Professional Documents

Culture Documents

PIMS Expert StudyGuide

Uploaded by

Ayman Fawzy0 ratings0% found this document useful (0 votes)

25 views5 pagesPIMS Expert StudyGuide

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPIMS Expert StudyGuide

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views5 pagesPIMS Expert StudyGuide

Uploaded by

Ayman FawzyPIMS Expert StudyGuide

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Aspen PIMS

Study Guide for Expert Level Certification

Aspen® Knowledge Learn. Apply. Succeed.

Who can take this certification?

The certification is a must-have for any users at the

PIMS/PIMS-AO intermediate level who want to prove

proficient in model building and trouble shooting. This is a

certification that measures both product skills and capital cost estimator

concepts. The exam contains both multiple choice questions and a lab. We

will provide the latest version of AspenTech software. All our exams are

conducted with a proctor, either in-person or through remote testing.

Step 1. Prepare with training

AspenTech offers a variety of delivery methods in which you can take training.

Here are the recommendations to be most successful on this exam.

Exam Scope for • Complete RPA201: Solve Refinery Planning Problems using Aspen PIMS

Expert Level

• Complete RPA221: Advanced Optimization Features using Aspen PIMS or

Certification

attain sufficient experience with PIMS-AO and its features

□ Introduction • At least 1-year of experience with PIMS including model building

□ Crude Unit

You may register through public or private training. If you already

□ Blending have proficiency in PIMS, you may be interested in refreshing your

□ Constraints knowledge with eLearning. While attending a training class prior to

□ Economic Analysis completing the exam is highly recommended, it is not required.

□ Troubleshooting

• Register for public training (face to face or virtual)

□ Model Structure

□ Case Stacking • Register for private training (face to face or virtual)

□ PIMS-AO

• Subscribe to eLearning (on-demand)

AspenTech Step 2. Practice before exam

Call | Email | Chat This guide contains 100% coverage of all objectives for the Aspen PIMS /

PIMS-AO expert level certification exam. You can use as both a study tool

and an on-the job reference.

Step 3. Get Certified

You will have up to 4 hours to complete the exam. You can expect to

receive your exam results in 2 weeks.

You may take the exam after completing training or view schedule to

register on a different day or time. In-person and remote testing are

available. Please make sure that you select the correct Location/Time

Zone.

After passing the exam you will receive an email to post your certificate

and digital badge on social media, which is a cross-industry recognition of

technical skills you may share on LinkedIn, as well as in your email

signature. View the instructions on how to post your credentials.

© 2020 Aspen Technology, Inc. All rights reserved. Rev3 1

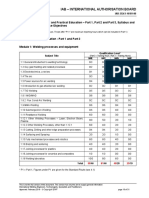

TECHNICAL

SCOPE COMPETENCY OBJECTIVE

CONTENT

Introduction Reports Summarize configuration and content

Access available report types

Data Configure data properly (format and content) in Excel tables

Initialization Summarize tables involved in DR model initialization

Matrix Generation Identify when the matrix is generated

Crude Unit Configuration Explain construction of crude unit capacities

Demonstrate how to configure for various types of crude unites

Demonstrate how to control stream segregation and naming

Blending Configuration Explain tables required for definition of a blend

Recognize the default product blending basis

Apply Table WSPECS

Constraints Process Limits Explain the types of equations that PROCLIM is intended for

Configure correctly the 2 different types of Proclim rows in Table

PROCLIM

Summarize impact of FREE columns and 0 coefficient on

calculations

Capacities Explain the types of equations that capacities are intended for

Miscellaneous Tables Configure and apply Table GROUPS

Explain possible configurations in Table MIP and possible

applications

Summarize Table ROWS and demonstrate how to build or access

matrix structure

Economic Breakeven Describe the impact price and volume has on analysis

Analysis

Calculate a breakeven from run results

Marginal Values Explain limitations of marginal values

Summarize sign conventions in PIMS reports for marginal values

Tiered Pricing Configure and apply tiered pricing correctly

Troubleshooting Tools Investigate a solution using XLR Viewer and troubleshoot

Summarize matrix structure and information provided in Matrix

Analyzer

© 2020 Aspen Technology, Inc. All rights reserved. Rev3 2

TECHNICAL

SCOPE COMPETENCY OBJECTIVE

CONTENT

Troubleshooting Tools Recognize Data Assistants

Errors and Warnings Investigate and prioritize messages

Apply methods of suppressing messages and evaluate if

appropriate

Interpret and evaluate messages at end of run

Penalties Apply penalties in various tables

Solution Problems Evaluate potential causes of non-convergence, local optima, and

materials out of balance

Model Structure Submodels Explain Base Delta configuration

Locate Base Delta "base" conditions

Configure Discrete Yield submodel structure

Evaluate when to apply various submodel structures (discrete,

base-delta, pooling, etc.)

