Professional Documents

Culture Documents

Sheet RB 3K YELLOW

Uploaded by

Communications ShipyardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheet RB 3K YELLOW

Uploaded by

Communications ShipyardCopyright:

Available Formats

DOCUMENTATION SHEET General

Our rubber bellows are made from various elastomers and provide the flexible element in pipe

Rubber Bellows work that is indispensable in today's technically advanced plant and machinery spaces.

Type 3K Yellow By using the best quality proven rubber compounds and a construction based on many years

of experience, our rubber bellows are produced to a high quality standard to guarantee maxi-

mum safety and performance.

3K YELLOW

Rubber bellows are used in various fields of industry like shipbuilding, offshore, dredging,

power plants, chemical industry, water works etc.

The rubber bellows provide:

Compensation of thermal or mechanical movement of pipe work in axial, lateral and/or

angular directions.

Absorption and isolation of vibration combined with damping of pipe work borne sound

transmission.

Reduction of pressure pulses in pipe work.

Compensation for pipe work misalignment on flexibly mounted installations.

Our program consists of rubber bellows with flanges, according all known standards as well as

special connections, and rubber and silicone bellows for installation with hose clamps.

Maximum temperature water: +70°C

Maximum temperature oil: +90°C

DIMENSIONS

1 RB / 3K YELLOW / AUG 2012

3K YELLOW

As an addition to the flanged bellow range our 3K and 3K2 rubber bellows have been de-

signed especially to provide small, low weight bellows which are both very flexible and simple

to install. The 3K ranges accommodate misalignment, axial and lateral pipe work movements

and dramatically reduce the transmission of noise, vibration and shock.

High tensile strength texture cord plies combined with proven synthetic rubber mixes guaran-

tee maximum reliability and an extended working life.

The burst pressure safety factor is 5 times the working pressure of 4 Bar. The minimum work

pressure is 70 kPa ( abs ) and can be lowered by fitting a vacuum support ring. Average

installed insulation is about 25 dB, a figure which is further improved by compressed installa-

tion.

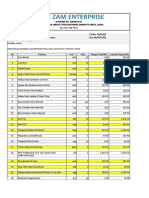

3K Bellows Allowable Weight Min. Max. Advised

YELLOW dimensions Displacement Pressure Hose

RING ( a bs ) clamp

ØA ØB C D E Ax. Lat. Ang.

Art.nr without clamps mm mm mm mm mm mm mm ° kg kPa MPa

KV025.0G1000 25,0 35 85 55 140 -15/+7 +/-10 7 0,2 70 0,4 40

KV032.0G1000 32,0 45 94 55 140 -15/+7 +/-11 7 0,3 70 0,4 45

KV033.7G1000 33,7 47 96 55 140 -15/+7 +/-12 7 0,3 70 0,4 45

KV038.0G1000 38,0 50 116 50 140 -15/+7 +/-12 7 0,3 70 0,4 45

KV042.4G1000 42,4 55 123 60 160 -19/+9 +/-14 7 0,4 70 0,4 55

KV044.5G1000 44,5 58 124 60 160 -19/+9 +/-14 7 0,4 70 0,4 55

KV048.3G1000 48,3 61 125 60 160 -19/+9 +/-14 7 0,4 70 0,4 60

KV054.0G1000 54,0 67 130 60 160 -19/+9 +/-14 7 0,5 70 0,4 65

KV057.0G1000 57,0 70 130 60 160 -19/+9 +/-14 7 0,5 70 0,4 65

KV060.3G1000 60,3 73 131 70 180 -19/+9 +/-14 7 0,6 70 0,4 70

KV063.5G1000 63,5 74 134 70 180 -19/+9 +/-14 7 0,6 70 0,4 70

KV076.1G1000 76,1 89 155 70 180 -19/+9 +/-14 7 0,8 70 0,4 85

KV088.9G1000 88,9 102 169 95 225 -20/+10 +/-15 7 0,9 70 0,4 95

KV108.0G1000 108,0 125 202 100 250 -25/+12 +/-16 7 1,6 70 0,4 115

KV114.3G1000 114,3 131 205 100 250 -25/+12 +/-16 7 1,7 70 0,4 125

KV115.8G1000 115,8 133 205 100 250 -25/+12 +/-16 7 1,7 70 0,4 125

KV139.7G1000 139,7 157 234 100 250 -25/+12 +/-16 7 2,0 70 0,4 150

KV168.3G1000 168,3 185 292 100 250 -30/+14 +/-21 7 2,6 70 0,4 170

TABLE

Pressure

The maximum working pressures are guaranteed by using the recommended power clamps in

steel ( galvanized ) or stainless steel according to the table.

