Professional Documents

Culture Documents

Guia de Conexión ZM303

Uploaded by

Irving Uriel Ruiz Viveros0 ratings0% found this document useful (0 votes)

57 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

57 views1 pageGuia de Conexión ZM303

Uploaded by

Irving Uriel Ruiz ViverosCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Start

YES Does the Indicator Turn on? NO

BAD INDICATOR: IF YOU SUSPECT A BAD INDICATOR,

THE EASIEST WAY TO CHECK IS TO TRY ANOTHER

IS THE READING ON THE INDICATOR STABLE? NO DISCONNECT THE WEIGHBAR INPUT: INDICATOR. EVEN IF THE INDICATOR IS A DIFFERENT

MODEL OR IS SET-UP FOR A DIFFERENT SCALE, IT AT

DISCONNECT ALL WEIGH BARS FROM THE BOTTOM OF THE INDICATOR. LEAST SHOULD TURN ON.

YES POOR CONNECTION: POOR CONNECTIONS CAN BE

TRICKY. IF IN DOUBT, DON’T JUST TIGHTEN THE

INSTALL DUMMY PLUGS:

CONNECTION. TAKE THEM APPART AND CLEAN

THEM FIRST. ANY CONNECTION WITH RUST OR PAINT

INSTALL DUMMY PLUGS INTO ALL WEIGH-BAR PORTS ON THE BOTTOM

STAND ON, HANG ON, OR PUT YOUR WEIGHT SHOULD BE SANDED OR WIRE BRUSHED.

OF THE INDICATOR.

OVER EACH WEIGH-BAR. DOES YOUR INDICATOR

RESPOND TO THE WEIGHT WHEN YOU STAND OR BAD BATTERY: IF YOU SUSPECT THE BATTERY, TRY

NOTE: IN ORDER TO TROUBLESHOOT A 4-PIN TYPE SCALE SYSTEM IT IS

HANG ON THE SCALE? REPLACING IT WITH ANOTHER ONE. DON’T BE

NECESSARY TO FIRST ELIMINATE THE INDICATOR AS THE SOURCE OF THE

FOOLED IF USING A VOLTMETER TO TEST YOUR

PROBLEM. IF YOU DO NOT HAVE ENOUGH DUMMY PLUGS (WEIGH-BAR

BATTERY. A WEAK BATTERY MAY TEST GOOD IF

SIMULATORS) AVAILABLE TO FILL ALL WEIGH-BAR PORT CONNECTORS AT

CHECKED WHEN THERE IS NO LOAD ON THE BATTERY.

THE BOTTOM OF YOUR INDICATOR, CONTACT SCALE-TEC 888-962-2344

YES FOR LOANER DUMMY PLUGS.

BAD POWER CABLE: MAKE SURE THE POWER

CABLE’S RED WIRE, OR IN SOME CASES WHITE WIRE,

IS CONNECTED TO THE PLUS (+) POSITIVE SIDE AND

ZERO THE INDICATOR: THE BLACK WIRE IS CONNECTED TO THE NEGATIVE

ARE THE READINGS ALL POSITIVE? IF NOT ONE

DEPENDING ON THE MODEL OF INDICATOR YOU MAY HAVE SIDE. IF USING A MULTIMETER TO CHECK FOR

OF THE WEIGH-BARS MAY BE INSTALLED UPSIDE

TO ZERO THE INDICATOR UTILIZING THE COARSE VOLTAGE, MEASURE BETWEEN 10.5 VDC – 14.5 VDC.

DOWN.

ADJUSTMENT, TYPICALLY LOCATED NEAR THE BOTTOM OF CHECK THE TRACTOR RECEPTICAL AS WELL.

THE INDICATOR.

CHECK FUSE: CHECK THE FUSE ON THE BOTTOM OF

YES THE INDICATOR. REPLACE IF BAD.

DOES THE WEIGHT STAY STABLE AT ZERO +/- 5 LBS?

DOES THE SCALE WEIGH YOU APPROXIMATLEY NO TROUBLESHOOT THE WEIGH-BARS:

THE SAME OVER ALL WEIGH-BARS? NO 1. TRACE THE WIRES AND IDENTIFY THE WEIGH-BARS

(BUT NOT THE CORRECT WEIGHT) YES 2. CONNECT THE WEIGH-BAR INTO THE INDICATOR

3. “ZERO” BALANCE THE INDICATOR

YOUR INDICATOR NEEDS

REPAIRED. CONTACT SCALE-TEC

(888) 962-2344

THE CALIBRATION SETTING ON YOUR INDICATOR DOES THE INDICATOR STAY STABLE AT ZERO?

