Professional Documents

Culture Documents

Ig Gabions May 2015

Uploaded by

LynxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ig Gabions May 2015

Uploaded by

LynxCopyright:

Available Formats

INSTALLATION GUIDE

Rev: 02, Issue Date May 2015

GABIONS

Reference

Please refer to full specifica on GALMAC 4.

Working at height - Refer to the Health and Safety provisions in Employ- Selvedge wire

ment Act 1992 regarding the need to take all prac cable steps to ensure

safety of workers. Further informa on of on how to prevent falls from

height can be obtained from the Department of Labour at

www.dol.govt.nz and Site Safe New Zealand at www.sitesafe.org.nz

Material Delivery

Gabions are manufactured with all components mechanically connected

during produc on. All gabions are supplied in the collapsed form, folded

and bundled. The bundles are compressed and strapped together at the

factory for easy shipping and handling. Lacing wire is shipped in coils. Ring

fasteners are shipped in boxes. Preformed bracing wires are shipped in

bundles.

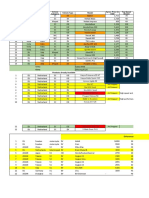

Assembly

Open and unfold each gabion on a flat, hard surface and remove any

shipping fold. The gabion boxes shall be assembled individually, by raising

the sides, ends and diaphragms, ensuring that all creases are in the cor-

rect posi on and that the tops of all four sides and the diaphragms are

even. (Fig 1)

Connect the back and the front panels of the gabion to the end panels and

center diaphragms. The top corner of the end panels and center

diaphragms have an extended selvedge wire extending approx. 0.1 m out

from the corner edge. Raise the end panels and the diaphragms to a

ver cal posi on and wrap the selvedge wire around the edge wire of the

top and back panels.

Connect the diaphragms by using either lacing wire or ring fasteners (Fig.2

and Fig.3). Ring fasteners shall not be spaced more than 150 mm apart. Figure 1

The procedure for using lacing wire consists of cu ng a sufficient length

of wire, and first looping and/or twis ng the lacing wire to the wire mesh.

Proceed to lace with alterna ng double and single loops through every

mesh opening approximately every 150 mm pulling each loop ght and

finally securing the end of the lacing wire to the wire mesh by looping

and/or twis ng. The assembly of mul ple gabion units via this procedure

is permi ed.

InstallaƟon and Filling

A er preparing the founda on, the pre-formed gabions are placed in their

150mm

proper loca on to form the structure. Before filling the units, all corners

MAX

should then be securely connected to the neighboring gabions using lac-

ing wire or ring fasteners and following the same procedure as described

for connec ng the diaphragms above.

The end from which work is to proceed, shall be secured either to the

completed work, or by rods or stakes driven into the ground. These

stakes must be secure and reach at least to the top of the gabion box.

Stretching of the gabion boxes shall be carried out using a pull-li of at

least one tonne capacity, firmly secured to the free end of the assembled

gabion boxes. Tension shall be released only when the gabions are fully Figure 2

laced and sufficiently full to prevent the mesh from slackening.

Rocks to be used for gabions shall be hard, angular to round, durable and Open Closed

of such quality that they shall not break down on exposure to water or

20mm

weathering during the life of the structure.

Gabion rocks shall range between 100mm and 200mm. A varia on of 5%

oversize and/or 5% undersize rock may be allowed, provided it is not

placed on the gabion exposed surface. In all cases, the 50mm

Figure 3

oversize rock shall not be larger than 250mm, and the undersize rock

shall not be less than 80mm.

When filling, manual rock placement is required to minimize voids.

1/3

The exposed faces may be carefully hand placed to give a neat, flat,

and compact appearance. The cells shall be filled in stages so that

1.00

local deforma on is avoided. At no me, shall any cell be filled to a 1/3

depth exceeding 0.3 m higher than the adjoining cell (Fig. 7).

1/3

Care should be taken when placing rocks to ensure that the wire

coa ng will not be damaged. Pre formed bracing wires shall be used 1/3 1/3 1/3

as indicated (Fig.5), fixed at 1/3 and 2/3 of the height for 1m deep

gabions to prevent distor on of the gabion units during filling and in

the completed structure. These bracing wires shall be wrapped

around two of the mesh wires and extend from front to back. Figure 5

When more than one layer of gabions is required, in order for the

individual units to become incorporated into one con nuous

structure, the next layer of gabions must be connected to the layer

underneath a er this layer has been securely closed. Placement Crow b ar Crowbar

should be front to front and back to back, so that pairs of facing lids

can be wired down in one process. .

Closing

To allow for se lement, level off the rock fill 20-30mm above the top

of the mesh. Be sure to keep the top edge of the diaphragm exposed.

Fold the lid down, pull the edges of the panels to be connected

where necessary using an appropriate tool such as a lid closer (Fig.4).

