Professional Documents

Culture Documents

Foster PDS 32 17 R0519 1

Uploaded by

Nashal KkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foster PDS 32 17 R0519 1

Uploaded by

Nashal KkCopyright:

Available Formats

32-17

Product Data Sheet

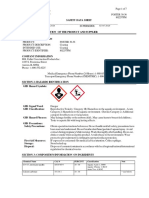

PROPERTIES FOSTER® SAFETEE™ DUCT SEALANT

COLOR:

Light Gray

APPLICATION CONSISTENCY:

Brush, trowel, caulking gun or power extrusion

FOSTER® SAFETEE™ DUCT SEALANT is a fire-resistive, fibrated,

AVERAGE WEIGHT / U.S. GALLON (ASTM D1475): water-based, indoor/outdoor vapor barrier sealant for low, medium

11.6 lbs. (1.35 kg/l) and high velocity heating and air conditioning ducts. It performs as a

tough and flexible adhesive and sealant, forming a durable seal

AVERAGE NON-VOLATILE (ASTM D2369): against air leakage when used with or without reinforcing tape or

55% by volume (69% by weight) membrane. Mechanical fasteners of the type and number normally

used for duct assemblies are required to provide rigidity to the duct

COVERAGE RANGE: system.

Brush: 25 – 50 sq. ft./gal. (0.6 – 1.2 m2/l) 0.064 in. – 0.032 in.

(1.6 mm – 0.8 mm) wet film thickness SAFETEE™ DUCT SEALANT has excellent weather resistance, low

water vapor permeance and good water resistance, allowing it to be

Caulking Gun: 125 linear ft. per 10.5 fluid oz. tube, 1/8 in. used outdoors and in high humidity environments. It is U.V. resistant.

bead (38 m per 0.31 liter tube, 3.2 mm bead) When dry, it may be painted with good quality, water-based paint.

30 linear ft. per 10.5 fluid oz. tube, 1/4 in. bead (9 m per 0.31

liter tube, 6.4 mm bead) SAFETEE™ DUCT SEALANT may be pressure tested within 16

hours dry time above 70ºF (21ºC) and below 60% RH. It quickly

SERVICE TEMPERATURE LIMITS: forms a strong bond to galvanized, aluminum or mild steel metal

20ºF to 200ºF (-7ºC to 93ºC) ducts. It has a mild odor when wet.

DRYING TIME 73ºF (23ºC) 50% RH: SAFETEE™ DUCT SEALANT will meet all SMACNA pressure

Set to Touch: 1 hour classes up to 10" w.g. and SMACNA seal classes A, B and C on

Dry Through: 24 hours ducts constructed to SMACNA standards. It has been tested up to

15" w.g. and passed with no sealant blow out.

SHORE HARDNESS (ASTM D2240):

Type A: 80 SAFETEE™ DUCT SEALANT 32-17 meets the requirements of:

• MAS Certified Green®

WATER VAPOR PERMEANCE (TYPICAL AVERAGE): • California Dept. of Public Health Standard Method v1.2

ASTM E96, PROCEDURE A: 0.45 perms (0.30 metric perms)

• VOC Emissions and Content requirements to contribute to

at 35 mils (0.9 mm) dry thickness

LEED v4 EQ Credit: Low Emitting Materials – Paints

WET FLAMMABILITY: and Coatings

No flash to boiling, over 210ºF (99ºC) • Collaborative for High Performance Schools EQ 7.1

SURFACE BURNING CHARACTERISTICS (ASTM E84): VOC Content: 45 g/l, less water and exempt solvents.

Flame Spread: 5

Smoke Developed: 0

Tested as applied in two 2 in. wide strips spaced 8 in. on

center at a coverage rate of 25 sq. ft./gal. Applied to 1/4 inch

(6.4 mm) inorganic reinforced cement board. The flame

spread may vary at different product thicknesses and/or when LIMITATIONS

applied over other surfaces. Store and apply between 40ºF (4ºC) and 100ºF (38ºC), protect from

freezing until dry.

SAFETEE™ DUCT SEALANT is produced under the

classification and follow-up service of Underwriter’s To resist rain washoff, allow at least 12-15 hours drying time above

Laboratories, Inc. and meets NFPA 90A and 90B 25/50 40ºF (4ºC), with a relative humidity of 50%. Higher humidity or lower

requirements. It is approved for use in the City of Los temperatures may retard drying.

