Professional Documents

Culture Documents

Data Sheet Medidor de Flujo

Data Sheet Medidor de Flujo

Uploaded by

Efrain J Colina AOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet Medidor de Flujo

Data Sheet Medidor de Flujo

Uploaded by

Efrain J Colina ACopyright:

Available Formats

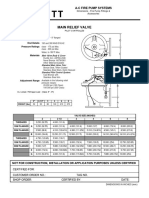

PFV Venturi

Fire Pump Systems

2" to 16" Low-Loss Venturi

The Model PFV FM approved Fire Pump System features the Preso CV Venturi. The CV is a differential pressure element

designed to accurately measure flow. It can be installed in any position with minimal straight pipe requirements (5 pipe

diameters upstream and 2 pipe diameters downstream). Preso can relate the success of the CV Venturi to the Low-Loss

design which amounts to over 35 years of field performance in a wide variety of applications.

Construction & Specifications

Material: Carbon Steel ASTM A53 / Carbon Steel Insert

Valves: 1/4" MSAE Flare Brass Ball

1/8" FNPT CS Weld Fitting: 150# for 1-1/4" thru 6"

3000# for 8" & up

Flange Option: 150# ANSI B 16.5 or

300# ANSI B 16.5

Identification Tag: Polycarbonate

Temperature: 250 °F (120 °C) Maximum

Pressure: 300 PSIG (2070 kPa) Maximum

Type of Pipe Installation

Schedule STD Carbon Steel

The gage is a Direct-Readout meter with a dial featuring a 270° arc

for fast and accurate reading. A precision engineered, dust-tight

case ensures trouble-free operation. Preso gages are protected

against overload by a unique diaphragm housing design. When

the pressure difference exceeds the range, the gage will accept

the accidental application of up to 60 PSIG without damage.

Under normal conditions the differential pressure should not

exceed the range of the gage.

MODEL SELECTOR: PPFV

PIPE SIZE TYPE HOSES RATING (Please see note)

A - 2" A - STANDARD DIAPHRAGM 1 - NYLON GPM (RANGE)

B - 2-1/2" B - DOUBLE BELLOWS 2 - SS BRAIDED A - 50 (25-100)

C - 3" B - 100 (50-200)

E - 4" GAGE MATERIAL C - 150 (75-300)

F - 5" A - BRASS/BRONZE D - 200 (100-400)

G - 6" B - 316 SS E - 250 (125-500)

H - 8" F - 300 (150-600)

I - 10" G - 400 (200-800)

J - 12" H - 450 (225-900)

K - 14" I - 500 (250-1000)

L - 16" NOTE - ONLY SELECT J - 750 (375-1500)

FM APPROVED PUMP PIPE K - 1000 (500-2000)

END CONNECTION RATINGS (GPM) FOR SIZES L - 1250 (625-2500)

(50) - 2"

A - RF FLANGE - 150# M - 1500 (750-3000)

(100) - 2-1/2"

B - RF FLANGE - 300# N - 2000 (1000-4000)

(150/200) - 3"

C - NPT (1/2" - 2") O - 2500 (1250-5000)

(250/300/400/450) - 4"

D - GROOVED P - 3000 (1500-6000)

(450/500/750) - 5"

E - BUTT WELD Q - 3500 (1750-7000)

(500/750/1000/1250) - 6"

R - 4000 (2000-8000)

(1000/1250/1500/2000/2500/3000) - 8"

DIAL SIZE S - 4500 (2250-9000)

(1500/2000/2500/3000/3500/4000/4500) - 10"

1 - 4" (100 mm) T - 5000 (2500-10000)

(2000/2500/3000/3500/4000/4500/5000) - 12"

2 - 6" (150 mm)

(3500/4000/4500/5000) - 14"

(4500/5000) - 16"

SPECIFICATIONS AND SUBMITTAL DATA

Model PFV Low-Loss Venturi

BW & GROOVED Flanged 150# Flanged 300#

SIZE MODEL B A APP A APP A APP

APP WEIGHT WEIGHT WEIGHT

inch (mm) inch (mm) lbs (kg) inch (mm) lbs (kg) inch (mm) lbs (kg)

2" PPFVAXXXXXX 3.5 (89) 6 (152) 3 (1.4) 11.63 (295) 15 (6.8) 11.63 (295) 21 (9.5)

2-1/2" PPFVBXXXXXX 3.5 (89) 6 (152) 3 (1.4) 11.63 (295) 19 (8.6) 12.63 (308) 27 (12.3)

3" PPFVCXXXXXX 3.5 (89) 6 (152) 5 (2.3) 11.63 (295) 25 (11.4) 12.38 (314) 35 (15.9)