The lids shall be ghtly laced along all edges, ends and diaphragms in

the same manner as described for assembling (Fig.6). Adjacent lids

may be securely a ached simultaneuosly. All end wires should then

be turned in. Figure 6

Phase 1

1. Pliers

A

Phase 2

2. Pliers with

Nipper

1 2 3

Phase 3

Pneuma c

B Lacing

tool

Figure 7

C Bracing Wire

Figure 4

D Lid Closing

tool

Figure 8

The information contained in this brochure is general in nature. In particular the content of this brochure does not take account of specific conditions that

Geofabrics New Zealand Ltd may be present at your site. Site conditions may alter the performance and longevity of the product and in extreme cases may make the product wholly

unsuitable. Actual dimensions and performance may vary. If your project requires accuracy to a certain specified tolerance level you must advise us

14 Goodman Place, PO Box 12536, Penrose, Auckland, New Zealand before ordering the product from us. We can then advise whether the product will meet the required tolerances. Where provided, installation instructions

cover installation of product in site conditions that are conducive to its use and optimum performance. If you have any doubts as to the installation

T: (+64) 9 6436495 F: (+64) 9 634 6492, FREEPHONE 0800 60 60 20 instructions or their application to your site, please contact us for clarification before commencing installation. This brochure should not be used for

construction purposes and in all cases we recommend that advice be obtained from a suitably qualified consulting engineer or industry specialist before

E: sales@geofabrics.co.nz proceeding with installation. This brochure is current as at the date printed below. Geofabrics New Zealand Ltd may make amendments to this document

www.geofabrics.co.nz at any time. Please refer to our website, or contact our nearest sales office to ensure you have the most current version. © Copyright held by Geofabrics

New Zealand Ltd. All rights are reserved and no part of this publication may be copied without prior permission.

You might also like

- TerrameshInstallationGuideNZ 0Document2 pagesTerrameshInstallationGuideNZ 0Jorge RosalNo ratings yet

- Gabions Install GuideDocument2 pagesGabions Install GuideTele2 Phone2100% (1)

- RST Instruments: Inclinometer Casing Repair ManualDocument4 pagesRST Instruments: Inclinometer Casing Repair ManualOscarAnibalAbantoCondoriNo ratings yet

- Concrete Pipe Installation Guide-CPMDocument17 pagesConcrete Pipe Installation Guide-CPMSankar CdmNo ratings yet

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Ribbon Splice Tray Instructions: After Splice Is CompleteDocument2 pagesRibbon Splice Tray Instructions: After Splice Is CompletedavidNo ratings yet

- Premcote Wrapping Manual IFUDocument4 pagesPremcote Wrapping Manual IFUNamta GeorgeNo ratings yet

- Light CrimpDocument19 pagesLight CrimpAlejandro PerezNo ratings yet

- 15kV PM Joints - Straight - KSU - 500-500sq - MMDocument8 pages15kV PM Joints - Straight - KSU - 500-500sq - MMabd elmohsen saedNo ratings yet

- Yale Operation & Maintenance Rev1aDocument13 pagesYale Operation & Maintenance Rev1aAnonymous bHh1L1No ratings yet

- Gelcap Insulating Splice Cover For 600V CableDocument2 pagesGelcap Insulating Splice Cover For 600V CableHelar Armejo VasquezNo ratings yet

- Powerduct Installation ManualDocument32 pagesPowerduct Installation Manualhuyang1111No ratings yet

- Yale FIGURE 500 & 500R Closure Operation and Maintenance InstructionsDocument12 pagesYale FIGURE 500 & 500R Closure Operation and Maintenance InstructionsShane CharltonNo ratings yet

- Installation Guide: Corrugated RoofDocument2 pagesInstallation Guide: Corrugated Roofaussie ladNo ratings yet

- DODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualDocument4 pagesDODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualALFONSO FERNANDEZ MULETNo ratings yet

- Conector LC Light Crimp - ManualDocument8 pagesConector LC Light Crimp - ManualTirso W. RodríguezNo ratings yet

- Fi - SCST Multimode Singlemode Connector - II PDFDocument4 pagesFi - SCST Multimode Singlemode Connector - II PDFmirkofedorNo ratings yet

- BB5006 Coastboat BentDocument24 pagesBB5006 Coastboat BentMunteanuCNo ratings yet

- Simpull Cable-In-Conduit: Installation GuideDocument16 pagesSimpull Cable-In-Conduit: Installation Guidesantiago foriguaNo ratings yet

- Scotchcast Power Cable Tap Splice Kit 90-B1: InstructionsDocument8 pagesScotchcast Power Cable Tap Splice Kit 90-B1: InstructionsWanessa SuárezNo ratings yet

