Professional Documents

Culture Documents

SP-50 GB

Uploaded by

jógvan NónOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SP-50 GB

Uploaded by

jógvan NónCopyright:

Available Formats

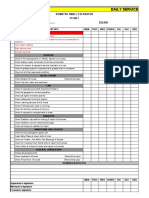

VOLVO CONSTRUCTION EQUIPMENT

Service Programme

ECR50D

Machine Model Serial No. Operating hours

SERVICE PROGRAMME

Delivery Date page

1(3)

Owner Date Dealer Sign

Foreword

The Service Programme is a checklist of all scheduled

maintenance intervals for a specific range of models under normal

operating conditions. The scheduled maintenance intervals must

be performed as specified in order to maintain the machine for

maximum reliability and performance.

For any factory warranty to be valid, the machine has to be

maintained according to this Service Programme. The completed

Service Programmes must be kept on file.

Some service steps may be performed by an operator unless

otherwise specified in the Operator's Manual. All other service

steps must be performed by a qualified service technician.

All service steps listed in the "First" and "Additional intervals"

columns must be performed in addition to the "Standard

intervals".

Service steps with varying intervals are marked with *. Further

information can be found in the Service Manual.

NOTE!

Read and understand the safety instructions in the Operator's

Manual and Service Information for the machine.

OPERATING HOURS / First Standard intervals, every (10 hours = Daily) Additional

INTERVAL intervals,

every

50 10 50 250 500 1000 1500 2000 3000 6000

Test-run and check

The machine, check for external

damages, cracks and wear

damages

Engine, oil level, check

Coolant, level, check

Hydraulic oil level, check

Fan belt, checking

Water separator, check

Thumb pivot pin, lubricate

Lubrication, see lubrication chart

Track tension, checking

Ref no: PUB Edition-C English

2019.07

Volvo Construction Equipment

Please send comments about the Service Programme to sp@volvo.com

VOLVO CONSTRUCTION EQUIPMENT

SERVICE PROGRAMME

Machine Model Serial No. Operating hours Delivery Date page

2(3)

OPERATING HOURS / First Standard intervals, every (10 hours = Daily) Additional

INTERVAL intervals,

every

50 10 50 250 500 1000 1500 2000 3000 6000

Track gearbox oil level, check

Hydraulic oil filter, changing

Change after first 50 hours, then

after every 500 hours

Fan belt and belt tension, check

Engine, changing oil and

replacing filter*

Water separator, cleaning

Fuel filter, change

Replace it at least once a year

Engine radiator and hydraulic oil

cooler, check (clean when

necessary)

Leakage oil filter, filter element

replace

Hydraulic pressure, checking

Air cleaner primary filter, change

every year or when warning light

illuminates

Valves, adjusting

Track gearbox oil, change

Cab main filter, replacing

Hydraulic oil tank, oil, change

Radiator hoses, checking

Fuel hoses, checking

Exhaust manifold, checking

Air intake hose, checking

Unit injectors, checking

Air cleaner secondary filter,

change

every third time Primary filter is

replaced or every 2 year.

Coolant freezing point, checking

Injection pump, checking

Injection timing, checking

Coolant, changing

At least every 4th year.

Service history (included in the

respective Operator's manual), fill

in.

VOLVO CONSTRUCTION EQUIPMENT

SERVICE PROGRAMME

Machine Model Serial No. Operating hours Delivery Date page

3(3)

You might also like

- Chapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, ChemistryDocument9 pagesChapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, Chemistrypumeananda100% (3)

- Volvo General Service ManualDocument84 pagesVolvo General Service ManualPrashant Varma100% (6)

- JCB VM115 Single Drum RollerDocument9 pagesJCB VM115 Single Drum Roller江柄宏100% (1)

- Isuzu Commercial Truck of America: Warranty Labor Time GuideDocument174 pagesIsuzu Commercial Truck of America: Warranty Labor Time GuideJustin Eggleston100% (3)

- O&M BC 772 RB-2 101570581130... 00806141.k10 EngDocument156 pagesO&M BC 772 RB-2 101570581130... 00806141.k10 Engcarlos serna100% (1)

