Professional Documents

Culture Documents

Commented - 8' PIPE TC

Uploaded by

Aqib Khan VCSPOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Commented - 8' PIPE TC

Uploaded by

Aqib Khan VCSPCopyright:

Available Formats

foRH/q&'or

UNITETf E

U\rad So!mleri luiul!.r pvi. ttd.

UNITED SEAMLESS TUBULAAR PVT. LTD

-:;

D. P. JINDAT GROUP OF INDUSTRIES

rm, Narketpally, Nalgonda Dlstrl€t, Telangana, INDIA - 509254

'WELL KNOWN PIPE E TUBE MAKER"

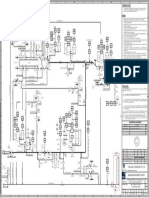

KrRM III-A (See regutatton 4(e))

FIGATT OF MTWUFACTURE AND TEST FOR PIPES (EN : 10204: 3.1)

Customer's Name & : PIPE HOUSE Name of Part PIPES

Address 987n.CIDCDaA:SIATI Makrn Nemc & UNTTED SEAMTESS TUBULAAR PVT. LTD

6UJRAr, 39m!0,t0!{ Addr€ss SREEPURAM.NARKETPALLY, NALGONDA DISTRICT

Customer Order No.

: VERBAI" 03.Gt2022

Test Certificato No.

I USTPL-2022/!BR/01

Date : O7.O3.N?2 Of Msnufacturc I SflE tlEOilL FNolccM/Roflh1l

Order Conflrmatlon No. : 73210715 DL04.03 n22 klllcd/Rlmmcd/sCml klllcd r fUt[Y KttfD AND ftNE GRAINET)

Process of Manufaciun : HOT FSISHED SEA ,iESS Tolsnnces : As p€r specification

Main Dimension : 219.10 X 8.18 MM Deslgn Pressure : NA

Plain/ Bevel End : EEVEL END DcslgnTemp : NA

Specifications & Gmdes : ASIM A106Gl'B/AsMtsJ 6GL8/lSIqAsl GR8 Drawing No. NA

- API 5T PSLI GR EAACE M 0lr5Dl0lMl6r tD{noN)

I 1800 psi=12.41

MPa> 10.75 from

Length D.t! ot

formula of ASTM Non

RM H..t USTPL. No. of Tobl 8.nd H..l

TostA530

5l No Range Hydrostalic Test PSI Mrnufr Driftfat tlange Tost Destruciive

(MtE)

& DatG no, Heat No. (rlrM) PIPE5 M!tffi ng T.sl Tcrt Trealmont

ctulc T.rtlng

JS3/0000036806

1 5to7 4122996 Y6 280 5 30.702 1800 len.22 NA OK NA NA NA NA NA

21,L2,2021

Mechanlcal Propertles (At Reom ture)

Chemical Compositlon (%) (H-Heat/P1-Product l/P2-Product 2)

GL=50.8MM.Width=12.5 MM {Lr al)

Nrmr ofl rr Stecl

Y.5t. Mak !a

TEST El96 H.rt No, c Mn P s sl Cr Ni Mo Cu v AI Ti CE

(MPA) Ircpc< lng

, Apth( Ity

Req.

240 411 22.O0 o290 0.100

(Min)

Rcq.

200 sHN 0.300 r.390 0.035 0.035 o.rt@ 0.400 0.150 0.400 0.080

(Max)

H ,INDAISII : AND

Oll0 0.580 o015 0.004 0.190 0.019 0.010 0.0010 0.008 0.0013 0.259

P1 334.21 472.t2 34.2E ' 138 POWIR L IIED 0.136 o673 o014 0.004 0.195 0.015 0.009 0.0015 0.004 0.0014 0.253

.twEt-t Y6

CHATTIS6A

82 3?7.5E 467,54 35.i14 137 0.137 0.672 0.014 0.001 0.197 o016 o009 0.0019 0.005 0.m17 0.254

