Professional Documents

Culture Documents

1LE7501 0DB22 3AA4 Datasheet en

Uploaded by

DOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1LE7501 0DB22 3AA4 Datasheet en

Uploaded by

DCopyright:

Available Formats

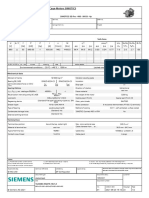

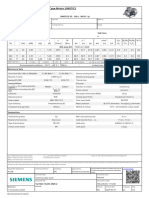

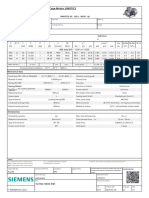

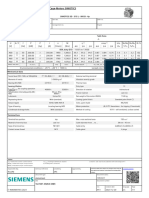

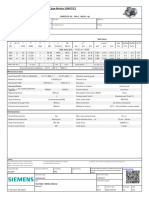

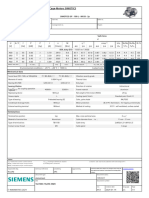

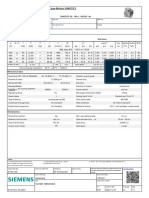

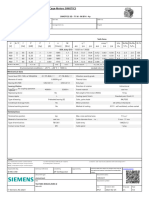

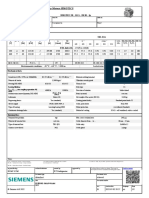

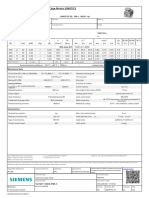

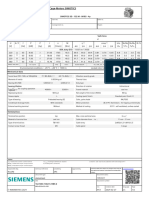

Data sheet for three-phase Squirrel-Cage-Motors SIMOTICS

Motor type: 7CV2082B SIMOTICS SD - 80M - IM B3 - 4 p

Client order no. Item-No. Offer no.

Order no. Consignment no. Project

Remarks

Electrical data Safe Area

U Δ/Y f P P I n M M η 3) cosφ 3) IA/IN MA/MN MK/MN IE-CL

[V]±10% [Hz]±5% [kW] [hp] [A] [1/min] [kgf.m] [Nm] 4/4 3/4 2/4 4/4 3/4 2/4

Motordaten / Motor Data

415 Y 50 0.55 -/- 1.40 1430 0.4 3.7 77.1 77.4 73.4 0.72 0.62 0.49 5.3 2.8 2.8 IE2

IM B3 / IM 1001 FS 80M 16 kg SF:1 IS 12615 / IEC 60034-1 -

Environmental conditions : -20 °C - +50 °C / 1,000 m Locked rotor time (hot / cold) : 15 s | 18 s

Mechanical data Locked rotor time (hot / cold) : 15 s | 18 s

Yes (standard)

Sound pressure level 50Hz | 60Hz 67 dB(A) 70 dB(A) External earthing terminal

Moment of inertia | Rotor GD² 0.0015 kg m² | 0.0061 kgf.m² Vibration severity grade A (Standard)

155(F) utilized to 130(B)

Bearing DE | NDE 6204 2ZC3 6204 2ZC3 Insulation

bearing lifetime Duty type S1

L10mh FRad max according catalogue 20.000 h 16.000 h Direction of rotation Bidirectional

50|60Hz 1)

L10mh FRad min for coupling operation Cast iron

50.000 h 40.000 h Frame material

50|60Hz 1)

Type of bearing Locating (fixed) bearing, NDE Forced ventilation motor details -/-

-/- g | -/- g

Relubrication interval/quantity DE | NDE Net weight of the motor (IM B3) 16 kg

-/- h

Type of construction IM B3 / IM 1001 Rotor weight 3 kg

Degree of protection IP55 Data of anti condensation heating -/- V, -/- W

Lubricants Esso Unirex N3 Coating (paint finish) Standard paint finish

-/-

Regreasing device Color, paint shade RAL7030

Grease nipple -/- Motor protection (A) without

No

Condensate drainage holes Method of cooling IC411 - Self ventilated, surface cooled

Terminal box

Cable diameter from ... to ...

