Professional Documents

Culture Documents

Adirondack Children

Uploaded by

Maria CristinaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adirondack Children

Uploaded by

Maria CristinaCopyright:

Available Formats

Child Plans

CHILD

Adirondack / Muskoka Chair Plans

Materials List

1/2" x 5 1/2" (13mm x 14cm) redwood or cedar fence boards or pine boards. Four, 5' (1.53m) boards

should make one chair depending on knots and layout.

8, 3/16" x 1 1/4" (5mm x 32mm) brass bolts, nuts and 16 washers.

50, #4 x 1" (2.54cm) brass square drive wood screws

Parts List

Part Description Quantity Standard Size Metric

A Side panel 2 19 3/8" x 2 5/8" x 1/2" 49.2cm x 6.55cm x 13mm

B Bottom back support 1 9 1/2" x 1 3/8" x 1/2" 24.1cm x 3.5cm x 13mm

C Front seat slat 1 9 1/2" x 1 3/8" x 1/2" 24.1cm x 3.5cm x 13mm

D Front leg 2 10" x 2 1/2" x 1/2" 25.4cm x 6.4cm x 13mm

E Back support 2 13"x 1 3/4" x 1/2" 33.0 x 4.5cm x 13mm

F Arm support 2 3 3/8" x 2 1/8" x 1/2" 8.6cm x 5.4cm x 13mm

G Arm 2 15 5/8" x 3 3/4" x 1/2" 39.6cm x 9.5cm x 13mm

H Top back support 1 9 1/2" x 1 7/8" x 1/2" 24.1cm x 4.5cm x 13mm

I Center back slat 1 17 3/8" x 1 3/8" x 1/2" 44.1cm x 3.5cm x 13mm

J Second back slat 2 17 1/4" x 1 3/8" x 1/2" 43.8cm x 3.5cm x 13mm

K Third back slat 2 17" x 1 3/8" x 1/2" 43.2cm x 3.5cm x 13mm

L Outer back slat 2 16" x 1 3/8" x 1/2" 40.6cm x 3.5cm x 13mm

M Seat slat between legs 3 9" x 15/16" x 1/2" 22.7cm x 24mm x 13mm

N Seat slats 6 9 1/2" x 15/16" x 1/2" 24.1cm x 24mm x 13mm

O Back seat slat 1 9 1/2" x 1 13/16" x 1/2" 24.1cm x 4.6cm x 13mm

Instructions:

Cut out all templates, on the INSIDE of the lines shown, and trace or glue onto hardboard for permanent

templates. Label all pieces. Trace all templates onto the final stock of pine or cedar, and cut each one out with a

sabre, table, or band saw. A taper jig on the table saw, works best for the back slats and back supports E. A shop

built sled is the quickest, easiest and safest taper jig. Use a scrap length of 6" (15.8cm) wide plywood, longer than

the back slats, and fasten clamps at each end. Line up the pattern line to the edge of the jig, and run it through

the blade.

file:///C|/barleyharvest/12558childplans44587.html (1 of 7) [2/24/2008 3:50:45 PM]

Child Plans

For all back slats, cut to the rough dimensions of part I, the longest slat. Then trace on template I, and taper the

one side for all parts I, J, K & L. The templates for J, K, & L can be traced onto the tapered stock, so all parts are

the same width at the bottom. Only one template of each is

necessary. Just flip each over for the opposite direction of the curve. Use whichever top pattern you choose from

the templates. You can make the slats the same length as the original I, J, K & L, to give the same curved top

appearance, or arrange to your taste.

Using a 3/16" (5mm) bit, drill the holes for the legs and back supports. If you have a jointer/planer, you may want

to clean up all straight edges. Any curved surfaces should be sanded with a drum sander before rounding over all

outside edges, with a router or sandpaper.

If you are painting the chair, it is best to prime all surfaces first before assembly, to ensure longer life against

moisture. Use an oil based paint like Varathane Colours, for the final coat.