Angeles, application number M-960081.

Always test foil and paper facings for acceptable adhesion.

Outdoor horizontal surfaces must always drain completely. A pitch of

at least 1/2 inch per foot (4 cm/m) is required.

™ Trademark of H.B. Fuller Construction Products Inc. If used between impermeable surfaces, drying time will be extended.

Visit us on the web at www.fosterproducts.com

H.B. Fuller Construction Products Inc.

1105 South Frontenac Street ○ Aurora, IL 60504 ○ 800-832-9002 ○ fax 800-952-2368

APPLICATION GUIDE

FOR

FOSTER 32-17 SAFETEE™ DUCT SEALANT

®

UL 181B-M

MATERIAL PREPARATION

DO NOT THIN. Apply only to clean, dry, oil-free surfaces. Keep container closed when not in use.

APPLICATION

UL 181B MASTIC CLOSURE OF UL 181 FLEXIBLE AIR DUCTS:

Apply to clean, dry, oil-free surfaces by brush, trowel or power extrusion. Uniformly brush out a 2” wide coat over the joint, at the

nominal rate of 2 gal./100 sq. ft. (0.8 l/m2). Total coverage rate to be 45 – 55 sq. ft./gal. (1.1 – 1.4 m2/l). Allow the completed joint to

dry at least 24 hours above 70ºF (21ºC) before pressure testing. High humidities (over 70%) and/or cooler temperatures may retard

drying. Total wet film thickness to be 32 mils +/- 3 mils.

OTHER SEALING APPLICATIONS – NOT UL 181:

Apply a continuous film of FOSTER® SAFETEE™ DUCT SEALANT over all areas of the indoor or outdoor duct system where air

leakage may occur. A brush may be used to work the sealant into joints and remove excess. On spiral ducts, apply a coat to the male

end of the coupling prior to fitting the straight run of spiral duct over it. Brush excess SAFETEE™ DUCT SEALANT over the joint to

complete the seal. Screw holes and flanges should also be sealed with a coat of SAFETEE™ DUCT SEALANT. It may be applied to

the inside or the outside of the duct.

POWER EXTRUSION:

SAFETEE™ DUCT SEALANT may be applied using a wide variety of power (pressure) extrusion equipment suitable for use with

water-based sealants. It is a soft buttery gel with a typical viscosity range of 130,000 – 160,000 cps. Corrosion resistant pumps and

fittings are suggested.

TOP COATING

After it is completely dry, SAFETEE™ DUCT SEALANT may be top coated with good quality water-based paint.

CLEAN UP

Use fresh water to clean brushes and equipment before product dries. Dry product may be removed with hot soapy water or strong

solvent such as chlorinated solvent (non-flammable) or xylol (flammable).

UL 181B-M

6P84

ALSO CLASSIFIED for

Surface Burning Characteristics

Applied to Inorganic Reinforced Cement Board

Flame Spread: 5

Smoke Developed: 0

Tested as applied in two 2 in. wide strips spaced 8 in. on center at a

coverage rate of 25 sq. ft./gal.

312U

CUSTOMER SERVICE: 800-832-9002

IMPORTANT: H.B. Fuller Construction Products Inc. warrants that each of its products will be manufactured in accordance with the specifications in effect on the date of

manufacture. WE MAKE NO OTHER WARRANTIES AND EXPRESSLY DISCLAIM ANY WARRANTIES OF MERCHANTIBILITY OR FITNESS FOR A PARTICULAR

PURPOSE. If a product fails to meet this limited warranty, purchaser’s sole and exclusive remedy is replacement of the product or, at our option, refund of the purchase

price. OUR ACCEPTANCE OF ANY ORDERS FOR THE PRODUCT IS EXPRESSLY CONDITIONAL UPON PURCHASER’S ASSENT TO THE TERMS ON THE

APPLICABLE INVOICE.

ADEQUATE TESTS: The information contained herein we believe is correct to the best of our knowledge and tests. The recommendations and suggestions herein are made

without guarantee or representation as to results. We recommend that adequate tests be performed by you to determine if this product meets all of your requirements. The

warranted shelf life of our products is twelve months from date of shipment to the original purchaser or as otherwise provided on the certificate of analysis.

For professional use only. Keep out of reach of children.

Consult Safety Data Sheet and container label for further information.

