Professional Documents

Culture Documents

Detecting Pump Cavitation With Vibration Sensor

Uploaded by

Himanshu SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detecting Pump Cavitation With Vibration Sensor

Uploaded by

Himanshu SharmaCopyright:

Available Formats

Maintenance Minders

Detecting Pump

Cavitation with a

Vibration Sensor

Renard Klubnik, Wilcoxon Research

C

avitation is a destructive condition that can destroy as a PLC or DCS, readily accept this type of input, and

the inside of a pump before you even realize it is alarm limits can be set.

occurring. Early detection can minimize damage, To prove its effectiveness, a pump manufacturer set up

reduce downtime, and save money. Cavitation involves the a controlled test by mounting the sensor on a positive dis-

creation of bubbles formed when the fluid being pumped placement pump. The pump was brought up to speed at

vaporizes due to a decrease in pressure as the fluid enters the 359-rpm. A vacuum pump attached to this pump’s input

pump. These bubbles are then acted on by the pump impel- provided the means of controlling the input head of the test

ler, causing them to implode. pump.

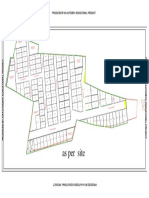

As these bubbles (also referred to as holes in the fluid) As the pump started, the sensor monitored the high

collapse, a noise similar to a ball peen hammer hitting sheet frequency vibration signals, represented in Figure 1 by the

metal can be heard. This action begins to erode the inside section of the graph where the vibration level is just above

of the pump. Left unchecked, the pump will eventually fail. the 4-mA level.

Cavitation can be prevented if the head at the suction end is The input pressure was then decreased. The pump began

higher than the vapor pressure head of the fluid. While this cavitating. An immediate rise is seen in the graph because

is the design goal, process variables can cause a loss of head the sensor recognized the “ball peen hammer effects” gener-

which, in turn, causes cavitation to occur. ated inside the pump as head pressure decreased and cavita-

The collapse of the bubbles is a violent process that tion started. Since high frequency signals tend to attenuate

creates an impacting action inside

the pump. This impact excites high Pump Cavitation Sensor Test

frequency resonances in the pump

20 mA

structure. Since these high frequen-

cies are outside the normal range of

pump operating frequencies, a special

16 mA

sensor was developed, tuned to these

higher frequencies.

This acceleration, true peak 12 mA

detection, frequency banded vibra-

tion sensor is sensitive only to those

frequencies normally excited during

8 mA

cavitation. Motor and pump 1X and

vane pass frequencies are excluded

from its measurement. This loop 4 mA

powered sensor provides a 4-mA to

20-mA output signal proportional

to the sensed vibration level. A 4-mA

to 20-mA output sensor was selected

sec

1.5

9.1

3.02

4.54

6.06

7.58

10.62

12.14

13.66

15.18

16.7

18.22

19.74

21.26

22.78

24.3

25.82

27.34

28.86

30.38

31.9

33.42

34.94

36.46

37.98

39.5

41.02

42.54

44.06

45.58

47.1

48.62

50.14

51.66

53.18

54.7

56.22

57.74

59.26

because process control systems, such Figure 1. Pump cavitation sensor test results.

58 JUNE 2007 www.pump-zone.com PUMPS & SYSTEMS

after short distances in mechanical structures, there is very little influence from

nearby machinery. Thus, there is little concern that the signal is being generated

from another piece of equipment.

The peak detection circuit inside the sensor aids in rapidly responding to an

increase in the vibration amplitudes in the frequency region associated with cavita-

tion. Using a long time constant on this peak detection circuit helps to hold these

peak levels long enough to be recorded.

Had a normal vibration transducer been used,

Figure 1 would not show any changes in amplitude

as cavitation began because the running speed

of the pump would dominate the vibration signal,

effectively masking the change in

the high frequency signal.