Assembly:

1 - Begin assembly by pre-drilling and screwing the

bottom back support, part B, to the slot in each part

A, the side panels. Leave a 1/4" (6mm) overlap on

each side. Use 1screw on each side of part B. Next

attach the front slat C, with 1 screw on each side, to

the front edges of parts A, flush with the bottom

edge, again with a 1/4" (6mm) overlap. This will give

you a carcass to work with. Check for square by

measuring corner to corner, both ways.

2 - Next, bolt on the front legs D, on the OUTSIDE of

parts A. Use washers on both sides. Tighten being

sure the legs are parallel with each other. Be sure

the bottoms of the side panels A, rest flat at the back.

3 - Bolt on the back supports E, on the INSIDE of

side panels A, again being sure they are parallel to

each other, and square to the work surface.

file:///C|/barleyharvest/12558childplans44587.html (2 of 7) [2/24/2008 3:50:45 PM]

Child Plans

4 - With two screws, attach the arm supports F,

centered flush with the top of the front legs D.

5 - Screw the arms G in place, as they rest on the

front leg supports. Double check to be sure the arms

are parallel to the ground. Put 2 screws through the

arms into front legs D, and 1 into supports F. They

should overhang the front legs by 1/4" (6mm) ,

leaving about 8 1/2" (21.6cm) between the arms.

6 - Draw a line at 9 3/4" (24.8cm) up from the bottom

of the back supports E. Put 1 screw in from the

inside of parts E, into the notch at the back of the

arm. Check to be sure the arms are parallel to the

work surface.

7 - Screw on the upper back support H, centered on

the tops of parts E, flush at the front.

8 - The back pieces can now be assembled, starting

with the middle slat I, centered at the top on part H,

and at the bottom, in the curve on part B,

overhanging 1/8" (3mm). Use one screw at the top

and bottom of each slat, being sure not to set the

screws too deep.

file:///C|/barleyharvest/12558childplans44587.html (3 of 7) [2/24/2008 3:50:45 PM]

Child Plans

9 - Next, screw on slats L, flush with the ends of part

H, and the curve in B. Then screw on slats J and K,

fanned evenly between I and L. You may want to pre-

drill holes in each slat and put in place with a small

nail temporarily, to balance the distance between

slats, before screwing in place.

10 - If you are using plugs to hide the screws, be

sure to add them NOW, to the bottom of the back

slats, and sand smooth.

11 - Attach part O, the back seat slat. You may have

to adjust the angles of the template pattern, to fit

properly to the back slats. The sides should hang

over by 1/8" (3mm) like parts C and A.

12 - The seat slats can now be assembled and

attached using one screw on each side. Cut out

parts M and N to the sizes in the parts list. Evenly

space all slats N, with 2 in front of the legs D, and 4

or 5 behind. The three slats M, are placed between

the legs, and spaced to match the others.

13 - The chair is now assembled, and ready for

finishing.If your are plugging the screw holes, I

recommend a tapered plug cutter, like the Veritas

Cutter from Lee Valley Tools.

file:///C|/barleyharvest/12558childplans44587.html (4 of 7) [2/24/2008 3:50:45 PM]

Child Plans

14 - Glue the plugs in place with exterior waterproof

glue, let dry, then cut off the excess with a chisel or

Japanese saw. The rest can be sanded smooth with

a random orbital sander. Touch up the plugs with

primer, if painting the chair.

The chair is now assembled, and ready for finishing. Hopefully, it will be around for years to come,

and used by the next generation of young ones.

Enjoy!

Phil Barley

www.plansinwood.com

file:///C|/barleyharvest/12558childplans44587.html (5 of 7) [2/24/2008 3:50:45 PM]

Child Plans

file:///C|/barleyharvest/12558childplans44587.html (6 of 7) [2/24/2008 3:50:45 PM]

Child Plans

file:///C|/barleyharvest/12558childplans44587.html (7 of 7) [2/24/2008 3:50:45 PM]

You might also like

- Pholstered Vanity Seat: MaterialsDocument5 pagesPholstered Vanity Seat: MaterialsFe TusNo ratings yet

- Adirondack ChairDocument2 pagesAdirondack ChairDenis Nantel100% (2)