Foster PDS 32-17 R0519

You might also like

- Foster 32 17Document2 pagesFoster 32 17mohabadel87No ratings yet

- Foster 32-17Document2 pagesFoster 32-17Mostafa AymanNo ratings yet

- Foster PDS 32 19 R0415Document2 pagesFoster PDS 32 19 R0415Simoncarter LawNo ratings yet

- Foster PDS 30 36 R0221Document2 pagesFoster PDS 30 36 R0221Abdel Mongy AhmedNo ratings yet

- Foster 32-19™: Properties Foster Duct-Fas™ Duct SealantDocument2 pagesFoster 32-19™: Properties Foster Duct-Fas™ Duct SealantOmar DiampuanNo ratings yet

- Electrical Works For Restarant Al Maha Camp - Foster Empire EstateDocument104 pagesElectrical Works For Restarant Al Maha Camp - Foster Empire Estateafzal empirestateNo ratings yet

- Foster: Properties Foster Sealfas CoatingDocument2 pagesFoster: Properties Foster Sealfas Coatingquang trinhNo ratings yet

- Foster PDS 95 44 R0722Document2 pagesFoster PDS 95 44 R0722Osama KheadryNo ratings yet

- Properties Foster Fire Resistive Anti-Abrasion Coating Water BasedDocument2 pagesProperties Foster Fire Resistive Anti-Abrasion Coating Water BasedMinh BảoNo ratings yet

- Properties Foster Sealfas Coating AF (Fungus Resistant) : Product Data SheetDocument2 pagesProperties Foster Sealfas Coating AF (Fungus Resistant) : Product Data SheetGiftson ImmanuelNo ratings yet

- Duct Sealant 32-17Document2 pagesDuct Sealant 32-17Amadou MokshaNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsMuthuKumarNo ratings yet

- TDS-Foster 95-44 EN PDFDocument2 pagesTDS-Foster 95-44 EN PDFEshaghNo ratings yet

- Properties Foster S.M. Adhesive: Product Data SheetDocument2 pagesProperties Foster S.M. Adhesive: Product Data SheetAamer Abdul MajeedNo ratings yet

- d2) Epilux218 4267Document2 pagesd2) Epilux218 4267Syed FaridNo ratings yet

- FF1021 Acoutstical Smoke Sealant SheetDocument2 pagesFF1021 Acoutstical Smoke Sealant SheetChinith012No ratings yet

- Magik 3217 Ul Classified Acrylic Sealant Anti Fungal Duct SealantDocument2 pagesMagik 3217 Ul Classified Acrylic Sealant Anti Fungal Duct SealantAhamed IbrahimNo ratings yet

- HempadurDocument2 pagesHempadurLuciano SalituriNo ratings yet

- Interzone 954Document0 pagesInterzone 954hennawijayaNo ratings yet

- Foster PDS 85 00 R0719 1Document2 pagesFoster PDS 85 00 R0719 1Deyah EldenNo ratings yet

- Foster 32-19™: Properties Foster Duct-Fas™ Duct SealantDocument2 pagesFoster 32-19™: Properties Foster Duct-Fas™ Duct SealantPraveen BhavishyatNo ratings yet

- Pds Foster 65-05 F.R.C.I. MasticDocument2 pagesPds Foster 65-05 F.R.C.I. MasticHanafi MansorNo ratings yet

- PDS HEMPADUR 47183 en-USDocument2 pagesPDS HEMPADUR 47183 en-USFreddy Carl Fredricksen0% (1)

- Technical Data Sheet for Tankguard Storage CoatingDocument5 pagesTechnical Data Sheet for Tankguard Storage Coatingabdulgafoor54No ratings yet

- Epilux 155 SFDocument2 pagesEpilux 155 SFMohamed NasifNo ratings yet

- High Solids Coal Tar Epoxy Product SpecificationsDocument2 pagesHigh Solids Coal Tar Epoxy Product SpecificationsAbuhurairah MunshiNo ratings yet

- Foster PDS 95 50 R0816Document2 pagesFoster PDS 95 50 R0816Ramy Abd Elkhalek Shahin100% (1)

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Heat Shield ™ EPX-H2O Thermal Insulation Coating: Very SimpleDocument2 pagesHeat Shield ™ EPX-H2O Thermal Insulation Coating: Very Simpleluis pi100% (1)

