Professional Documents

Culture Documents

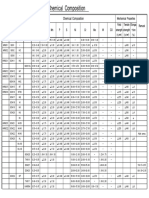

化学成分表

Uploaded by

Duy Nguyen0 ratings0% found this document useful (0 votes)

411 views1 pageThis document provides specifications for 38 high temperature alloy materials, including their typical chemical compositions, mechanical properties, and intended use temperatures. Each alloy is assigned a number and corresponding specification names from standards organizations like ASTM, JIS, and others. The mechanical properties include yield strength, tensile strength, and elongation percentages, along with minimum requirements. Intended use temperatures range from room temperature up to 1,200°C for some alloys.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for 38 high temperature alloy materials, including their typical chemical compositions, mechanical properties, and intended use temperatures. Each alloy is assigned a number and corresponding specification names from standards organizations like ASTM, JIS, and others. The mechanical properties include yield strength, tensile strength, and elongation percentages, along with minimum requirements. Intended use temperatures range from room temperature up to 1,200°C for some alloys.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

411 views1 page化学成分表

Uploaded by

Duy NguyenThis document provides specifications for 38 high temperature alloy materials, including their typical chemical compositions, mechanical properties, and intended use temperatures. Each alloy is assigned a number and corresponding specification names from standards organizations like ASTM, JIS, and others. The mechanical properties include yield strength, tensile strength, and elongation percentages, along with minimum requirements. Intended use temperatures range from room temperature up to 1,200°C for some alloys.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Casting Materials Specifications of High Temperature Alloys(Ⅰ)

Corresponding Specification Chemical Composition(Wt%) Mechanical Properties Use Mechanical Properties

No. ASTM JIS TKK Nb 0.2% Yield Tensile Elongation(%) Temperature 0.2% Yield Tensile Elongation(%) NOTE

DURALOY (DAEJIN) KUBOTA C Si Mn Cr Ni W Co Mo Strength Strength CEN./ST. ℃ Strength Strength CEN./ST.

