Professional Documents

Culture Documents

Wheelchair Development

Uploaded by

KABIR BATRA0 ratings0% found this document useful (0 votes)

4 views7 pagesOriginal Title

Wheelchair development

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views7 pagesWheelchair Development

Uploaded by

KABIR BATRACopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

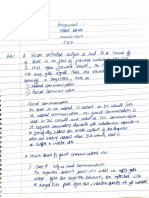

Future Developments

Wheelchair Standards : An Overview

by Colin A . McLaurin, ScD and Peter Axelson, MSME

Peter Axelson is President of Beneficial Designs, Inc ., Santa Cruz, CA, and succeeded

Dr . McLaurin upon his

retirement as Chairman, ANSI/RESNA Wheelchair Technical Advisory Group.

A series of wheelchair standards are currently in

the final phase of approval by the American

National Standards Institute (ANSI) . These stan-

dards have been under development for several

years, working closely with the International Stan-

dards Organization (ISO) so that the ANSI stan-

dards will be essentially the same as those in the

other participating countries.

The development of standards has been a long

and tedious process involving participation from

many disciplines and interests . The ANSI Technical

Advisory Group (TAG), organized by RESNA,

operates under a grant from the Veterans Adminis-

tration, with a secretariat at RESNA.

The main purpose of these standards is to pro-

vide the user and prescriber with the knowledge and

assurance that a product measures up in durability

and performance . The standards are of value to the

manufacturer on an international basis because it

enhances their position in foreign markets and

restricts the sale of imports that do not meet these

standards . The standards define test procedures that

are useful to the Veterans Administration and other

national purchasing agencies in establishing accep-

tance criteria for domestic or imported products.

The ANSI TAG has a diverse membership

consisting of users, manufacturers, engineers, testing

Portions of this material previously appeared in Caliper, Vol . XLII, No.

1, 1987, pp . 20-22, published by the Canadian Paraplegic Association .

authorities, therapists and distributors . As each of

these professionals may have differing requirements,

considerable discussion and testing is required in

order to reach a decision . It is then followed by the

drafting and redrafting of documents particularly

within the ISO since language also plays a part in

arriving at understandable and unequivocal state-

ments . Throughout the entire process, there is one

paramount concern and that is that the standards do

not restrict innovation by specifying a particular

material or construction . The standards are there-

fore Performance Standards that establish means by

which durability and performance may be measured.

In some cases levels of acceptance may be recom-

mended, in others only the disclosure of the results

is required.

ISO standards must undergo a rigorous proce-

dure which includes a majority vote from all

participating and observer countries that are in-

volved . At the national level, the ANSI/RESNA

TAG is developing standards that will be adopted as

U.S . standards once they have been subjected to

public comment and have been approved by ANSI's

Standards Review Board . The standards, once they

come into effect, are voluntary standards, not law.

ANSI is strictly a private, non-government, insti-

tute . It is in the interest of manufacturers to adhere

to the standards so that they may be so labeled . Any

wheelchair that does not carry the ANSI label will

be at a real disadvantage in the market place.

100

101

MCLAURIN and AXELSON : Wheelchair Standards

Currently there are 17 standards under consid-

eration. Four of these are general in nature covering

terms and definitions, overall dimensions, test

dummy specifications and the procedure for meas-

uring the coefficient of friction of test surfaces.

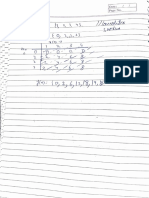

The dummy is a simple design used to load the

wheelchair in a manner equivalent to typical users.

Four dummies are used with overall weights of 25,

50, 75 and 100 Kg representing children, small

adults, average adults and large adults, respectively.

The results of tests that include the use of dummies

must always include the weight of the dummy(s)

used .

One other general test concerns burning ; haz-

ards associated with cigarettes and matches igniting

upholstery . The test procedures are adapted directly

from those already in use for furniture.

The nature and status of selected standards are

as follows:

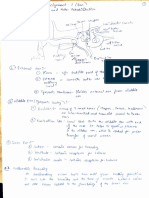

Nomenclature, Terms, and Definitions (Final)

This national standard defines the basic ele-

ments of wheelchairs (manual, electric, and others)

and gives terms and definitions for these elements in

an illustrated glossary . It also illustrates the dimen-

sions commonly used to describe wheelchair physical

characteristics.

