Professional Documents

Culture Documents

Aalco Metals LTD - Aluminium Alloy 1050A H14 Sheet - 57

Aalco Metals LTD - Aluminium Alloy 1050A H14 Sheet - 57

Uploaded by

Moube HortelioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aalco Metals LTD - Aluminium Alloy 1050A H14 Sheet - 57

Aalco Metals LTD - Aluminium Alloy 1050A H14 Sheet - 57

Uploaded by

Moube HortelioCopyright:

Available Formats

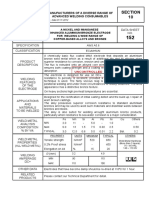

Aluminium Alloy

1050A H14 Sheet

SPECIFICATIONS SUPPLIED FORMS

Plain sheet

Commercial 1050A Plain sheet with a PVC coating on one side

EN 1050A Stucco sheet

Stucco sheet with a PVC coating on one side

Shate

Aluminium alloy 1050 is a popular grade of aluminium • Sheet

for general sheet metal work where moderate strength

is required.

Alloy 1050 is known for its excellent corrosion GENERIC PHYSICAL PROPERTIES

resistance, high ductility and highly reflective finish.

Property Value

Applications - Alloy 1050 is typically used for: Density 2.71 g/cm³

Chemical process plant equipment

Food industry containers Melting Point 650 °C

Pyrotechnic powder Thermal Expansion 24 x10-6 /K

Architectural flashings

Modulus of Elasticity 71 GPa

Lamp reflectors

Cable sheathing Thermal Conductivity 222 W/m.K

Electrical Resistivity 0.0282 x10-6 Ω .m

CHEMICAL COMPOSITION

BS EN 573-3:2009 MECHANICAL PROPERTIES

Alloy 1050A

Element % Present BS EN 485-2:2008

Sheet

Iron (Fe) 0.0 - 0.40 0.2mm to 6.00mm

Silicon (Si) 0.0 - 0.25 Property Value

Zinc (Zn) 0.0 - 0.07 Proof Stress 85 Min MPa

Magnesium (Mg) 0.0 - 0.05 Tensile Strength 105 - 145 MPa

Titanium (Ti) 0.0 - 0.05 Hardness Brinell 34 HB

Manganese (Mn) 0.0 - 0.05 Elongation A 12 Min %

Copper (Cu) 0.0 - 0.05 Properties above are for material in the H14 condition

Other (Each) 0.0 - 0.03

Aluminium (Al) Balance WELDABILITY

When welding 1050 to itself or an alloy from the same

subgroup the recommended filler wire is 1100. For

ALLOY DESIGNATIONS welding to alloys 5083 and 5086 or alloys from the

Aluminium alloy 1050A also corresponds to the 7XXX series, the recommend wire is 5356. For other

following standard designations and specifications but alloys use 4043 filler wire.

may not be a direct equivalent:

AA1050 FABRICATION

S1B

Workability – Cold: Excellent

A91050

Machinability: Poor

Weldability – Gas: Excellent

Weldability – Arc: Excellent

TEMPER TYPES Weldability – Resistance: Excellent

The most common tempers for 1050 aluminium are: Brazability: Excellent

Solderability: Excellent

• H14 - Work hardened by rolling to half hard, not

annealed after rolling

[1 OF 2] CONTINUED

Aalco is a registered trademark of Aalco Metals Ltd

© Copyright: Aalco Metals Ltd, Parkway House, Unit 6 Parkway Industrial Estate, Wednesbury WS10 7WP

Aluminium Alloy

1050A H14 Sheet

CONTACT

Address: Please make contact directly with your local

service centre, which can be found via the

Locations page of our web site

Web: www.aalco.co.uk

REVISION HISTORY

Datasheet Updated 18 July 2019

DISCLAIMER

This Data is indicative only and as such is not to be relied upon in place of

the full specification. In particular, mechanical property requirements vary

widely with temper, product and product dimensions. All information is

based on our present knowledge and is given in good faith. No liability will

be accepted by the Company in respect of any action taken by any third

party in reliance thereon.

Please note that the 'Datasheet Update' date shown above is no guarantee

of accuracy or whether the datasheet is up to date.

The information provided in this datasheet has been drawn from various

recognised sources, including EN Standards, recognised industry references

(printed & online) and manufacturers’ data. No guarantee is given that the

information is from the latest issue of those sources or about the accuracy of

those sources.

Material supplied by the Company may vary significantly from this data, but

will conform to all relevant and applicable standards.