& etc N/㎟ Kgf/㎟ N/㎟ Kgf/㎟ N/㎟ Kgf/㎟ N/㎟ Kgf/㎟

1 SCH1 0.2-0.4 1.5-3.0 ≤1.00 12.0-15.0 ≤1.00 ≥490 / ≥50 R/T-700

2 HC SCH2 TAH6 ≤0.40 ≤2.00 ≤1.00 25.0-28.0 ≤1.00 ≥340 R/T-550

3 SCH3 TAH3 ≤0.40 ≤2.00 ≤1.00 12.0-15.0 ≤1.00 ≤0.50 ≥490 / ≥50 R/T-700

4 HD SCH11 TAH10 ≤0.40 ≤2.00 ≤1.00 24.0-28.0 4.00-6.00 ≤0.50 ≥590 R/T-700

5 HF SCH12 TAH12H 0.20-0.40 ≤2.00 ≤2.00 18.0-23.0 8.0-12.0 ≤0.50 ≥235 / ≥24 ≥490 / ≥50 ≥23 815 245.2 521.5 26.7

6 HH SCH13 TAH13 0.20-0.50 ≤2.00 ≤2.00 24.0-28.0 11.0-14.0 ≤0.50 ≥235 / ≥24 ≥490 / ≥50 ≥8 870 26.5 57 9.2

7 HH2 SCH13A TAH13S 0.25-0.50 ≤1.75 ≤2.50 23.0-26.0 12.0-14.0 ≤0.50 ≥235 /≥ 24 ≥490 / ≥50 ≥8 870 28 57.5 9

8 HT SCH15 TAH21 0.35-0.70 ≤2.50 ≤2.00 15.0-19.0 33.0-37.0 ≤0.50 ≥440 / ≥45 ≥4 R/T-1,050

9 HT30 SCH16 0.20-0.35 ≤2.50 ≤2.00 13.0-17.0 33.0-37.0 ≥195 ≥440 / ≥45 ≥13 R/T-1,000

10 HE SCH17 TAH11 0.20-0.50 ≤2.00 ≤2.00 26.0-30.0 8.0-11.0 ≤0.50 ≥275 ≥540 ≥5 815-1,050

11 HI SCH18 TAG5C 0.20-0.50 ≤2.00 ≤2.00 26.0-30.0 14.0-18.0 ≤0.50 ≥235 / ≥24 ≥490 / ≥5 ≥8 760-1,050

12 HN SCH19 0.20-0.50 ≤2.00 ≤2.00 19.0-23.0 23.0-27.0 ≥390 ≥5 980-1,100

13 HU SCH20 0.35-0.75 ≤2.50 ≤2.00 17.0-21.0 37.0-41.0 ≥390 ≥4 R/T-1,100

14 HK30 SCH21 TAH18B 0.25-0.35 ≤1.75 ≤1.50 23.0-27.0 19.0-22.0 ≤0.50 ≥235 / ≥24 ≥441 / ≥45 ≥8 870-1,100

15 HK40 SCH22 TAH18C 0.35-0.45 ≤1.75 ≤1.50 23.0-27.0 19.0-22.0 ≤0.50 ≥235 / ≥24 ≥440 / ≥45 ≥8 870-1,100 250 / 25.4 490.5/ 50.2 9.5

16 HL SCH23 0.20-0.60 ≤2.00 ≤2.00 28.0-32.0 18.0-22.0 ≥245 / 25 ≥450 ≥8 R/T-1,100 250 490.5 9.5

17 HL-W 030-0.35 0.5-0.8 1.0-1.5 29.0-31.0 19.0-21.0 1.25-1.75 ≤0.50 P & S ≤0.50 R/T-1,100

18 ISCH23 TAH919 0.25-0.35 1.0-1.5 1.0-1.5 29.0-31.0 19.0-21.0 1.25-1.75 ≤0.50 ≥235 / ≥24 ≥441 / ≥45 ≥8

19 HP SCH24 TAH27A 0.35-0.75 ≤2.00 ≤2.00 24.0-28.0 33.0-37.0 ≤0.50 ≥235 / ≥24 ≥440 / ≥45 ≥5 900-1,150 255 485 6.5 比重 7.86

20 Hi-Ka1B TAH18Y 0.35-0.45 ≤1.75 ≤1.50 23.0-26.0 20.0-23.0 ≤0.50 α ≥235 / ≥24 ≥441 / ≥45 ≥8

21 IN519 TAH19 0.20-0.40 ≤1.50 ≤1.50 22.0-25.0 23.0-27.0 ≤0.50 Nb+Tal.0-2.0 ≥235 / ≥24 ≥441 / ≥45 ≥10

22 HOM TAH22T 0.30-0.50 ≤2.50 ≤2.50 24.0-28.0 33.0-37.0 1.0-2.0 ≥196 / ≥20 ≥412 / ≥42 ≥6

23 HOM3 0.25-0.50 - - 24.0-27.0 44.0-47.0 2.5-4.0 2.5-4.0 2.5-4.0

24 IN600 G. TAH26C 0.20-0.40 ≤1.00 ≤2.00 18.0-22.0 65.0-69.0 ≤1.00 1.0-2.0 ≥235 / ≥24 ≥390 ≥5

25 TAH26K 0.20-0.40 ≤2.50 ≤2.00 15.0-19.0 64.0-68.0 1.0-2.0 ≥235 / ≥24 ≥441 / ≥45 ≥5

26 TAH28 ≤0.20 ≤1.50 ≤1.50 19.0-22.0 31.0-34.0 ≤0.50 Nb+Tal.0.8-1.5 ≥196 / ≥20 ≥441 / ≥45 ≥10

27 NA22H DHNA22H TAH32 0.40-0.60 ≤2.00 ≤2.00 25.0-29.0 45.0-50.0 4.00-6.00 ≤0.50 ≥196 / ≥20 ≥412 / ≥42 ≥6 1,100 210 425 8 TH921

