Professional Documents

Culture Documents

Technical Features of a DOT 200x35 N Benchtop Marking System

Uploaded by

Mohamed AbdelhakamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Features of a DOT 200x35 N Benchtop Marking System

Uploaded by

Mohamed AbdelhakamCopyright:

Available Formats

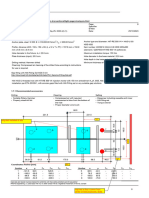

TECHNICAL FEATURES

DOT 200x35 N

DEEP MARKING

BENCHTOP SYSTEMS · DOT PEEN MARKING

• Dot peen marking station, autonomous, with height regulation,

for deep marking. Especially designed for marking small batches

and changing productions of of pieces with treatment afterward,

(blasting, machining, grinding, painting, etc.).

ADVANTAGES

• Very deep mark, more than 0.5 mm, at optimum speed. • Versatility in the size of the pieces to be marked, thanks to

• Highly robust, long-lasting and resistant, especially regulation up to 250 mm in height, so you can mark everything

designed for the most demanding industrial settings - from thin sheets to large pieces, including fastening.

heavy duty industry. • Machined work surface, guaranteeing precision in marking.

• Marking for all kinds of materials and hardnesses, up to • T-slot to facilitate tool placement.

62HRC. • Possibility of anchoring the table to a surface for greater

stability.

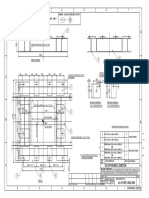

236

45

378,5

704

206,5

659

126

125,5

8,5

X=200

162,5 Y=35

10

Area Dimensions (mm) Weight

18

0-250

70

16,5

XxY Width Depth Height Kg 60 180 60 75 117,25

200 x 35 400 538 704 50.5 150 150 230

60,5 300 39,5 420

400 Área Dimensiones (mm) Peso

538

X x Y Anch. Prof. Alto Kg

200 x 35 400 538 704 50.5

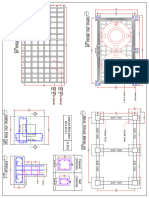

CHARACTERISTICS

• Table for placing tools and plate stand. • N34 pneumatic header, special for deep marking, and optional

• Column with height regulation up to 250 mm N20 pneumatic header.

• 200 x 35 mm marking area. • Protection system option.

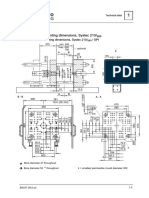

• Speed up to 4 characters/second (large characters) • 2.5-meter robotics cable, with customisation possibilities.

• 6-bar air pressure. • Connection with COUTH control unit for integration into

• Hardness of materials to mark up to 62HRC. production lines (see technical file for more information).

• Wide range of characters, from 0.1 mm to complete area. • PC edition software.

• Marking alphanumeric codes, logotypes, DATAMATRIXTM, QR

January 2019

codes, etc.

www.couth.com

You might also like

- APQP With Flow of ProcessDocument8 pagesAPQP With Flow of ProcessVarun KumarNo ratings yet

- Smartbox 2023 ENDocument4 pagesSmartbox 2023 ENMohamed AbdelhakamNo ratings yet

- Crushing - GrindingDocument118 pagesCrushing - GrindingHarrison Antonio Mira NiloNo ratings yet

- Atc 4020V 200 90Document1 pageAtc 4020V 200 90Lokesh LokiNo ratings yet

- Benchtop Standard Dot Marking Machine 90x60n 1Document1 pageBenchtop Standard Dot Marking Machine 90x60n 1Mohamed AbdelhakamNo ratings yet

- DOT 72x35 N benchtop dot peen marking system for deep marking of small batchesDocument1 pageDOT 72x35 N benchtop dot peen marking system for deep marking of small batchesMohamed AbdelhakamNo ratings yet

- Benchtop Standard Dot Marking Machine 150x100n 1Document1 pageBenchtop Standard Dot Marking Machine 150x100n 1Mohamed AbdelhakamNo ratings yet

- Esh Series Operating Characteristics at 50 HZ, 2 Poles: ESH 65-160 2900 (RPM) ISO 9906:2012 - Grade 3BDocument1 pageEsh Series Operating Characteristics at 50 HZ, 2 Poles: ESH 65-160 2900 (RPM) ISO 9906:2012 - Grade 3Bterrazas.danielNo ratings yet

- Technical Data - Pumps - ARP-Line - ENDocument2 pagesTechnical Data - Pumps - ARP-Line - ENluca nicoliniNo ratings yet