MAK€i

Properties at Elevated Temperature (Et = 0.2% roof stress at temperoture)

METAL TEMP. "C 250 275 )0 325 350 375 400 425 450 475 500 525 550 575 600

Et. (N/mm'z)

Sc. (N/mmr)

Sr. (N/mm2)

MAWP

Certified that particulars entered here ln are do €ct. The PIPES has been designed and constructed to comply wlth the Boller Regulations for a maximum

working pressure, Maximum Temperaturcr & sl lsfactory withstood hydro test pressutr msntlon abov. ln th€ PrGsGnc6 of our responslble rePresentative whose

ignature is appended here under.

The pipes have besn Manufactursd & Tested at rur worke as per specification ASTM A 1OO GR. B/ASME SAL06 GR.B/A53 GR B/NACE. MR0175/0103.

Remarks:-

ldentificetionmarks:'U}:JINDA[- . UNITE -F AsrM A 106 bR B/AsMfjfiff .51$iB 5t PSL1 GR B/ NACE MR 0103/ MR 017s oD x wr rrts KG/MTR HEATxo Psr '

Place : Narketpally

UfE HAV E Tf{t

}:OLLOWING MATEENL TO <oz?e3

Date: 07.03.2022

.tW @@:

As

n.

/.-\-'-tfD-g

sh rhakur - rr

-

-vtu..54.ifMrH'fl

Exe.SOPplPE HOUSE

PO. No.......r\...x.....

Maker

e.

Rahul Pushpatode -

&o'ji

Makers epresentative (Name & Signature)

We have satisfied ourselves that the PIPES hav been constructed in accordance with Indian Boiler Regulations, 1950. rrj

The tests conducted on the sanlples taken fror the finished PIPES have been witnessed by us and

the partlculars entered herein are /.dt

Warning: Modification or unauthorized use of prohibited' violation calls for crlminal prosecution'

at qut *::f,::::::strictlv

ty@unitedseamless,ln Q-- ..:*-:*,r

For authenticity verification, contact us

Rahul Pushpatode -

Name & Signature of lnspecting Authority/ Well

Known pipes Maker

Test certificate valid with original Hologram, o

tffi

ln. ruo.'--Z{--l

m

ffip)

You might also like

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Mgoha : ' "Xsjjl8Document1 pageMgoha : ' "Xsjjl8PetroPower OilandgasNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- Tram Grooved Rails New Catalog January 2018Document12 pagesTram Grooved Rails New Catalog January 2018Szabolcs Attila KöllőNo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Mechnical Property For Q235B Carbon SteelDocument3 pagesMechnical Property For Q235B Carbon SteelPritom Ahmed100% (1)

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- Astm A36 Chapa Grossa Ate 19mm PDFDocument1 pageAstm A36 Chapa Grossa Ate 19mm PDFHugo RodriguezNo ratings yet

- Ss Grade 50 - Galvanized Steel Coils & SheetsDocument1 pageSs Grade 50 - Galvanized Steel Coils & SheetshealgoseNo ratings yet

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEDocument1 pageHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeNo ratings yet

- TC No-1451Document1 pageTC No-1451Structures ProductionNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- Test Certificate: D & H Secheron Electrodes Pvt. LTDDocument1 pageTest Certificate: D & H Secheron Electrodes Pvt. LTDSagar KumarNo ratings yet

- Flange 8 Inch RTJDocument3 pagesFlange 8 Inch RTJreniNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- MTC - Oufo (Argentina) - 16Document1 pageMTC - Oufo (Argentina) - 16Aceros DessolNo ratings yet

- Material Product Data SheetDocument4 pagesMaterial Product Data SheethungNo ratings yet

- Asme Section Ii A-2 Sa-815 Sa-815mDocument10 pagesAsme Section Ii A-2 Sa-815 Sa-815mdavid perezNo ratings yet

- Teava Rect 50X50X3MM PDFDocument1 pageTeava Rect 50X50X3MM PDFCiprian ShaolinNo ratings yet