Rubber Design B.V.

Industrieweg 21

2995BE Heerjansdam

The Netherlands

Phone: +31 ( 0 ) 78 677 87 78

Fax: +31 ( 0 ) 78 677 10 38

TYPE APPROVAL Email: info@rubberdesign.nl

Web: www.rubberdesign.nl

2 RB / 3K YELLOW / AUG 2012

You might also like

- Documentation Sheet Rubber Bellows General: Maximum Temperature Water: +70°C Maximum Temperature Oil: +90°CDocument2 pagesDocumentation Sheet Rubber Bellows General: Maximum Temperature Water: +70°C Maximum Temperature Oil: +90°CLorena IHCNo ratings yet

- HT CompensatorDocument1 pageHT CompensatorJezrell JaravataNo ratings yet

- 3 Lifeline CPVC Hot and Cold Plumbing SystemDocument4 pages3 Lifeline CPVC Hot and Cold Plumbing SystemNikita KadamNo ratings yet

- Spiral Hose Guard: REF Length Wall ID OD Range Box WeightDocument2 pagesSpiral Hose Guard: REF Length Wall ID OD Range Box Weightviktor_gligorovNo ratings yet

- H05VV5-F (Nyslyö-Jz)Document2 pagesH05VV5-F (Nyslyö-Jz)Luis AguilarNo ratings yet

- Victaulic's CouplingsDocument6 pagesVictaulic's CouplingsKumaresan VasudevanNo ratings yet

- Alfagomma - Oil & GasDocument115 pagesAlfagomma - Oil & GasIgor Bastos100% (1)

- Ari SafeDocument40 pagesAri SafetiptoptammyNo ratings yet

- N Tscgewã U 8 715kv and 12 20kv Submersible CableDocument3 pagesN Tscgewã U 8 715kv and 12 20kv Submersible Cableheri fauziNo ratings yet

- ERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Document6 pagesERIKS - Simrit Merkel Omegat Stangafdichtingen (OMS-SPR)Sérgio GomesNo ratings yet

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- A029 A030 H05VVC4V5 K - NYSLYCYO - ControlDocument2 pagesA029 A030 H05VVC4V5 K - NYSLYCYO - ControlJosé CamposNo ratings yet

- Catalogo Marazzi Rev04 09 04Document2 pagesCatalogo Marazzi Rev04 09 04nexus41No ratings yet

- Flexible Rubber Joint TozenDocument5 pagesFlexible Rubber Joint Tozenzaem afifiNo ratings yet

- 201012182932953Document5 pages201012182932953Sanjay Singh100% (1)

- Rubber LiningDocument16 pagesRubber Liningbbmoksh100% (1)

- StraubClamp NEU (E)Document4 pagesStraubClamp NEU (E)paulpopNo ratings yet

- KE Masterflex RubberDocument4 pagesKE Masterflex RubberBenjamin StricklandNo ratings yet

- TOZEN Flexible Rubber JointDocument5 pagesTOZEN Flexible Rubber JointDidit PandithaNo ratings yet

- Style 77 Standard Flexible Coupling: Product DescriptionDocument0 pagesStyle 77 Standard Flexible Coupling: Product DescriptionAnibal MoralesNo ratings yet

- Company Profile (Latest)Document4 pagesCompany Profile (Latest)divyaNo ratings yet

- Jubilee Product BrochureDocument36 pagesJubilee Product BrochureAnonymous Wyb8Y1No ratings yet

- h07rn 8 F Bs en 50525 2 21 Flexible Rubber CableDocument2 pagesh07rn 8 F Bs en 50525 2 21 Flexible Rubber Cableheri fauziNo ratings yet