Since many pumps are located in remote locations or in locations not regu-

larly frequented by plant personnel, the ability to accurately, quickly, and remotely

sense a cavitation condition is important. If the 4-mA to 20-mA signal is output

the fine art

from the sensor and fed to a DCS or PLC, the loop powered sensor can be used to

alarm an operator about an errant pump so corrective action can be taken before

irreversible damage occurs.

of intricate

Even if it is not possible to shut the pump down once cavitation is detected,

the knowledge that it is occurring can be used by plant personnel. In some applica- duplication.

tions, such as food processing, this knowledge could affect the overall quality of

the final product.

There is no pump part so compli-

Another concern may relate to cooling requirements. Since pumping capac-

cated that ProCast can’t replicate

ity reduces once cavitation begins, a plant operator armed with this knowledge

may have to bring more pumps on-line in order to maintain minimum needs. it, quickly and inexpensively. Our

The bottom line here is minimal cost; the operator can keep his equipment run- laser measuring technology and

ning efficiently, prevent costly repairs and possibly improve his overall process digital patterning process make an

performance. exacting mold of the original—and

The complete data plot in Figure 1 shows the 4-mA to 20-mA loop signal our foundry and machining services

output during the test run. Cavitation begins to appear at 21.26-sec. The pump do the rest. What emerges is a

is in full cavitation by 24.98-sec, before being manually shut down at 48.12-sec. piece of pure hand-crafted precision,

The data indicates that the sensor detected initial evidence of cavitation at around

ready to bolt in and go to work.

circle 146 on card or go to psfreeinfo.com

21-sec, when the vibration level first went above 8-mA, while easily detecting the

presence of full cavitation at 25-sec. Normal pump running produced only a small Visit procastparts.com or call

increase in the vibration signal (0-sec to18-sec) and the sensor output returned to 1-800-543-6263.

the quiescent 4-mA after the pump shut down.

ProCast

It is interesting to note that had a normal vibration transducer been used,

Figure 1 would not show any changes in amplitude as cavitation began because the

running speed of the pump would dominate the vibration signal, effectively mask-

ing the change in the high frequency signal represented above.

P&S

Renard Klubnik is an applications engineer at Wilcoxon Research, Inc., 20511

Seneca Meadows Parkway, Germantown, MD 20876, 301-330-8811, Fax:

301-330-8873, www.wilcoxon.com.

PUMPS & SYSTEMS www.pump-zone.com JUNE 2007 59

You might also like

- Remarks: Point2 Point1Document1 pageRemarks: Point2 Point1Abdullateef ElgailaniNo ratings yet

- GraphsDocument8 pagesGraphsPuneeth kumar j kNo ratings yet

- Plano 001Document1 pagePlano 001soledadvasquezgNo ratings yet

- Lead Screw Phi 18Document1 pageLead Screw Phi 18bhageshlNo ratings yet

- Farmland DimensionsDocument1 pageFarmland DimensionsKumar KingslyNo ratings yet

- Marvin Colonia-Presentación1Document1 pageMarvin Colonia-Presentación1Manuel TenorioNo ratings yet

- L ModelDocument1 pageL Modelkenneth taleteNo ratings yet

- 2004 Rcs C SpecificationDocument1 page2004 Rcs C SpecificationJaime Morales BazalduaNo ratings yet

- Gwapo FloorplanDocument1 pageGwapo FloorplanJayLord Mico PacisNo ratings yet

- Contoh Form AbsensiDocument23 pagesContoh Form AbsensiFeronika KurniaNo ratings yet

- BlugrehydraulicDocument1 pageBlugrehydrauliczaccNo ratings yet

- MCA Floor PlanDocument1 pageMCA Floor PlanMarin BerovićNo ratings yet

- Chapter 8, Harmonic Analysis With Digsilent Software: June 2018Document30 pagesChapter 8, Harmonic Analysis With Digsilent Software: June 2018Cư Trần MinhNo ratings yet