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiNo ratings yet

- Zincanode 304 pc142Document3 pagesZincanode 304 pc142kushar_geoNo ratings yet

- Econ 60 TBDocument2 pagesEcon 60 TBfivade5459No ratings yet

- Concresive Fluido: Two-Pack Solvent-Free Fluid Epoxy Adhesive For Fixings, Construction Joints and AnchoragesDocument3 pagesConcresive Fluido: Two-Pack Solvent-Free Fluid Epoxy Adhesive For Fixings, Construction Joints and AnchoragesKarl FarrugiaNo ratings yet

- Hempadur 85531 PDFDocument2 pagesHempadur 85531 PDFvitharvan0% (1)

- Ex Pan Proof 100Document3 pagesEx Pan Proof 100Amar WadoodNo ratings yet

- PDS FOSTER - 30-45N - Foamseal Sealant PDFDocument2 pagesPDS FOSTER - 30-45N - Foamseal Sealant PDFHanafi MansorNo ratings yet

- Heat Shield™ EPX-H2O Thermal Insulation Coating: Product Data SheetDocument2 pagesHeat Shield™ EPX-H2O Thermal Insulation Coating: Product Data SheetvtnhoemNo ratings yet

- Tankguard 412 Jotun PaintDocument6 pagesTankguard 412 Jotun PaintGurdeep Sungh AroraNo ratings yet

- Foster90 66Document2 pagesFoster90 66didapopescuNo ratings yet

- El Hyperdesmo-ClassicDocument4 pagesEl Hyperdesmo-ClassicΙοαννης ΡενκοNo ratings yet

- Elastiseal Sealant 95-88: PropertiesDocument2 pagesElastiseal Sealant 95-88: PropertiesMyluv MyluvNo ratings yet

- Flexible Pu SealantDocument2 pagesFlexible Pu SealantGi GoNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Coaltar Epoxy - Epilux5 - 0474Document2 pagesCoaltar Epoxy - Epilux5 - 0474GautamNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Foster Weatherite Mastic: Technical Data SheetDocument2 pagesFoster Weatherite Mastic: Technical Data SheetAhmed SaadNo ratings yet

- Paint Specification HamadourDocument2 pagesPaint Specification HamadourAbdul Majid LodhiNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- HEMPADUR MULTI-STRENGTH 35530 BlackDocument2 pagesHEMPADUR MULTI-STRENGTH 35530 BlackRuby Faith EspinosaNo ratings yet

- Waterproof acrylic cement coating protects concreteDocument2 pagesWaterproof acrylic cement coating protects concreteFourier MakambioNo ratings yet

- 151SGDocument2 pages151SGdcsamaraweeraNo ratings yet

- Sikafloor261sys1 PdsDocument4 pagesSikafloor261sys1 PdsTPNo ratings yet

- Ambigard - 2K Waterproof Coating For ConcreteDocument4 pagesAmbigard - 2K Waterproof Coating For ConcreterudrabirNo ratings yet

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaNo ratings yet

- Sikacem®-711 Elastic: Provisional Product Data SheetDocument4 pagesSikacem®-711 Elastic: Provisional Product Data SheetDavid V. BaltazarNo ratings yet

- Flexible Cement Waterproof CoatingDocument2 pagesFlexible Cement Waterproof CoatingDharryl Dharryl DharrylNo ratings yet

- DELMON ProfileDocument77 pagesDELMON ProfileFAIYAZ AHMEDNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

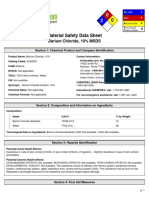

- Foster 32 17 SDS R0317Document7 pagesFoster 32 17 SDS R0317Nashal KkNo ratings yet

- Foster SDS 30 36 R0220 1Document7 pagesFoster SDS 30 36 R0220 1Nashal KkNo ratings yet

- Hot Water BoqDocument2 pagesHot Water BoqNashal KkNo ratings yet

- Solar Water Heater SystemDocument1 pageSolar Water Heater SystemNashal KkNo ratings yet

- BARIUM CHLORIDE GuideDocument5 pagesBARIUM CHLORIDE GuideDaphne Lianne DegayNo ratings yet

- Chloride Analyzer ManualDocument23 pagesChloride Analyzer ManualChromatic ShadeNo ratings yet

- Pharmaceutical Process Scale Up Case StudyDocument8 pagesPharmaceutical Process Scale Up Case StudypratikNo ratings yet