MAY NOT BE CORRECT. TO VERIFY CORRECT

CALIBRATION REFER TO YOUR WEIGH-BARS. ALL

AVERY WEIGH-TRONIX WEIGH-BARS HAVE A DISCONNECT ONE OF THE DUMMY PLUGS FROM THE

CALIBRATION SIZE IDENTIFIED ON A STICKER BOTTOM OF THE INDICATOR.

LOCATED ON THE WEIGH-BAR. IF YOU ARE NO YES

UTILIZING A WEIGH-BAR OTHER THAN AVERY NOTE: THE NEXT STEP IS TO INDIVIDUALLY ISOLATE

WEIGH-TRONIX PLEASE CONTACT SCALE-TEC FOR THE WEIGH-BARS ON YOUR SCALE SYSTEM. UNPLUG

CALIBRATION ASSISTANCE. 888-962-2344. ONE OF THE DUMMY PLUGS FROM THE 4-PIN

CONNECTOR AT THE BOTTOM OF THE INDICATOR.

PLACE WEIGHT OVER THE TOP OF THE

FOR AVERY WEIGH-TRONIX CALIBRATION WEIGH-BAR…

PROCEDURES REFER TO YOUR INDICATOR 1. STEP ON OR PLACE WEIGHT ON TOP OF

OPERATORS MANUAL. OPERATORS MANUALS THE WEIGH-BAR.

ARE AVAILABLE FREE FOR DOWNLOAD AT SCALE- IF THE INDICATOR DISPLAYS +RANGE OR

2. THE WEIGHT SHOULD DISPLAY POSITIVE.

TEC.COM, OR CONTACT 888-962-2344 FOR –RANGE, ERROR, OR DRIFTS WEIGHT

3. THE WEIGHT SHOULD BE THE KNOWN

ASSISTANCE. ERRATICALLY….

WEIGHT MULTIPLIED BY THE AMOUNT OF

WEIGHBARS ON THE SYSTEM. FOR

EXAMPLE….

1. CHECK WEIGH-BAR CABLE FOR BAD OR 200 LBS X 4 WEIGHBARS=800 LBS.

PINCHED SPOTS.

2. SPLICE WEIGH-BAR CABLE AND REPAIR

CABLE WITH SOLDER AND HEAT SHRINK.

CONTACT SCALE-TEC 888-962-2344 FOR DOES THE INDICATOR GO TO A POSITIVE

ANY QUESTIONS. WEIGHT, RETURN TO ZERO AND STABILIZE?

3. IF NO BAD SPOTS ARE FOUND IN THE

CABLE, REPLACE WEIGH-BAR. CONTACT

SCALE-TEC 888-962-2344 FOR

REPLACEMENT WEIGH-BAR.

NO YES

IF AFTER PLACING WEIGHT ABOVE THE

WEIGHBAR THE INDICATOR DISPLAYS

+RANGE OR –RANGE, ERROR, OR DRIFTS TAP AROUND THE WEIGH-BAR WITH A

WEIGHT ERRATICALLY, OR IS NOT WITHIN HAMMER. NOTE: DO NOT TAP ON THE

SCOPE OF KNOWN WEIGHT…. PROTECTIVE SHROUD OF THE WEIGH-BAR AS

DAMAGE CAN OCCUR. IF UNABLE TO TAP ON

THE WEIGHBAR, TAP ON THE FRAME

AROUND IT. THE OBJECTIVE IS TO INDUCE

DOES THE INDICATOR REMAIN AT ZERO WITH VIBRATION.

NO DRIFTING OR ERRACTIC WEIGHT

READINGS?

AT THIS POINT, THE WEIGH-BAR IS

CONSIDERED GOOD. DISCONNECT THIS

WEIGH-BAR AND PROCEED TO CHECK

ANOTHER.

NOTE: IF UTILIZING A JUNCTION BOX AND ALL

NO YES

WEIGH-BARS TEST BAD, YOUR JUNCTION BOX

IS MORE THAN LIKELY THE PROBLEM. CHECK

TROUBLESHOOTING GUIDE FOR CONTINUITY ON THE JUNCTION BOX CABLE

AVERY WEIGH-TRONIX SCALE TO VERIFY GOOD OR BAD. CONTACT SCALE-

TEC 888-962-2344 FOR A REPLACEMENT

INDICATORS WITH 4-PIN BASE JUNCTION BOX OR JUNCTION BOX CABLE.

CONNECTION.