Configure a recursed pool

Set up compositional pooling and depooling

Configure custom constraints using control rows (E, L, and G rows)

Case Stacking Configuration Create a case

Identify the use of case stacking keywords – EMPTY, MODIFIES

Explain how to modify table content in T. CASE

PIMS-AO Settings Recognize impact of settings such as Epsilon, Improve Local

Solution, Fix Qualities of Zero Flow Streams, Hyrbrid Quality

Initialization, PGUESS Confidence Value, etc.

Matrix Structure Explain how qualities are modeled (vs DR)

Initialization Create an input solution file via various methods

Features Configure and run Global Optimization

Configure and run Parametric Analysis

Configure and run Ranging Analysis

Configure and run Goal Programming

Configure and run Feedbasket Reduction

© 2020 Aspen Technology, Inc. All rights reserved. Rev3 3

About Aspen Technology

Aspen Technology (AspenTech) is a leading software supplier for optimizing asset performance. Our products

thrive in complex, industrial environments where it is critical to optimize the asset design, operation and

maintenance lifecycle. AspenTech uniquely combines decades of process modeling expertise with machine

learning. Our purpose-built software platform automates knowledge work and builds sustainable competitive

advantage by delivering high returns over the entire asset lifecycle. As a result, companies in capital-intensive

industries can maximize uptime and push the limits of performance, running their assets safer, greener, longer

and faster. Visit AspenTech.com to find out more.

© 2020 Aspen Technology, Inc. AspenTech®, Aspen®, aspenONE®, the Aspen leaf logo, the aspenONE logo

and OPTIMIZE are trademarks of Aspen Technology, Inc. All rights reserved. AT-05200

© 2020 Aspen Technology, Inc. All rights reserved. Rev3 4

You might also like

- 24 Zero Emission Steam Generation With eGBPectricityDocument4 pages24 Zero Emission Steam Generation With eGBPectricityAyman FawzyNo ratings yet

- Haz30 102-JonesDocument37 pagesHaz30 102-JonesAyman FawzyNo ratings yet

- Water TreatmentDocument31 pagesWater TreatmentAyman FawzyNo ratings yet

- Economic Feasibility Studies For Carbon Capture and Utilisation Technologies A Tutorial ReviewDocument40 pagesEconomic Feasibility Studies For Carbon Capture and Utilisation Technologies A Tutorial ReviewAyman Fawzy100% (1)

- Flange Reference ChartDocument3 pagesFlange Reference ChartAyman FawzyNo ratings yet

- Rhenium A Hidden AssetDocument3 pagesRhenium A Hidden AssetAyman FawzyNo ratings yet

- SHAW SU2 Sample System Specification Sheet Iss1.4Document1 pageSHAW SU2 Sample System Specification Sheet Iss1.4Ayman FawzyNo ratings yet

- Studying The Role of System Aggregation in EnergyDocument28 pagesStudying The Role of System Aggregation in EnergyAyman FawzyNo ratings yet

- V12 ApcDocument8 pagesV12 ApcAyman FawzyNo ratings yet

- Alternative Production of Methanol From Industrial CO2Document25 pagesAlternative Production of Methanol From Industrial CO2Ayman FawzyNo ratings yet

- MSC - Software S Pte. Ltd. Master Software License Agreement January 2022 VersionDocument9 pagesMSC - Software S Pte. Ltd. Master Software License Agreement January 2022 VersionAyman FawzyNo ratings yet

- Preliminary Estimation of Natural Gas Pipeline Construction Costs With Regression AnalysisDocument10 pagesPreliminary Estimation of Natural Gas Pipeline Construction Costs With Regression AnalysisAyman FawzyNo ratings yet

- MPDFDocument775 pagesMPDFAyman FawzyNo ratings yet

- AT-05200 - PIMS Study GuideDocument8 pagesAT-05200 - PIMS Study GuideAyman FawzyNo ratings yet

- Nalpeiron Software Licensing Models GuideDocument24 pagesNalpeiron Software Licensing Models GuideAyman FawzyNo ratings yet

- Estimating The Cost of Pipeline Transportation in CanadaDocument15 pagesEstimating The Cost of Pipeline Transportation in CanadaAyman FawzyNo ratings yet

- PC - 4 - 2017 - Nagam All Eswara - 51cor3Document10 pagesPC - 4 - 2017 - Nagam All Eswara - 51cor3Ayman FawzyNo ratings yet

