2 pagesGW - MS G3 - Datasheet-EN - Catálogo InversorGustavo Sá BarretoNo ratings yet

- Digital AC DC Clamp Meter HIOKI 3288Document2 pagesDigital AC DC Clamp Meter HIOKI 3288Sourabh ChoudharyNo ratings yet

- A9k27210 PDFDocument2 pagesA9k27210 PDFThanh Luân HuỳnhNo ratings yet