1) Static Stability (Final)

This applies to manual and powered wheel-

chairs and refers to the tipping angle of the

wheelchair with and without locked brakes when

loaded with the appropriate dummy . The tipping in

the forward, rearward and lateral directions is

determined plus any other direction that may be

more critical . The standard will not include accep-

tance levels, but requires the disclosure of the test

results so that the consumer or prescriber may make

an informed choice.

The mean value of the test results of other

wheelchairs in the same category will be included in

the disclosure . Since some wheelchairs have adjust-

able wheel or seat positions, the maximum and

minimum values are recorded.

2) Dynamic Stability of Electric Wheelchairs

(Final)

This standard is concerned with the stabil-

ity of an electric wheelchair when turning at full

speed.

3) Efficiency of Brakes (Final)

This test is concerned with the ability of wheel

locks to hold the wheelchair and dummy on a slope.

The stopping distance from maximum speed both on

the level and on a 5-degree slope is measured on

powered wheelchairs . It also applies to wheelchairs

with mechanical brakes that are sometimes used on

European wheelchairs.

4) Energy Consumption of Electric Wheelchairs

(Final)

In this test, the energy consumption is recorded

over a standard course that includes turns and

slopes . From the test results, the theoretical range

can be calculated for indoor and outdoor conditions

based on the nominal capacity of the battery(s).

5) Overall Dimensions, Mass and Turning Space

(Final)

The overall dimensions are self explanatory and

include the folded position with and without de-

mountable parts such as footrests . The turning space

includes the smallest turning radius and the narrow-

est corridor in which the wheelchair can reverse

direction with a single backing operation.

6) Maximum Speed and Acceleration of Electric

Wheelchairs (Final)

The maximum speed is determined on a level

surface loaded with the appropriate dummy or a

person of the same weight . The maximum accelera-

tion requires the use of the dummy to ensure

consistency . The acceleration is measured by an

accelerometer mounted on the dummy and filtered

to eliminate all frequencies higher than 30 Hz . The

results indicate the wheelchair performance but are

also concerned with the comfort and stability of the

user under maximum acceleration.

7) Seating Dimensions (Under Development)

This proposed standard is still under devel-

opment . It is based on loading the wheelchair with

a specified loader gauge to form the upholstery

into the shape it would assume in normal use.

From this position, 26 measurements are record-

ed on the dimensions of the seat, backrest, foot-

rests and armrests . For ergonomic reasons, the

position of the seat with respect to the handrim

or other propulsion device is included . The

loader gauge, based on a design used in the

102

JRRD Clinical Supplement No . 2 : Choosing a Wheelchair System

European furniture industry, will be available in

child and adult sizes.

8) Static Impact and Fatigue Strength (Under

Development)

This is one of the few instances where minimum

levels of performance are recommended . The actual

test values are based on dummy size, and the test

results must state which dummy was used, indicating

the weight of the person for whom the wheelchair is

suitable.

The static test consists of applying a load to

various parts of the wheelchair.

The impact testing has several parts . For testing

casters, footrests and other parts subject to impact

against curbs and potholes, the wheelchair is loaded

with the appropriate dummy and crashed into the

obstacle at a pre-determined speed . The seat and

backrest are tested by dropping a soccerball fitted

with 25 kg of lead shot on specific areas and in

specific directions . The wheel and axle assemblies

are tested by dropping the wheelchair loaded with

the appropriate dummy from a prescribed height so

as to land on each wheel separately . The test

simulates the stresses incurred when rolling off a

curb . The handrims are tested with a weighted

pendulum which simulates the accidental striking of

the handrims on a door frame.

The fatigue test is conducted using a two-drum

test machine . The wheelchair is positioned on the

test machine so that the front and rear wheels will

run on the drums.

The wheelchair loaded with the appropriate

dummy is secured by the axles while the drums are

rotated at a speed corresponding to about 1 meter

per second . Fastened to each drum are slats,

one-half x 1 and one-half inches. The number of

cycles satisfactorily completed is then disclosed.

The order of testing is specified and one

wheelchair must be used for all tests . The disclosed

values include the static forces applied, the velocity

or dropheight of the impact and the number of

fatigue cycles completed without structural failure.

9) Climatic Tests for Electric Wheelchairs (Final)

There are two parts for this test . One involves

the use of a water spray, simulating heavy rain, to

determine any safety hazards or performance defi-

ciencies under these conditions . The second part

tests the wheelchair's performance after exposure to

hot and cold conditions . The temperature range for

operating conditions is from – 20 degrees C to + 50

degrees C and for storage at temperatures from – 40

degrees C to + 65 degrees C.