- Chikalaguriki 100Document1 pageChikalaguriki 100VB665No ratings yet

- SF No 28 Kadhampadi ModelDocument1 pageSF No 28 Kadhampadi ModelmanojNo ratings yet

- SF No 28 Kadhampadi ModelDocument1 pageSF No 28 Kadhampadi ModelmanojNo ratings yet

- My House Layout2Document1 pageMy House Layout2Saad ZagadiNo ratings yet

- 21st CenturyDocument13 pages21st CenturyCollegesecond semNo ratings yet

- HR Block VLDocument1 pageHR Block VLgutenberghoNo ratings yet

- L & T Catalogue 14Document4 pagesL & T Catalogue 14amulya00428No ratings yet

- BG150Document1 pageBG150fit asmarufNo ratings yet

- Hari 1 Hari 2 Hari 3 Hari 4 Hari 5 Hari 6 Hari 7 Hari 8 Hari 9 Hari 10 Hari 11 Hari 12 Hari 13 Hari 14Document3 pagesHari 1 Hari 2 Hari 3 Hari 4 Hari 5 Hari 6 Hari 7 Hari 8 Hari 9 Hari 10 Hari 11 Hari 12 Hari 13 Hari 14Marchel Eka YantoNo ratings yet

- VFD HarmonicsDocument1 pageVFD HarmonicstwinvbooksNo ratings yet

- VDS MasterplanDocument1 pageVDS MasterplanSamudrala SreepranaviNo ratings yet

- SRMPCDocument3 pagesSRMPCBHANUKRISHNA VISAKOTANo ratings yet

- Electric Mining Shovel General Specification: Capacity Working RangesDocument2 pagesElectric Mining Shovel General Specification: Capacity Working RangesfabioxavNo ratings yet

- BL2XL5DV CM01Document1 pageBL2XL5DV CM01santhoshNo ratings yet

- 2-Wi Nding.. 64.7Document1 page2-Wi Nding.. 64.7MICHAEL MEDINA FLORESNo ratings yet

- Plano Casas (Sin Muebles)Document1 pagePlano Casas (Sin Muebles)Roberto HueramanNo ratings yet

- Hadiyol SR No - 398 - Pareshbhail DT - 30-05-2019-ModelDocument1 pageHadiyol SR No - 398 - Pareshbhail DT - 30-05-2019-ModelharshNo ratings yet

- Hadiyol SR No - 398 - Pareshbhail DT - 30-05-2019-ModelDocument1 pageHadiyol SR No - 398 - Pareshbhail DT - 30-05-2019-ModelharshNo ratings yet

- Comparison of RefrigerantsDocument11 pagesComparison of RefrigerantsansudasinghaNo ratings yet

- Ai Se Eu Te Pego Soprano SaxophoneDocument1 pageAi Se Eu Te Pego Soprano SaxophoneCharles MoreiraNo ratings yet

- SR MargaritaDocument1 pageSR MargaritaAntonioCisnerosNo ratings yet

- Eksisting PRSUDocument1 pageEksisting PRSURidwansyah Sembiring MilalaNo ratings yet

- JEE Main Quiz-28 (Student Copy)Document9 pagesJEE Main Quiz-28 (Student Copy)ashutosh.mishra0051No ratings yet

- CAPDEVILLE AP05 Temp (DWG2013) ModelDocument1 pageCAPDEVILLE AP05 Temp (DWG2013) ModelHadj IBRIRNo ratings yet

- Materi Pak YunartoDocument13 pagesMateri Pak YunartoAsiska SiswiyonoNo ratings yet

- Cross Section - MC-100 (ABD) ModelDocument1 pageCross Section - MC-100 (ABD) ModelSulung ApriyantoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterArmando Gárate CastroNo ratings yet

- Ap - Ar-002 Nivel 1Document1 pageAp - Ar-002 Nivel 1claudia LBNo ratings yet

- Candidate Name Centre Number Candidate Number Module (Shade One Box) Academic General Training Test DateDocument6 pagesCandidate Name Centre Number Candidate Number Module (Shade One Box) Academic General Training Test DateMandeep BatraNo ratings yet

