Professional Documents

Culture Documents

Analog Display Digital VFO

Uploaded by

testOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analog Display Digital VFO

Uploaded by

testCopyright:

Available Formats

Doing lt By Design

C D

3,3V

Si5351A module

R

3,3V 2.2k

ESP32-DevKitC

GND 3.3V

vcc 1

TFT LCD

ST7735 (128"160)

3,3V

R

3.3V 150

OLED

R R

2,2.k 2,2k

Rotary Enc. 1-'s~ ------ - ~

40p/rev GND

NHD-l.69-160128UGC3

Steve Macdonald G4AQB

practicalwireless@warnersgroup.co.uk Building an Analogue

W

e have come a lang way since the tim es

when building a VFO for a receiver or

transmitter required careful coil winding,

variable capacitors, silver mica capacitors and

Display Digital VFO

frequency drift. 1spent many happy hours align- Steve Macdonald G4AQB describes how to build an

ing VFOs, trying to get them stable and to tune in analogue VFO using modern techniques and components.

a linear fashion for use with a mechanical drive.

Nowadays accurate multiband VFOs can be built did later find a couple of sites, one from Australia In the past I have built Arduino Nano VFOs and

easily using an Arduino or similar microcontroller and one from the USA, by other amateurs who am fam iliar with the Arduino IDE, but have never

and programmable clock generator. have built and developed one of these VFOs. used an ESP32 for this purpose. The Arduino

There are two versions of the VFO, the first is for IDE can be used to edit and upload the sketch to

Digital VFOs Basic Tuning and the second uses Adaptive Step the ESP32, but it is important that you download

While searching for information about an Arduino Control. The hardware is the same for both ver- and install the board drivers first for the different

Nano based VFO, 1 stumbled across a video by sions . versions of ESP32 processors. 1 used the 38-pin

JF3HZB of a wonderful digital VFO with an ana- 1decided to build the Adaptive Step Control ver- ESP32 DevKitC as shown in the original diagram,

logue display. This display looks very much like a sion because thi s enables tuning without having but it is possible to use the smaller 30-pin ESP32

traditional mechanical VFO that would have been to add a separate frequency step and bands- microcontrollers with adjustments to the pin

used in older transceivers. witch . connections.

This whet my appetite to find out more and have The JF3HZB VFO uses an ESP32 DevKitC mi-

a go at building one of these VFOs. After further crocontroller along with an Si5351 a programma- Construction

searching for more information about this project ble clock generator. The display gives a choice Construction requires an ESP32 DevKitC

1 found very little apart from a link to JF3HZB giv- of 1.Bin TFT (ST7735 Type) or OLED (see circuit Microcontroller, Si5351 a Clock Generator, TFT

ing the circuit and software sketch downloads. 1 diagram, Fig. 1). or OLED Display and a suitable Rotary Encoder.