10) Obstacle Climbing for Electric Wheelchairs

(Final)

This test determines the ability of a powered

wheelchair to climb a step or curb both from a

standing start and from a run of 0 .5 meters.

For the test, the simulated step is progressively

increased from 20 to 200 mm (3/4 inch to 8 inches)

and the maximum heights recorded . As in other

tests, the dummy size is specified, although a person

of the same weight may be used.

1 1) Test Dummies (Final)

This part of the ANSI/RESNA national wheel-

chair standard outlines the construction of test

dummies of nominal mass 25, 50, 75, and 100 kg

(55, 110, 165, 220 pounds) . The dummies are

intended for tests in which the wheelchair is required

to be loaded.

13) Coefficient of Friction of Test Surfaces

(Final)

Several test procedures for wheelchairs require

that the coefficient of friction of the test surface be

within specified limits.

This part of the standard specifies a method for

determining the coefficient of friction of a test

surface that has a rough texture, such as unfinished

concrete.

14) Power and Controls (Under Development)

This standard embodies a series of tests to

ensure electrical safety, controller performance, and

safety from unintentional access to hazardous areas

and pinch points.

15) Disclosure Requirements (Under

Development)

This standard specifies the information that is

required to be disclosed in the user manuals,

103

MCLAURIN and AXELSON : Wheelchair Standards

product literature, and other documentation related

to wheelchairs.

91) Burning Behavior (Under Development)

This standard specifies a procedure for deter-

mining the ignitability characteristics of a wheel-

chair's upholstered surface .

93) Overall Dimensions (Final)

This standard defines the maximum dimensions

recommended for manual and powered wheelchairs.

This standard serves as a reference for environmen-

tal designers to enable wheelchair-accessible hotels,

buses, trains, etc ., to be designed (28 inches wide, 51

inches long, and 43 inches high) .

You might also like

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Analysis and Optimisation of All Terrain WheelchairDocument10 pagesAnalysis and Optimisation of All Terrain WheelchairAshish NandaNo ratings yet

- Design of High-Speed Railway Turnouts: Theory and ApplicationsFrom EverandDesign of High-Speed Railway Turnouts: Theory and ApplicationsRating: 4.5 out of 5 stars4.5/5 (4)

- Dame Project Machine Element IiDocument6 pagesDame Project Machine Element IiBirbirsa BetieNo ratings yet

- Advanced Seat Suspension Control System Design for Heavy Duty VehiclesFrom EverandAdvanced Seat Suspension Control System Design for Heavy Duty VehiclesNo ratings yet

- Helmet StandardDocument9 pagesHelmet StandardjusendqNo ratings yet

- Chassis Dynamometer Testing: Addressing the Challenges of New Global LegislationFrom EverandChassis Dynamometer Testing: Addressing the Challenges of New Global LegislationNo ratings yet

- Research Paper On AtvDocument6 pagesResearch Paper On Atvtxnqwcvkg100% (1)

- Iso 18164 2005 - Measuring Rolling ResistanceDocument28 pagesIso 18164 2005 - Measuring Rolling ResistancewhitemithrilNo ratings yet

- Braking Distance ForwardDocument9 pagesBraking Distance ForwardAjay AgarwalNo ratings yet

- Structural Analysis of Steering Knuckle For Weight ReductionDocument6 pagesStructural Analysis of Steering Knuckle For Weight ReductionMithun V KulkarniNo ratings yet

- .Review of Seat Testing and Evaluation RegulationDocument5 pages.Review of Seat Testing and Evaluation RegulationmohammadNo ratings yet

- Ansi Icwm-2018Document57 pagesAnsi Icwm-2018Alec HernandezNo ratings yet

- Design of Suspension System For Formula Student RaDocument13 pagesDesign of Suspension System For Formula Student RapaarthNo ratings yet

- Push-pull forces of wheeled equipment on carpetsDocument48 pagesPush-pull forces of wheeled equipment on carpetseromax1No ratings yet

- Prosthetic Foot Project PDFDocument45 pagesProsthetic Foot Project PDFtesterNo ratings yet

- Complete Design Report Team JaabazDocument89 pagesComplete Design Report Team JaabazpiyushnsitNo ratings yet

- Proven Success Driven PileDocument9 pagesProven Success Driven Piletim_lim12No ratings yet

- Vehicle Steering Systems - Hardware-In-The-Loop Simulator DrivinDocument234 pagesVehicle Steering Systems - Hardware-In-The-Loop Simulator DrivinmacorcheroNo ratings yet