28 Super Them TAH33 0.35-0.55 ≤2.00 ≤2.00 24.0-28.0 33.0-37.0 4.00-6.00 14.0-16.0 ≤0.50 ≥196 / ≥20 ≥412 / ≥42 ≥5 1,150

29 IN657 TAH34 ≤0.20 ≤0.20 ≤0.20 48.0-52.0 Bal. ≤0.50 Nb+Ta l.0-2.0 ≥235 / ≥24 ≥441 / ≥45 ≥8

30 HX DH65 0.35-0.75 ≤2.50 ≤2.00 15.0-19.0 64.0-68.0 ≥235 / ≥24 ≥441 / ≥45 ≥5 R/T-1,150

31 DHS2 KHRS2 0.35-0.45 ≤2.00 ≤2.00 24.0-27.0 22.0-25.0 1.80-2.30 14.00-18.00 ≥245 / ≥25 ≥490 / ≥50 ≥6 900-1,100

32 DH35C KHR35C 0.40-0.50 ≤1.50 ≤1.50 24.0-28.0 34.0-37.0 Nb 0.6-1.5 ≥225 / ≥23 ≥440 / ≥45 ≥6 900-1,100 比重 8.03

33 MO-RE1 DH35H 0.40-0.50 1.0-1.5 0.5-1.25 25.0-28.0 35.0-38.0 1.25-2.00 P & S ≤0.0.4 ≥245 / ≥25 ≥440 / ≥45 ≥8 / ≥6 900-1,100 35.7 47 6.4 比重 8.03

34 KHR35H 0.37-0.47 0.83-1.5 1.0-1.5 24.0-28.0 34.0-37.0 1.0-1.5 ≥245 / ≥25 ≥440 / ≥45 ≥8 / ≥6 900-1,100 35.5 63.8 8 比重 8.03

35 MO-RE1B DHM1B TAH37B 0.30-0.50 ≤2.00 ≤2.00 26.0-30.0 31.0-35.0 1.00-2.00 ≤0.50 ≥196 / ≥20 ≥412 / ≥42 ≥6 900-1,100

36 New MO-RE1B DHNM1B TAH37Y 0.30-0.50 ≤2.00 ≤2.00 26.0-30.0 31.0-35.0 1.00-2.00 ≤0.50 α ≥196 / ≥20 ≥412 / ≥42 ≥6

37 MO-RE2 DHSA KHRSA 0.40-0.50 ≤0.50 0.3-0.6 28.0-31.0 47.0-51.0 12.0-14.0 ≥295 / ≥30 ≥490 / ≥50 ≥3 1,050-1,200 比重 8.65

38 MO-RE2 DH48N2 TAH39 ≤0.30 ≤0.50 ≤0.50 32.0-36.0 ≥48.0 14.0-17.0 ≤0.50 ≥235 / ≥24 ≥490 / ≥50 ≥3 1,050-1,200 比重 8.65

39 SUPER22H DHS22H TAH38 0.30-0.50 ≤2.00 ≤2.00 26.0-30.0 46.0-50.0 4.00-6.00 2.00-4.00 ≤0.50 ≥196 / ≥20 ≥441 / ≥45 ≥6 1,050-1,200 比重 8.03