Terminal box position Top 9.0 mm - 17.0 mm

Material of terminal box Aluminium Cable entry 1xM16x1.5+1xM25x1.5

Type of terminal box TB7 D04 Cable gland 2 Plugs

Contact screw thread M4

Max. cross-sectional area 6 mm2

Notes:

IA/IN = locked rotor current / current nominal

MA/MN = locked rotor torque / torque nominal

MK/MN = break down torque / nominal torque 3) Value is valid only for DOL operation with motor design IC411

1) L10mh according to DIN ISO 281 10/2010

responsible dep. technical reference created by approved by Technical data are subject to change! There may be Link documents

discrepancies between calculated and rating plate

DI MC LVM DT Configurator values.

document type document status

datasheet released

MLFB and Order Code document number

1LE7501-0DB22-3AA4

rev. creation date language Page

© Siemens AG 2022 01 2022-12-22 en 1/1

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 1LE7503-0CB32-3AA4 Datasheet enDocument1 page1LE7503-0CB32-3AA4 Datasheet enLuis RomeroNo ratings yet

- 1LE7501-1BB23-5AA4 Datasheet enDocument1 page1LE7501-1BB23-5AA4 Datasheet enVinit ShrivastavaNo ratings yet

- 1LE7501-1CB23-5FA4 Datasheet enDocument1 page1LE7501-1CB23-5FA4 Datasheet enMUKESH VERMANo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3073B Simotics SD - 71M - Im B3 - 4 PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3073B Simotics SD - 71M - Im B3 - 4 PSHYAM SHARMANo ratings yet

- 1LE7603-0CB22-3FA4 Datasheet enDocument1 page1LE7603-0CB22-3FA4 Datasheet enrequirement.dcNo ratings yet

- 1LE7503 2BB03 5AA4 Datasheet enDocument1 page1LE7503 2BB03 5AA4 Datasheet enhafidz.maxonNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252B Simotics SD - 250M - Im B3 - 4 PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252B Simotics SD - 250M - Im B3 - 4 Pravi kumarNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3282B Simotics SD - 280M - Im B3 - 4 PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3282B Simotics SD - 280M - Im B3 - 4 Pravi kumarNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252C Simotics SD - 250M - Im B3 - 6 PDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3252C Simotics SD - 250M - Im B3 - 6 Pravi kumarNo ratings yet

- 1LE7503-3AB23-4AA4-Z L53 Datasheet enDocument2 pages1LE7503-3AB23-4AA4-Z L53 Datasheet enjoy baruaNo ratings yet

- 1LE1001-1AB42-2JA4 Datasheet enDocument1 page1LE1001-1AB42-2JA4 Datasheet enMulyanto Abinya Farras-IzyanNo ratings yet

- 1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enDocument2 pages1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enUmair MirzaNo ratings yet

- 1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enDocument2 pages1LE1003-0EB42-2FA4-Z F01+F11 Datasheet enUmair MirzaNo ratings yet

- 3 Phase Motor DetailDocument1 page3 Phase Motor Detailhashir zamanNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4PDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4Pnadia perezNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV3104A Simotics GP - 100 L - Im B14 - 2PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV3104A Simotics GP - 100 L - Im B14 - 2PTio SNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1073D Simotics GP - 71 M - Im B5 - 8PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1073D Simotics GP - 71 M - Im B5 - 8PdianerlNo ratings yet

- 1LE1003-1AA43-4FA4-Z B02 Datasheet enDocument2 pages1LE1003-1AA43-4FA4-Z B02 Datasheet enRefresh DrNo ratings yet

- 1LE1503-1DB43-4FK4_datasheet_enDocument1 page1LE1503-1DB43-4FK4_datasheet_enNicolas RossettoNo ratings yet

- 1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enDocument2 pages1LE1023-1AA43-4AB4-Z L22+L23 Datasheet enTien NguyenNo ratings yet

- 1LE1002-1DA33-4AA4-Z Q02 Datasheet en PDFDocument2 pages1LE1002-1DA33-4AA4-Z Q02 Datasheet en PDFhmfNo ratings yet

- Silnik - Karta Katalogowa 1LE1002 0EB02 2JA4Document2 pagesSilnik - Karta Katalogowa 1LE1002 0EB02 2JA4artur.sowaNo ratings yet

- 1LE1002-1DB43-4FB4 Datasheet enDocument1 page1LE1002-1DB43-4FB4 Datasheet enshashibagewadiNo ratings yet

- siemens motors datasheetDocument2 pagessiemens motors datasheetFar DesignNo ratings yet

- Silnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99Document2 pagesSilnik - Karta Katalogowa 1LE1002 1AB42 2FA4 Z Y99artur.sowaNo ratings yet