- TL BluESP AspenTec Digital Roadmaps Putting Solutions Into PracticeDocument6 pagesTL BluESP AspenTec Digital Roadmaps Putting Solutions Into PracticeAyman FawzyNo ratings yet

- Flexmonster Software License AgreementDocument7 pagesFlexmonster Software License AgreementAyman FawzyNo ratings yet

- Tcs MSCSoftwareDocument12 pagesTcs MSCSoftwareAyman FawzyNo ratings yet

- V11 ApcDocument10 pagesV11 ApcAyman FawzyNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Dell PowerEdge RAID Controller H330Document2 pagesDell PowerEdge RAID Controller H330danxl007No ratings yet

- List of Accredited Software and - or Hardware (CRM - POS) As of 11-Dec-2018Document310 pagesList of Accredited Software and - or Hardware (CRM - POS) As of 11-Dec-2018Verscel Malalis GuisadioNo ratings yet

- TJP 4.x - 1VLC000524 Rev.5, enDocument6 pagesTJP 4.x - 1VLC000524 Rev.5, enTetianaNo ratings yet

- ClickFunnels Vs WebsiteDocument2 pagesClickFunnels Vs WebsiteJOEYNo ratings yet

- Ottlite Executive Desk Lamp ManualDocument1 pageOttlite Executive Desk Lamp ManualVlad75% (4)

- From The President's Desk: in This IssueDocument6 pagesFrom The President's Desk: in This IssueJayant ShaligramNo ratings yet

- Definitions of Each of The 20 Tools of Process ControlDocument2 pagesDefinitions of Each of The 20 Tools of Process Control88No1FanNo ratings yet

- Licenseid TDD/FDD License DescriptionDocument34 pagesLicenseid TDD/FDD License DescriptionfazadoNo ratings yet

- Clause by Clause Explanation of ISO 27001 enDocument26 pagesClause by Clause Explanation of ISO 27001 ennacho1963No ratings yet

- DSE335 Operators ManualDocument90 pagesDSE335 Operators ManualcarlosrmtzNo ratings yet

- Chapter 1Document6 pagesChapter 1Bhuvaneswari TSNo ratings yet

- Industrial Wiring and Design ProjectDocument3 pagesIndustrial Wiring and Design ProjectJibril JundiNo ratings yet

- 5G Transport Network Requirements, Architecture and Key TechnologiesDocument27 pages5G Transport Network Requirements, Architecture and Key TechnologiesFreedomNo ratings yet

- LT1168 0500 MagDocument2 pagesLT1168 0500 MagBillyNo ratings yet

- Indicative ProfileDocument5 pagesIndicative ProfileYashveer TakooryNo ratings yet

- 65kVA GSW65P P Pramac 2021Document1 page65kVA GSW65P P Pramac 2021RafatNo ratings yet

- IWE SyllabusDocument4 pagesIWE Syllabusmdasifkhan2013No ratings yet

- Mc2550 Tech GuideDocument42 pagesMc2550 Tech Guidecynneath4045No ratings yet

- T21 FSAE PowertrainOptimization BS ThesisDocument171 pagesT21 FSAE PowertrainOptimization BS ThesisSayanSanyalNo ratings yet

- Hierarchy in PDMS - World, Site, ZoneDocument6 pagesHierarchy in PDMS - World, Site, Zones_baishyaNo ratings yet

- M340 and ATV71 Using ModbusTCPIP and Data - Exch FunctionDocument9 pagesM340 and ATV71 Using ModbusTCPIP and Data - Exch FunctionJose MarcialNo ratings yet

- DWDM Notes 1-5 UnitsDocument192 pagesDWDM Notes 1-5 UnitsGURAKA BHARGAVA KUMAR,CSE(19-23) Vel Tech, ChennaiNo ratings yet

- Chapter Five RVU MT&PDocument39 pagesChapter Five RVU MT&PSisay DeresaNo ratings yet

- Company ProfileDocument15 pagesCompany ProfilerishdugarNo ratings yet

- Waaree Corporate PPT - V3Document53 pagesWaaree Corporate PPT - V3Bhushan MalsheNo ratings yet

- File 000096Document196 pagesFile 000096Wahyu PranataNo ratings yet

- Placer National High SchoolDocument2 pagesPlacer National High SchoolCortez JeromeNo ratings yet

- Aircraft Landing Gear Design ProjectDocument20 pagesAircraft Landing Gear Design Projectchristo.t.josephNo ratings yet

- Express Specialization RequirementsDocument8 pagesExpress Specialization RequirementsZeus TitanNo ratings yet

- ADAS Automotive EngineeringDocument15 pagesADAS Automotive EngineeringAman PatelNo ratings yet