- Futuro Proyecto "San Valentin: Via ProyectadaDocument1 pageFuturo Proyecto "San Valentin: Via ProyectadaHanani Hernan Aguilar LoconiNo ratings yet

- Historico PIB MexicoDocument1 pageHistorico PIB MexicoJUAN SINMIEDONo ratings yet

- Ultrahigh-Definition Color Display Horizontal Deflection Output ApplicationsDocument4 pagesUltrahigh-Definition Color Display Horizontal Deflection Output ApplicationsManuel MartinezNo ratings yet

- Answer SheetDocument1 pageAnswer SheetNeilbert ReyesNo ratings yet

- TareaDocument1 pageTareaGilmerYhonContrerasNo ratings yet

- Ground FloorDocument1 pageGround FloortahaelnourNo ratings yet

- DDC Guyana, Riser Spanner Joint 27.56 TonDocument1 pageDDC Guyana, Riser Spanner Joint 27.56 TonGreg BiddleNo ratings yet

- NEET/JEE: 2020-21: Solutions GOCDocument5 pagesNEET/JEE: 2020-21: Solutions GOCshantinath123gmailcoNo ratings yet

- Airline Operations Regulatory Issues in India: by K Gohain Joint Director General of Civil AviationDocument39 pagesAirline Operations Regulatory Issues in India: by K Gohain Joint Director General of Civil AviationphantodNo ratings yet

- Lecture 26-Problems On Cell Growth KineticsDocument15 pagesLecture 26-Problems On Cell Growth KineticsHemanth Peddavenkatappa GariNo ratings yet

- Regal Beloit America, Inc.: Dash Frame B C 2F 2FF BS 2875 2875Document1 pageRegal Beloit America, Inc.: Dash Frame B C 2F 2FF BS 2875 2875MNo ratings yet

- Climate of Smart City - Aurangabad State:-Maha Rashtra, Dist: - AurangabadDocument1 pageClimate of Smart City - Aurangabad State:-Maha Rashtra, Dist: - AurangabadBhavik TrivediNo ratings yet

- Lista de Chales1Document1 pageLista de Chales1valentina monteiroNo ratings yet

- Primer Piso 2do. PISO Azotea: Patio de ServicioDocument1 pagePrimer Piso 2do. PISO Azotea: Patio de ServicioNavi HefrankNo ratings yet

- Walk in Closet Toilet Walk in Closet ToiletDocument1 pageWalk in Closet Toilet Walk in Closet Toiletpraisejah moyoNo ratings yet

- Class Attendance Paper Name Space VerticalDocument1 pageClass Attendance Paper Name Space VerticalLeina Cruzalegui SifuentesNo ratings yet

- Ground Floor Plan Second Floor Plan: Road RoadDocument1 pageGround Floor Plan Second Floor Plan: Road RoadAmanda SmithNo ratings yet

- EHB en 9-MaterialsDocument57 pagesEHB en 9-MaterialsVishalDhimanNo ratings yet

- Finite Element AnalysisDocument25 pagesFinite Element AnalysisAnonymous lV8E5mEONo ratings yet

- TEMA Flow Induced VibrationDocument1 pageTEMA Flow Induced VibrationHimanshu SharmaNo ratings yet

- Full Text 01Document103 pagesFull Text 01Himanshu SharmaNo ratings yet

- Changes To API 650 Twelfth EditionDocument3 pagesChanges To API 650 Twelfth EditionHimanshu SharmaNo ratings yet

- Thermodynamics, Heat Transfer, and Fluid Flow 2Document80 pagesThermodynamics, Heat Transfer, and Fluid Flow 2Elia AliNo ratings yet