- DPL MDDocument3 pagesDPL MDCoy IngramNo ratings yet

- Service Programme: Volvo Construction EquipmentDocument4 pagesService Programme: Volvo Construction Equipmentp_jankoNo ratings yet

- BL 71 BDocument5 pagesBL 71 BSmolovic SrdjanNo ratings yet

- Manual de Taller Tractor l4100Document120 pagesManual de Taller Tractor l4100Jorge Puentes SeoaneNo ratings yet

- MODEL 525 (SERIALS - 0001 THRU - 0684 AND - 0686 THRU - 0799) : Inspection Document 17Document1 pageMODEL 525 (SERIALS - 0001 THRU - 0684 AND - 0686 THRU - 0799) : Inspection Document 17Pilar-Jose Luis Sanchez-GarciaNo ratings yet

- DSRDocument2 pagesDSRJosé Carlos CarvalhoNo ratings yet

- (MITSUBISHI) Manual de Taller Mitsubishi L 200 1996 (0001-0500) PDFDocument500 pages(MITSUBISHI) Manual de Taller Mitsubishi L 200 1996 (0001-0500) PDFDaniel Reconco88% (8)

- Eng GB SP A60h Stage IV V DDocument8 pagesEng GB SP A60h Stage IV V DYudha SetiawanNo ratings yet

- Fire Suppression System PDFDocument2 pagesFire Suppression System PDFBurik8No ratings yet

- Eng GB SP SD110 BSIII - FDocument4 pagesEng GB SP SD110 BSIII - FImam MuhhudaNo ratings yet

- Fork Lift MaintenanceDocument7 pagesFork Lift Maintenancedanide.musicNo ratings yet

- 02 - MaintInspecForm - Booms HartDocument5 pages02 - MaintInspecForm - Booms HartOtto PlataformasNo ratings yet

- Kubota Richtzeiten 07-E3B SERIE (9Y112-00282)Document49 pagesKubota Richtzeiten 07-E3B SERIE (9Y112-00282)Henri KujalaNo ratings yet

- Manual de Taller V3600T Motosoldadora LinconDocument48 pagesManual de Taller V3600T Motosoldadora LinconCarlos100% (1)

- 02 MaintInspecForm ScissorsDocument4 pages02 MaintInspecForm ScissorsWilliam RodriguezNo ratings yet

- 02 MaintInspecForm BoomsDocument5 pages02 MaintInspecForm BoomsImam AffandyNo ratings yet

- Treatment Plant PresentationDocument103 pagesTreatment Plant Presentationgamini ranaweeraNo ratings yet

- Excerpt KD62V12 Engine Operation Manual - Maintenance Intervals Standby Power ESPDocument9 pagesExcerpt KD62V12 Engine Operation Manual - Maintenance Intervals Standby Power ESPspamnest2No ratings yet

- Eng GB CI InspReport ART - ADocument5 pagesEng GB CI InspReport ART - AAwanNo ratings yet

- PMChecklist ReportDocument2 pagesPMChecklist ReportVicente Nicolás Orrego TiradoNo ratings yet

- The Atlas Copco Divisions: Construction and Mining Technique Compressor Technique Industrial Technique Rental ServiceDocument22 pagesThe Atlas Copco Divisions: Construction and Mining Technique Compressor Technique Industrial Technique Rental ServiceSheel JhaNo ratings yet

- Tractor: TracteurDocument118 pagesTractor: TracteuryogismNo ratings yet

- Livret GBDocument16 pagesLivret GBилья100% (1)

- Volvo Standard Time Guide (VSTG), Foreword and Introduction: Volvo Car Corporation / Dealership DevelopmentDocument27 pagesVolvo Standard Time Guide (VSTG), Foreword and Introduction: Volvo Car Corporation / Dealership DevelopmentpngchanhNo ratings yet

- 2935 0144 20 Overhaul - Service - en - 150ppi - SCREENDocument2 pages2935 0144 20 Overhaul - Service - en - 150ppi - SCREENSalim DoumbiaNo ratings yet

