Professional Documents

Culture Documents

Bomba Inyectora

Bomba Inyectora

Uploaded by

np0 ratings0% found this document useful (0 votes)

14 views7 pagesOriginal Title

BOMBA INYECTORA

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views7 pagesBomba Inyectora

Bomba Inyectora

Uploaded by

npCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

Section 24

Page 14 1098 Service Training

2.4.1.9 INJECTION PUMP

24. 1 REMOVALANDINSTALLATION OF THEINJECTION PUMP, VERSION WITH SETSCREW

‘TIMING

Two different types of series DP 200 fuel injection pumps are installed in engines types 903.27 and

903.27 HR. One type is provided with setscrew timing, the other with pin timing. The following assembly

instructions take this fact into consideration.

REMOVAL OF THE INJECTION PUMP

- Set the crankshaft to the TOC of cylinder 1 (valves

closed), and use the blocking drift (1) Part No.

000 008 61 00 to secure it against twisting.

- Loosen grub screw (1) of the injection pump by

approx. ¥turn.

~ Slide the locking plate (2) so thatit contacts the larger

recess on the screw head.

- Tighten the grub screw. This will block the injection

pump shaft.

- Dismount all fuel lines on the pump.

- Pull off the electrical connecting cables from the

shut-off valve and cold start injection advance.

- Separate the speed control linkage.

- Remove the cover for the drive wheel of the injection

pump at the timing case cover.

- Unscrew the driveshaft nutof the injection pump and

remove the snap ring.

- Unscrew the hexagon nuts ofthe pump flangeand the

rear pump bracket on the engine cylinder block.

- Loosen the injection pump from the pump shaft with

extractor WM 146.

- Remove the pump and make sure that the wedge (4)

does not slip off the shaft.

Service Training

Section 21

15/22

10.98 Page 15

INSTALLATION OF THE INJECTION PUMP

- Set the crankshaft to the TDC of cylinder 1 and

secure it against twisting with the blocking drift

- Eveninits as-supplied condition, the injection pump

is blocked in start of delivery cylinder 4 status.

- Insert the injection pump into the engine cylinder

block

- Look out for the wedge (4) and the O-ring (3).

- Mount the snap ring and the hexagon nut on to the

drive shaft. Tighten the nut with 80 Nm.

- Tum the pump in direction of the engine cylinder

block in order to eliminate the side play. The three

retaining nuts must be tightened in this position.

- Check the tightening torque of the drive shaft nuts

again and mount the end cover.

- Mount the rear pump bracket.

- Loosen the pump block and the locking plate back

into position. The loosened drive shaft corresponds

to the smaller elongated hole in the locking plate.

- Remove the blocking drift of the crankshaft.

- Mount the fuel lines.

~ Attach the throttle linkage.

- Connect the electrical connecting cables.

NOTE: Ifthe setscrew was loosened inadvert-

ently after the removal of the pump or a

new pump was delivered without the

pump shaft fixed in place, adjust the

fixing angle as described below.

Section 24

Page 16 1088 Service Training

CHECKING THE FIXING ANGLE FOR THE INJECTION PUMP SETTING

Required special tools:

Universal adjusting device MS.67B

Intermediate gear PD.67-3

CAUTION: Thefollowinginstructions shouldbe

followed closely if:

- the engine performance is poor,

~ the setscrew forthe injection pump

shaftwas loosened afterremoval of

the fuel injection pump from the

engine.

NOTE: —Thecodeletters for fuel injectionpumps

used on 900 series engines are AN or

BN.

- Remove the fuel injection pump.

CAUTION: Ifthe pump is clamped in a vice, do

not exert any pressure on the alu-

minium parts.

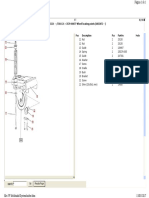

- Securely clamp the pumpin a vice. Install the interme-

diate gear PD.67-3 (1) for the universal adjusting

device MS.6713 (5) on the injection pump shaft.

Fasten the intermediate gear with the nut for the

injection pump gear; tighten the nut with the fingers

only.

- Loosen the setscrew (2) on the universal adjusting

device andset the adjusting device for pumps with the

code letters AN to 89°, for pumps with the code letters

BN to 88°. Retighten the setscrew on the universal

adjusting device. These angles are called the fixing

angles.