NOTE: SHOULD YOU FIND A BAD WEIGH-BAR BY TROUBLESHOOTING THE

CONTACT SCALE-TEC FOR SCALE SYSTEM, AVERY WEIGH-TRONIX STOPPED MANUFACTURING 4-PIN

REPAIR PARTS AND SERVICE WEIGH-BARS IN 2012 AND CURRENTLY ONLY OFFERS 5 PIN WEIGH-BAR

QUESTIONS 888-962-2344 REPLACEMENTS. 4-PIN WEIGH BARS AND 5-PIN WEIGH-BARS ARE NOT

COMPATIBLE. SCALE-TEC TRIES TO MAINTAIN USED 4-PIN WEIGH-BARS IN

WWW.SCALE-TEC.COM STOCK HOWEVER SUPPLY IS LIMITED AND MAY REQUIRE UPDATING YOUR

SCALE SYSTEM TO 5-PIN LOAD-CELLS AND INDICATOR. IF YOUR INDICATOR

IS BAD, WE CAN STILL MAKE A NEW INDICATOR FUNCTION WITH OLD 4-PIN

WEIGHBARS WITH THE USE OF A JUNCTION BOX AND INTERFACE CABLE.

NOTE: This troubleshooting method will identify the majority of issues with your scale system, however there may be more required troubleshooting to identify further issues in your scale

system. This troubleshooting method does not require ohm testing the weigh-bars. Ohming the weigh-bars can not identify a “zero point shift” in a weigh-bar. By utilizing the technique

outlined, it will not be necessary to ohm out the weigh-bars, and not require a multi meter for troubleshooting the weigh-bars.

You might also like

- SPRING BOX INSTALLATION GUIDE-Layout1Document1 pageSPRING BOX INSTALLATION GUIDE-Layout1glynsimmonds45No ratings yet

- User'S Manual: UL 217 UL 2034 StandardsDocument2 pagesUser'S Manual: UL 217 UL 2034 StandardsStephen RivettNo ratings yet

- Ic Feedback TechniquesDocument8 pagesIc Feedback TechniquesAinee Marie Lumerio HomerezNo ratings yet

- UPS Installation Procedure 4Document6 pagesUPS Installation Procedure 4vimal alaberahNo ratings yet

- Owner'S Manual: 12-Channel Compact MixerDocument28 pagesOwner'S Manual: 12-Channel Compact MixerAphra SchnaelNo ratings yet

- Setting Up Your Solar Kit GuideDocument2 pagesSetting Up Your Solar Kit GuideAlan RichardsonNo ratings yet

- Prepare for Emergencies with an ID and Essentials KitDocument1 pagePrepare for Emergencies with an ID and Essentials KitDainielleTabordanNo ratings yet

- Unit 1-10 PDFDocument20 pagesUnit 1-10 PDFbaba ioanaNo ratings yet

- Troubleshooting Defective Fluorescent Lamp FixturesDocument19 pagesTroubleshooting Defective Fluorescent Lamp FixturesJonald Salinas67% (3)

- Neon P0016Document5 pagesNeon P0016Carlos Awo OsaureNo ratings yet

- Electricity PosterDocument2 pagesElectricity Posteraniketp11No ratings yet

- Owner'S Manual: 16-Channel 4-Bus Compact MixerDocument32 pagesOwner'S Manual: 16-Channel 4-Bus Compact MixerPlissken ArmitageNo ratings yet

- Radio Do's and Dont's Log AbbreviationsDocument3 pagesRadio Do's and Dont's Log AbbreviationsManuel EchánoveNo ratings yet

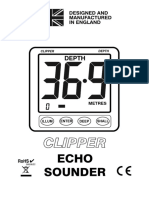

- Clipper DepthDocument20 pagesClipper DepthMaciej RoszkowskiNo ratings yet

- Unleash Your Inner Inventor.: Gizmos & GadgetsDocument13 pagesUnleash Your Inner Inventor.: Gizmos & GadgetssherxanNo ratings yet

- DISTRIBSYS - Reviewer 1 5 EliDocument3 pagesDISTRIBSYS - Reviewer 1 5 EliKal AsmrNo ratings yet

- Controls: Instructions For The Installation and Operation ofDocument6 pagesControls: Instructions For The Installation and Operation ofJeffrey WoodenNo ratings yet

- Seismo Rev4Document2 pagesSeismo Rev4jelogon10No ratings yet

- MPS 100 Cargo TransportDocument4 pagesMPS 100 Cargo TransportcavmroNo ratings yet

- OR-CR-205 Manual ENDocument2 pagesOR-CR-205 Manual ENKaya EmanuelNo ratings yet