As the products detailed may be used for a wide variety of purposes and as

the Company has no control over their use; the Company specifically

excludes all conditions or warranties expressed or implied by statute or

otherwise as to dimensions, properties and/or fitness for any particular

purpose, whether expressed or implied.

Advice given by the Company to any third party is given for that party’s

assistance only and without liability on the part of the Company. All

transactions are subject to the Company’s current Conditions of Sale. The

extent of the Company’s liabilities to any customer is clearly set out in those

Conditions; a copy of which is available on request.

[2 OF 2]

Aalco is a registered trademark of Aalco Metals Ltd

© Copyright: Aalco Metals Ltd, Parkway House, Unit 6 Parkway Industrial Estate, Wednesbury WS10 7WP

You might also like

- Manufacturing Engineering and Technology 7th Edition Kalpakjian Solutions ManualDocument36 pagesManufacturing Engineering and Technology 7th Edition Kalpakjian Solutions Manualbuccinalfaithful06dtie96% (24)

- Standard Hooks Card-ASTMDocument2 pagesStandard Hooks Card-ASTMAnonymous ANo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- SFS Tech - ValuesDocument88 pagesSFS Tech - ValuesSathishbhaskarNo ratings yet

- Aalco Metals LTD - Aluminium Alloy - 1050 H14 - 57Document2 pagesAalco Metals LTD - Aluminium Alloy - 1050 H14 - 57lincinkrishnanNo ratings yet

- Aluminium Alloy 1050 H14 TDSDocument1 pageAluminium Alloy 1050 H14 TDSfaria1969No ratings yet

- Aalco Metals LTD - Copper and Copper Alloys CW508L Sheet - 114Document2 pagesAalco Metals LTD - Copper and Copper Alloys CW508L Sheet - 114Mihai ChitibaNo ratings yet

- Aluminium Alloy 5754 - H114 SheetDocument2 pagesAluminium Alloy 5754 - H114 SheetPraveen Kumar JeyaprakashNo ratings yet

- Aalco Metals LTD Aluminium Alloy 5754 H22 Sheet and Plate 153Document2 pagesAalco Metals LTD Aluminium Alloy 5754 H22 Sheet and Plate 153a1528347No ratings yet

- GapenDocument5 pagesGapenasyifafredasalsabNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Copper and Copper Alloys CW024A Sheet and Plate: Specifications Generic Physical PropertiesDocument2 pagesCopper and Copper Alloys CW024A Sheet and Plate: Specifications Generic Physical PropertiesAhmed AlsabaaNo ratings yet

- Aluminium Alloy 7075 Data SheetDocument1 pageAluminium Alloy 7075 Data SheetFaris AlmarshadNo ratings yet

- Aalco Metals LTD Aluminium AlloyDocument2 pagesAalco Metals LTD Aluminium Alloyanwarali1975No ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Document2 pagesAalco Metals LTD Aluminium Alloy 6061 T6 Extrusions 145Ahmad Jasir RasyidiNo ratings yet

- Aalco Metals LTD Aluminium Alloy 5052 H32 Sheet and Treadplate 138Document2 pagesAalco Metals LTD Aluminium Alloy 5052 H32 Sheet and Treadplate 138Edgardo PeñaNo ratings yet

- Pure Copper:-Copper Alloy C101Document9 pagesPure Copper:-Copper Alloy C101Senthil KumarNo ratings yet

- Aluminium Alloy 5083 - '0' - H111 Sheet and PlateDocument2 pagesAluminium Alloy 5083 - '0' - H111 Sheet and PlateOmarNo ratings yet

- Aluminium Alloy 5251 - H22 Sheet and PlateDocument2 pagesAluminium Alloy 5251 - H22 Sheet and Platecoronado777No ratings yet

- Aalco Metals LTD - Aluminium Alloy 5083 H32 Sheet - 140 PDFDocument2 pagesAalco Metals LTD - Aluminium Alloy 5083 H32 Sheet - 140 PDFAhmad Renaldy Jurais0% (1)

- Aalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144Document2 pagesAalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144anilbabu4No ratings yet

- Copper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsDocument2 pagesCopper and Copper Alloys CW614N Brass Flat Bar and Profiles: Specifications Supplied FormsAnonymous v7XdaQuNo ratings yet

- Copper and Copper Alloys CW614N Brass Rod: Specifications Supplied FormsDocument2 pagesCopper and Copper Alloys CW614N Brass Rod: Specifications Supplied Formsdipesh6030No ratings yet

- Aluminium Alloy 6060 - T5 T595: Physical PropertiesDocument2 pagesAluminium Alloy 6060 - T5 T595: Physical Propertieschaval01No ratings yet

- Aalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFDocument2 pagesAalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFOvidiu ChertesNo ratings yet

- Aalco Metals LTD Stainless Steel 14021 Bar 311Document2 pagesAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNo ratings yet

- Wilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200Document2 pagesWilsons LTD Aluminium Alloy QQ A 25011 T6 Sheet 200williamNo ratings yet

- Aluminium 1100Document2 pagesAluminium 1100Anup DalalNo ratings yet

- Aluminium Alloy 1100 Data SheetDocument1 pageAluminium Alloy 1100 Data SheetMarium ZahidNo ratings yet

- Brass Cz108-Cw508L Sheet: SpecificationsDocument1 pageBrass Cz108-Cw508L Sheet: SpecificationsSuhas AnanthaNo ratings yet

- Aluminium Alloy QQ A 25011 T651 Plate - 222Document2 pagesAluminium Alloy QQ A 25011 T651 Plate - 222somashekar1510No ratings yet

- Aluminium Alloy 5083H116 Data SheetDocument1 pageAluminium Alloy 5083H116 Data SheetTarek MassimoNo ratings yet

- Aluminium Alloy 1100 Data SheetDocument1 pageAluminium Alloy 1100 Data SheetKhaja NawasNo ratings yet

- Data Sheet AL-BRONZEDocument1 pageData Sheet AL-BRONZEAris WicaksonoNo ratings yet

- AA 3105-F Tread/Chequered Plates: Aluminium AlloyDocument1 pageAA 3105-F Tread/Chequered Plates: Aluminium AlloyAbolfazl HabibiNo ratings yet

- Thyssenkrupp Materials (UK) LTD Aluminium Alloy 1050 H14: Material Data SheetDocument2 pagesThyssenkrupp Materials (UK) LTD Aluminium Alloy 1050 H14: Material Data SheetsurajpkNo ratings yet

- Aero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200Document2 pagesAero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200erikaNo ratings yet

- Aluminium Alloy 6082 - T4 ExtrusionsDocument2 pagesAluminium Alloy 6082 - T4 ExtrusionsRaj DomadiyaNo ratings yet

- Aluminium Alloy 3003 0 Sheet 59Document2 pagesAluminium Alloy 3003 0 Sheet 59Permaedhy BNo ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- Aalco Metals LTD Aluminium Alloy 5052 H32 Sheet and Treadplate 138Document2 pagesAalco Metals LTD Aluminium Alloy 5052 H32 Sheet and Treadplate 138AndryyanNo ratings yet

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- COPPER-110: Nearest StandardDocument3 pagesCOPPER-110: Nearest StandardPS Pinturas pinturasNo ratings yet

- Material Product Data Sheet Pure Aluminum Thermal Spray WiresDocument4 pagesMaterial Product Data Sheet Pure Aluminum Thermal Spray WiresМихаил ИвахновNo ratings yet

- 3003Document1 page3003YovitaAyuningtyasNo ratings yet

- En 24Document1 pageEn 24Puneet BNo ratings yet

- Stainless Steel ASTM A815 S31803: Specifications Alloy DesignationsDocument2 pagesStainless Steel ASTM A815 S31803: Specifications Alloy Designationsallouche_abdNo ratings yet

- Cu ZN 05Document2 pagesCu ZN 05wjjt6chgtmNo ratings yet

- Aalco Metals LTD - Aluminium Alloy - 3003 '0' (Soft) - 59Document2 pagesAalco Metals LTD - Aluminium Alloy - 3003 '0' (Soft) - 59Mohammed Hossam ZaherNo ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperPradeep KumarNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.No ratings yet

- Stabilized Ferritic Stainless Steel: General CharacteristicsDocument37 pagesStabilized Ferritic Stainless Steel: General CharacteristicsBina Niaga MultiusahaNo ratings yet

- 400 SeriesDocument37 pages400 SeriesShashank SaxenaNo ratings yet

- AL 4104 BAlSi-11 TDSDocument2 pagesAL 4104 BAlSi-11 TDSsheikmoin100% (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Lifting Eye CalcsDocument14 pagesLifting Eye CalcsSathishbhaskarNo ratings yet

- J57S-5005 Sheets PDFDocument2 pagesJ57S-5005 Sheets PDFSathishbhaskarNo ratings yet

- Flexural Torsional Buckling 3 PDFDocument2 pagesFlexural Torsional Buckling 3 PDFSathishbhaskarNo ratings yet

- Steel Bars, Carbon, Hot-Wrought,. Special Quality, Mechanical PropertiesDocument3 pagesSteel Bars, Carbon, Hot-Wrought,. Special Quality, Mechanical PropertiesFRANZ RICHARD SARDINAS MALLCONo ratings yet