- Install the adjusting device and spacer (4) on the

intermediate gear located on theinjection pump shaft.

Section 24

Service Training oe owe

- Loosen the setscrew (6) on the adjusting device and

move the pointer (3) forward until its front edge is

located over the centre of the injection pump flange;

then retighten the setscrew. Check that the adjust-

ment mark on the flange is in the centre of the notch

on the pointer.

- Ifthe adjustment mark position isnot correct, remove

the adjusting device and the intermediate gear. Take

the pump to your nearest Perkins dealer and have it

checked. Ifthe adjustment mark isin the centre of the

notch on the pointer, remove theadjusting device and

the intermediate gear from the pump.

~ Install the fuel injection pump.

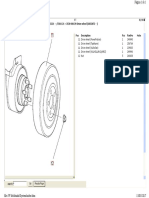

2.1.1.9.2 FUELINJECTION PUMPS WITH PIN TIMING

Fuel injection pumps with a timing pin (1) meet the

emission control requirements and are provided with

untamperable adjusting screws.

This pump type has a drilled hole in the injection pump

flange through which a timing pin (1) is inserted to hold (4)

the injection pump shaftin adefined position relative to

thepumphousing. On this pumptypethe injection pump

shaftisalsofixed with a setscrew (4). Itisimportantthat

the setscrew is loosened and the pump shaft can turn

when the pumpisinstalled in the engine. An electrically

operated cold startinjection advance (3), which retards

the start of injection for normal operation, and a cut-off

magnet (2) are installed in the pump. The pumpisself-

priming.

Section 24

Page 8 1098 Service Training

REMOVING THE FUEL INJECTION PUMP

Required special tools

Timing pin for pump 276 10.033

Blocking drift for crankshaft 000 008 61 00

Torx bit 276 10 122

~ Bring the crankshaft to TDC of the number 1 cylinder

(valves closed) and prevent it from turning with a

blocking drift (1), Part No. 000 008 6100.

~ Remove all fuel lines at the pump.

- Disconnect the electriccablesat the shutoff valve and

cald start injection advance.

- Detach the throttle linkage.

- Remove the injection pump gear cover.

CAUTION: Insert a lint-free cloth between the

front side of the injection pump gear

and timing case to ensure that the

screws (5)used for fastening the gear

tothe pumphub cannotdropintothe

timing case. If this happens, the tim-

ing case must be removed.

~ Slide the timing pin (7) through the injection pump gear

and pump hub into the cutout in the pump housing.

This is done to check that the piston of the number 1

cylinder is at TDC of the compression stroke.

- Remove the four screws (5) and take the injection

pump gear off the pump hub.

- Unscrew the nuts (4) securing the injection pump

flange and withdraw the pump andtiming pin from the

injection pump gear.

Service Training

Section 24

10.98 Page 92219

INSTALLING THE FUEL INJECTION PUMP.

CAUTION:

Before the installation of the injection

pump inthe engine, set the piston of

the number 1 cylinder to TDC of the

compression stroke. Ifthe crankshaft

must be rotated, the pump must be

installed temporarily, otherwise the

loose injection pump gear could dam-

age the timing case.

The pump shaft may not be turned

without the spacer (1) being installed

under the setscrew (2). Turning the

pump shaftwith the setscrewtighton

the shaft will damage the shaft.

The spacer (1) must be installed un-

derneath the setscrew (2) before the

installation of the injection pump so

that the pump shaft can rotate.

- Check the O-ring (5) on the pump flange and, if

required, renewit. Apply a thin film of clean engine oil

to the O-ring

~ Insert the 8 mm timing pin (4) through the drilled hole

in the pump hub into the recess in the pump housing.

= Place the pump on the three timing case studs and

make sure that the timing pin is inserted in the slot in

the injection pump gear. Press the pump fully against

the timing case. Screw the injection pump flange nuts

(3) completely against the rear of the timing case.

~ Install the screw and nut for the mounting bracket.

Ensure that the mounting bracket does not exert any

force on the pump during the installation.

- Tighten the injection pump flange nuts (3) to a torque

of 22 Nm (2.2 kgf m).