- PPR-C Pipe SpecificationDocument25 pagesPPR-C Pipe SpecificationAlex Dulay85% (13)

- Sigurnosni Ventili - ARI 900001-2Document36 pagesSigurnosni Ventili - ARI 900001-2jack-bc100% (1)

- Installation Manual - GRE PIPE - For Marine - Rev.2Document37 pagesInstallation Manual - GRE PIPE - For Marine - Rev.2HuongtrinhAkay100% (1)

- Saga Series 2013Document6 pagesSaga Series 2013Kuldeep SharmaNo ratings yet

- Igus Control CablesDocument27 pagesIgus Control CablesigusukNo ratings yet

- DEUTSCH DT Series Backshells: Backshell Solutions For DT ApplicationsDocument2 pagesDEUTSCH DT Series Backshells: Backshell Solutions For DT ApplicationsSamir FerreiraNo ratings yet

- A1200 Red Thread II PipingDocument0 pagesA1200 Red Thread II PipingjimmycabreraNo ratings yet

- Lifeline: Product CatalogueDocument44 pagesLifeline: Product CatalogueAbhijeetNo ratings yet

- Din en 857 1 SC: Compact Hydraulic Hose Construction Acc. To EN 857 1 SCDocument1 pageDin en 857 1 SC: Compact Hydraulic Hose Construction Acc. To EN 857 1 SCSaeed MahmoudabadiNo ratings yet

- GF Multi Joint WA2089p 0307 GBDocument12 pagesGF Multi Joint WA2089p 0307 GBJovanka JadrovskaNo ratings yet

- N Tscgecewã U 3 6 6kv and 6 10kv Submersible CableDocument3 pagesN Tscgecewã U 3 6 6kv and 6 10kv Submersible Cableheri fauziNo ratings yet

- PC WireDocument7 pagesPC Wirejupe01No ratings yet

- Lifeline: Product CatalogueDocument43 pagesLifeline: Product CatalogueSANGHVI OVERSEASNo ratings yet

- Geberit HDPE: Installation GuideDocument78 pagesGeberit HDPE: Installation GuideSong ThomsonNo ratings yet

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 pagesElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNo ratings yet

- Calculation PP Piping SystemDocument24 pagesCalculation PP Piping SystemDavid FonsecaNo ratings yet

- 1E) Exhaust FlametrapsDocument3 pages1E) Exhaust FlametrapsSonthi MooljindaNo ratings yet

- Din en 857 2 SC: Compact Hydraulic Hose Construction Acc. To EN 857 2 SCDocument1 pageDin en 857 2 SC: Compact Hydraulic Hose Construction Acc. To EN 857 2 SCZoran JankovNo ratings yet

- Plain End Piping System For High Density Polyethylene Pipe: Product DescriptionDocument1 pagePlain End Piping System For High Density Polyethylene Pipe: Product DescriptionAbbas RizviNo ratings yet

- John Crane 502Document6 pagesJohn Crane 502Eh OngNo ratings yet

- Sheet CM RD 244 ALUDocument2 pagesSheet CM RD 244 ALUSea Man MktNo ratings yet

- BROCHURE ODE Bassa - Valv para Maq CaféDocument7 pagesBROCHURE ODE Bassa - Valv para Maq Caféjf2003No ratings yet

- Minimess CouplingDocument39 pagesMinimess Couplingani_datNo ratings yet

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 pagesTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNo ratings yet

- SB 295 355 297 RR 052 001Document6 pagesSB 295 355 297 RR 052 001EDDIN1960100% (1)

- DS HLTP 60 Rev12 1107Document2 pagesDS HLTP 60 Rev12 1107Luisito Aguilar RojasNo ratings yet

- Ring JointDocument2 pagesRing JointarianaseriNo ratings yet

- Inova Hydraulic Wedge Grips GDDocument2 pagesInova Hydraulic Wedge Grips GDSympatyagaNo ratings yet

- N Tscgewã U 3 6 6kv and 6 10kv Submersible CableDocument3 pagesN Tscgewã U 3 6 6kv and 6 10kv Submersible Cableheri fauziNo ratings yet