- Country Bench: Project 10307EZDocument8 pagesCountry Bench: Project 10307EZBSulliNo ratings yet

- Adirondack PlansDocument5 pagesAdirondack PlansDebbie Mack100% (2)

- Arched Aurora NightstandDocument7 pagesArched Aurora NightstandRoberto LandaNo ratings yet

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeFrom EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeNo ratings yet

- Ukulele Kit Assembly Instructions: Getting Started Supplies ContinuedDocument10 pagesUkulele Kit Assembly Instructions: Getting Started Supplies ContinuedPablo PolettoNo ratings yet

- Porch Swing: Project 16258EZDocument5 pagesPorch Swing: Project 16258EZBSulli100% (1)

- Porch SwingDocument3 pagesPorch SwingManuel RomeroNo ratings yet

- Ingerie Resser LAN: PlansDocument10 pagesIngerie Resser LAN: PlansGsmHelpNo ratings yet

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- Eoxqyx 1 ZDocument9 pagesEoxqyx 1 ZRogal DuarteNo ratings yet

- Medieval Folding Stool - Popular WoodworkingDocument32 pagesMedieval Folding Stool - Popular WoodworkingplaytesteurNo ratings yet

- How To Build An Adirondack Chair: Introduction and Cutting ListDocument6 pagesHow To Build An Adirondack Chair: Introduction and Cutting ListSamir Joguncic100% (1)

- nesting-chair-plans-1 (2)Document3 pagesnesting-chair-plans-1 (2)Noel MatumbaNo ratings yet

- Bench - Classic Cedar Garden PDFDocument11 pagesBench - Classic Cedar Garden PDFmarianrkwNo ratings yet

- Roll-Away Patio Chair: Project PlanDocument6 pagesRoll-Away Patio Chair: Project PlanAhmed FaroukNo ratings yet

- Beginner Folding Work BenchDocument12 pagesBeginner Folding Work BenchB. Ionut100% (1)

- DIY Work Table v4Document6 pagesDIY Work Table v4sgenco.circlelineNo ratings yet

- High Chair: Project 12075EZDocument4 pagesHigh Chair: Project 12075EZBSulliNo ratings yet

- Manufacturing A CheeseboardDocument14 pagesManufacturing A Cheeseboardapi-602237392No ratings yet

- Fold-out table: Get extra table space with our compact folding designDocument1 pageFold-out table: Get extra table space with our compact folding designmmylitoNo ratings yet

- Build Classic Cedar Garden Bench Under 40 CharactersDocument11 pagesBuild Classic Cedar Garden Bench Under 40 Charactersvdbroger100% (1)

- Dresser PlanDocument11 pagesDresser PlanGsmHelpNo ratings yet

- Ultimate WorkbenchDocument8 pagesUltimate WorkbenchEric Gruff0% (1)

- Build a Pocket Hole JigDocument5 pagesBuild a Pocket Hole Jighutch buddy7100% (1)

- Wall-Hung Telephone Cabinet: Project 11257EZDocument6 pagesWall-Hung Telephone Cabinet: Project 11257EZBSulli100% (1)

- Minwax Advanced Project Adirondack ChairDocument9 pagesMinwax Advanced Project Adirondack ChairPetrus Cassu Menck100% (1)

- Arts and Crafts ChairDocument9 pagesArts and Crafts Chairlight darkNo ratings yet

- 11489stoplock55698 PDFDocument1 page11489stoplock55698 PDFzementheadNo ratings yet

- Stop Lock 55698Document1 pageStop Lock 55698Ken PostleNo ratings yet

- But Don't Be Impatient To See How The Legs WillDocument5 pagesBut Don't Be Impatient To See How The Legs WillJimNo ratings yet

- Easy-to-Build Table Saw Crosscut SledDocument7 pagesEasy-to-Build Table Saw Crosscut SledJonathan ScottNo ratings yet