40 DH48N KHR48N 0.40-0.60 ≤1.50 ≤1.50 25.0-30.0 45.0-50.0 4.00-6.00 ≥295 / ≥30 ≥390 / ≥40 ≥5 900-1,200

41 DH37 0.40-0.50 ≤1.50 ≤1.50 25.0-28.0 35.0-38.0 1.25-2.00 ≥196 / ≥20 ≥412 / ≥42 ≥6 900-1,150

42 DH50 0.15-0.25 ≤0.50 0.3-0.6 32.0-40.0 48.0-52.0 15.0-17.0 ≥235 / ≥24 ≥490 / ≥50 ≥3 1,050-1,250

43 DH48WCO 0.40-0.60 ≤1.50 ≤1.50 26.0-30.0 46.0-50.0 4.00-6.00 2.50-4.00 ≥196 / ≥20 ≥441 / ≥45 ≥6 900-1,200

44 DH45A KHR45A 0.40-0.60 ≤2.00 ≤2.00 30.0-35.0 40.0-46.0 Nb+Tal.0.5-1.8 ≥235 / ≥24 ≥440 / ≥45 ≥3 900-1,200

45 UMCO40 DHCO40 ≤0.15 0.5-1.0 0.3-1.0 25.0-29.0 15.0-19.0 0.50-1.50 38.00-42.00 1,100-1,250

46 UMCO50 DHCO50 0.05-0.12 0.5-1.0 0.3-1.0 26.0-30.0 47.00-52.00 P&S:≥0.04 1,100-1,250

47 HiCrMn HiCrMn HiCrMn 0.35-0.45 ≤1.00 14.0-17.0 14.0-17.0 1.70-2.30 0.70-1.30 P&S:≥0.05 / ≥60 ≥6 HB ≥33

48 HiCr HiCr HiCr 2.70-3.50 ≤1.00 0.40-1.10 24.0-28.0 ≥15.0 P:≤0.15 1.0-3.0 S:≥0.04 / ≥60 Impact>0.3J/㎠ HS 75-80

49 SIC 3.1 0.55 0.58 25.2 0.67 - 0.8 ≥390 / Impact>2.5J/㎠ HS 75-80

50 KCP12 KCP12 0.20-0.40 0.40-0.60 0.70-1.00 0.40-0.60 1.00-1.40 - 0.30-0.60 V:≤0.1 85 / ≥105 / ≥5 HB ≥250

51 KCP15 KCP15 0.25-0.30 0.35-0.55 0.90-1.20 1.00-1.20 1.80-1.90 - 0.45-0.50 V:≤0.1 100 / ≥120 / ≥3 HB ≥300

52 SNA32B 0.35-0.45 0.30-0.60 1.20-1.60 0.80-1.20 - - - 0.20-0.40 100 / ≥105 / ≥8 HB ≥240

53 SUJ2 0.95-1.10 0.15-0.35 ≤0.50 1.30-1.60 - - P&S:≤0.025

54 SCS13 TAC42 ≤0.08 ≤2.00 ≤2.00 18.0-21.0 8.00-11.00 - P&S:≤0.040 185 / ≥440 / ≥35 HB ≥183

55 SCS14 ≤0.08 ≤2.00 ≤2.00 17.0-20.0 10.00-14.00 - 2.00-3.00 P&S:≤0.040 185 / ≥440 / ≥28 HB ≥183

56 SCS15 ≤0.08 ≤2.00 ≤2.00 17.0-20.0 10.00-14.00 Cu 1.0-2.5 1.75-2.75 P&S:≤0.040 189 / 19 ≥440 / ≥15 ≥28 HB ≥183

57 SCS22 ≤0.08 ≤2.00 ≤2.00 17.0-20.0 10.00-14.00 P&S:≤0.040 2.00-3.00 Nb+Ta l.0×C%≤ 1.35%이하 165 / 17 ≥390 / ≥40 ≥30 HB ≥183

You might also like

- Stainless steel composition guideDocument1 pageStainless steel composition guideHassan MostajabNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiamengineeringNo ratings yet

- Calitate EN - OTEL CARBON SI DE CALITATEDocument2 pagesCalitate EN - OTEL CARBON SI DE CALITATETudor SerbanNo ratings yet

- VSP Special Steels Wire Rod Coils and Rounds Product GuideDocument4 pagesVSP Special Steels Wire Rod Coils and Rounds Product GuideArijit MajumdarNo ratings yet

- Casting AlloysDocument2 pagesCasting Alloysgalvaosilva100% (1)

- Seal Kit DesignDocument7 pagesSeal Kit DesignAbbas Mohammed AbbasNo ratings yet

- Heat Resistant Alloy Chemical CompositionDocument2 pagesHeat Resistant Alloy Chemical Compositionsusisaravanan100% (1)

- Quadro Cargas - Distribuição GeralDocument5 pagesQuadro Cargas - Distribuição GeralAkillys FelipeNo ratings yet

- Lecture 8Document195 pagesLecture 8Nguyệtt HươnggNo ratings yet

- Kinetics of KIO3 dissolution rate vs timeDocument5 pagesKinetics of KIO3 dissolution rate vs timedafneNo ratings yet

- Varistor 2Document3 pagesVaristor 2dkelicNo ratings yet

- Sistema de Abastecimento de Água Rede MalhadaDocument5 pagesSistema de Abastecimento de Água Rede MalhadaMárcioNo ratings yet

- Material SpecDocument456 pagesMaterial SpecAyush Narang70% (10)

- GTP - Eff 2 Endura SeriesDocument24 pagesGTP - Eff 2 Endura SeriesNaveen GuptaNo ratings yet