- QueryDocument2 pagesQueryTu PhamNo ratings yet

- Technical Data 37 FlaredDocument13 pagesTechnical Data 37 FlaredhernychtNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- Datasheet BES02EU 553743 enDocument2 pagesDatasheet BES02EU 553743 enCommunications ShipyardNo ratings yet

- Belimo LH24A100 Datasheet En-GbDocument3 pagesBelimo LH24A100 Datasheet En-GbCommunications ShipyardNo ratings yet

- Data Sheet Standard-Temperature Sensors TFDocument2 pagesData Sheet Standard-Temperature Sensors TFCommunications ShipyardNo ratings yet

- DI-9102E Intelligent Photoelectric Smoke Detector Installation and Operation Manual Issue1.06Document2 pagesDI-9102E Intelligent Photoelectric Smoke Detector Installation and Operation Manual Issue1.06Communications ShipyardNo ratings yet

- Camcolms 4 A 6 V 02Document34 pagesCamcolms 4 A 6 V 02Communications ShipyardNo ratings yet

- OptimDocument9 pagesOptimCommunications ShipyardNo ratings yet

- Belimo LH..A On-Off Installation-InstructionsDocument2 pagesBelimo LH..A On-Off Installation-InstructionsCommunications ShipyardNo ratings yet

- Refit Checklist - GyroDocument1 pageRefit Checklist - GyroCommunications ShipyardNo ratings yet

- Di09 FP GB Rev 0Document2 pagesDi09 FP GB Rev 0Communications ShipyardNo ratings yet

- Donaldson Blue Hydraulic FiltersDocument4 pagesDonaldson Blue Hydraulic FiltersCommunications ShipyardNo ratings yet

- DDP 1 4 - 400 P 260111 enDocument5 pagesDDP 1 4 - 400 P 260111 enCommunications ShipyardNo ratings yet

- Gate ValvesDocument2 pagesGate ValvesCommunications ShipyardNo ratings yet

- Model 460 ManualDocument6 pagesModel 460 ManualCommunications ShipyardNo ratings yet

- DownloadDocument2 pagesDownloadCommunications ShipyardNo ratings yet

- 2005 PS250Document229 pages2005 PS250Communications ShipyardNo ratings yet

- WritingDocument4 pagesWritingCommunications ShipyardNo ratings yet

- Atlas Copco gx7 Air Compressor ManualDocument6 pagesAtlas Copco gx7 Air Compressor ManualCommunications ShipyardNo ratings yet

- Computer 1Document6 pagesComputer 1Communications ShipyardNo ratings yet

- KM 6310in ManualDocument27 pagesKM 6310in ManualCommunications ShipyardNo ratings yet

- GrammarDocument5 pagesGrammarCommunications ShipyardNo ratings yet

- Kavlico: Technical SpecificationDocument3 pagesKavlico: Technical SpecificationCommunications ShipyardNo ratings yet

- Story KeyDocument5 pagesStory KeyCommunications ShipyardNo ratings yet

- Analog Electronic E-ME-AC Drivers: Obsolete Components - Availability On RequestDocument4 pagesAnalog Electronic E-ME-AC Drivers: Obsolete Components - Availability On RequestCommunications ShipyardNo ratings yet

- Axial-Turbochargers Whitepaper PjdeDocument1 pageAxial-Turbochargers Whitepaper PjdeCommunications ShipyardNo ratings yet

- Pressure Controls With Narrow Differential: General DescriptionDocument2 pagesPressure Controls With Narrow Differential: General DescriptionCommunications ShipyardNo ratings yet

- Analog Electronic E-BM-AC Drivers: Obsolete Components - Availability On RequestDocument4 pagesAnalog Electronic E-BM-AC Drivers: Obsolete Components - Availability On RequestCommunications ShipyardNo ratings yet

- Lynx Distributor-EnDocument31 pagesLynx Distributor-EnCommunications ShipyardNo ratings yet

- Chelation Info Doctors Data WDocument12 pagesChelation Info Doctors Data WCommunications ShipyardNo ratings yet

- Electronic Drivers E-Rp-Ac: Analog, Sealed and Rugged Box, For Proportional Valves Without TransducerDocument4 pagesElectronic Drivers E-Rp-Ac: Analog, Sealed and Rugged Box, For Proportional Valves Without TransducerCommunications ShipyardNo ratings yet