- JVL High Quality, High Torque AC Servo Motors MSE400, 800, 1K5 and 3K0Document4 pagesJVL High Quality, High Torque AC Servo Motors MSE400, 800, 1K5 and 3K0ElectromateNo ratings yet

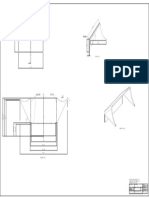

- Drawbar 2.60M. DetailsDocument3 pagesDrawbar 2.60M. DetailsEdward CelebreNo ratings yet

- 3.6 Rencana Balok AtapDocument1 page3.6 Rencana Balok Ataptrisna WidhiaNo ratings yet

- DPX DPX DPX DPXDocument9 pagesDPX DPX DPX DPXAs MawiNo ratings yet

- Usi Corp N PDFDocument1 pageUsi Corp N PDFRaluca NicuNo ratings yet

- Papuci Cupru Tip D - Klauke - Gerkon ElectroDocument2 pagesPapuci Cupru Tip D - Klauke - Gerkon ElectroVasilicaNo ratings yet

- SK6382AZ - IEC132 - 132MH/4: Date Name Drawn SystemDocument1 pageSK6382AZ - IEC132 - 132MH/4: Date Name Drawn SystemHugo AcevedoNo ratings yet

- Structure Design For Horizontal ElementsDocument14 pagesStructure Design For Horizontal ElementsesNo ratings yet

- EVO 50 G.A Drwing WITH BASE FRAMEDocument1 pageEVO 50 G.A Drwing WITH BASE FRAMEmanukishnaNo ratings yet

- Peta Geologi Sungai Muncar Kebumen Jawa TengahDocument1 pagePeta Geologi Sungai Muncar Kebumen Jawa Tengahaloysius andriantoNo ratings yet

- Hmi Pendant 1Document1 pageHmi Pendant 1Pranav ShuklaNo ratings yet

- Cut & Bent Reinforcement TolerancesDocument3 pagesCut & Bent Reinforcement TolerancesConradNo ratings yet

- Catalogo Aros de Teflon SKFDocument3 pagesCatalogo Aros de Teflon SKFGaston VilchesNo ratings yet

- Hallite CatalogueDocument374 pagesHallite Cataloguegeovane cardosoNo ratings yet

- Splice DetailDocument1 pageSplice DetailDJNo ratings yet

- Poly V PulleysDocument12 pagesPoly V Pulleyskevin YachaNo ratings yet

- MAS1006026R5 CAD DrawingDocument1 pageMAS1006026R5 CAD Drawingluis.chuquimiaNo ratings yet

- La Guia MetAs 10 06 Densidad AguaDocument19 pagesLa Guia MetAs 10 06 Densidad AguaMayreneDavilaNo ratings yet

- MOTEUR AEROS PLAN 751472-474-478-11716473L1L4L7 - Et11p - 50081 - 02Document1 pageMOTEUR AEROS PLAN 751472-474-478-11716473L1L4L7 - Et11p - 50081 - 02MussardNo ratings yet

- Cooker Hood: User ManualDocument124 pagesCooker Hood: User ManualRadu PopescuNo ratings yet

- SP02-TA01-105: Detail A Scale 1: 5Document1 pageSP02-TA01-105: Detail A Scale 1: 5kartik spectomsNo ratings yet

- Foundation Details and Reinforcement LayoutDocument1 pageFoundation Details and Reinforcement LayoutGerold MolinaNo ratings yet

- Electrical diagram of industrial motor control systemDocument1 pageElectrical diagram of industrial motor control systemHugo AcevedoNo ratings yet

- A2-GVHY-2021-001 BASE FRAME FOR FLOWMORE VT PUMP FOR PCMC RAVET-ModelDocument1 pageA2-GVHY-2021-001 BASE FRAME FOR FLOWMORE VT PUMP FOR PCMC RAVET-ModelRujuta kemkar MsebNo ratings yet

- HiPosMicro UOMT INNO 7850629 PDFDocument1 pageHiPosMicro UOMT INNO 7850629 PDFDado OgameNo ratings yet

- Po JB2202-003-00Document3 pagesPo JB2202-003-00John Aaron ComiaNo ratings yet

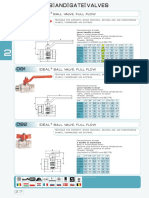

- Ball ValveDocument1 pageBall ValveThalib RettobNo ratings yet

- Ribwithplate PDFDocument1 pageRibwithplate PDFDesignNo ratings yet

- Pressure Test Chart: Job Activity: DateDocument1 pagePressure Test Chart: Job Activity: DateYongki SuharyaNo ratings yet