Sign up to our FREE email newsletter at www.radioenthusiast. eo .uk

56 PRACTICAL WIRELESS October 2022

Doing lt By Design

VFOsys_ntep I Arduino 1.3..16 □ X

Fil, Edit Sketch fo ols Help_

-- -

~ C- -_"! rc-;i ~: D

~~~2

#sl!: :'. i::e 1oi t_!req 110.JOO0 : ::i::.eul f ::, ~-1.-:e:,·[B=J

~.:J:_: o!!ut_!:cq • BS.SfSOO ; :=-! ! s et F:e~..:e~y [:'l::J

:.::-:J:_::. car_!rq • ess,~soo; /J C•:r:.e:: !'::e:ri!l:;.y{ E.: !

~i;r.;a::1 ct-A: ! _carOH ,. !; ::-U 'C!!" : a: 9:.T,141

f;ie ! i.ce fr.u: 150000000 !'.u: !:e:t11e ney [B..: J

Ue!!:-.e ! u.-: 100000 Mi.-: !'::e"Nen,;:y{E: J

i1e :'. :.::e !req_step 10 / Mm SU► [ fi : j

1

Fig. 1: Circuit of the JF3HZB VFO. https://tinyurl.com/ynzsts7a

II Fig. 2: Wiring the modules using DuPont You now need to open the Sketch that you have

Connectors. Fig. 3: Lines from the sketch for saved an your computer into Arduino IDE. The

changing. Fig. 4: Working display of the VFO. Sketch file is the one ending with .ino. When it is

Fig. 5: Mounting the modules into the box. loaded, you may want to make some changes to

Fig. 6: View of the inside of the box. the code in order toset the offset frequency and

Fig. 7: Completed JF3HZB VFO. initial start-up frequency, Fig. 3.

When you are ready, select 'Sketch', 'Verify/

tab on the protective film. The one that I used had Compile'. The code will now be compiled and

a Green protective tab. show up any errors. This may take a few minutes.

Once the hardware has been constructed, the Once compiled, connect a suitable USB lead

next step is to program the ESP32 by uploading from your computer to the ESP32 board USB

the Sketch. socket.

Go to 'Tools' and select 'Ports', choose the port

Programming that you are using. lf you are not sure which port

Although using a breadboard may be preferred 1 found that programming was the trickiest part is in use, disconnect the USB lead and look again

by some, 1 chose to wire the mod ules by using of the VFO project. Here are the steps that I took at the listed ports . The active port will not show.

female-to-female DuPont connectors. As the wir- to upload the software required to complete the Plug the USB in again and it will reappear.

ing is fairly simple, it is easy to see and follow the working VFO. Go to 'Sketch' and 'Upload' (This will take a few

connections as weil as making later adjustments First, you will need to have installed a copy of minutes to first compile again and then upload).

easy if required . The DuPont connectors used are Arduin o IDE and libraries an your computer. You lf everything is correct, the VFO Dial should

20mm lang, later I reduced the size of these to can fi nd it here: burst into life when upload has completed, Fig. 4.

10mm so that the project would fit neatly into a www.arduino.cc/en/software lf you find that the display is not working

diecast box, Fig. 2. Arduino IDE is used to upload the software correctly or that the display is showing incorrect

When wiring the boards, check carefully the pin that you need to the ESP32. You will also need colours, it may be because of the type of TFT

numbers and labels on each module as you con- to install the ESP32 library of boards. Ta da this, you are using. 1have read an one of the websites

nect them and always recheck before powering start up Arduino IDE and select 'Tools', 'Boards', that if this happens, you may need to make some

up. The ESP32 board provides 3.3V VCC, which 'Board Manager'. Search for ESP32 and install. changes to the software. Detailsare an this

is the same as the Si5351 a and OLED. lf using a When installed go back to 'Boards' and select website:

1.Bin TFT, there is usually a link on the board for ESP32 Arduino. Vou will see a list of boards, https://tinyurl.com/mryjk54w

5V or 3.3V. This needs tobe set to 3.3V. lnitially, select the board that you are using, in my case

1used a cheap 24-pulse Rotary Encoder Board, ESP32 Dev Module. Testing

which was adequate for test purposes. Next, go to github.com (URL below), select the First of all check that the display is working

lf you are using a TFT display, make sure that version that you want to make, either VFOsys or correctly and the Rotary Encoder moves the

you are using an SPI ST7735 (12Bx160) type. VFOsys-astep. Click the 'Code' button on the left, display frequency up and down. Connect an

Unfortunately, there are many variations of TFT. this takes you to another screen . Select the Green oscilloscope/frequency counter to each of

The most common way of identifying the differ- 'Code' button on the right and select 'Download the outputs of the si5351 a clock generator

ent types seems tobe by the colour of the plastic zip'. Unzip and save the file on your computer. board (CLKO, CLK1 , CLK2) . Make sure that the

Read more radio news and reviews at www.radioenthusiast.eo .uk/news

October 2022 PRACTICAL WIRELESS 57

Doing lt By Design

Parts List

• ESP32 OevKitC(38 Pin) Microcontroller

• Si 5351aClock Generator

• TFTType SPI ST7735 1.Bin 12Bx160 or OLEO

• CNC RotaryEncoder 100pulse

• 4x2.2k0 1/4W Resistors

• DuPont Female·to-FemaleConnectors(20mm and10mm)

• SMA Sockets

• Power Socket

• StandardDiecast Box 120x95x57mm

• Single sidedCopper Cladboardapprox. 70x50mm

• 12V to SVBuckConverter (if required)

frequencies correspond to those in the software

taking account of any offsets. 1only used the

CLK2 (Local Oscillator) signal for my project.

Rotary Encoder

On the circuit diagram, it is recommended that a

40-pulse rotary encoder is used as a minimum.

1tested mine with a 24-pulse encoder and

found that it is too slow. 1 decided to look for

an alternative and came across some very nice

100-pulse CNC Rotary Encoders. These are

available in two sizes, 60mm and 80mm, either

Black or Silver and are very reasonably priced .

They are made of solid aluminium and are quite connectors where they connected to each of ming can further develop and customise this pro-

heavy, ideal for a VFO project. Connecting to the the ESP32 and si5351 a boards. Later, spots of ject and add other useful features such as band

CNC Rotary Encoder is straightforward, simply hot glue were applied to hold everything still. switching . lt can be used to drive an SDR receiver

connect to A, B, VCC and GND marked on the The loops are soldered to the underside of the or transceiver by using the clock outputs (CLKO

encoder. 1 connected the VCC to 3.3V and found copper-clad board, Fig. 5. and CLKl) for I and Q. 1 have tried to keep thi s

that it does not require the two pull-up resistors 1 reduced the length of the DuPont connectors project as simple as possible so as not to put off

shown on the circuit. lt is also easy to remove the to 10mm and also added a buck converter to anyone wish ing to try building one of these. My

detents (clicks) making the drive very smooth . provide the SV to the ESP32 USB from a 12V thanks to Ross G6GVI for helping me out with the

This link shows a video of how it is done: supply. The TFT Display and Bezel is mounted to software.

https://tinyurl.com/26mssbww the front panel using spots of hot glue, Fig. 6. On

The CNC Encoder works a treat and really the back is a si ngle SMA socket for the LO output References