- Astom Products CatalogueDocument10 pagesAstom Products Cataloguelkumar4454No ratings yet

- Methodology and Data Presentation: Pamantasan NG Lungsod NG MaynilaDocument86 pagesMethodology and Data Presentation: Pamantasan NG Lungsod NG MaynilaCharles Amiel DionisioNo ratings yet

- An Investigation Into The Effect of The Concentration of Different Household Chemical Cleaning Products On The Effects of GerminationDocument18 pagesAn Investigation Into The Effect of The Concentration of Different Household Chemical Cleaning Products On The Effects of GerminationDhruv (Dhruv) AbrolNo ratings yet

- Corona & Plasma: For ExtrusionDocument8 pagesCorona & Plasma: For ExtrusionHuy Tuan QuachNo ratings yet

- ArinDocument39 pagesArinanirudha22No ratings yet

- ASME BPV - 08 Section II SFA 5.9 PDFDocument24 pagesASME BPV - 08 Section II SFA 5.9 PDFCarlos PovedaNo ratings yet

- Myths Human GeneticsDocument72 pagesMyths Human GeneticsfukusacoNo ratings yet

- US20030075077A1Document12 pagesUS20030075077A1Kyaw Kyaw LinnNo ratings yet

- Chemistry Project Class 12Document12 pagesChemistry Project Class 12mihir khabiyaNo ratings yet

- Monday 4 May 2020: BiologyDocument20 pagesMonday 4 May 2020: Biologycye23No ratings yet

- 2.3 Electron ConfigurationsDocument1 page2.3 Electron ConfigurationsEoghan KuiperNo ratings yet

- Basic Chemistry (6) : Composition of Substances and SolutionsDocument7 pagesBasic Chemistry (6) : Composition of Substances and SolutionsNurharis MunandarNo ratings yet

- The Leaching of Gold in Cyanide Solutions in The Presence of Impurities, The Effect of LeadDocument6 pagesThe Leaching of Gold in Cyanide Solutions in The Presence of Impurities, The Effect of LeadArief RHNo ratings yet

- INTRODUCTIONDocument16 pagesINTRODUCTIONJo RajNo ratings yet

- Astm21 1510Document18 pagesAstm21 1510Robert ChenNo ratings yet

- Tolerances: RWP SCO .X .XX .XXX ANGLE 0 30' Fractions 1/4" Third Angle ProjectionDocument1 pageTolerances: RWP SCO .X .XX .XXX ANGLE 0 30' Fractions 1/4" Third Angle ProjectionJorge OrihuelaNo ratings yet

- 15 MSDS WKWKWK PDFDocument138 pages15 MSDS WKWKWK PDFKurir PinrangNo ratings yet

- Dreiding Stereomodels: Technical BulletinDocument2 pagesDreiding Stereomodels: Technical BulletinAlberto JimenezNo ratings yet

- Altering Product Strength, Use of Stock Solutions, and Problem Solving by AllegationDocument34 pagesAltering Product Strength, Use of Stock Solutions, and Problem Solving by AllegationMint PaclebNo ratings yet

- Sikafloor® CureHard 24Document2 pagesSikafloor® CureHard 24Harold SanaresNo ratings yet

- Enthalpy change of alcoholsDocument4 pagesEnthalpy change of alcoholsJulia QistinaNo ratings yet

- Individuality and personality traitsDocument18 pagesIndividuality and personality traitsERNANIE LLAVORENo ratings yet

- Veratherm: High-Temperature Water-Based Drilling FluidDocument8 pagesVeratherm: High-Temperature Water-Based Drilling FluidSupanca Ade Putri100% (1)

- ACIDS AND BASES DEFINED VIA THREE THEORIESDocument21 pagesACIDS AND BASES DEFINED VIA THREE THEORIESDerekNo ratings yet

- Hach Online Alkalinity MonitorDocument5 pagesHach Online Alkalinity MonitorArul KumarNo ratings yet

- General Chemistry 2 q3 Slm4Document15 pagesGeneral Chemistry 2 q3 Slm4Christine Mae LlabanNo ratings yet

- DETC2018-86042: Review of Natural Fiber Reinforced Elastomer CompositesDocument11 pagesDETC2018-86042: Review of Natural Fiber Reinforced Elastomer CompositesSanjayvadamudulaNo ratings yet