- Yaesu FT-727R Technical Supplement Service ManualDocument33 pagesYaesu FT-727R Technical Supplement Service ManualYayok S. AnggoroNo ratings yet

- Summary Water Turbine-CFDDocument2 pagesSummary Water Turbine-CFDHaposanNo ratings yet

- Chapter 7 Directional OcDocument10 pagesChapter 7 Directional OcTana AzeezNo ratings yet

- Gold CodeDocument3 pagesGold CodeTruong van Truong100% (1)

- CD1000A - User Manual V1.0Document88 pagesCD1000A - User Manual V1.0Engr ShoaibNo ratings yet

- Cummins: Fault Code: 429 PID: P097 SPN: 097 FMI: 4Document4 pagesCummins: Fault Code: 429 PID: P097 SPN: 097 FMI: 4Enrrique LaraNo ratings yet

- AC Voltage Controllers: AC To Ac ConvertersDocument25 pagesAC Voltage Controllers: AC To Ac ConvertersPhạm Hữu Kỳ0% (1)

- Esa-110 111 OmeDocument28 pagesEsa-110 111 OmeHikmat RahimovNo ratings yet

- Monitor Huntleigh SC1000 Service ManualDocument66 pagesMonitor Huntleigh SC1000 Service ManualHomeroLeon100% (3)

- Kia Sedona Manual de ServicoDocument131 pagesKia Sedona Manual de ServicojoshuaslNo ratings yet

- MARTES Double Cross AntennaDocument3 pagesMARTES Double Cross Antennacodycat4No ratings yet

- TtiDocument7 pagesTtivaish20No ratings yet

- AWG Vs Metric Ampacity - ChartDocument1 pageAWG Vs Metric Ampacity - Chartstor138No ratings yet

- Reflector Antennas LecturesDocument46 pagesReflector Antennas Lecturesvipin sainiNo ratings yet

- Mercedes Benz HMS 990 ManualDocument5 pagesMercedes Benz HMS 990 ManualARUPNo ratings yet

- Work Function and Process IntegrationDocument203 pagesWork Function and Process IntegrationPranita SwainNo ratings yet

- Class 9 and 10 Electrical EngineeringDocument50 pagesClass 9 and 10 Electrical EngineeringAvik Poudel100% (1)

- Weidmuller 2001350000 - CAT8 - 2015 - 16 - ENDocument497 pagesWeidmuller 2001350000 - CAT8 - 2015 - 16 - ENdNo ratings yet

- HD8205A Data SheetDocument6 pagesHD8205A Data SheetFélixNo ratings yet

- Electric Drives Kee075Document2 pagesElectric Drives Kee075xefedoy533No ratings yet

- DC Bus Voltage RegulationDocument2 pagesDC Bus Voltage RegulationHasRasfaNo ratings yet

- 2N5294 2N5296 2N5298 NPN Silicon Transistor DescriptionDocument4 pages2N5294 2N5296 2N5298 NPN Silicon Transistor DescriptionVenu Gopal Rao AggressNo ratings yet

- Evdo 2Document29 pagesEvdo 2Win LinnNo ratings yet

- Led Display PDFDocument12 pagesLed Display PDFIrwin DarmansyahNo ratings yet

- Advanced Ergo Manual WebDocument11 pagesAdvanced Ergo Manual WebBillNo ratings yet

- Camera InstallationChecklistDocument2 pagesCamera InstallationChecklistsyed nadeemNo ratings yet

- Difference Between: Two Cavity Klystron Reflex KlystronDocument27 pagesDifference Between: Two Cavity Klystron Reflex Klystronece placementNo ratings yet

- Auto Turnoff Soldering Iron CircuitDocument1 pageAuto Turnoff Soldering Iron CircuitJessicaNo ratings yet

- Users Manual: Industrial ScopemeterDocument96 pagesUsers Manual: Industrial Scopemeterene sorinNo ratings yet

- Assignment 1Document4 pagesAssignment 1Vishal BhaskarNo ratings yet