shows how useful the adaptive step control can and a 12V power socket. T.J. Uebo JF3HCB, Main Project Software and

be, especially when changing bands. Circuit:

Conclusion https://tinyurl.com/ynzsts7a

Mountingthe VFO The JF3HZB VFO provides a very smooth and ac- SADARC (Australia):

Now that we have a working VFO it needs tobe curate digital/analogue display. The VFO works https://tinyurl.com/mryjk54w

mounted in a screened box. 1 used a standard at frequencies up to 150MHz. The CNC Rotary WA2FZW - lt's not just another Digital VFO :

diecast box size 115 x 90 x 55mm. To mount the Encoder looks and feel s like that used on an ex- https://tinyurl.com/mpmb67rh

modules I used a piece of single-sided copper pensive transceiver, Fig. 7. The VFO could also Removing the detent (clicks) on the CNC Encoder:

clad board bolted to the base of the box (copper be integrated into a larger project such as a multi- https://tinyurl.com/26mssbww

side underneath). Small holes were drilled in band receiver or transceiver. JF3HZB Video of the VFO:

order to make wire loops to hold the DuPont l'm sure that anyone with skills in program- https://tinyurl.com/2p847vhw

Sign up to our FREE email newsletter at www.radioenthusiast.co.uk

58 PRllCTICllL WIRELESS October 2022

You might also like

- Overvoltage Protection of Electric Vehicle (EV) Charging Infrastructures GloballyDocument8 pagesOvervoltage Protection of Electric Vehicle (EV) Charging Infrastructures GloballySatadal DashNo ratings yet

- VX-261 Uhf SM Ec128u90cDocument19 pagesVX-261 Uhf SM Ec128u90cDavid FabianNo ratings yet

- RF Agile Transceiver: Data SheetDocument32 pagesRF Agile Transceiver: Data SheetKristen FieldsNo ratings yet

- DDS VFO Guide Build Own Multi-Band HF TransceiverDocument14 pagesDDS VFO Guide Build Own Multi-Band HF TransceiveryogosNo ratings yet

- Raspberry Pi Day ExtravaganzaDocument82 pagesRaspberry Pi Day ExtravaganzaNaryesha FontanillaNo ratings yet

- Arm Case-Study: The Raspberry Pi: Razvan Bogdan Microprocessor SystemsDocument115 pagesArm Case-Study: The Raspberry Pi: Razvan Bogdan Microprocessor SystemsSilvana StefanovNo ratings yet

- MEGA2560 Arduino SCHDocument1 pageMEGA2560 Arduino SCHArief Nurhakiki100% (1)

- Simple Broadband Power AmplifiersDocument6 pagesSimple Broadband Power AmplifiersYoussef FayadNo ratings yet

- Hellenized SRF59 HandbookDocument4 pagesHellenized SRF59 Handbookmax_orwell100% (1)

- Analog and Mixed VLSI DesignDocument256 pagesAnalog and Mixed VLSI DesignGIRISH GIDAYENo ratings yet

- 3172V21 - Synthesised WBFM TransmitterDocument6 pages3172V21 - Synthesised WBFM Transmitterjoniez14No ratings yet

- UHF Digital/Analog Mobile Transceiver Service Manual: Vertex Standard LMR, IncDocument31 pagesUHF Digital/Analog Mobile Transceiver Service Manual: Vertex Standard LMR, IncIng Marco Antonio Hernandez LimaNo ratings yet

- MCS2000 Detailed Service 6881083C20-DDocument244 pagesMCS2000 Detailed Service 6881083C20-DBenjamin DoverNo ratings yet

- AMD Picasso FP5 APU M/B Schematic DocumentsDocument44 pagesAMD Picasso FP5 APU M/B Schematic DocumentsspspzNo ratings yet

- GPS Neo-6m-V12 SCHDocument1 pageGPS Neo-6m-V12 SCHKwok Chung Chu100% (1)

- 1M - 50MHZ 1W Broadband Power Amplifier Circuit Diagram - Circuit Diagram WorldDocument1 page1M - 50MHZ 1W Broadband Power Amplifier Circuit Diagram - Circuit Diagram WorldK Raja Sekar100% (1)

- Best dual-band VHF/UHF antenna for any locationDocument5 pagesBest dual-band VHF/UHF antenna for any locationWellington Ramos Barboza100% (1)

- HF Transceiver PDFDocument16 pagesHF Transceiver PDFHaggai Ben BaruchNo ratings yet

- ESP32Document19 pagesESP32Agus SuwardonoNo ratings yet