- Tests of Cycling Performance: Carl D. Paton and Will G. HopkinsDocument8 pagesTests of Cycling Performance: Carl D. Paton and Will G. HopkinsCristianLopezNo ratings yet

- MET2020 Patel MoxitDocument17 pagesMET2020 Patel MoxitSaleh AlotaibiNo ratings yet

- Editors' Perspectives:: Road Vehicle Suspension Design, Dynamics, and ControlDocument34 pagesEditors' Perspectives:: Road Vehicle Suspension Design, Dynamics, and ControlTech DudeNo ratings yet

- Paine Esc TestsDocument30 pagesPaine Esc TestsNicolae-Eugen StoichitaNo ratings yet

- Bearing Fault Detection Techniques - A Review: Nabhan, A., Nouby, M., Sami, A.M., Mousa, M.ODocument18 pagesBearing Fault Detection Techniques - A Review: Nabhan, A., Nouby, M., Sami, A.M., Mousa, M.ObeingraviNo ratings yet

- Sciencedirect: Design & Development of Special Automobile Interior Testing MachineDocument9 pagesSciencedirect: Design & Development of Special Automobile Interior Testing MachineMuthu KumarNo ratings yet

- Design of Suspension System For Formula Student RaDocument13 pagesDesign of Suspension System For Formula Student RaVishal ThakurNo ratings yet

- Influence of Factors on ISO Gear CalculationDocument25 pagesInfluence of Factors on ISO Gear Calculationpablo_stzNo ratings yet

- Evaluation of Selected Ultralight Manual Wheelchairs Using A1/JSI/RESNA StandardsDocument6 pagesEvaluation of Selected Ultralight Manual Wheelchairs Using A1/JSI/RESNA Standardsosama taisirNo ratings yet

- Suspension FinalDocument12 pagesSuspension FinalShefaliNo ratings yet

- Tests of Cycling Performance: Sports Medicine February 2001Document9 pagesTests of Cycling Performance: Sports Medicine February 2001Mohammad FarhanNo ratings yet

- Brake Roughness - Disc Brake Torque Variation, Rotor Distortion and Vehicle ResponseDocument15 pagesBrake Roughness - Disc Brake Torque Variation, Rotor Distortion and Vehicle Responsedebisi14140100% (1)

- Double Wishbone Suspension DesignDocument7 pagesDouble Wishbone Suspension DesignganamNo ratings yet

- s12877-023-04443-7Document14 pagess12877-023-04443-7Anescu MihaiNo ratings yet

- OS 01 Optimisation of Effective-TATATechnologiesDocument8 pagesOS 01 Optimisation of Effective-TATATechnologiesNagaArjunNo ratings yet

- 142 ClamShell ReportDocument44 pages142 ClamShell Reportjmz mtzNo ratings yet

- Crosswind Sensitivity of Passenger Cars and The Influence of ChassisDocument6 pagesCrosswind Sensitivity of Passenger Cars and The Influence of ChassisInternational Journal of computational Engineering research (IJCER)No ratings yet

- Establishing Inspection Criteria To Verify The Dynamic Behaviour of The Vehicle Suspension System by A Platform Vibrating Test BenchDocument18 pagesEstablishing Inspection Criteria To Verify The Dynamic Behaviour of The Vehicle Suspension System by A Platform Vibrating Test BenchMuhammad FaisalNo ratings yet

- Different Type of Crash Testing: Vidiyasagar Gavali, Dipak Dond, Ankit KumarDocument2 pagesDifferent Type of Crash Testing: Vidiyasagar Gavali, Dipak Dond, Ankit KumarerpublicationNo ratings yet

- Design Analysis and Verification of An Open-Wheeled Formula-StyDocument49 pagesDesign Analysis and Verification of An Open-Wheeled Formula-StyRushik KudaleNo ratings yet

- Testing: Valvetrain Systems For Combustion EnginesDocument48 pagesTesting: Valvetrain Systems For Combustion EnginesJose Luis RattiaNo ratings yet

- Optimization of Torsional Stiffness of A Eicher 11.10 Chesis Using Evolutionary Methods With A Heterogeneous Genotype RepresentationDocument4 pagesOptimization of Torsional Stiffness of A Eicher 11.10 Chesis Using Evolutionary Methods With A Heterogeneous Genotype RepresentationSaikiranSayabugariNo ratings yet