- Method Statement - Cable Joint LVDocument4 pagesMethod Statement - Cable Joint LVanuraj arackal60% (5)

- Slope ProtectionDocument3 pagesSlope Protectionshima2727No ratings yet

- MS For Installation of GRE PipingDocument9 pagesMS For Installation of GRE PipingN P Srinivasarao100% (2)

- IG de Reno Mattresses InstallationDocument2 pagesIG de Reno Mattresses InstallationSílvio GonçalvesNo ratings yet

- 2005 - 2009 Water Leak RepairsDocument5 pages2005 - 2009 Water Leak RepairsJuan CandiaNo ratings yet

- Chum Saf-Xt ManualDocument8 pagesChum Saf-Xt Manualingrojas_No ratings yet

- Gabions: Product Installation GuideDocument2 pagesGabions: Product Installation Guidesgm6911No ratings yet

- Penstock Installation ManualDocument10 pagesPenstock Installation ManualNicat MammadovNo ratings yet

- WCD Densopol Tapes - IfU 2020Document5 pagesWCD Densopol Tapes - IfU 2020Makamu Max Las MokgaoganyiNo ratings yet

- Index Marine Waterproof Gland Installation Guide 2 2Document4 pagesIndex Marine Waterproof Gland Installation Guide 2 2Cardon IulianNo ratings yet

- PDFDocument10 pagesPDFPaul HuaraychiriNo ratings yet

- NXS Series Cable Fitting GuideDocument10 pagesNXS Series Cable Fitting GuideFalsoNo ratings yet

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceNo ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- MOS - Cable InstallationDocument7 pagesMOS - Cable InstallationAzree Mohd NoorNo ratings yet

- PW-552TBL Part List CartonsealerDocument52 pagesPW-552TBL Part List CartonsealerTeguh HariyadiNo ratings yet

- Manual Propeller Shaft Earthing System Althen SensorsDocument12 pagesManual Propeller Shaft Earthing System Althen SensorsAndrewNo ratings yet

- Baier Rail Single Bolt Manway IMO ManualDocument12 pagesBaier Rail Single Bolt Manway IMO ManualFelipe OliveiraNo ratings yet

- Cyprus Shower Floor InstructionsDocument8 pagesCyprus Shower Floor InstructionsJamie CampbellNo ratings yet

- Sliding Door Installation InstructionsDocument2 pagesSliding Door Installation InstructionsJaseSG1No ratings yet

- Installation Instruction Heashrink Joint To Suit 3 Core 33Kv Polymeric Cable Type Spaj 36XDocument6 pagesInstallation Instruction Heashrink Joint To Suit 3 Core 33Kv Polymeric Cable Type Spaj 36XJaaffer AliNo ratings yet

- 2080velocity Duct Gasket Installation Instruction - SEMCO 2016-11Document2 pages2080velocity Duct Gasket Installation Instruction - SEMCO 2016-11Bülent KabadayiNo ratings yet

- Hose AssemblyDocument1 pageHose AssemblyScott SepperNo ratings yet

- Mike Humphreys TutorialDocument49 pagesMike Humphreys Tutorialtonytravel100% (1)

- Standard TorqueDocument12 pagesStandard TorqueEDY AZHARINo ratings yet

- Anleitung GgvenglishDocument10 pagesAnleitung GgvenglishAdnan HalilovicNo ratings yet

- Conax MHM Series Assembly InstructionsDocument4 pagesConax MHM Series Assembly InstructionsColin ZhangNo ratings yet

- Method Statement For HV Cables Laying at Multi Storey Car Park Building at BWTC ComplexDocument9 pagesMethod Statement For HV Cables Laying at Multi Storey Car Park Building at BWTC Complexfibin haneefaNo ratings yet

- 8 - Banding Tool (Operating Instruction)Document8 pages8 - Banding Tool (Operating Instruction)Luis Enrique La Font FrancoNo ratings yet

- Sky Pod InstallDocument12 pagesSky Pod InstalldisasterdazNo ratings yet

- Terramesh Install Guide PDFDocument2 pagesTerramesh Install Guide PDFJorge RosalNo ratings yet

- Bidim Storage Installation Guide M142Document6 pagesBidim Storage Installation Guide M142rolandchalfounNo ratings yet

- VDO Fuel Level Sender - Install. Instruct. (220.003, 220.004, 220.005)Document2 pagesVDO Fuel Level Sender - Install. Instruct. (220.003, 220.004, 220.005)Anonymous vqsuRyNo ratings yet

- MFS Installation Instructions35aDocument12 pagesMFS Installation Instructions35a7bqbrvxk5yNo ratings yet

- 800 - 800w - 855 - g2-800 - Handrails - INSTALL V2Document6 pages800 - 800w - 855 - g2-800 - Handrails - INSTALL V2engelboghdady86No ratings yet