- 1LE1503-2BB03-4AA4 Datasheet enDocument1 page1LE1503-2BB03-4AA4 Datasheet enAnil Kumar KnNo ratings yet

- 1LE1501-3AB53-4AB4 Datasheet enDocument1 page1LE1501-3AB53-4AB4 Datasheet enfarid.chira2No ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2252B Simotics SD - 250 M - Im B5 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2252B Simotics SD - 250 M - Im B5 - 4PrezaNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1164B Simotics GP - 160 L - Im B3 - 4PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1164B Simotics GP - 160 L - Im B3 - 4PMeky Bima TokoNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3105B Simotics SD - 100 L - Im V1 - 4PDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3105B Simotics SD - 100 L - Im V1 - 4PrifkikhafidNo ratings yet

- 1LE1003-1AA43-4AB4 Datasheet enDocument1 page1LE1003-1AA43-4AB4 Datasheet enAhmed Mahmoud AliNo ratings yet

- 1LE1002-1CB02-2AA4 Datasheet enDocument1 page1LE1002-1CB02-2AA4 Datasheet enLance AyoubNo ratings yet

- 1LE1501-1EB43-4JA4 Datasheet enDocument1 page1LE1501-1EB43-4JA4 Datasheet enIbraheem AlfalahatNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4jitendra patelNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CD3094B Simotics XP - 90 L - Im B3 - 4PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CD3094B Simotics XP - 90 L - Im B3 - 4PToko DownloadNo ratings yet

- 1LE1623-3AB53-5GB4 Datasheet enDocument1 page1LE1623-3AB53-5GB4 Datasheet enSergio FerrariNo ratings yet

- 1LE1601 2DC03 4AB4 Z L51 Datasheet enDocument2 pages1LE1601 2DC03 4AB4 Z L51 Datasheet enFaziNo ratings yet

- 1LE1503-0CB22-2KA4-Z_H22+L25Document3 pages1LE1503-0CB22-2KA4-Z_H22+L2501666754614No ratings yet

- 1LE1501-3AA59-0AA4 M1B Datasheet enDocument2 pages1LE1501-3AA59-0AA4 M1B Datasheet enRICARDO JOHAN ROJAS YUPANNo ratings yet

- 1le1503 3ab53 4ab4Document2 pages1le1503 3ab53 4ab4Whipman ArduinoNo ratings yet

- 1LE1501 2DA03 4AA4 Datasheet enDocument1 page1LE1501 2DA03 4AA4 Datasheet enGismart 11No ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- 1LE1601-1AB53-4FB4-Z F01+F11+F50+L05 Datasheet enDocument2 pages1LE1601-1AB53-4FB4-Z F01+F11+F50+L05 Datasheet enTien NguyenNo ratings yet

- 1LE1504-3AB23-4AB4 Datasheet enDocument1 page1LE1504-3AB23-4AB4 Datasheet enOkke BoykeNo ratings yet

- 1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- 1le1523 1eb43 4ab4Document2 pages1le1523 1eb43 4ab4pmf engineering limitedNo ratings yet

- 1LE1502 1EB23 4AA4 Datasheet enDocument1 page1LE1502 1EB23 4AA4 Datasheet enRasool SabeghiNo ratings yet

- 250kW VDFDocument3 pages250kW VDFalex.burgosNo ratings yet

- 1LE1073-1AB66-4AA5 Datasheet enDocument1 page1LE1073-1AB66-4AA5 Datasheet enursantanaaNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-0DB32-3FA4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-0DB32-3FA4-Zjitendra patelNo ratings yet

- 1le1002 1ca13 4aa4Document3 pages1le1002 1ca13 4aa4Atlanta BoliviaNo ratings yet

- 1MB1553 2DB03 4JB4 Z B02 Datasheet enDocument2 pages1MB1553 2DB03 4JB4 Z B02 Datasheet enadriansya7No ratings yet

- 1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enDocument2 pages1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enranjithNo ratings yet

- 1LE1523-2DC23-4JA4 Datasheet enDocument1 page1LE1523-2DC23-4JA4 Datasheet enAdalbertoNo ratings yet

- 1LE1503-1CB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1CB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- 1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1EB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- 1LE5604-3BB34-0AB6-Z_L51Document3 pages1LE5604-3BB34-0AB6-Z_L51MostafaElrakhawyNo ratings yet