- 7-Calculo de Caida TensionDocument3 pages7-Calculo de Caida TensionJC ZhambNo ratings yet

- Loop Pipe K Q 2 HF 2hf/qo HF 2hf/Q HFDocument2 pagesLoop Pipe K Q 2 HF 2hf/qo HF 2hf/Q HFGuillaume WoukouoNo ratings yet

- Logsheet Boiler 10-06-2023Document696 pagesLogsheet Boiler 10-06-2023GAMING ChannelNo ratings yet

- Folha3 Metodos Numericos Iterativos Equacoes de Estado Etano TabelasDocument4 pagesFolha3 Metodos Numericos Iterativos Equacoes de Estado Etano TabelasAna CarolinaNo ratings yet

- Ship stability and displacement data tableDocument5 pagesShip stability and displacement data tableAlex BarbanNo ratings yet

- Viscosity of c5h802 - 16Document1 pageViscosity of c5h802 - 16CharlesNo ratings yet

- San Ace 80 9R: General SpecificationsDocument3 pagesSan Ace 80 9R: General Specificationsİbrahim DemircioğluNo ratings yet

- San Ace 120gv25 eDocument4 pagesSan Ace 120gv25 eRodrigo GonçalvesNo ratings yet

- Ufo Led 200w 230vDocument13 pagesUfo Led 200w 230vDimay LedNo ratings yet

- #Kobelco Welding Hand BookDocument1 page#Kobelco Welding Hand BookIradahNo ratings yet

- Ufo Led 100w 230vDocument12 pagesUfo Led 100w 230vDimay Led100% (1)

- Low Cost Medium Power Surface Mount Inductors: Electrical / EnvironmentalDocument2 pagesLow Cost Medium Power Surface Mount Inductors: Electrical / EnvironmentalMorteza BaratzadehNo ratings yet

- 1.0SMB SeriesDocument6 pages1.0SMB SeriesPablo AllosiaNo ratings yet

- Rebel Band 100 Pro RGBW 5DDocument15 pagesRebel Band 100 Pro RGBW 5DNabil MounayerNo ratings yet

- High Torque Hybrid Stepping Motor Specifications: Electrical Specifications General SpecificationsDocument2 pagesHigh Torque Hybrid Stepping Motor Specifications: Electrical Specifications General SpecificationsRafael AlzateNo ratings yet

- San Ace 60A25 E-1283912 PDFDocument4 pagesSan Ace 60A25 E-1283912 PDFThi NguyễnNo ratings yet

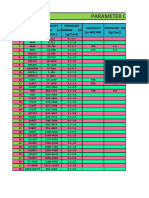

- Parameter CalculatorDocument6 pagesParameter CalculatorAnkit GuptaNo ratings yet

- P355GH boiler plate steel specsDocument1 pageP355GH boiler plate steel specsCommercial MarocNo ratings yet

- Sheet1: 1. Mencari Dew Point Temperature Dan Boiling Point TemperatureDocument19 pagesSheet1: 1. Mencari Dew Point Temperature Dan Boiling Point TemperatureJoel TeslaNo ratings yet

- ISO 9001 Certified Zener Diodes 1N746 to 1N759 400mW 3.3V to 12VDocument1 pageISO 9001 Certified Zener Diodes 1N746 to 1N759 400mW 3.3V to 12VAlejandro G SantosNo ratings yet

- Conductoare Neizolate Din Al: Po (KW) PSCC (KW)Document5 pagesConductoare Neizolate Din Al: Po (KW) PSCC (KW)Ciprian ApalaghițeiNo ratings yet

- Zeners 1N746A - 1N759A: Absolute Maximum RatingsDocument3 pagesZeners 1N746A - 1N759A: Absolute Maximum RatingsWalter António CumbucaneNo ratings yet

- BZX16Document3 pagesBZX16srikrishNo ratings yet

- Plates Steel MetalDocument12 pagesPlates Steel MetalAnonymous aWpx7nENo ratings yet

- Chemical Composition of Stainless Steels To BS EN 10088-2Document41 pagesChemical Composition of Stainless Steels To BS EN 10088-2amit_91340% (1)

