Professional Documents

Culture Documents

IMG - 0152 PSME Code 2008 144

Uploaded by

bnqr584bOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMG - 0152 PSME Code 2008 144

Uploaded by

bnqr584bCopyright:

Available Formats

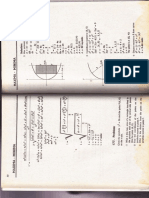

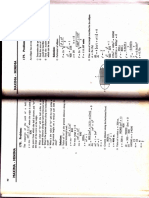

CHAPTER 7 - BOILERS AND PRESSURE VESSELS

TI

fuel and ash. A leak from a tube frequently The plant inspector should inspect the boiler

al

causes serious erosion action on a number for alignment, setting, loss of plumb, (r

of tubes in its immediate vicinity. The abnormal movement such as displacement of - it

p

exterior of the tubes should be inspected for drums or other pressure parts. He shouH

G

scale and deposits. Thb space between the ensure that provisions are made for expansion

p

tubes should be made visible by lowering a and contraction of the boiler and setting, that

small light between them for the purpose of external clearances for boiler expansion are

T

making sure that there is no restriction of unobstructed, and that all supports are in

circulation. proper condition to carry loads irnposed on

them. Permanent reference marks tr

6.4.10.2 Ligaments Between Tube Holes indicators on drums and headers are

recommended to enable rechecking the,

The ligaments between tube holes in the position (both hot and cold). The plail

heads of all fire tube boilers should be inspector should verify that proper expansion

inspected. lf leakage is noted, broken movement occurs as the boiler is returned b

ligaments could be the reason. service after an outage. Water sealed

expansion joints between the furnace and ash

6.4.10.3 Manholes and Other Openings pit should be examined for leaks in the baffle

and for accumulation of sludge.

The manholes and other reinforcing plates,

as well as nozzles and other flanged or lnspection should be made for evidence of

screwed connections on the boiler, should corrosion of the exterior of drums or tubes and

be inspected internally and externally to see a check made for leaks from root, stacks,

that they are not cracked or deformed. valves, or pipes. Riveted joints, butt straps,

Manhole ring surfaces should be examined and riveted heads should be examined for

for erosion and corrosion. Particular leaks or wastage. lf tell tale holes are provided

attention should be given to areas of the on stays, they should be kept clean. lf there is

shell where feedwater piping terminates. evidence of leakage, the stay should be

Whenever possible, observation should be replaced. Where butt straps are covered by

made from inside the boiler to check masonry or insulation, periodic testing and

soundness of pipe connections to the boiler. inspection for expansion is recommended.

All opening to external attachments, such as Supporting steel, buck stays, and tie rods

connections to the lbw water cutoff and should be inspected for condition and possible

opening to safety relief devices, should be shifting from place.

inspected to see that they are from

obstruction. .-.1 6.5.2 Piping

6.4.'|-0.4 Fire Surfaces !t The condition of the main steam header, its

connections to the boiler, and its support units

Firetubes sometimes blister but rarely should be inspected to determine that it is

collapse. The plant inspector should properly supported, that allowance is made for e5.4

examine the tubes for such defects; if any expansion and contraction without exerting

are found to have sufficient distortion to excessive stress or strain on the pressure

warrant it, they should be replaced. parts of the boiler, and that the non return and

stop valves in good working condition.

lnspection of firetube boilers include a check

for any impingment of flame on dry sheets, All piping should be inspected for leaks; if any

particularly at the back arch of return tubular are found, it should be determined whether

boiler. The arch should be entirely clear of they are the result of excessive strains due to

the rear tube sheets with sheet metal or expansion or contraction or other causes. The

asbestos rope closing the gap. general arrangement of the piping in regard to

the provisions for expansion and drainage, as

6.5 lnspection of ExternalSurfaces and Part well as adequate support at the proper points

should be carefully noted. There should be no

6.5.1 General pockets in the connecting piping that can hold

water unless they can be drained or equipped

with stream traps.