4" PPFVEXXXXXX 3.5 (89) 6 (178) 7 (3.2) 13.13 (334) 37 (16.8) 13.88 (353) 57 (25.9)

5" PPFVFXXXXXX 3.5 (89) 8.5 (216) 9 (4.1) 15.63 (397) 47 (21.4) 16.38 (416) 73 (33.2)

6" PPFVGXXXXXX 3.5 (89) 9.5 (241) 17 (7.7) 16.63 (422) 65 (29.5) 17.38 (441) 101 (45.9)

8" PPFVHXXXXXX 3.25 (83) 13.5 (343) 35 (15.9) 21.63 (549) 113 (51.4) 22.38 (568) 169 (76.8)

10" PPFVIXXXXXX 3.25 (83) 16 (406) 59 (26.8) 24.13 (613) 163 (74.1) 25.38 (645) 241 (109.5)

12" PPFVJXXXXXX 3.25 (83) 17.25 (438) 106 (48.2) 26.38 (670) 266 (120.9) 27.63 (702) 386 (175.5)

14" PPFVKXXXXXX 3.25 (83) 19.25 (489) 130 (59.1) 29.38 (746) 350 (159.1) 30.63 (778) 490 (222.7)

16" PPFVLXXXXXX 3.25 (83) 20.25 (514) 160 (72.7) 30.38 (772) 440 (200) 31.88 (810) 660 (300)

Gage Data

Construction: Brass Body

Operation: Diaphragm (Beryllium Copper)

Dial: 4" or 6" / 270° Arc

Accuracy: ±1.75% Full Scale

Temperature: 180 °F (80 °C)

Pressure: 500 PSIG (3450 kPa)

Approx. Wt.: 6" = 4.25 lbs (1.9 kgs)

Approx. Wt.: 4" = 3.75 lbs (1.7 kgs)

OPERATING INSTRUCTIONS:

FM PRESO FIRE PUMP SYSTEM FM 1. CLOSE SYSTEM VALVE.

2. OPEN SYSTEM BY-PASS VALVE AND THROTTLE

APPROVED APPROVED VALVE.

3. PURGE GAGE LOCATED ON PFV AS FOLLOWS:

Throttle Valve System By-pass Valve

Flow OPEN GAGE BY-PASS VALVE ( BLUE), PFV

Discharge Air Vent SHUT-OFF VALVES (RED & YELLOW) AND VENT

VALVES (ABOVE GAGE). WHEN A STEADY

STREAM OF WATER IS PASSING THROUGH

PRESO EACH PLASTIC HOSE, GAGE IS PURGED OF AIR.

Optional to (3) (7)

PFV CLOSE VENT VALVES AFTER PURGING IS

Pump Inlet

Pipe Diameters from Valve COMPLETE.

4. START FIRE PUMP, CLOSE GAGE BY-PASS

Valve System Valve VALVE (BLUE) AND READ GAGE IN GPM.

Flow 5. REFER TO PUMP GPM REQUIREMENT AND

ADJUST THROTTLE VALVE FOR THIS

Supply

REQUIREMENT.

6. AFTER TEST OPEN SYSTEM VALVE AND CLOSE

Fire Pump SYSTEM BY-PASS AND THROTTLE VALVES.

Typical Piping Configuration

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- f150 Wiring PDFDocument163 pagesf150 Wiring PDFJustin Clark100% (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- NetScaler Fundamentals Lab GuideDocument74 pagesNetScaler Fundamentals Lab Guidekayudo80No ratings yet

- ISO 13849 PL Calculations SimplifiedDocument119 pagesISO 13849 PL Calculations SimplifiedAnonymous jW9BkgbQmENo ratings yet

- ValveDocument2 pagesValveRamKS80No ratings yet

- DeZURIK KCG Knife Gate ValvesDocument12 pagesDeZURIK KCG Knife Gate ValvesKithkarnonNo ratings yet

- King 7750 Series FlowmeterDocument2 pagesKing 7750 Series Flowmeterehab8320014413No ratings yet

- K Series 1/2" To 4" Stainless Steel Control Valves: DescriptionDocument2 pagesK Series 1/2" To 4" Stainless Steel Control Valves: DescriptionarafardNo ratings yet

- Storagetech 100 Pressure Vacuum Relief Valve SMDocument4 pagesStoragetech 100 Pressure Vacuum Relief Valve SMkhaled SAYEDNo ratings yet

- Foot Valve Cataloque IFCDocument2 pagesFoot Valve Cataloque IFCPuntanata SiagianNo ratings yet

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoNo ratings yet

- WWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesDocument10 pagesWWW - Ventile.cz 7. Instrument Manifold Amp Gauge ValvesNilesh MistryNo ratings yet

- Actuador NeumaticoDocument12 pagesActuador NeumaticoJose Alfredo Rojas UribeNo ratings yet