- Beitman 1949 TVDocument212 pagesBeitman 1949 TVDirceu RodriguesNo ratings yet

- LCD KeyPad Shield - IntroductionDocument5 pagesLCD KeyPad Shield - IntroductionKroscop San Martin de LunaNo ratings yet

- Basic RC Oscillator CircuitsDocument8 pagesBasic RC Oscillator CircuitsZsori CorinaNo ratings yet

- Electronic - Schematic Circuits For The HobbyistDocument159 pagesElectronic - Schematic Circuits For The HobbyistDaniel ComeglioNo ratings yet

- Building and Operating The Digital Sony SRF-39Document4 pagesBuilding and Operating The Digital Sony SRF-39englagraNo ratings yet

- LV MaxSonar EZ1 DatasheetDocument2 pagesLV MaxSonar EZ1 DatasheetSuLi Warraich100% (1)

- 5324 DP-4090 5090 D-S300Document28 pages5324 DP-4090 5090 D-S300roca9oNo ratings yet

- Pavilion ZD7000 NT1 QuantaDocument35 pagesPavilion ZD7000 NT1 QuantaMicu Adrian DanutNo ratings yet

- Dual-Band TransceiverDocument6 pagesDual-Band TransceiverTrueno LocoNo ratings yet

- Band Pass Filter Design for 2m Ham RadioDocument5 pagesBand Pass Filter Design for 2m Ham RadioshubhamformeNo ratings yet

- External PTT Pedal Circuit (RS232)Document2 pagesExternal PTT Pedal Circuit (RS232)SmartPTT100% (1)

- The Defpom CB Radio PLL List Page 2Document9 pagesThe Defpom CB Radio PLL List Page 2Todd HoferNo ratings yet

- VHF SWR MeterDocument3 pagesVHF SWR MeterSaimonKNo ratings yet

- Simple RF PCB Layout Tips (2.4GHz and 5GHz Bands)Document11 pagesSimple RF PCB Layout Tips (2.4GHz and 5GHz Bands)Mehmet Kibar100% (1)

- Service Manual VX 21002200 Series VHFDocument44 pagesService Manual VX 21002200 Series VHFRubem A S FigueiraNo ratings yet

- All-in-One Data Acquisition Solution on a ChipDocument34 pagesAll-in-One Data Acquisition Solution on a ChipVport PortNo ratings yet

- D. Y. Patil College of Engineering, Akurdi. Department of Electronics & TelecommunicationDocument9 pagesD. Y. Patil College of Engineering, Akurdi. Department of Electronics & TelecommunicationSukanyaNo ratings yet

- Microwave Journal-March 2021Document168 pagesMicrowave Journal-March 2021Petros TsenesNo ratings yet

- ISSCC2023-5G and Satcom Receivers and TransmittersDocument174 pagesISSCC2023-5G and Satcom Receivers and Transmittershello worldNo ratings yet

- Schematic FM-Radio Sheet-1 20190702002800Document1 pageSchematic FM-Radio Sheet-1 20190702002800Mr Swan100% (2)

- CRG40T60AN3HDocument9 pagesCRG40T60AN3HVadim PopovichNo ratings yet

- Micropython On ESP8266 Workshop Documentation: Release 1.0Document35 pagesMicropython On ESP8266 Workshop Documentation: Release 1.0Hendri Kus23No ratings yet

- SSB Exciter Circuits Using The 7360Document10 pagesSSB Exciter Circuits Using The 7360Rose Ann SarcedaNo ratings yet

- Ic-7400 SM 3Document84 pagesIc-7400 SM 3Luciano HoraNo ratings yet

- DsPIC Seminar Q205Document147 pagesDsPIC Seminar Q205ecfdcv100% (1)

- Yaesu Ft-991 Technical SupplementDocument150 pagesYaesu Ft-991 Technical SupplementFelicianoNo ratings yet

- Bandpass SignalingDocument76 pagesBandpass SignalingJonathan SanchezNo ratings yet

- Cs Tcom RF 7800h MP Wideband HF VHF Tactical Radio System DatasheetDocument2 pagesCs Tcom RF 7800h MP Wideband HF VHF Tactical Radio System DatasheetOmar Karwi100% (1)

- Yaesu FT-817 service menu overviewDocument6 pagesYaesu FT-817 service menu overviewDaniel CoslovskyNo ratings yet

- Nordic Semiconductor ASA nRF52840 Bluetooth Low Energy/ANT/802.15.4/2.4GHz RF Development Board (PCA10056Document13 pagesNordic Semiconductor ASA nRF52840 Bluetooth Low Energy/ANT/802.15.4/2.4GHz RF Development Board (PCA10056Thanga rajNo ratings yet