- Controlfire Troubleshooting GuideDocument30 pagesControlfire Troubleshooting GuideSamuel BrandNo ratings yet

- SW Series - Owner S ManualDocument8 pagesSW Series - Owner S ManualMohmed HafejeeNo ratings yet

- Panasonic SA VK62D Instruction ManualDocument96 pagesPanasonic SA VK62D Instruction ManualBobby HartantoNo ratings yet

- NAD-916 ManualDocument20 pagesNAD-916 ManualDonaldNo ratings yet

- Yakima Jack HolderDocument12 pagesYakima Jack HolderJorge VillanuevaNo ratings yet

- Fluorescent Ballast Troubleshooting Guide ADVANCE 1Document11 pagesFluorescent Ballast Troubleshooting Guide ADVANCE 1franklynNo ratings yet

- Getting Started: Build A Simple Led Flasher LE D: NNN NDocument3 pagesGetting Started: Build A Simple Led Flasher LE D: NNN NVicente CapitoNo ratings yet

- ST74 ManualDocument3 pagesST74 Manualluis palominoNo ratings yet

- p0344 NeonDocument6 pagesp0344 NeonCarlos Awo OsaureNo ratings yet

- Telco Flowchart 2Document1 pageTelco Flowchart 2p01zawjNo ratings yet

- RSBL'DXN EpsieDocument1 pageRSBL'DXN EpsieSonaina KhanNo ratings yet

- CPC BookDocument49 pagesCPC Bookmotrenko123No ratings yet

- vertex_vx-410_420_operatingmanualDocument8 pagesvertex_vx-410_420_operatingmanualDonovan WalkerNo ratings yet

- EziweighDocument4 pagesEziweighBerney RyxlerNo ratings yet

- ICPNA ADV 09 JDocument9 pagesICPNA ADV 09 JIrina ChalametNo ratings yet

- Dragon Ball Volume 25Document219 pagesDragon Ball Volume 25sidqaraNo ratings yet

- Thumbnail PDFDocument1 pageThumbnail PDFEmanuel John BangoNo ratings yet

- Worksheet 3.2 - ElectronicsDocument2 pagesWorksheet 3.2 - ElectronicsKaela SamonteNo ratings yet

- ElectricalDocument27 pagesElectricaleunica_dolojan100% (1)

- Electrical Symbols Abbreviations: Key PlanDocument9 pagesElectrical Symbols Abbreviations: Key PlanGary FortuinNo ratings yet

- SCRIPTS FOR TECHNICAL SCENARIO BY EDMARDocument9 pagesSCRIPTS FOR TECHNICAL SCENARIO BY EDMARnoralieNo ratings yet

- User'S Manual: How Your Smoke/Co Alarm Works Smoke & Carbon Monoxide AlarmDocument2 pagesUser'S Manual: How Your Smoke/Co Alarm Works Smoke & Carbon Monoxide AlarmReyy MereloxNo ratings yet

- Installation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Document1 pageInstallation Instructions: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5No ratings yet

- La Société: Aliases Means RefreshDocument13 pagesLa Société: Aliases Means RefreshbobyNo ratings yet

- Is PF8601Document1 pageIs PF8601dayshift5No ratings yet

- 3-GMDSS İngilizce Kelimeler PDFDocument10 pages3-GMDSS İngilizce Kelimeler PDFismail yıldırımNo ratings yet

- LD200EM8: 20" Digital / Analog LCD TV Built-In DVD PlayerDocument48 pagesLD200EM8: 20" Digital / Analog LCD TV Built-In DVD PlayerWesley MoyerNo ratings yet

- Professional Stepper-Motor Analogue Pressure Gauge: Caution!Document4 pagesProfessional Stepper-Motor Analogue Pressure Gauge: Caution!tito titoNo ratings yet

- Etfb 00Document2 pagesEtfb 00mickey finniganNo ratings yet

- Maintenance UpsDocument11 pagesMaintenance UpsacademicNo ratings yet

- Controlador Regulador Carga Solar MPPT 100a 1224Document1 pageControlador Regulador Carga Solar MPPT 100a 1224frodriguez71971847No ratings yet

- Is DW1506Document1 pageIs DW1506dayshift5No ratings yet

- Digital Scale ManualDocument9 pagesDigital Scale ManualMatjaž LekšanNo ratings yet

- m104 Man WebDocument2 pagesm104 Man WebDaniel FloresNo ratings yet

- 7020bsl Hardwired Led Strobe Light Manual PDFDocument2 pages7020bsl Hardwired Led Strobe Light Manual PDFFernanda RojasNo ratings yet