- Digitilt Horizontal Probe Manual 2006Document17 pagesDigitilt Horizontal Probe Manual 2006Mahesh JalluNo ratings yet

- Volvo D16-500V - 2050-Xe PDFDocument2 pagesVolvo D16-500V - 2050-Xe PDFDIONYBLINK100% (1)

- Hino E13C Engine Workshop Manual II PDFDocument272 pagesHino E13C Engine Workshop Manual II PDFThiha Aung89% (28)

- U1262 - SCP (J1850) Communication Bus Fault: What Does Code U1262 Mean?Document12 pagesU1262 - SCP (J1850) Communication Bus Fault: What Does Code U1262 Mean?jj bfNo ratings yet

- Catalog Big Capacity AHU DX DuctedDocument28 pagesCatalog Big Capacity AHU DX DuctedBistok ManurungNo ratings yet

- Test Report For LV PanelDocument8 pagesTest Report For LV PanelJayaprakash M PNo ratings yet

- Saki BF Frontier IIDocument2 pagesSaki BF Frontier IIPraveen SainiNo ratings yet

- Technology in Action Complete 9th Edition Evans Test BankDocument20 pagesTechnology in Action Complete 9th Edition Evans Test BankMrsKellyHammondqrejw100% (11)

- Electronic Wiring Diagram Zafira MY 2001 PDFDocument315 pagesElectronic Wiring Diagram Zafira MY 2001 PDFAdrian Chippendale100% (1)

- Fabrication of Bladeless Wind Turbine-1Document10 pagesFabrication of Bladeless Wind Turbine-1SHAJAKHAN RNo ratings yet

- DoorGuard Command CNTRL ProgDocument4 pagesDoorGuard Command CNTRL ProgtbmullinsNo ratings yet

- WF Catalogue TRITECH 50 Triaxia Load FrameDocument6 pagesWF Catalogue TRITECH 50 Triaxia Load FrameYaredNo ratings yet

- Lit 11616 06 16Document319 pagesLit 11616 06 16dcapito4017100% (1)

- Hand Tool TrainingDocument7 pagesHand Tool TrainingtuNo ratings yet

- Sinclair Um Wired Controller Chillers KJRM 120d enDocument22 pagesSinclair Um Wired Controller Chillers KJRM 120d enManuel Jesus Carrasco MaturanaNo ratings yet

- Disconnect SwitchesDocument27 pagesDisconnect SwitchesDE VERA, KENNETH GABRIEL D.No ratings yet

- Bench-Marking Vehicles To Purchase From Global MarketsDocument76 pagesBench-Marking Vehicles To Purchase From Global Marketsamber hasanNo ratings yet

- Herion Poppets PDFDocument20 pagesHerion Poppets PDFhamzaNo ratings yet

- Tiltable Nitrogen and Oxygen CartsDocument2 pagesTiltable Nitrogen and Oxygen CartsAlejandro GómezNo ratings yet

- IEEE STD ANSI-IEEE STD 668-1987Document24 pagesIEEE STD ANSI-IEEE STD 668-1987abdou samiNo ratings yet

- Section 3: Wellhead Control, Test and Injection UnitsDocument34 pagesSection 3: Wellhead Control, Test and Injection UnitsOvRrj Ahmed100% (3)

- Turolla Hydraulic Gear Pumps Group2 Catalogue en l1016341Document44 pagesTurolla Hydraulic Gear Pumps Group2 Catalogue en l1016341Даниил СторчеусNo ratings yet

- Nissan RH10 - Service Manual Free Download, Schemat PDFDocument3 pagesNissan RH10 - Service Manual Free Download, Schemat PDFHungaga100% (8)

- Nissan ElectricoDocument194 pagesNissan ElectricoGustavo Belgrano100% (3)

- Caixas de Merchas Euro V PDFDocument24 pagesCaixas de Merchas Euro V PDFJorge Alberto100% (1)

- Testing and Commissioning Procedure No 4 Lift Escalator Passenger ConveyorDocument50 pagesTesting and Commissioning Procedure No 4 Lift Escalator Passenger ConveyorknsbNo ratings yet

- E560 CSR01 DB PDFDocument2 pagesE560 CSR01 DB PDFOleg UskovNo ratings yet

- LA SpecificationDocument3 pagesLA SpecificationVino VinoNo ratings yet

- MB Manual Ga-g31m-Es2l (Es2c) v2Document84 pagesMB Manual Ga-g31m-Es2l (Es2c) v2maraniko100% (1)

- MK8 SVMOD 0002 - PeripheralsDocument48 pagesMK8 SVMOD 0002 - Peripheralswillian eduardo santiago cardenasNo ratings yet

- 793D MantenimientoDocument86 pages793D MantenimientoOscar Coaquira Feliciano100% (1)