- Din 17102 PDFDocument10 pagesDin 17102 PDFEvriMert RüzgArdaNo ratings yet

- PotensiometriDocument3 pagesPotensiometriAaron Thomas Kingsley IIINo ratings yet

- Hatz Dieselmotoren ES71 E785 Service Manual in German (Auf Deutsch)Document63 pagesHatz Dieselmotoren ES71 E785 Service Manual in German (Auf Deutsch)czwnkNo ratings yet

- Tehnicki - Podaci HATZ MotoriDocument4 pagesTehnicki - Podaci HATZ MotoriVikko TriNo ratings yet

- Diodo BZXDocument3 pagesDiodo BZXAndrey SilvaNo ratings yet

- PH-A280 Series: 50W To 300W, 200 To 425VDC Input DC-DC ConvertersDocument2 pagesPH-A280 Series: 50W To 300W, 200 To 425VDC Input DC-DC Converterskhanafzaal2576No ratings yet

- Inchang ElectronicsDocument5 pagesInchang ElectronicsVicenteAMartinezGNo ratings yet

- BS 3059-2Document11 pagesBS 3059-2abhiNo ratings yet

- Data Sheet For LED UFO High Bay Light: Philips SMD 100watt IP65 Mean Well Driver 125Lumen/WDocument12 pagesData Sheet For LED UFO High Bay Light: Philips SMD 100watt IP65 Mean Well Driver 125Lumen/WDimay LedNo ratings yet

- CoefficientDocument103 pagesCoefficientpanji uteNo ratings yet

- LM555/NE555: Single TimerDocument8 pagesLM555/NE555: Single TimerlancasaNo ratings yet

- Bzx83c SeriesDocument2 pagesBzx83c SeriesFefe BulNo ratings yet

- Viscosity of c5h802 - 22Document1 pageViscosity of c5h802 - 22CharlesNo ratings yet

- N-CH & P-CH MosfetsDocument1 pageN-CH & P-CH MosfetsscribddderNo ratings yet

- Viscosity of c5h802 - 21Document1 pageViscosity of c5h802 - 21CharlesNo ratings yet

- TPS Series: Low EsrDocument13 pagesTPS Series: Low EsrJoão Paulo Lucas BarbosaNo ratings yet

- Chemical Composition Raw Material Grade: Ref - No JSPL/ANGUL/TDC-003493C Rev. 1 Date of Issue 11/11/2022Document3 pagesChemical Composition Raw Material Grade: Ref - No JSPL/ANGUL/TDC-003493C Rev. 1 Date of Issue 11/11/2022MAHESH BELENo ratings yet

- Report 3Document3 pagesReport 3Jaafar KhalifeNo ratings yet

- 04Cr18Ni10 PDFDocument3 pages04Cr18Ni10 PDFAvishekNo ratings yet

- Katalog Komposisi Lengkap New VersionDocument8 pagesKatalog Komposisi Lengkap New VersionSontani PurnamaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Voa Learning English: A Dictionary of The Most Useful Words For Learning American EnglishDocument112 pagesVoa Learning English: A Dictionary of The Most Useful Words For Learning American EnglishDuy NguyenNo ratings yet

- PLC HandbookDocument83 pagesPLC HandbookmlcsdrNo ratings yet

- Project Manager Interview QuestionsDocument66 pagesProject Manager Interview QuestionsMahadeo100% (12)

- 1677153021241Document251 pages1677153021241Duy NguyenNo ratings yet

- Microsoft Modern Usb C Speaker ZwartDocument2 pagesMicrosoft Modern Usb C Speaker ZwartDuy NguyenNo ratings yet

- Bluetooth SpeakersDocument18 pagesBluetooth SpeakersPhil Nayebi100% (3)

- Confined Space Entry Permit - MCBCL FormDocument1 pageConfined Space Entry Permit - MCBCL FormVenkata Suresh MandavaNo ratings yet

- UPA Type Series BookletDocument122 pagesUPA Type Series BookletRicardo BarrosNo ratings yet

- Description and Operation: Unison Industries Component Maintenance Manual Ignition LeadsDocument2 pagesDescription and Operation: Unison Industries Component Maintenance Manual Ignition Leadsmaty englerNo ratings yet