- Electroencephalograph Infographics Diane AbanillaDocument1 pageElectroencephalograph Infographics Diane AbanillaDiane AbanillaNo ratings yet

- #15 Laying Down PipeDocument1 page#15 Laying Down PipekhurramNo ratings yet

- Failure Mode Effect Analysis (FMEA) for Simple Toaster SystemDocument2 pagesFailure Mode Effect Analysis (FMEA) for Simple Toaster Systemrengarajan nNo ratings yet

- CrashDocument4 pagesCrashzDarkCodexNo ratings yet

- Assignment/ Tugasan - Object-Oriented ProgrammingDocument10 pagesAssignment/ Tugasan - Object-Oriented Programmingmaslianah gudingNo ratings yet

- 4.1.1.2 Packet Tracer - Packet Tracer Physical ViewDocument16 pages4.1.1.2 Packet Tracer - Packet Tracer Physical ViewBetelihem DawitNo ratings yet

- RelNot Opis OPisDocument59 pagesRelNot Opis OPisxxxNo ratings yet

- L&T Interview QuestionsDocument3 pagesL&T Interview QuestionsAnup BorseNo ratings yet

- ARM7 TDMI Manual Pt3Document46 pagesARM7 TDMI Manual Pt3Deepanshu UpadhyayNo ratings yet

- Guidelines for Application FormDocument12 pagesGuidelines for Application FormAmarNo ratings yet

- Provide Five Definitions of IctDocument1 pageProvide Five Definitions of IctFaiyaj Bin RezaNo ratings yet

- Swinburne Assignment 1: HTML, CSS WebsiteDocument6 pagesSwinburne Assignment 1: HTML, CSS WebsiteSanamNo ratings yet

- History of EdutechDocument4 pagesHistory of EdutechMaripaz MorelosNo ratings yet

- MIT2 14S14 Prob Archive PDFDocument674 pagesMIT2 14S14 Prob Archive PDFKamal PatelNo ratings yet

- David Millman ResumeDocument2 pagesDavid Millman Resumeapi-260193384No ratings yet

- PowerPoint VBA TutorialDocument17 pagesPowerPoint VBA TutorialKalai selvanNo ratings yet

- Nokia Centralized Domain Proxy ParametersDocument96 pagesNokia Centralized Domain Proxy ParametersSourabh BajpaiNo ratings yet

- Houston Oilfield Catalog Adjustable ChokeDocument20 pagesHouston Oilfield Catalog Adjustable ChokeelvagojpNo ratings yet

- Ultrasonido BKM Pro Focus 2202Document368 pagesUltrasonido BKM Pro Focus 2202Mariö OlveraNo ratings yet

- Riphah University ACP Final ExamDocument3 pagesRiphah University ACP Final ExamUsama ArshadNo ratings yet

- It Era Final ModuleDocument103 pagesIt Era Final ModuleLeonso Visto JrNo ratings yet

- Transferring Mat Type From R3 To GTSDocument20 pagesTransferring Mat Type From R3 To GTSAnandNo ratings yet

- DC - Sop - EenDocument8 pagesDC - Sop - EenBilal KhalidNo ratings yet

- Challenge1 50Document7 pagesChallenge1 50qweertyNo ratings yet

- Mazatrol Matrix Nexus Connection and Maintenance ManualDocument155 pagesMazatrol Matrix Nexus Connection and Maintenance ManualAlex Man100% (4)

- SerialPort and DataReceived EventDocument2 pagesSerialPort and DataReceived EventThiru93456No ratings yet

- Hackathon-PSP Server Integration and UsageDocument26 pagesHackathon-PSP Server Integration and Usageoptimium888No ratings yet

- GSM System Survey: Overview of Ericsson's GSM SystemsDocument10 pagesGSM System Survey: Overview of Ericsson's GSM SystemsHedayatullah NiaziNo ratings yet

- KingView 6.52 Introduction PDFDocument108 pagesKingView 6.52 Introduction PDFconan lcNo ratings yet

- Sta733 AukDocument3 pagesSta733 AukJhon Arenas100% (1)

- Cat Forklift Npp60 Service ManualDocument21 pagesCat Forklift Npp60 Service Manualpatrickheath070882eqa100% (123)

- Stata RR AllDocument1 pageStata RR AllIndra DwinataNo ratings yet

- Panasonic+Ag-hvx200p An e Mc,+Ag-hvx202en+Parts,+Service+ManualDocument382 pagesPanasonic+Ag-hvx200p An e Mc,+Ag-hvx202en+Parts,+Service+ManualDJDogbone100% (1)