- 45-01772Document8 pages45-01772khans.martinNo ratings yet

- Swing Garden SwingDocument7 pagesSwing Garden SwingAlicia MariaNo ratings yet

- The Cutting List Where To Drill The Holes: Item Id Description Stock Size Length Pieces (A) (B) (C) (D) (E) (F)Document2 pagesThe Cutting List Where To Drill The Holes: Item Id Description Stock Size Length Pieces (A) (B) (C) (D) (E) (F)Exartis GeorgeNo ratings yet

- Mission Side Chair Cutting DiagramsDocument14 pagesMission Side Chair Cutting DiagramsFeng Shu jiNo ratings yet

- Simple Table Saw Sled v1Document7 pagesSimple Table Saw Sled v1Becon AjoonuNo ratings yet

- Artists EaselDocument13 pagesArtists Easelkhunchaiyai100% (3)

- Classic RockerDocument9 pagesClassic Rocker- yAy3e -No ratings yet

- Plans: Anel AWDocument11 pagesPlans: Anel AWElysita Macedo SalvadorNo ratings yet

- All-Weather Morris Chair PlansDocument7 pagesAll-Weather Morris Chair PlansrelbuhmNo ratings yet

- Dining Room ChairsDocument16 pagesDining Room Chairsrhinorod100% (1)

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- Lower Wing Build Up Section IiiDocument15 pagesLower Wing Build Up Section Iiimohamed sidkyNo ratings yet

- Book Case - AnniversaryDocument10 pagesBook Case - AnniversaryCris CondeNo ratings yet

- 10 06 WorkshopDocument5 pages10 06 WorkshopMiguel Angel Rodríguez Zenteno100% (2)

- Box of Shapes Toy: Project 18618EZDocument5 pagesBox of Shapes Toy: Project 18618EZBSulliNo ratings yet

- Style StitchesDocument18 pagesStyle Stitcheschina_bella81100% (1)

- Chair Project InstructionsDocument4 pagesChair Project InstructionsRicardo SantosNo ratings yet

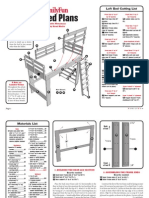

- Loft Bed PlansDocument6 pagesLoft Bed PlansDarryl Lashambe100% (2)

- Drill Press Organizer: Project 20068EZDocument5 pagesDrill Press Organizer: Project 20068EZBSulli100% (1)

- Trestle Table and Benches: Project 18444EZDocument5 pagesTrestle Table and Benches: Project 18444EZAndre GaioNo ratings yet

- The Pochade and Wet Panel Carrier Do It Yourself PlanFrom EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanRating: 4 out of 5 stars4/5 (1)

- How to Make Picture Frames (Best of AW): 12 Simple to Stylish Projects from the Experts at American Woodworker (American Woodworker)From EverandHow to Make Picture Frames (Best of AW): 12 Simple to Stylish Projects from the Experts at American Woodworker (American Woodworker)Rating: 5 out of 5 stars5/5 (1)

- Hexie Garden Quilt: 9 Whimsical Hexagon Blocks to Appliqué & PieceFrom EverandHexie Garden Quilt: 9 Whimsical Hexagon Blocks to Appliqué & PieceNo ratings yet

- Build DIY Hnefatafl Game BoardDocument9 pagesBuild DIY Hnefatafl Game BoardVictor M GonzalezNo ratings yet

- Brandub Print-And-Play: Assembly InstructionsDocument5 pagesBrandub Print-And-Play: Assembly InstructionsVictor M GonzalezNo ratings yet

- Sea Battle Print and PlayDocument6 pagesSea Battle Print and PlayVictor M GonzalezNo ratings yet

- Ancient Use of The Knuckle-Bone For Rituals and Gaming PieceDocument11 pagesAncient Use of The Knuckle-Bone For Rituals and Gaming PieceVictor M GonzalezNo ratings yet

- Men The Game of 16 LinesDocument8 pagesMen The Game of 16 LinesVictor M GonzalezNo ratings yet

- Roll The Dice Iron Age II Gameboards andDocument21 pagesRoll The Dice Iron Age II Gameboards andVictor M GonzalezNo ratings yet