CAUTION:

Do not remove the nut (7) on the

injection pump shaft. The injection

pump hub is mounted on the injec-

tion pump shaft inthe factory sothat

the pumpcan beadjusted correctlyin

relation to the engine. If the hul

removed, it must be reinstalled by a

Perkins dealer who has the special

equipment required for this work.

Section 24

Pege 20 10.98 Service Training

~ Position the injection pump gearso thatitcontacts the

pump hub. Screw the screws (6) through the slots in

the injection pump gear into the pump hub,

- Exert pressure on the injection pump gear in a anti-

clockwise direction to take up any backlash.

Fully tighten the screws to 28 Nm (2.9 kgf m). With-

draw the timing pin (4) and refit the injection pump gear

cover on the timing case cover.

~ Pull the blocking drift out of the flywheel.

2.1.1.10 EXPLANATION OF COLD START ADVANCE (CSA)

The Lucas injection pump possesses a starting aid

device (CSA) which advances the fuel injection timing

inorder to prevent the formation of white smoke, and to

enable a better starting procedure. This device is

electrically activated and works with a wax-flled ex-

pansion element

With a cold engine and a cooling water temperature of

less than 50 °C, the fuel injection timing is 11° BTDC.

As soon as the engine reaches its normal operating

temperature, a sensor in the cooling water circulation

of the cylinder head releases a voltage of 12 V. This

causes awax-filled element to be heated, and theearly

setting from 11° to 4° is cancelled again

2.1.4.11 FUEL SUPPLY PUMP

REMOVAL

~ Disconnect the fuel lines at the fuel supply pump.

- Loosen the four fastening screws (3), and remove

the fuel supply pump with both retaining plates. In

some cases, removing the fuel supply pump is

problematic. In such cases, tum the crankshatt until

the camshaft eccentric cam releases the drive lever

of the supply pump

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Partslist Avant500Series 260302Document52 pagesPartslist Avant500Series 260302npNo ratings yet

- 3530-00139 Drive Wheel (6032072 - )Document1 page3530-00139 Drive Wheel (6032072 - )npNo ratings yet

- 3570-00077 Wheel Locating Points (6032072 - )Document1 page3570-00077 Wheel Locating Points (6032072 - )npNo ratings yet

- 3580-00063 Guide Rollers Wheels (6053221 - )Document1 page3580-00063 Guide Rollers Wheels (6053221 - )npNo ratings yet

- 0390-00483 Battery Compartment Parts - LARGE (6053221 - )Document1 page0390-00483 Battery Compartment Parts - LARGE (6053221 - )npNo ratings yet

- 0390-00482 Battery Compartment Parts - MEDIUM (6053221 - )Document1 page0390-00482 Battery Compartment Parts - MEDIUM (6053221 - )npNo ratings yet

- 0390-00475 Battery Compartment Parts - LARGE (6053221 - )Document1 page0390-00475 Battery Compartment Parts - LARGE (6053221 - )npNo ratings yet

- 4110-00512 Steering Armwheellever (6032072 - ) 2Document1 page4110-00512 Steering Armwheellever (6032072 - ) 2npNo ratings yet

- 0340-00648 Inspection Covers (6032072 - )Document1 page0340-00648 Inspection Covers (6032072 - )npNo ratings yet

- 0380-00745 Fork Frame (Low Lifters) - e 180 MM (6053221 - )Document1 page0380-00745 Fork Frame (Low Lifters) - e 180 MM (6053221 - )npNo ratings yet

- 01Document31 pages01npNo ratings yet

- 447Document2 pages447npNo ratings yet

- Mesa de La EmtDocument6 pagesMesa de La EmtnpNo ratings yet

- LDC6 400 L16Document2 pagesLDC6 400 L16npNo ratings yet

- 448Document5 pages448npNo ratings yet

- Ebm Papst S4E315AC0807-1879477Document6 pagesEbm Papst S4E315AC0807-1879477npNo ratings yet

- LDC6 275Document2 pagesLDC6 275npNo ratings yet

- 4820472914839-Tiller 1133Document2 pages4820472914839-Tiller 1133npNo ratings yet

- Dokumen - Tips - Toyota BT C3e150r Forklift Service Repair Manual 1623177478Document22 pagesDokumen - Tips - Toyota BT C3e150r Forklift Service Repair Manual 1623177478npNo ratings yet