- Mitsubishi l200 1996 Mitsubishi enDocument1,723 pagesMitsubishi l200 1996 Mitsubishi enMaksym Shevchenko100% (4)

- Maintenance EquipmentsDocument9 pagesMaintenance EquipmentsSuneed SkNo ratings yet

- Supplement 1990 ChassisDocument358 pagesSupplement 1990 Chassisalexandremartins.getNo ratings yet

- Chery Sqr7080R Service Manual: Chery Automobile Co., LTDDocument57 pagesChery Sqr7080R Service Manual: Chery Automobile Co., LTDUmar ShamsudinNo ratings yet

- Twin Air XRV946 - XRV2000Document198 pagesTwin Air XRV946 - XRV2000w_ibisonogNo ratings yet

- R924 G5.0-D IIIA 1444-1445 42836 2020-02-03 enDocument300 pagesR924 G5.0-D IIIA 1444-1445 42836 2020-02-03 enП' Апиэ100% (1)

- PS 3 Generac O&M WW-Sección 4 MantenimientoDocument15 pagesPS 3 Generac O&M WW-Sección 4 MantenimientoRobertNo ratings yet

- E55 60Hz OMM Parts ManualDocument82 pagesE55 60Hz OMM Parts Manualdonono0% (1)

- Informe Inspc Genie TijeraDocument4 pagesInforme Inspc Genie Tijeraanmec20No ratings yet

- BAM User ManualDocument66 pagesBAM User ManualTonyNo ratings yet

- 3090 KubotatDocument119 pages3090 KubotatArie GolfNo ratings yet

- Serviceflyer en Wema Final 2017 KomprDocument16 pagesServiceflyer en Wema Final 2017 KomprGM- MAANo ratings yet

- Operating and Maintenance InstructionsDocument24 pagesOperating and Maintenance Instructionsgermain pinedaNo ratings yet

- Importance of Maintenance ManagementDocument38 pagesImportance of Maintenance ManagementMeon Parvez100% (1)

- Daily Service: Komatsu Small ExcavatorDocument9 pagesDaily Service: Komatsu Small ExcavatorHebert SozinyuNo ratings yet

- SM103 - SN - Preventive Maintenance For Synchronous Motors and Generators en RevB - LowresDocument2 pagesSM103 - SN - Preventive Maintenance For Synchronous Motors and Generators en RevB - LowresArindam SamantaNo ratings yet

- 00 GะัเะะENERALDocument92 pages00 GะัเะะENERALBank 1991No ratings yet

- Labor Time Guide: Section IndexDocument124 pagesLabor Time Guide: Section IndexQuay Finefrock80% (5)

- 02 MaintInspecForm TelehandlersDocument3 pages02 MaintInspecForm TelehandlersLeobardo Genaro Roque NájeraNo ratings yet

- SPERREDocument6 pagesSPERRESalman KapoorNo ratings yet

- Atlas Copco HiLight Light TowersDocument12 pagesAtlas Copco HiLight Light TowersAlexeiv TRD0% (1)

- Delivery Report Form BreakerDocument1 pageDelivery Report Form BreakerAkbarNo ratings yet

- Complete Fleet Maintenance Programs 20 05Document2 pagesComplete Fleet Maintenance Programs 20 05Franco MaderaNo ratings yet

- Liebherr R924Document339 pagesLiebherr R924Denys PechenyiNo ratings yet

- Detroit Diesel: Series I900Document53 pagesDetroit Diesel: Series I900Jose SantosNo ratings yet

- SGT 750Document5 pagesSGT 750rudiyanarefaceNo ratings yet

- SB 160 COS 131 Ver 1 SD110 Lubricant Specifications and Service Interval Changes - 20210113Document1 pageSB 160 COS 131 Ver 1 SD110 Lubricant Specifications and Service Interval Changes - 20210113Imam MuhhudaNo ratings yet

- Manuel de Maintenance ATV-45 (EN)Document32 pagesManuel de Maintenance ATV-45 (EN)Chaib MostafaNo ratings yet