- Intern Report - S.varun KumarDocument14 pagesIntern Report - S.varun KumarVarun KumarNo ratings yet

- Choke SlideDocument23 pagesChoke SlideCharles Adefemi Omowole100% (1)

- Sage X3 - User Guide - HTG-Printing CLOB Comments PDFDocument8 pagesSage X3 - User Guide - HTG-Printing CLOB Comments PDFcaplusinc100% (1)

- Tuticorin Thermal Power Project Structural Steel Rate ScheduleDocument13 pagesTuticorin Thermal Power Project Structural Steel Rate ScheduleVinod Kumar Verma100% (1)

- CN0125 PDFDocument4 pagesCN0125 PDFPuerco_EspinNo ratings yet

- Carestation 650 Brochure PDFDocument12 pagesCarestation 650 Brochure PDFzulfiah100% (1)

- Dropped ObjectsDocument26 pagesDropped Objectsgunnery0250% (2)

- Compressor Tech May 2013Document89 pagesCompressor Tech May 2013H.a. UlicesNo ratings yet

- Bil Jax 2622T - ManualDocument60 pagesBil Jax 2622T - ManualDuynamndk100% (1)

- QUOTATION For ARIS 05 12 23Document5 pagesQUOTATION For ARIS 05 12 23Kasarachi AmadiNo ratings yet

- Wire Size Chart NEC 2011Document1 pageWire Size Chart NEC 2011Gustavo TovarNo ratings yet

- Python3 Tutorial PDFDocument26 pagesPython3 Tutorial PDFferronatto11100% (1)

- Galaxy Y S5360 Android 2.3.6 Gingerbread Official FirmwareDocument23 pagesGalaxy Y S5360 Android 2.3.6 Gingerbread Official Firmwarekharishkhan0% (1)

- 2nd Quarter Week 3 Parallel CircuitDocument12 pages2nd Quarter Week 3 Parallel CircuitjNo ratings yet

- GIS Mapping Powers Electricity Planning in BasraDocument25 pagesGIS Mapping Powers Electricity Planning in BasraYaser Al-SolimiNo ratings yet

- Aa 02 Short-Circuit Iec StandardDocument58 pagesAa 02 Short-Circuit Iec StandardSupriyanto SuhonoNo ratings yet

- Kleppner (Introduction To Mechanics) (Errata)Document3 pagesKleppner (Introduction To Mechanics) (Errata)almarpa0% (1)

- OEM Connections Sensor +5 Volt Supply #4Document2 pagesOEM Connections Sensor +5 Volt Supply #4ibrahem100% (2)

- Fortune500 CIO DatabaseDocument120 pagesFortune500 CIO Databasegomzy_45650% (2)

- Champ Gyro User Guide Rev4.1Document33 pagesChamp Gyro User Guide Rev4.1Vicente AguirreNo ratings yet

- Implementation of Shortest Path in Packet Switching Network Using Genetic AlgorithmDocument6 pagesImplementation of Shortest Path in Packet Switching Network Using Genetic Algorithmeditor_ijarcsseNo ratings yet

- Samputensili Tools en v007Document24 pagesSamputensili Tools en v007M.NatarajanNo ratings yet

- C3 - WO9 - Steel Structure Works - Internal Schedule (Metal Building Factory) PDFDocument1 pageC3 - WO9 - Steel Structure Works - Internal Schedule (Metal Building Factory) PDFAdel MorsyNo ratings yet

- PBL BrochureNov04Document26 pagesPBL BrochureNov04Pedro Antonio Lea Plaza Rico100% (1)

- Linksys SRW-2048 User GuideDocument96 pagesLinksys SRW-2048 User GuideshiuksliadezesNo ratings yet

- Coil Caliburn GDocument1 pageCoil Caliburn GLukman Arsyanto WibowoNo ratings yet

- CV - Teguh Agung Kusuma - COC I - Chief Mate - AHTS, Survey, AWBDocument7 pagesCV - Teguh Agung Kusuma - COC I - Chief Mate - AHTS, Survey, AWBTeguh Agung KusumaNo ratings yet

- Life Cycle AssesmentDocument34 pagesLife Cycle AssesmentMayank Joshi100% (1)

- TP ConductionDocument25 pagesTP Conductionizham shukeriNo ratings yet

- Naukri RohinLohat (10y 0m) PDFDocument5 pagesNaukri RohinLohat (10y 0m) PDFayesha siddiquiNo ratings yet