- Valvula Check 6000 Lbsv3xDocument6 pagesValvula Check 6000 Lbsv3xMaik AmayaNo ratings yet

- Metric Section BDocument26 pagesMetric Section BniladriprasadrNo ratings yet

- NeedleValve LT0389Document8 pagesNeedleValve LT0389zkmostafaNo ratings yet

- Clamps PDFDocument36 pagesClamps PDFDhim131267No ratings yet

- Piping - Spec - 요약본 Rev1Document3 pagesPiping - Spec - 요약본 Rev1vangie3339515No ratings yet

- Bell & Gossett SuctionDiffusersDocument4 pagesBell & Gossett SuctionDiffusersAnonymous 7xHNgoKE6eNo ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- FP2.7 CMRV 314Document1 pageFP2.7 CMRV 314ehab ahmedNo ratings yet

- Brochure 3Document12 pagesBrochure 3Gohilakrishnan ThiagarajanNo ratings yet

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocument20 pagesBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelNo ratings yet

- TFM - Turbine Flowmeter PDFDocument2 pagesTFM - Turbine Flowmeter PDFAlaaNo ratings yet

- Mar Win SteamDocument33 pagesMar Win SteamChristopher RequintoNo ratings yet

- PL 008748Document10 pagesPL 008748ronaldxmenNo ratings yet

- Mangueras Flexibles SwagelokDocument28 pagesMangueras Flexibles SwagelokCristian OtivoNo ratings yet

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter SpecificationsMechanicalMarwanNo ratings yet

- MS 01 34Document8 pagesMS 01 34Agustin CesanNo ratings yet

- Needle ValvesDocument18 pagesNeedle ValvesPablo RodriguezNo ratings yet

- AAP S6 High Pressure Fittings E2 SDocument23 pagesAAP S6 High Pressure Fittings E2 SJusthyTaquiri0% (1)

- Literature Force Floating Ball Valve CatalogDocument16 pagesLiterature Force Floating Ball Valve CatalogJohn Néstor Ramirez CalderónNo ratings yet

- Spirax Sarco Commissioning Strainer 1Document3 pagesSpirax Sarco Commissioning Strainer 1swaraj4uNo ratings yet

- Calculator ASME B31 4Document11 pagesCalculator ASME B31 4Denstar Ricardo Silalahi50% (2)

- Navco b2 BrochureDocument16 pagesNavco b2 Brochurejorge28csNo ratings yet

- Rhinoflex Metal Seated Unidirectional Knife Gate Valve-Rfs - 37-10Document3 pagesRhinoflex Metal Seated Unidirectional Knife Gate Valve-Rfs - 37-10Yerson JuarezNo ratings yet

- Flanged Swing Check Valve PDFDocument2 pagesFlanged Swing Check Valve PDFuki12345No ratings yet

- Swagelok PFA Tube FittingsDocument4 pagesSwagelok PFA Tube FittingstotcsabNo ratings yet

- Selection Chart CreatorDocument201 pagesSelection Chart CreatorrenepunterNo ratings yet

- A2 1 16junDocument2 pagesA2 1 16junamitrai86No ratings yet

- PD05P XXX XXX B SeDocument2 pagesPD05P XXX XXX B SemaaoeNo ratings yet

- Regulador American Meter PDFDocument6 pagesRegulador American Meter PDFjmcg1974No ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- Non Rising Stem REL-PIV-L388F R0050CDocument2 pagesNon Rising Stem REL-PIV-L388F R0050CCoordinador TecnicoNo ratings yet

- Swagwlok Lap Flange PDFDocument6 pagesSwagwlok Lap Flange PDFPraveen KumarNo ratings yet

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDocument24 pagesDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymNo ratings yet

- Tank WeightsDocument48 pagesTank WeightsHamzaHashimNo ratings yet

- Series B6400-SE Specification SheetDocument2 pagesSeries B6400-SE Specification SheetWattsNo ratings yet

- MasterSeries 876V Specification SheetDocument4 pagesMasterSeries 876V Specification SheetFEBCONo ratings yet

- High Pressure Needle ValvesDocument11 pagesHigh Pressure Needle ValvesNilesh MistryNo ratings yet

- Double Block Bleed TOSVDocument8 pagesDouble Block Bleed TOSVplanet123No ratings yet

- 05 Needle ValveDocument12 pages05 Needle ValvePukhraj DagaNo ratings yet

- 200 Series Check ValvesDocument2 pages200 Series Check ValvesMoanquileNo ratings yet

- Downhole Tubing/casingDocument6 pagesDownhole Tubing/casingDwiki RamadhaniNo ratings yet