- Multivariable Predictive Control: Applications in IndustryFrom EverandMultivariable Predictive Control: Applications in IndustryNo ratings yet

- M 02 0001Document3 pagesM 02 0001Miguel ruizNo ratings yet

- D4530Document5 pagesD4530rimi7al100% (1)

- Almugea or Proper FaceDocument5 pagesAlmugea or Proper FaceValentin BadeaNo ratings yet

- Pism Pub Line Up - Jul-Dec - 2022Document1 pagePism Pub Line Up - Jul-Dec - 2022Yus CeballosNo ratings yet

- Metal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatDocument13 pagesMetal, Metallurgy, Music, Husserl, Simondon Richard Pinhas: I Have Two Questions To Formulate Regarding The Last Session, Although WhatbluexpectroNo ratings yet

- Theoretical Grammar of EnglishDocument132 pagesTheoretical Grammar of EnglishMisarabbit NguyenNo ratings yet

- Definition, Scope and Nature of EconomicsDocument29 pagesDefinition, Scope and Nature of EconomicsShyam Sunder BudhwarNo ratings yet

- Lesson 2 - Reflection PaperDocument2 pagesLesson 2 - Reflection PaperkristhelynNo ratings yet

- Listening Lesson PlanDocument3 pagesListening Lesson PlanPınar AkgünNo ratings yet

- BUCA IMSEF 2021 Jury Evaluation ScheduleDocument7 pagesBUCA IMSEF 2021 Jury Evaluation SchedulePaulina Arti WilujengNo ratings yet

- Green ICT: A Study of Awareness, Attitude and Adoption Among IT/Computer Engineering Students of LDRP-ITR, GandhinagarDocument13 pagesGreen ICT: A Study of Awareness, Attitude and Adoption Among IT/Computer Engineering Students of LDRP-ITR, GandhinagarAHMAD ARESYADNo ratings yet

- Product Matrix: Network Security Platform - Top Selling Models MatrixDocument6 pagesProduct Matrix: Network Security Platform - Top Selling Models MatrixWashington CárdenasNo ratings yet

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDocument3 pagesIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriNo ratings yet

- Microwave Project ReportDocument30 pagesMicrowave Project ReportMd RakibNo ratings yet

- p-100 Vol2 1935 Part5Document132 pagesp-100 Vol2 1935 Part5Matias MancillaNo ratings yet

- Certification Roadmap 11-30-16Document1 pageCertification Roadmap 11-30-16Cristian Gavilanes MontoyaNo ratings yet

- How To Get Jobs in Neom Saudi Arabia 1703510678Document6 pagesHow To Get Jobs in Neom Saudi Arabia 1703510678Ajith PayyanurNo ratings yet

- Maya Evaluating InterfacesDocument6 pagesMaya Evaluating InterfacesChristopher WalkerNo ratings yet

- A.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskDocument28 pagesA.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskArul brittoNo ratings yet

- Civil & Structural Designer'S Data Pack: Section 7: MasonryDocument5 pagesCivil & Structural Designer'S Data Pack: Section 7: MasonryMirea Florentin0% (1)

- Oracle Pac 2nd KeyDocument48 pagesOracle Pac 2nd KeyKrishna Kumar GuptaNo ratings yet

- Overview of Risk Based Audit ProcessDocument17 pagesOverview of Risk Based Audit ProcessAira Nhaira Mecate100% (1)

- Assignment ProblemsDocument22 pagesAssignment ProblemsPooja Yadav100% (1)

- Chemistry Project Paper ChromatographyDocument20 pagesChemistry Project Paper ChromatographyAmrita SNo ratings yet

- Nteq Lesson PlanDocument4 pagesNteq Lesson Planeva.bensonNo ratings yet

- Executive Shirt CompanyDocument6 pagesExecutive Shirt CompanyPramod kNo ratings yet

- Business Design Thinking - Nguyễn Quang MinhDocument39 pagesBusiness Design Thinking - Nguyễn Quang MinhbuikimhoangoanhtqkNo ratings yet

- ExerciseDocument10 pagesExerciseNguyen Mai QuynhNo ratings yet