- Inspectioncam - Spec Sheet v3Document2 pagesInspectioncam - Spec Sheet v3Communications ShipyardNo ratings yet

- Catalogo Productos Ul-Fm Mueller PDFDocument6 pagesCatalogo Productos Ul-Fm Mueller PDFAngeloNo ratings yet

- Lapox ARPN-54: Technical Data Sheet - Polymers BusinessDocument2 pagesLapox ARPN-54: Technical Data Sheet - Polymers BusinessniteshacharyaNo ratings yet

- ITM - Undercarriage Solutions and Components - WebDocument8 pagesITM - Undercarriage Solutions and Components - WebElizah GerrysonNo ratings yet

- Com Su 5315 ADocument39 pagesCom Su 5315 AolalekanNo ratings yet

- Contract: Nat Goods International KFTDocument4 pagesContract: Nat Goods International KFTTatiana NavarreteNo ratings yet

- 3M Work Gloves BrochureDocument4 pages3M Work Gloves BrochureherminNo ratings yet

- Silicone Emulsions: Shin-Etsu Chemical Co., LTDDocument10 pagesSilicone Emulsions: Shin-Etsu Chemical Co., LTDKalai SelvanNo ratings yet

- SECTION 09 96 00 High Performance Coatings GeneralDocument8 pagesSECTION 09 96 00 High Performance Coatings Generalraja qammarNo ratings yet

- Hafizam Enterprise KimpalanDocument2 pagesHafizam Enterprise KimpalanHanif HalinNo ratings yet

- Viton FreflowDocument8 pagesViton FreflowGopal ChavanNo ratings yet

- Sample Project Method Statement Rev 0 04/04/2016: Installation of Windows, Doors, Curtain Wall and Terracotta RainscreenDocument32 pagesSample Project Method Statement Rev 0 04/04/2016: Installation of Windows, Doors, Curtain Wall and Terracotta RainscreenpeterandreaNo ratings yet

- Michelin v. Tri-Ace Wheel & Tire - ComplaintDocument25 pagesMichelin v. Tri-Ace Wheel & Tire - ComplaintSarah BursteinNo ratings yet

- 10GPTP038 FullLineCatalog PDFDocument136 pages10GPTP038 FullLineCatalog PDFsirbu mariusNo ratings yet

- 2150 CuttersDocument8 pages2150 Cuttersrayyan2007No ratings yet

- Catalogue FCO ABBDocument2 pagesCatalogue FCO ABBMesseňger HệŢhống100% (1)

- KIADB BangaloreDocument160 pagesKIADB Bangalorevenkatesh_1829100% (1)

- Jayshree Machines and Tools - Introduction Epp MoldDocument14 pagesJayshree Machines and Tools - Introduction Epp MoldRaviNo ratings yet

- Nitrile ASTM D6319 StandardDocument4 pagesNitrile ASTM D6319 Standardrenny krisnawati100% (1)

- An Introduction To Single Screw ExtrusionDocument6 pagesAn Introduction To Single Screw ExtrusionMuhammad HammadNo ratings yet

- Tech International Catalog4-2013Document127 pagesTech International Catalog4-2013Edwin VacaNo ratings yet

- B2316752 Schedule 1000 Work GlovesDocument32 pagesB2316752 Schedule 1000 Work GlovesSharon KagiraNo ratings yet

- Duorest JUNIOR User GuideDocument18 pagesDuorest JUNIOR User Guidestscribd1No ratings yet

- Catalogo Gasket InternationalDocument33 pagesCatalogo Gasket InternationalrohitalurkarNo ratings yet

- Design For Manufacture and Assembly Luggage Trolley DesignDocument37 pagesDesign For Manufacture and Assembly Luggage Trolley DesignNeville Lawless100% (6)

- O RingDocument424 pagesO Ringhemantabhale100% (1)

- PolyurethaneDocument44 pagesPolyurethaneljv004No ratings yet

- Module 5 (Composite Manufacturing Process)Document37 pagesModule 5 (Composite Manufacturing Process)FITIWINo ratings yet

- Wacker-Organofunctional SilanesDocument20 pagesWacker-Organofunctional SilanesIrmaNo ratings yet