- 36 Dice BGSDocument12 pages36 Dice BGSVictor M GonzalezNo ratings yet

- Beat The Dealer: A Winning Strategy For The Game of Twenty-One, 240 Pages, Edward O. Thorp, 0307784010, 9780307784018, Random House LLCDocument19 pagesBeat The Dealer: A Winning Strategy For The Game of Twenty-One, 240 Pages, Edward O. Thorp, 0307784010, 9780307784018, Random House LLCVictor M GonzalezNo ratings yet

- Passing From The Middle To The New KingdDocument7 pagesPassing From The Middle To The New KingdVictor M GonzalezNo ratings yet

- Ancient Egyptian Game of Hounds and JackalsDocument8 pagesAncient Egyptian Game of Hounds and JackalsVictor M GonzalezNo ratings yet

- An Inscribed AstragalusDocument3 pagesAn Inscribed AstragalusVictor M GonzalezNo ratings yet

- Learn to Play Ancient Egyptian Senet Board GameDocument2 pagesLearn to Play Ancient Egyptian Senet Board GameVictor M GonzalezNo ratings yet

- Scrap Adirondack ChairDocument9 pagesScrap Adirondack ChairVictor M GonzalezNo ratings yet

- Beat The Dealer: A Winning Strategy For The Game of Twenty-One, 240 Pages, Edward O. Thorp, 0307784010, 9780307784018, Random House LLCDocument19 pagesBeat The Dealer: A Winning Strategy For The Game of Twenty-One, 240 Pages, Edward O. Thorp, 0307784010, 9780307784018, Random House LLCVictor M GonzalezNo ratings yet

- Ancient Egyptian board game of SenetDocument2 pagesAncient Egyptian board game of SenetVictor M GonzalezNo ratings yet

- Knossos GameDocument8 pagesKnossos GameVictor M GonzalezNo ratings yet

- Pallet Adirondack Chair 1Document9 pagesPallet Adirondack Chair 1Victor M GonzalezNo ratings yet

- Make and Play SenetDocument4 pagesMake and Play SenetVictor M GonzalezNo ratings yet

- On The Rules For The Royal Game of UrDocument17 pagesOn The Rules For The Royal Game of UrCraulabeshNo ratings yet

- More How To Draw Manga Vol. 1 - The Basics of Character Drawing.rDocument120 pagesMore How To Draw Manga Vol. 1 - The Basics of Character Drawing.rGabriel Faria100% (2)

- Senet PDFDocument4 pagesSenet PDFAngeliki SourvinouNo ratings yet

- Mod Podge Projects: Volume 2: Photo TransfersDocument17 pagesMod Podge Projects: Volume 2: Photo TransfersVictor M GonzalezNo ratings yet

- SENETDocument1 pageSENETbionicrasNo ratings yet

- How to Play Ancient Egyptian Game of SenetDocument1 pageHow to Play Ancient Egyptian Game of SenetVictor M GonzalezNo ratings yet

- Four Ancient Egyptian Board GamesDocument3 pagesFour Ancient Egyptian Board Games55475547No ratings yet

- In Search of The Meaning of SenetDocument4 pagesIn Search of The Meaning of SenetVictor M GonzalezNo ratings yet

- Make Your Own Senet Game - 0Document4 pagesMake Your Own Senet Game - 0Victor M GonzalezNo ratings yet

- How to Play the Ancient Egyptian Board Game SenetDocument8 pagesHow to Play the Ancient Egyptian Board Game SenetVictor M GonzalezNo ratings yet

- Make and Play SenetDocument4 pagesMake and Play SenetVictor M GonzalezNo ratings yet

- Play The Game of Senet Teacher Lesson PlanDocument7 pagesPlay The Game of Senet Teacher Lesson PlanVictor M GonzalezNo ratings yet

- Shopdog Download PackageDocument18 pagesShopdog Download PackageqNo ratings yet

- Stages of Layout PDFDocument2 pagesStages of Layout PDFCak Jo100% (1)

- Mini Amigurumi Advent CalendarDocument76 pagesMini Amigurumi Advent CalendarAlmedinaĐonkoKaračić100% (3)