- Jord Y-Type Strainer DatasheetDocument1 pageJord Y-Type Strainer DatasheetSpoonful BurnsideNo ratings yet

- Rociadores STD TycoDocument86 pagesRociadores STD TycoIvAldreteNo ratings yet

- Swagelok HoseDocument28 pagesSwagelok HoseRashi Akmal0% (1)

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- Goulds Pumps 3355 SeriesDocument7 pagesGoulds Pumps 3355 Seriesmcastillo7385100% (1)

- Series dc125Document2 pagesSeries dc125Daniel FigueroaNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Spec - Hs-Udimm U1 ddr3 1600mhz (421838)Document3 pagesSpec - Hs-Udimm U1 ddr3 1600mhz (421838)Seguritec Gpt SasNo ratings yet

- The Motherboard Voltage Regulator CircuitDocument11 pagesThe Motherboard Voltage Regulator CircuitAnonymous fE8Oa3WUNo ratings yet

- DCM60R enDocument1 pageDCM60R enAllan A GegantocaNo ratings yet

- Securities and Exchange Commission of Thailan - Internal Control Sufficiency Evaluation FormDocument14 pagesSecurities and Exchange Commission of Thailan - Internal Control Sufficiency Evaluation FormkimmywongyinNo ratings yet

- TM 5-4930-363-24P 800,000 Gallon FSSPDocument332 pagesTM 5-4930-363-24P 800,000 Gallon FSSPAdvocateNo ratings yet

- ViVIX-S Wireless Service Manual - V1.3 - EN PDFDocument148 pagesViVIX-S Wireless Service Manual - V1.3 - EN PDFscribangelofNo ratings yet

- June 2002 Q8 & Dec 2003 Q10Document14 pagesJune 2002 Q8 & Dec 2003 Q10romedic36No ratings yet

- Powersuite Software Workshop: Presentation, FunctionsDocument4 pagesPowersuite Software Workshop: Presentation, FunctionsKurniadi SetyantoNo ratings yet

- DefinitionsDocument50 pagesDefinitionsRaajeshkrishnaNo ratings yet

- Geberit New Ideas For Your Bathroom August 2013Document44 pagesGeberit New Ideas For Your Bathroom August 2013Timar MihalyNo ratings yet

- Power Mig 255 754Document8 pagesPower Mig 255 754Diego Jaramillo PeñalozaNo ratings yet

- IACS-UR-P - Pipes & Pressure Vessels PDFDocument67 pagesIACS-UR-P - Pipes & Pressure Vessels PDFSerggie TabanaoNo ratings yet

- Min FlowDocument4 pagesMin FlowashrafNo ratings yet

- Switching Core Network Signalling: Message Transfer PartDocument76 pagesSwitching Core Network Signalling: Message Transfer PartGeraldinBikekNo ratings yet

- Lorentz - Pvcombiner 1000 125 4 Manual - en PDFDocument10 pagesLorentz - Pvcombiner 1000 125 4 Manual - en PDFLuis RolaNo ratings yet

- P Annexe E5.1 Digipro Pour cd2000 GB v01 - 2001Document24 pagesP Annexe E5.1 Digipro Pour cd2000 GB v01 - 2001Putra Eka Wiguna MandiriNo ratings yet

- Reinsurance CasestudyDocument2 pagesReinsurance CasestudyGanesh RahulNo ratings yet

- Technical Information Manual: 12 January 2010 Revision n.2Document33 pagesTechnical Information Manual: 12 January 2010 Revision n.2bhooNo ratings yet

- Refurbishment of Signage and Way Finding Systems: Case Study of Urban Spaces of JaipurDocument7 pagesRefurbishment of Signage and Way Finding Systems: Case Study of Urban Spaces of JaipurCherukupalli Gopala KrishnaNo ratings yet

- ABB Electromagnetic FlowmetersDocument48 pagesABB Electromagnetic Flowmetersn_zeinounNo ratings yet

- Lesson 6: Continuous Process ImprovementDocument46 pagesLesson 6: Continuous Process ImprovementBilly Vince AlquinoNo ratings yet

- R-290 Service ManualDocument19 pagesR-290 Service ManualEdinaldo ManuelNo ratings yet

- Das Nas San CasDocument4 pagesDas Nas San CastomitsrockingNo ratings yet

- Sample Project Charter 01Document14 pagesSample Project Charter 01Syaiful Azhar SchmidwaldNo ratings yet

- Chevrolet MyLink Video Interface ManualDocument28 pagesChevrolet MyLink Video Interface ManualkoloristaNo ratings yet

- Networking Full Version - ZahidDocument5 pagesNetworking Full Version - ZahidNazmul HasanNo ratings yet

- Caja SinotruckDocument96 pagesCaja SinotruckRodolfo Alberto Muñoz Carcamo100% (5)