- Design and Layout of 1.8V Two Stage CMOS Operational Amplifier (Unbuffered)Document5 pagesDesign and Layout of 1.8V Two Stage CMOS Operational Amplifier (Unbuffered)sudarshan poojaryNo ratings yet

- Manual Nanovna F v2 Rev 2.0 Firm v.0.3.0Document40 pagesManual Nanovna F v2 Rev 2.0 Firm v.0.3.0Osvaldo EmilioNo ratings yet

- A68 RF Hardware Trouble Shooting Guide - WO - SA - A8960 - 1001 PDFDocument56 pagesA68 RF Hardware Trouble Shooting Guide - WO - SA - A8960 - 1001 PDFDnw DigitalprintingNo ratings yet

- Z80 ProgrammingDocument30 pagesZ80 ProgrammingDusan TrisicNo ratings yet

- AR313 Application Note MRF141GDocument6 pagesAR313 Application Note MRF141GerdemsecenNo ratings yet

- Stockton - Fabc (Series S)Document76 pagesStockton - Fabc (Series S)Gabriel SandovalNo ratings yet

- Radiotron Radio Set Socket Layout 1921 1935Document257 pagesRadiotron Radio Set Socket Layout 1921 1935Bel SamNo ratings yet

- LV MaxSonar EZ DatasheetDocument12 pagesLV MaxSonar EZ DatasheetOscar Maldonado100% (3)

- Si4734 35 FM Radio ReceiverDocument42 pagesSi4734 35 FM Radio ReceiverChua BoonLian100% (1)

- ROV Control Sketches - Fourth Edition: ROV HS5803-14BA Depth Sensor HMC5883L Digital CompassDocument19 pagesROV Control Sketches - Fourth Edition: ROV HS5803-14BA Depth Sensor HMC5883L Digital CompassCarlos Daniel Rodrigo CNo ratings yet

- Micromis Base V1 - Quick Start GuideDocument17 pagesMicromis Base V1 - Quick Start GuideDominik NuszkiewiczNo ratings yet

- CQ Amateur Radio 07-2019Document116 pagesCQ Amateur Radio 07-2019testNo ratings yet

- CQ Amateur Radio 2019 09 PDFDocument116 pagesCQ Amateur Radio 2019 09 PDFJuan Manuel Sánchez GarciaNo ratings yet

- Firmware Upgrade Via Desktop Arduino IDEDocument6 pagesFirmware Upgrade Via Desktop Arduino IDEtestNo ratings yet

- CQ Amateur Radio 08-2019Document116 pagesCQ Amateur Radio 08-2019testNo ratings yet

- CQ Amateur Radio 06-2019Document116 pagesCQ Amateur Radio 06-2019testNo ratings yet

- CQ Amateur Radio 02-2019Document116 pagesCQ Amateur Radio 02-2019testNo ratings yet

- The ElektorDSP Radio Part 1Document6 pagesThe ElektorDSP Radio Part 1testNo ratings yet

- CQ Amateur Radio 12-2016Document116 pagesCQ Amateur Radio 12-2016testNo ratings yet

- CQ Amateur Radio 05-2019Document116 pagesCQ Amateur Radio 05-2019testNo ratings yet

- Grasshopper Module Guide - Wheat v1.0: Onfiguration River PtionsDocument5 pagesGrasshopper Module Guide - Wheat v1.0: Onfiguration River PtionstestNo ratings yet

- Light Burn DocsDocument187 pagesLight Burn DocstestNo ratings yet

- Assembly Instructions SI4732-35Document13 pagesAssembly Instructions SI4732-35testNo ratings yet

- Raudive Diode "EVP" (Electronic Voice Phenomena) Receiver For Smart-Phones and LaptopsDocument6 pagesRaudive Diode "EVP" (Electronic Voice Phenomena) Receiver For Smart-Phones and LaptopstestNo ratings yet

- How To Build A Fuel CellDocument7 pagesHow To Build A Fuel CellleechsterNo ratings yet

- Light Burn DocsDocument187 pagesLight Burn DocstestNo ratings yet

- Light Burn DocsDocument187 pagesLight Burn DocstestNo ratings yet

- Software Testing BooksDocument13 pagesSoftware Testing BooksNenad PetrövicNo ratings yet

- Mircom TX3-DATA-MDM Data SheetDocument2 pagesMircom TX3-DATA-MDM Data SheetJMAC SupplyNo ratings yet

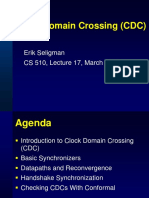

- Clock Domain Crossing (CDC) : Erik Seligman CS 510, Lecture 17, March 2009Document39 pagesClock Domain Crossing (CDC) : Erik Seligman CS 510, Lecture 17, March 2009Rohan PeterNo ratings yet

- Echague 09162022Document25 pagesEchague 09162022Garyl FebNo ratings yet

- Maintenance Parts Excellence Course Final v3Document12 pagesMaintenance Parts Excellence Course Final v3Diego Pérez AlarcónNo ratings yet