- ACE Pilot User GuideDocument109 pagesACE Pilot User GuideEnrique Tejada FarfanNo ratings yet

- 6EP13322BA20 Datasheet enDocument4 pages6EP13322BA20 Datasheet enLucas Vinícius CostaNo ratings yet

- Limitations of RxQual and Advantages of SQIDocument2 pagesLimitations of RxQual and Advantages of SQIGaurav Chopra100% (3)

- Daily Forklift CheckDocument4 pagesDaily Forklift CheckSrimannarayana NandamNo ratings yet

- HMS Electrical Drawings - CAT PDFDocument19 pagesHMS Electrical Drawings - CAT PDFEdison BarrionuevoNo ratings yet

- Components of A LAN NetworkDocument8 pagesComponents of A LAN Networkranadip dasNo ratings yet

- 615 Series Quick Start Guide 757435 ENa. Relay ABBDocument4 pages615 Series Quick Start Guide 757435 ENa. Relay ABBTung NguyenNo ratings yet

- Vol-III - Sec-IV - Civil All Items ONGC Spec FenceDocument4 pagesVol-III - Sec-IV - Civil All Items ONGC Spec FenceKrm ChariNo ratings yet

- Apega Salary PDFDocument137 pagesApega Salary PDFharshdNo ratings yet

- 7.4 Emf and Internal Resistance 09Document11 pages7.4 Emf and Internal Resistance 09b_syiera100% (1)

- EPRI PMBD Gap Analysis TemplateDocument4 pagesEPRI PMBD Gap Analysis TemplatedanishaslNo ratings yet

- Four Laning Irc SP 84 2019Document3 pagesFour Laning Irc SP 84 2019Suyog Gore100% (2)

- Cranes Us ArmyDocument21 pagesCranes Us ArmyNancyNo ratings yet

- DS Ass IDocument2 pagesDS Ass Inalluri_08No ratings yet

- OpenStage Provisioning Interface Developer's GuideDocument182 pagesOpenStage Provisioning Interface Developer's GuideEstêvão Samuel Procópio AmaralNo ratings yet

- 9 Ray Optics and Optical Instruments: SolutionsDocument48 pages9 Ray Optics and Optical Instruments: SolutionsVISHAL SINGHNo ratings yet

- Microprocessor AND Microcontroller Practical Lab File: Name-Enrollment No. - Course/Branch - Btech/MaeDocument11 pagesMicroprocessor AND Microcontroller Practical Lab File: Name-Enrollment No. - Course/Branch - Btech/MaeShuktika SrivastavaNo ratings yet

- 1 Rate of ReactionDocument21 pages1 Rate of ReactionEila AriffinNo ratings yet

- DCB Disconnecting Circuit Breakers ABB Buyers and Application GuideDocument48 pagesDCB Disconnecting Circuit Breakers ABB Buyers and Application GuideAnu Sun100% (1)

- Nireesh Nagaraj: Astute It Business Executive - Vice PresidentDocument3 pagesNireesh Nagaraj: Astute It Business Executive - Vice PresidentUtpal GhoshNo ratings yet

- IIIE Student Project Reports Covering Quality, Lean, Automation & MoreDocument17 pagesIIIE Student Project Reports Covering Quality, Lean, Automation & MoreSwarup mishraNo ratings yet

- Project Engineer - Mechanical Design (CATIA - CREO) PDFDocument3 pagesProject Engineer - Mechanical Design (CATIA - CREO) PDFsubhrajit.omNo ratings yet

- Hydrogen AgeingDocument5 pagesHydrogen AgeingChaitanya ShakyaNo ratings yet

- Rotrex Technical Datasheet C30 RangeDocument7 pagesRotrex Technical Datasheet C30 RangeSidney RiveraNo ratings yet

- B.tech. Civil Engineering Full Syllabus IndiaDocument118 pagesB.tech. Civil Engineering Full Syllabus IndiaAnubhav GargNo ratings yet

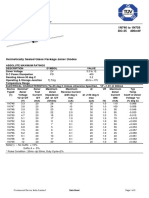

- En Iso 13919-1 - 1996Document9 pagesEn Iso 13919-1 - 1996MNo ratings yet