- FSAE SuspensionDocument37 pagesFSAE SuspensionDonald MuchemwaNo ratings yet

- Seb ProjectDocument32 pagesSeb ProjectperthlingNo ratings yet

- ASTM International: Submitted By: Surbhi Goyal (18) Swati Suman (19) Bft-IvDocument13 pagesASTM International: Submitted By: Surbhi Goyal (18) Swati Suman (19) Bft-IvSurbhi GoyalNo ratings yet

- BIOMECHANICAL ANALYSIS OF LUGGAGE PULLING TASKDocument13 pagesBIOMECHANICAL ANALYSIS OF LUGGAGE PULLING TASKSujal RaijadeNo ratings yet

- 2011 ME 493 Human Powered Vehicle Design ReportDocument69 pages2011 ME 493 Human Powered Vehicle Design ReportJia Wei NgNo ratings yet

- HWWE 2017 CH 79Document12 pagesHWWE 2017 CH 79DEEPAK S SEC 2020No ratings yet

- MinorPROJECT 2020Document34 pagesMinorPROJECT 2020SNEHASIS MOHANTYNo ratings yet

- Technical Paper For Students and Young Engineers: - Fisita World Automotive Congress, Barcelona 2004Document15 pagesTechnical Paper For Students and Young Engineers: - Fisita World Automotive Congress, Barcelona 2004rike.spNo ratings yet

- Current Trends in Bumper Design For Pedestrian ImpactDocument16 pagesCurrent Trends in Bumper Design For Pedestrian ImpactSahaya robin singh MNo ratings yet

- IJIE 07 211 R1 EdDocument39 pagesIJIE 07 211 R1 EdAnand sharmaNo ratings yet

- Shoe Testing MachineDocument6 pagesShoe Testing MachineUsMan MuhammadNo ratings yet

- Fatigue AnalysisDocument23 pagesFatigue AnalysisAlexanderPetrovNo ratings yet

- HSILSOTDocument18 pagesHSILSOTkazibeiglooNo ratings yet

- Fatigue Analysis and Optimization of Upright of A FSAE VehicleDocument6 pagesFatigue Analysis and Optimization of Upright of A FSAE Vehiclepreetham saiNo ratings yet

- 2011 MCC Baja SAE Design ReportDocument14 pages2011 MCC Baja SAE Design ReportRonald George100% (3)

- Shell Thickness PDFDocument6 pagesShell Thickness PDFLucia ZambranoNo ratings yet

- Energy EfficiencyDocument76 pagesEnergy Efficiencydan_artimof100% (1)

- FIR Filter DesignDocument46 pagesFIR Filter DesignKABIR BATRANo ratings yet

- Assignment 2 (EAR) 2019UIC3619Document10 pagesAssignment 2 (EAR) 2019UIC3619KABIR BATRANo ratings yet

- Prs Tuuad: Kaer EeDocument4 pagesPrs Tuuad: Kaer EeKABIR BATRANo ratings yet

- Actq::: Date: Page NoDocument25 pagesActq::: Date: Page NoKABIR BATRANo ratings yet

- Robotics Vision: Camera Calibration and SensorsDocument42 pagesRobotics Vision: Camera Calibration and SensorsKABIR BATRANo ratings yet

- Steps: Miaude ReprezesdateDocument5 pagesSteps: Miaude ReprezesdateKABIR BATRANo ratings yet

- Visiting Card PDFDocument1 pageVisiting Card PDFKABIR BATRANo ratings yet

- IAS Hub Web UI PDFDocument1 pageIAS Hub Web UI PDFKABIR BATRANo ratings yet

- NETAJI SUBHAS UNIVERSITY ELECTRONIC INSTRUMENTATIONDocument2 pagesNETAJI SUBHAS UNIVERSITY ELECTRONIC INSTRUMENTATIONKABIR BATRANo ratings yet

- Concept Classes - Physics, Maths, JEE/NEET BatchesDocument1 pageConcept Classes - Physics, Maths, JEE/NEET BatchesKABIR BATRANo ratings yet

- Visiting Card PDFDocument1 pageVisiting Card PDFKABIR BATRANo ratings yet

- EG CoursesDocument1 pageEG CoursesKABIR BATRANo ratings yet

- Inter-Society Sports TournamentDocument1 pageInter-Society Sports TournamentKABIR BATRANo ratings yet

- Subhasha OrientationDocument16 pagesSubhasha OrientationKABIR BATRANo ratings yet

- Material Handling: Tires & WheelsDocument8 pagesMaterial Handling: Tires & WheelsMichael AkhramovichNo ratings yet