- BARTOLO M1 Chemistry and Materials ScienceDocument14 pagesBARTOLO M1 Chemistry and Materials ScienceHABIB MAHMUDNo ratings yet

- Glass Ionomer Cement: Recent Advances inDocument19 pagesGlass Ionomer Cement: Recent Advances inRana SayedNo ratings yet

- Application Guide CAB O SIL Fumed Silica in Epoxy CoatingsDocument2 pagesApplication Guide CAB O SIL Fumed Silica in Epoxy CoatingsdamiendamNo ratings yet

- Design of Elastomeric Bearing: (For Effective Span of 20.95M)Document8 pagesDesign of Elastomeric Bearing: (For Effective Span of 20.95M)vivekNo ratings yet

- OCW Rigid PavementDocument25 pagesOCW Rigid PavementFung XinRuNo ratings yet

- Applied Sciences: Reliability Study On FRP Composites Exposed To Wet-Dry CyclesDocument17 pagesApplied Sciences: Reliability Study On FRP Composites Exposed To Wet-Dry Cyclesjohnjon MeiNo ratings yet

- Lgu Masinloc Ihcs HSDCDocument11 pagesLgu Masinloc Ihcs HSDCMalson GutierrezNo ratings yet

- TG7 PipeDocument48 pagesTG7 PipeMahesh ReddyNo ratings yet

- MerpauhDocument2 pagesMerpauhChiat Oon TanNo ratings yet

- Company Profile Power PointDocument12 pagesCompany Profile Power PointAzzus BkhaNo ratings yet

- Dayton Superior - Barl-Lock CouplerDocument66 pagesDayton Superior - Barl-Lock CouplerMikeNo ratings yet

- Plug Cable Assembly With Sculcon Rev F FMDocument2 pagesPlug Cable Assembly With Sculcon Rev F FMJeins'c JocętNo ratings yet

- Total Seriola 22 68Document1 pageTotal Seriola 22 68Daryl ChianNo ratings yet

- CE 415 2 Analysis and Design of Rectangular Beams For FlexureDocument103 pagesCE 415 2 Analysis and Design of Rectangular Beams For FlexureLhee Ann GarboNo ratings yet

- Mapefibre BG 55: Technical Data SheetDocument2 pagesMapefibre BG 55: Technical Data SheetKothiyal MukeshNo ratings yet

- B2B Ahmedabad 3300Document296 pagesB2B Ahmedabad 3300maxisinc.inNo ratings yet

- Thermal Properties of Jute Fiber Reinforced Chemically Functionalized High Density Polyethylene (JF/CF-HDPE) Composites Developed by Palsule ProcessDocument12 pagesThermal Properties of Jute Fiber Reinforced Chemically Functionalized High Density Polyethylene (JF/CF-HDPE) Composites Developed by Palsule ProcessManju ANNo ratings yet

- Chapter 2 Limit State Design For Flexure: Reinforced Concrete Structures I (Ceng-3111)Document50 pagesChapter 2 Limit State Design For Flexure: Reinforced Concrete Structures I (Ceng-3111)Muaz HararNo ratings yet

- Construction TechnologyDocument55 pagesConstruction TechnologyshingkeongNo ratings yet

- Durability Studies On Structural Light Weight Concrete Final PPPPTDocument17 pagesDurability Studies On Structural Light Weight Concrete Final PPPPTVishwas N V VishwaNo ratings yet

- Effects of Sugarcane Bagasse Ash and Nano Eggshell Powder On High Strength Concrete PropertiesDocument18 pagesEffects of Sugarcane Bagasse Ash and Nano Eggshell Powder On High Strength Concrete PropertiesAce De GuzmanNo ratings yet

- z.2. Sertifikat + Materi Seminar Internasional Usm 2022 (Lengkap)Document6 pagesz.2. Sertifikat + Materi Seminar Internasional Usm 2022 (Lengkap)Sutarno -No ratings yet

- IndexDocument135 pagesIndexNatalie DimovNo ratings yet

- Waterproofing Catalogue: Parchem Construction SuppliesDocument20 pagesWaterproofing Catalogue: Parchem Construction SuppliesJet ToledoNo ratings yet

- HINDALCO Aluminium Cladding SheetDocument9 pagesHINDALCO Aluminium Cladding SheetGovindarajanNo ratings yet

- Delta MembraneDocument3 pagesDelta MembraneSlinky BillNo ratings yet

- 525 KV HVDCDocument16 pages525 KV HVDCRomani FahmiNo ratings yet