- ENEDA1LDocument4 pagesENEDA1LPatricia GalorioNo ratings yet

- Mazda Bongo Rear Side Kitchen Design: Iain Sharp - 1 April 2006Document7 pagesMazda Bongo Rear Side Kitchen Design: Iain Sharp - 1 April 2006vertigo568No ratings yet

- Denah Lantai 10 (Top Floor) - ModelDocument1 pageDenah Lantai 10 (Top Floor) - Modelari dwi nNo ratings yet

- Verande: SIP. 98.8 MDocument1 pageVerande: SIP. 98.8 MRizi BaroNo ratings yet

- Sieve Analysis of Granular Sub Base: As Per MORT&H TABLE 400-1Document1 pageSieve Analysis of Granular Sub Base: As Per MORT&H TABLE 400-1Amjad PathanNo ratings yet

- SZ 50-55 100 hp-730 Rpm-ModelDocument1 pageSZ 50-55 100 hp-730 Rpm-ModelmzakriasesNo ratings yet

- MZ Sk9042.1azd-132mp4tfDocument1 pageMZ Sk9042.1azd-132mp4tfpmf engineering limitedNo ratings yet

- Proposed Residential Apartments. 01Document2 pagesProposed Residential Apartments. 01Daniel OkereNo ratings yet

- Hilti PROFIS Engineering 3.0.88: WWW - hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/malaysia - HTMLDocument1 pageHilti PROFIS Engineering 3.0.88: WWW - hilti.group/content/hilti/CP/XX/en/non-transactional/light-pages/malaysia - HTMLSantosoNo ratings yet

- Jasper PCB and Panel MeasurementsDocument3 pagesJasper PCB and Panel MeasurementsBruno MacagnaniNo ratings yet

- 0509 Anna Tampak ModelDocument1 page0509 Anna Tampak Modelmaintenance anmedNo ratings yet

- TS-SL-1 - POST - Rev 0Document1 pageTS-SL-1 - POST - Rev 0eva maniceNo ratings yet

- Center Hole M16 acc. to DIN 332 part 2 form D technical drawingDocument1 pageCenter Hole M16 acc. to DIN 332 part 2 form D technical drawingHugo AcevedoNo ratings yet

- Technical Details ENDocument5 pagesTechnical Details ENhenk.schepers01No ratings yet

- CZ LOKO Catalogue of Locomotives and Special Vehicles1Document32 pagesCZ LOKO Catalogue of Locomotives and Special Vehicles1frtanay12No ratings yet

- Gunung Garuda - AngleDocument14 pagesGunung Garuda - AngleAchmad Oktafiono STNo ratings yet

- Mior 6/15/2020: Designed by Checked by Approved by Date DateDocument1 pageMior 6/15/2020: Designed by Checked by Approved by Date DatemiorNo ratings yet

- Industrial Engineering Vaibhav G. Bandekar M2020096Document20 pagesIndustrial Engineering Vaibhav G. Bandekar M2020096Vaibhav BandekarNo ratings yet

- Gambar Tandon Tipe 1 (Tandon 2 X 1200 Ltr. Tinggi 4 Meter)Document2 pagesGambar Tandon Tipe 1 (Tandon 2 X 1200 Ltr. Tinggi 4 Meter)andryNo ratings yet

- OPTIMIZED DIMENSIONSDocument1 pageOPTIMIZED DIMENSIONSSalima DwiNo ratings yet

- Columns in Concrete - CDRDocument1 pageColumns in Concrete - CDRTeknikSipilUsmNo ratings yet

- 210ton Sumitomo - PLATENDocument1 page210ton Sumitomo - PLATENcountzeroaslNo ratings yet

- SK SeriesDocument1 pageSK SeriesanggieNo ratings yet

- Prosperity in The Islamic WorldDocument1 pageProsperity in The Islamic WorldMohamed AbdelhakamNo ratings yet

- Benchtop Superfast Dot Marking Machine 50x17n 1Document1 pageBenchtop Superfast Dot Marking Machine 50x17n 1Mohamed AbdelhakamNo ratings yet

- Fast marking benchtop system for small batchesDocument1 pageFast marking benchtop system for small batchesMohamed AbdelhakamNo ratings yet

- Portable Standard Dot Marking Machine 90x60pDocument1 pagePortable Standard Dot Marking Machine 90x60pMohamed AbdelhakamNo ratings yet