- Ambedkar Instt Project ReportDocument93 pagesAmbedkar Instt Project ReportSatyabrata MohantyNo ratings yet

- Reversible Mood Octopus Crochet Pattern Materials:: Finish Off. Leave Long Tails For AssemblyDocument2 pagesReversible Mood Octopus Crochet Pattern Materials:: Finish Off. Leave Long Tails For AssemblyDaxxii100% (4)

- Pfaff Ambition 620/quild Ambition 630 Sewing Machine Instruction ManualDocument68 pagesPfaff Ambition 620/quild Ambition 630 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Singer Professional 5: Overlock WorkbookDocument238 pagesSinger Professional 5: Overlock WorkbookTasheenaNo ratings yet

- Astm D 4884Document6 pagesAstm D 4884Sebastián RodríguezNo ratings yet

- Report On of Sitara TextileDocument25 pagesReport On of Sitara Textilemoonusman80% (15)

- Frutas EróticasDocument10 pagesFrutas EróticasAna Carolina Bastos100% (3)

- GEC 06 - Art App (Painting) PDFDocument98 pagesGEC 06 - Art App (Painting) PDFDavid BernalNo ratings yet

- Curriculum Map: Subject: Arts Grade Level: 7 Quarter: First QuarterDocument4 pagesCurriculum Map: Subject: Arts Grade Level: 7 Quarter: First QuarterKristela Mae ColomaNo ratings yet

- (B. Inggris) Kel. Lr. Jaya LaksanaDocument2 pages(B. Inggris) Kel. Lr. Jaya Laksanaeazim shoesNo ratings yet

- Brocade TextilesDocument9 pagesBrocade TextilesTapan SharmaNo ratings yet

- Fabric Structure and DesignDocument73 pagesFabric Structure and Designfuad ahmed100% (2)

- DARNING ModuleDocument2 pagesDARNING ModuleMary Chris BigaoNo ratings yet

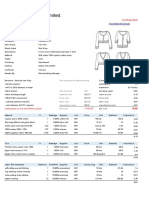

- Costing Sheet Excel FormatDocument2 pagesCosting Sheet Excel FormatDeny ArisandiNo ratings yet

- Tutorial Harness 1016Document24 pagesTutorial Harness 1016VaLe CoTo100% (1)

- Create Scary Dinosaur SculptureDocument1 pageCreate Scary Dinosaur SculptureCliane LlamasNo ratings yet

- Stegosaurus Crochet Pattern - v1Document5 pagesStegosaurus Crochet Pattern - v1juraj gresner100% (1)

- Phrasal VerbsDocument2 pagesPhrasal VerbsMaria Antonia Rodriguez RodriguezNo ratings yet

- Count and GSM RelationDocument4 pagesCount and GSM RelationNipu SenNo ratings yet

- Crochet Pattern - Snuggles The PenguinDocument5 pagesCrochet Pattern - Snuggles The PenguinWubNo ratings yet

- VidarDocument1 pageVidarPrincess Margarette Ann DiancoNo ratings yet

- Full Size Arcade Cabinet Plans - We Build StuffDocument5 pagesFull Size Arcade Cabinet Plans - We Build StuffDaniel FunesNo ratings yet

- Classification of Hand ToolsDocument85 pagesClassification of Hand ToolsGodfrey CasinilloNo ratings yet

- Flying Squirrel Free Pattern FinalDocument13 pagesFlying Squirrel Free Pattern FinalJosefina DabaNo ratings yet

- Readymade Garment: Report Title: Prepare A Part Breakdown & Operation Sheet For ADocument8 pagesReadymade Garment: Report Title: Prepare A Part Breakdown & Operation Sheet For AShahedul IslamNo ratings yet

- What Is A Drill Press ViseDocument9 pagesWhat Is A Drill Press ViseBiruk Damtew Ze MerhabeteNo ratings yet

- The 14th Century Bocksten Man's Preserved Woolen TunicDocument10 pagesThe 14th Century Bocksten Man's Preserved Woolen TunicBenton D. Fagan100% (3)