- Illustrated Parts List MODEL NO. 96041029801 Customer Catalog No. M200-117T PRODUCT NO. 960 41 02-98Document18 pagesIllustrated Parts List MODEL NO. 96041029801 Customer Catalog No. M200-117T PRODUCT NO. 960 41 02-98geoffrey vaillantNo ratings yet

- Model Car Builder 1Document40 pagesModel Car Builder 1naruemon khongmiNo ratings yet

- 07-124 Motor CharlynDocument12 pages07-124 Motor CharlynMiguel Angel Santos Pintado100% (2)

- Cummins QSK60 and QSK95 Engine Overhaul PartsDocument9 pagesCummins QSK60 and QSK95 Engine Overhaul PartsTong Hai WangNo ratings yet

- Hyundai Venue-N-Line-BrochureDocument10 pagesHyundai Venue-N-Line-BrochureRasakNo ratings yet

- Bosch PST MARINE Injector Calibration and Test ResultsDocument2 pagesBosch PST MARINE Injector Calibration and Test Resultsคุณชายธวัชชัย เจริญสุขNo ratings yet

- Operator Manual: Front LoaderDocument142 pagesOperator Manual: Front LoaderJORGE LUIS SILVA MEDRANONo ratings yet

- RACOR Fuel Water SeperatorDocument27 pagesRACOR Fuel Water SeperatorDmitriy AntonenkoNo ratings yet

- Tds Total Rubia SXDocument1 pageTds Total Rubia SXDANIEL DIAZNo ratings yet

- Champion Rescue SuperBeastDocument2 pagesChampion Rescue SuperBeastForum PompieriiNo ratings yet

- frick1Document3 pagesfrick1Chris Doncillo DondonNo ratings yet

- Audi Q7 4MB 4M 2015-2017 Service ManualDocument8,540 pagesAudi Q7 4MB 4M 2015-2017 Service Manualpeter11100% (1)

- Varun SeminarDocument16 pagesVarun SeminarVarun YadavNo ratings yet

- 9 Hydraulic System, Load CarrierDocument29 pages9 Hydraulic System, Load CarrierAdrian MotocNo ratings yet

- XD - STPIE - 20210909 - 1729 - Vehículo Ligeros906657 - 8AC906657KE150803 - JRCJ14 INDocument3 pagesXD - STPIE - 20210909 - 1729 - Vehículo Ligeros906657 - 8AC906657KE150803 - JRCJ14 INFabian IrarrazabalNo ratings yet

- Engine Electrical: Group 16Document35 pagesEngine Electrical: Group 16heroki wdyaNo ratings yet

- Duraturn TBR 2021Document28 pagesDuraturn TBR 2021IgorNo ratings yet

- Service Manual-C5, B5, GT-Engine - Euro IVDocument152 pagesService Manual-C5, B5, GT-Engine - Euro IVEdgar PinedaNo ratings yet

- Snugride 30: Read This Instruction ManualDocument37 pagesSnugride 30: Read This Instruction ManualMayerlin CastilloNo ratings yet

- American AutoDocument37 pagesAmerican Automatthew barryNo ratings yet

- CST H450K User ManualDocument156 pagesCST H450K User Manualvjvijay88100% (1)

- SP Training Manual 1Document302 pagesSP Training Manual 1alex morris100% (2)

- q8 e Tron 55 BrochureDocument6 pagesq8 e Tron 55 BrochureBigBoiNo ratings yet

- Mitsubishi 3000gt 1997 Wiring DiagramsDocument58 pagesMitsubishi 3000gt 1997 Wiring DiagramsThanh LiemNo ratings yet

- Jaguar Land Rover ReportDocument3 pagesJaguar Land Rover ReportAmar narayanNo ratings yet

- RAV4 Online Brochure 20211125Document30 pagesRAV4 Online Brochure 20211125sopedalleyNo ratings yet

- The Passive Exercises - Ejercicios de Pasiva - 4 EXERCISES Complete The Sentences With The Correct - StuDocuDocument1 pageThe Passive Exercises - Ejercicios de Pasiva - 4 EXERCISES Complete The Sentences With The Correct - StuDocuNEREA DE ASIS MOLLEJANo ratings yet

- GB GW01 28 01 04Document2 pagesGB GW01 28 01 04Armağan DemirelNo ratings yet

- Inspection Report For NarmulDocument3 pagesInspection Report For NarmulmelakuNo ratings yet