- Portable Standard Dot Marking Machine 150x100p 2Document1 pagePortable Standard Dot Marking Machine 150x100p 2Mohamed AbdelhakamNo ratings yet

- Portable Superfast Dot Marking Machine 100x17p 1 2Document1 pagePortable Superfast Dot Marking Machine 100x17p 1 2Mohamed AbdelhakamNo ratings yet

- Fastest Portable Dot Peen MarkerDocument1 pageFastest Portable Dot Peen MarkerMohamed AbdelhakamNo ratings yet

- Kalawang Steel CoDocument2 pagesKalawang Steel CoJanna Katrina De TorresNo ratings yet

- Reservdelskatalog Parts Catalogue: Park 220Document33 pagesReservdelskatalog Parts Catalogue: Park 220DupratNo ratings yet

- T2397489 RR - 139231029Document3 pagesT2397489 RR - 139231029Ikhtiander IkhtianderNo ratings yet

- Fdas765 Data SheetDocument2 pagesFdas765 Data SheettanadfNo ratings yet

- G Ym 6 F 8 HEtoev 4 GEbDocument6 pagesG Ym 6 F 8 HEtoev 4 GEbPrakhar AgarwalNo ratings yet

- TCLDocument13 pagesTCLYc ChenNo ratings yet

- Use of Source MAC Address Field in SpannDocument6 pagesUse of Source MAC Address Field in SpannPraveen RaiNo ratings yet

- Introduction To LabVIEW ShortDocument46 pagesIntroduction To LabVIEW ShortMiguelNo ratings yet

- Web301 - Prelim LessonDocument85 pagesWeb301 - Prelim LessonJessabel DigaoNo ratings yet

- Hydraulic Regenerative Braking System PDFDocument12 pagesHydraulic Regenerative Braking System PDFhai dangNo ratings yet

- VTU B.E CSE Sem 8 Software Testing NotesDocument26 pagesVTU B.E CSE Sem 8 Software Testing NotesAravind RossiNo ratings yet

- J410-06 Exercise 6.1 - RevA2Document8 pagesJ410-06 Exercise 6.1 - RevA2khanhNo ratings yet

- Modern Work Plan Comparison EnterpriseDocument10 pagesModern Work Plan Comparison EnterpriseRicardo SilvaNo ratings yet

- DSL 2730EUser ManualDocument93 pagesDSL 2730EUser Manualdillamirl100% (1)

- Practical Guide to Boosting Automotive EfficiencyDocument75 pagesPractical Guide to Boosting Automotive EfficiencyAleksa Nataša RančićNo ratings yet

- Chat SystemDocument4 pagesChat SystemDeepak VermaNo ratings yet

- Shortlist For Ericsson Cloud Technology Elective Online TestDocument14 pagesShortlist For Ericsson Cloud Technology Elective Online TestRounak Roy ChowdhuryNo ratings yet

- Hormann Lineamatic Gate OperatorsDocument46 pagesHormann Lineamatic Gate OperatorsGiorgos GewrgiouNo ratings yet

- FJRX 84 EngDocument22 pagesFJRX 84 EngPalade LiviuNo ratings yet

- Object Motion Detection in Home Security System Using The Binary-Image Comparison Method Based On Robot Operating System 2 and Raspberry PiDocument8 pagesObject Motion Detection in Home Security System Using The Binary-Image Comparison Method Based On Robot Operating System 2 and Raspberry PiRukmyy SapsuhaNo ratings yet

- Robosapien X Manual PDFDocument20 pagesRobosapien X Manual PDFbiroupersonal100% (1)

- TALENT PIPELINEDocument6 pagesTALENT PIPELINEJayNo ratings yet

- IntroQRM Verjan2019Document73 pagesIntroQRM Verjan2019Jeffrey RamosNo ratings yet

- ME 600 Infusion Pump SpecificationDocument3 pagesME 600 Infusion Pump Specification王明杰No ratings yet

- Thesis Topics On Production EngineeringDocument7 pagesThesis Topics On Production Engineeringafknojbcf100% (2)

- 3406 Performance Specification PDFDocument2 pages3406 Performance Specification PDFaliNo ratings yet

- Data Guard CheatsheetDocument8 pagesData Guard CheatsheetMohammad Mizanur RahmanNo ratings yet

- Voltage Source Inverter Drive: Ece 504 - Experiment 2Document17 pagesVoltage Source Inverter Drive: Ece 504 - Experiment 2Olimpiu StoicutaNo ratings yet

- OBIA Overview PDFDocument13 pagesOBIA Overview PDFDilip Kumar AluguNo ratings yet