144

You might also like

- IMG - 0150 PSME Code 2008 142Document1 pageIMG - 0150 PSME Code 2008 142Arwyn BermasNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Inspection Procedure of Medium Risk Installed Boilers As Per IBR, 1950Document2 pagesInspection Procedure of Medium Risk Installed Boilers As Per IBR, 1950ratanNo ratings yet

- Drydocking InspectionDocument26 pagesDrydocking Inspectiondan_artimofNo ratings yet

- Boiler MaintenanceDocument4 pagesBoiler Maintenancekeerthi dayarathnaNo ratings yet

- 2.1 Boiler Surveys (2013)Document58 pages2.1 Boiler Surveys (2013)Diegos44No ratings yet

- Recommended Practice For Prevention, Detection and Correction of Deaerator CrackingDocument2 pagesRecommended Practice For Prevention, Detection and Correction of Deaerator CrackingAnonymous gr5Pr9AV0% (1)

- Repairs in Marine BoilersDocument9 pagesRepairs in Marine BoilersSwarg VibhaNo ratings yet

- Pipeline and Hazardous Materials Safety Admin., DOT 178.337-9Document2 pagesPipeline and Hazardous Materials Safety Admin., DOT 178.337-9AssemNo ratings yet

- Annexure 3 External Inspection ChecklistDocument5 pagesAnnexure 3 External Inspection Checklistankur100% (1)

- Hose OEM MaintenanceDocument54 pagesHose OEM MaintenanceBayu Jatmiko100% (1)

- Installation, Operation and Maintenance Instructions: Hancock Forged Steel - Gate, Globe and Check ValvesDocument6 pagesInstallation, Operation and Maintenance Instructions: Hancock Forged Steel - Gate, Globe and Check ValvesÁlvaro Martínez FernándezNo ratings yet

- Status of Drill-Stem Testing Techniques and Analysis: H. K. Van PoollenDocument7 pagesStatus of Drill-Stem Testing Techniques and Analysis: H. K. Van Poollenvictor gerardoNo ratings yet

- Heat Exchanger Tube Bundle InspectionDocument3 pagesHeat Exchanger Tube Bundle InspectionVenkatesh Natla100% (4)

- Boiler Safety Systems and InstrumentsDocument6 pagesBoiler Safety Systems and InstrumentsАртем БабенкоNo ratings yet

- H. BibliographyDocument50 pagesH. BibliographyClaudio Figueroa RoaNo ratings yet

- Guidance Notes - Descaling Plate Heat Exchangers - FWF - 15iDocument2 pagesGuidance Notes - Descaling Plate Heat Exchangers - FWF - 15iOmid LarkiNo ratings yet

- Asset Record For Job No 96082Document21 pagesAsset Record For Job No 96082Mehdi HassanNo ratings yet

- Tank in Service Inspection ChecklistDocument8 pagesTank in Service Inspection ChecklistAhmadiBinAhmad100% (3)

- Boilers InspectionDocument62 pagesBoilers Inspectionrty288% (16)

- Boiler Inspections GudeDocument4 pagesBoiler Inspections GudeJayanath Nuwan SameeraNo ratings yet

- Maintenance Plan - ACUDocument5 pagesMaintenance Plan - ACUTESDA PasMakNo ratings yet

- Check Valve: Product Bulletin 50-13 CDocument2 pagesCheck Valve: Product Bulletin 50-13 CHuong QuangNo ratings yet

- Maintaining Valves The Right Way: by Nwaoha Chikezie of CASEIDocument2 pagesMaintaining Valves The Right Way: by Nwaoha Chikezie of CASEIRajibNo ratings yet

- Installation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersDocument5 pagesInstallation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersCLIFFORDPANo ratings yet

- Emd Mi549Document7 pagesEmd Mi549DerekNo ratings yet

- Emd-Mi549 RadiadoresDocument7 pagesEmd-Mi549 RadiadoresVictor Raul Tobosque MuñozNo ratings yet

- Coiled Tubing Emergency ProceduresDocument46 pagesCoiled Tubing Emergency Proceduresazareiforoush0% (1)

- SECTION 23 21 00: Underground Chilled Water Systems (Issued Ad-6)Document4 pagesSECTION 23 21 00: Underground Chilled Water Systems (Issued Ad-6)vuhalamNo ratings yet

- Gujarat Vist ObservationDocument3 pagesGujarat Vist Observationbmanojkumar16No ratings yet

- C) Odour TestDocument4 pagesC) Odour Testa_j_sanyal259No ratings yet

- NPR050 Pre-Piped Vertical Bladder Tank PDFDocument4 pagesNPR050 Pre-Piped Vertical Bladder Tank PDFLuis Joel Ramos RamosNo ratings yet