- Earth Ground Resistance Testing Methods for Accurate Low-Voltage System EvaluationsDocument8 pagesEarth Ground Resistance Testing Methods for Accurate Low-Voltage System EvaluationsTana AzeezNo ratings yet

- Hollysys: LK Programmable Logic ControllerDocument17 pagesHollysys: LK Programmable Logic ControllerClear MindNo ratings yet

- Automation Attendance Systems Approaches: A Practical ReviewDocument9 pagesAutomation Attendance Systems Approaches: A Practical ReviewBOHR International Journal of Internet of Things ResearchNo ratings yet

- User Manual: Control Process Controller D500Document32 pagesUser Manual: Control Process Controller D500boyerNo ratings yet

- EN81-28 Risk of Trapping FlowChart v3Document1 pageEN81-28 Risk of Trapping FlowChart v3Ashraful ShohagNo ratings yet

- Sample TemplateDocument1 pageSample TemplatePramod SultaneNo ratings yet

- Dmcplus™ For Honeywell TDC 3000 User'S Guide: Reach Your True PotentialDocument92 pagesDmcplus™ For Honeywell TDC 3000 User'S Guide: Reach Your True Potentialluan zhiye0% (1)

- Http://d1.scribdassets - com/ScribdViewer - Swf?document Id 108992419&access Key Key-13davbcdewnewn9m5w02Document4 pagesHttp://d1.scribdassets - com/ScribdViewer - Swf?document Id 108992419&access Key Key-13davbcdewnewn9m5w02Dhoom Dhoom40% (5)

- Check Your ECDIS Uses Latest IHO S-52 StandardsDocument4 pagesCheck Your ECDIS Uses Latest IHO S-52 StandardsgongaxNo ratings yet

- PMBOK Guide (7th Edition) - June. 2022Document90 pagesPMBOK Guide (7th Edition) - June. 2022Ahmed Idrees94% (16)

- Binary & Logic OperationDocument16 pagesBinary & Logic OperationEssamNo ratings yet

- Case Study Report Sheet - Timmons TemplateDocument3 pagesCase Study Report Sheet - Timmons TemplateEmmanuel DianaNo ratings yet

- Introduction to Radio Network Planning Tools Excel Mapinfo GoogleEarthDocument17 pagesIntroduction to Radio Network Planning Tools Excel Mapinfo GoogleEarthctorres2012No ratings yet

- Revolusi Industri 4.0: Desain Perkembangan Transaksi Dan Sistem Akuntansi Keuangan Agung Prajanto Ririh Dian PratiwiDocument17 pagesRevolusi Industri 4.0: Desain Perkembangan Transaksi Dan Sistem Akuntansi Keuangan Agung Prajanto Ririh Dian PratiwiFirdausNo ratings yet

- Cummins Engine Type S38Document3 pagesCummins Engine Type S38edspt8No ratings yet

- FT Historian SE Upgrade and Migration GuideDocument96 pagesFT Historian SE Upgrade and Migration Guidefrancois lecreuxNo ratings yet

- Diseño de sistemas mecánicos: Electric motor selection and specificationsDocument3 pagesDiseño de sistemas mecánicos: Electric motor selection and specificationsFrein Fernando VeraNo ratings yet

- Board of Technical Education Uttar Pradesh Lucknow: Odd Semester Result December-2018 Marks SheetDocument1 pageBoard of Technical Education Uttar Pradesh Lucknow: Odd Semester Result December-2018 Marks SheetMayankNo ratings yet

- Top Risk 2021Document18 pagesTop Risk 2021NelsonNo ratings yet

- Certificate Declaration Index and AcknowledgementDocument5 pagesCertificate Declaration Index and AcknowledgementNidhi ShahNo ratings yet

- Essential Copying and Pasting From Stack OverflowDocument10 pagesEssential Copying and Pasting From Stack OverflowGermán MéndezNo ratings yet

- Com - Com: Solid State Protective RelaysDocument23 pagesCom - Com: Solid State Protective Relaysshehroz baigNo ratings yet

- Ericsson BSC PDFDocument2 pagesEricsson BSC PDFMatt0% (2)

- Karnataka Power Sector Reforms: Interface & Boundary MeteringDocument19 pagesKarnataka Power Sector Reforms: Interface & Boundary MeteringnsewwandikaNo ratings yet

- GB Relay PDFDocument1 pageGB Relay PDFAbraham PerezNo ratings yet