- Corrosion Fatigue PDFDocument2 pagesCorrosion Fatigue PDFvelu111No ratings yet

- Preventive Maintenance ChecklistDocument2 pagesPreventive Maintenance ChecklistAnonymous 6gB0helNo ratings yet

- VB Om2 0Document5 pagesVB Om2 0THEO CHASIOTISNo ratings yet

- API 510 Petrosync Course PDFDocument301 pagesAPI 510 Petrosync Course PDFAkramKassis100% (1)

- CHAPTER 20 Water Distribution SystemsDocument14 pagesCHAPTER 20 Water Distribution SystemsPrescila QuietaNo ratings yet

- A eDocument17 pagesA eReden H. ArgawanonNo ratings yet

- Terminology Operations PDFDocument5 pagesTerminology Operations PDFDulgheru Catalin GeorgeNo ratings yet

- Maintenance Boiler Maintenance - Thermal Power Plant A-ZDocument4 pagesMaintenance Boiler Maintenance - Thermal Power Plant A-ZkriziameiahnNo ratings yet

- Embankment: Inspection Checklist GuidelinesDocument2 pagesEmbankment: Inspection Checklist GuidelinesGHL AdaroNo ratings yet

- 08-INSTALLATION - (A) Ball ValvesDocument4 pages08-INSTALLATION - (A) Ball ValvesModassir ZaheenNo ratings yet

- Julian2014 PDFDocument9 pagesJulian2014 PDFmahmoud korieshNo ratings yet

- STI - SP001-00 - Standard For Inspection of In-Service Shop Fabricated Aboveground Tanks For Storage of Combustible and Flammable LiquidsDocument20 pagesSTI - SP001-00 - Standard For Inspection of In-Service Shop Fabricated Aboveground Tanks For Storage of Combustible and Flammable LiquidsJoe BetkerNo ratings yet

- Maintenance - Hyundai Elantra (2009) ManualDocument1 pageMaintenance - Hyundai Elantra (2009) ManualDroid WRNo ratings yet

- Parting The PipeDocument9 pagesParting The Pipephucbm bmNo ratings yet

- IMG - 0140 PSME Code 2008 132Document1 pageIMG - 0140 PSME Code 2008 132Arwyn BermasNo ratings yet

- Comparison of Crossflow VS Counterflow Cooling TowerDocument2 pagesComparison of Crossflow VS Counterflow Cooling TowerShahab Z Ahmed100% (1)

- NPR040 Horizontal Bladder Tank SystemDocument6 pagesNPR040 Horizontal Bladder Tank SystemRomner CordovaNo ratings yet

- Asme B31Document18 pagesAsme B31rWin doNo ratings yet

- Of in Service Storage Tank Inspection and Verification ChecklistDocument16 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- Section 21 Hull OutfitDocument4 pagesSection 21 Hull OutfitJ T Mendonça SantosNo ratings yet

- Lesson 2Document3 pagesLesson 2Jenelyn Dela CruzNo ratings yet

- Learning From IncidentsDocument60 pagesLearning From IncidentsMario CoronelNo ratings yet

- Iom Forged GGC ValvesDocument12 pagesIom Forged GGC ValvesMohamadIbnuHassanNo ratings yet

- Internal & External Inspection GuidelinesDocument5 pagesInternal & External Inspection Guidelinesgeverett2765No ratings yet

- Boiler MaintenanceDocument7 pagesBoiler MaintenancekapenziaNo ratings yet

- IMG - 0102 MCQ in Calculus 155Document1 pageIMG - 0102 MCQ in Calculus 155bnqr584bNo ratings yet

- IMG - 0108 MCQ in Calculus 167Document1 pageIMG - 0108 MCQ in Calculus 167bnqr584bNo ratings yet

- Img - 0062 MCQ For Power & Ipe 114Document1 pageImg - 0062 MCQ For Power & Ipe 114bnqr584bNo ratings yet

- Img - 0066 MCQ For Power & Ipe 119Document1 pageImg - 0066 MCQ For Power & Ipe 119bnqr584bNo ratings yet

- Img - 0133 MCQ Ece Board Exam 251Document1 pageImg - 0133 MCQ Ece Board Exam 251bnqr584bNo ratings yet

- Img - 0067 MCQ For Power & Ipe 121Document1 pageImg - 0067 MCQ For Power & Ipe 121bnqr584bNo ratings yet

- Img - 0061 MCQ For Power & Ipe 113Document1 pageImg - 0061 MCQ For Power & Ipe 113bnqr584bNo ratings yet

- Img - 0064 MCQ For Power & Ipe 116Document1 pageImg - 0064 MCQ For Power & Ipe 116bnqr584bNo ratings yet

- Img - 0063 MCQ For Power & Ipe 115Document1 pageImg - 0063 MCQ For Power & Ipe 115bnqr584bNo ratings yet

- IMG - 0084 MCQ in Calculus 136Document1 pageIMG - 0084 MCQ in Calculus 136bnqr584bNo ratings yet

- Img - 0069 MCQ For Power & Ipe 127Document1 pageImg - 0069 MCQ For Power & Ipe 127bnqr584bNo ratings yet

- Img - 0140 MCQ Ece Board Exam 265Document1 pageImg - 0140 MCQ Ece Board Exam 265bnqr584bNo ratings yet

- Img - 0068 MCQ For Power & Ipe 125Document1 pageImg - 0068 MCQ For Power & Ipe 125bnqr584bNo ratings yet

- Img - 0139 MCQ Ece Board Exam 263Document1 pageImg - 0139 MCQ Ece Board Exam 263bnqr584bNo ratings yet

- Img - 0131 MCQ Ece Board Exam 247Document1 pageImg - 0131 MCQ Ece Board Exam 247bnqr584bNo ratings yet

- Img - 0134 MCQ Ece Board Exam 253Document1 pageImg - 0134 MCQ Ece Board Exam 253bnqr584bNo ratings yet

- Img - 0136 MCQ Ece Board Exam 257Document1 pageImg - 0136 MCQ Ece Board Exam 257bnqr584bNo ratings yet

- IMG - 0094 MCQ College Algebra 179Document1 pageIMG - 0094 MCQ College Algebra 179bnqr584bNo ratings yet

- Img - 0132 MCQ Ece Board Exam 249Document1 pageImg - 0132 MCQ Ece Board Exam 249bnqr584bNo ratings yet

- Img - 0135 MCQ Ece Board Exam 255Document1 pageImg - 0135 MCQ Ece Board Exam 255bnqr584bNo ratings yet

- Img - 0138 MCQ Ece Board Exam 261Document1 pageImg - 0138 MCQ Ece Board Exam 261bnqr584bNo ratings yet

- IMG - 0093 MCQ College Algebra 183Document1 pageIMG - 0093 MCQ College Algebra 183bnqr584bNo ratings yet

- IMG - 0092 MCQ College Algebra 175Document1 pageIMG - 0092 MCQ College Algebra 175bnqr584bNo ratings yet

- IMG - 0093 MCQ College Algebra 179aDocument1 pageIMG - 0093 MCQ College Algebra 179abnqr584bNo ratings yet

- IMG - 0055 MCQ in Calculus 85Document1 pageIMG - 0055 MCQ in Calculus 85bnqr584bNo ratings yet

- IMG - 0054 MCQ in Calculus 83Document1 pageIMG - 0054 MCQ in Calculus 83bnqr584bNo ratings yet

- IMG - 0056 MCQ in Calculus 87Document1 pageIMG - 0056 MCQ in Calculus 87bnqr584bNo ratings yet

- IMG - 0053 MCQ in Calculus 81Document1 pageIMG - 0053 MCQ in Calculus 81bnqr584bNo ratings yet

- IMG - 0057 MCQ in Calculus 89Document1 pageIMG - 0057 MCQ in Calculus 89bnqr584bNo ratings yet

- Img - 0140 MCQ Ree Board Exam 273Document1 pageImg - 0140 MCQ Ree Board Exam 273bnqr584bNo ratings yet

- Screw and Centrifugal: Chiller SeriesDocument5 pagesScrew and Centrifugal: Chiller Serieseladio arciaNo ratings yet

- Harga Pekerjaan Repair Valve Rev1Document21 pagesHarga Pekerjaan Repair Valve Rev1sandrositohangNo ratings yet

- Module 1.3 Reversed Carnot CycleDocument18 pagesModule 1.3 Reversed Carnot CycleMikko Arvin ChuaNo ratings yet

- Bosch 10P Water WizardDocument7 pagesBosch 10P Water WizardlamtamnhuNo ratings yet

- Price List Air Coolers enDocument78 pagesPrice List Air Coolers enCKS CateringNo ratings yet

- Sheraton Hanoi: The Green HotelDocument23 pagesSheraton Hanoi: The Green Hotellethanhvan186No ratings yet

- Automotive Cooling SystemDocument58 pagesAutomotive Cooling SystemMoniruzzaman ShuvoNo ratings yet

- Able Hydraulics BrochureDocument8 pagesAble Hydraulics BrochureYee Moses7o897u77No ratings yet

- Broan Replacement Parts Guide PDFDocument136 pagesBroan Replacement Parts Guide PDFRomankoNo ratings yet

- E32 P R340 2136Document5 pagesE32 P R340 2136Ranish P. KurianNo ratings yet

- Emkarate Approval ListDocument3 pagesEmkarate Approval ListVanderlei ConterNo ratings yet

- Replacing The Heating Element: No.A1321 (900M - 900L - 907 - 908 - 913 - 914 - 951 - 952)Document1 pageReplacing The Heating Element: No.A1321 (900M - 900L - 907 - 908 - 913 - 914 - 951 - 952)navin agarwalNo ratings yet

- Pip PNF0200 (2018)Document140 pagesPip PNF0200 (2018)Cristian Bravo100% (5)

- BE CYK Res Novartis CS PDFDocument9 pagesBE CYK Res Novartis CS PDFRanga VamshiNo ratings yet

- Hydraulic System (Control Valve) PDFDocument26 pagesHydraulic System (Control Valve) PDFMarco Fam's100% (4)

- Psychrometry PDFDocument10 pagesPsychrometry PDFmukund holkarNo ratings yet

- Method of Statement For Precommissioning & Commissioning of ChillersDocument4 pagesMethod of Statement For Precommissioning & Commissioning of Chillersvin ssNo ratings yet

- Copeland ScrollDocument7 pagesCopeland ScrollPascual DuqueNo ratings yet

- General Ventilation RequirementsDocument19 pagesGeneral Ventilation RequirementsNelson VargasNo ratings yet

- ESV - ASNZS5601 Road Show Presentation 2014Document48 pagesESV - ASNZS5601 Road Show Presentation 2014IanNo ratings yet

- FTN-AV1K, RN-AV1K Catalogue ENDocument4 pagesFTN-AV1K, RN-AV1K Catalogue ENOdumosu SamuelNo ratings yet

- Certified RACSplitDocument16 pagesCertified RACSplitSteven ReyesNo ratings yet

- Group 8 - Technical ReportDocument59 pagesGroup 8 - Technical ReportNathan EvangelistaNo ratings yet

- Plumbing Interview Questions by Prosen SirDocument10 pagesPlumbing Interview Questions by Prosen SirBlue Eye'sNo ratings yet

- SL 19530 Manual PDFDocument60 pagesSL 19530 Manual PDFDiego Saravia JordanNo ratings yet

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Document1 pagePipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Scribd meNo ratings yet

- Unsused EnegoibhjasDocument80 pagesUnsused Enegoibhjaskamal_arbabNo ratings yet

- Screw Chiller Report: Unit InformationDocument8 pagesScrew Chiller Report: Unit InformationYosephanderNo ratings yet

- Compressor Replacement ProcedureDocument2 pagesCompressor Replacement ProcedurebassouadNo ratings yet

- Concealed YSBDocument2 pagesConcealed YSBHoàng Chí LinhNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Deepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeFrom EverandDeepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesFrom EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesRating: 5 out of 5 stars5/5 (7)

- Offshore Projects and Engineering ManagementFrom EverandOffshore Projects and Engineering ManagementRating: 5 out of 5 stars5/5 (2)

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Ship and Mobile Offshore Unit Automation: A Practical GuideFrom EverandShip and Mobile Offshore Unit Automation: A Practical GuideNo ratings yet

- The Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoFrom EverandThe Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoNo ratings yet

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonFrom Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonNo ratings yet

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsFrom EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNo ratings yet

- Practical Engineering Management of Offshore Oil and Gas PlatformsFrom EverandPractical Engineering Management of Offshore Oil and Gas PlatformsRating: 4 out of 5 stars4/5 (7)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)