- 30 MM Round Bar - EN8 - MTCDocument1 page30 MM Round Bar - EN8 - MTCMohammad Adil0% (1)

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- CF8M VS CF8 Stainless Steel Casting - JC CastingDocument7 pagesCF8M VS CF8 Stainless Steel Casting - JC CastingSHivaprasad APITNo ratings yet

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- DB-En 19 R-2-829 PDFDocument4 pagesDB-En 19 R-2-829 PDFashokNo ratings yet

- Vedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKDocument23 pagesVedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKPRAKASH PANDEYNo ratings yet

- WNRF 2 MFF ItalyDocument1 pageWNRF 2 MFF ItalyMohamed RaafatNo ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- 1 MTCDocument2 pages1 MTCRazvan CristeaNo ratings yet

- Inspection Certificate 3.1 As Per JIS G0415:2014, EN 10204:2004, ISO 10474:2013 Cert No: 1000040855 Page 1 of 2Document2 pagesInspection Certificate 3.1 As Per JIS G0415:2014, EN 10204:2004, ISO 10474:2013 Cert No: 1000040855 Page 1 of 2Silverio AcuñaNo ratings yet

- DIN 3015 ClampsDocument17 pagesDIN 3015 ClampsBalderas Rosas WilibaldoNo ratings yet

- Conversion Car Shed BOQDocument16 pagesConversion Car Shed BOQPraveen JoseNo ratings yet

- S235JR SteelDocument1 pageS235JR SteelNguyễn Thanh CườngNo ratings yet

- 14mm Gr60Document1 page14mm Gr60alshaya steelNo ratings yet

- Chemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateDocument2 pagesChemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateVarun Malhotra100% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh MehtaNo ratings yet

- TECHBID - PT75 Iocl WBDocument84 pagesTECHBID - PT75 Iocl WBhemuagNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- MTC 8,10Document2 pagesMTC 8,10Vu NamNo ratings yet

- Quality Certificated 123Document1 pageQuality Certificated 123Zaid Raslan Ayoub100% (1)

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- En 8Document3 pagesEn 8ajaykrishnaaNo ratings yet

- CV Painting InsulationDocument3 pagesCV Painting Insulationhamza brahmiNo ratings yet

- JCOUSER03Document1 pageJCOUSER03Neem LalNo ratings yet

- Check Valve 6in HT 6YF4Document1 pageCheck Valve 6in HT 6YF4Juan Pablo Perdomo OrtizNo ratings yet

- Material Test Certificates: Supplied ToDocument2 pagesMaterial Test Certificates: Supplied ToShaheen Andre ChikkuNo ratings yet

- Outokumpu: Si MN P S CR NiDocument3 pagesOutokumpu: Si MN P S CR NiDarkedgeNo ratings yet

- 9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFDocument1 page9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFantonio larotta100% (1)

- hot rolled Φ60 AISI 304L (14.230)Document3 pageshot rolled Φ60 AISI 304L (14.230)A. ΒρατσισταNo ratings yet

- TV 100x100x5#S235JRDocument5 pagesTV 100x100x5#S235JRRazvan CristeaNo ratings yet

- Round Bar 60mm, Square Bar 50 MM - MTCDocument1 pageRound Bar 60mm, Square Bar 50 MM - MTCMohammad Adil0% (1)

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocument1 pageLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCNo ratings yet

- 60 MM SA 516 GR 70 MTCDocument21 pages60 MM SA 516 GR 70 MTCgeoanburajaNo ratings yet

- Varilla B7 3-8 X 144 MT (B7)Document1 pageVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoNo ratings yet

- WPS PQR CompressedDocument5 pagesWPS PQR CompressedBalaje MantravadiNo ratings yet

- C211050 01 VCS Iocl Tender 001 - D2Document619 pagesC211050 01 VCS Iocl Tender 001 - D2Aqib Khan VCSPNo ratings yet

- 2007 Datasheet QOECDocument2 pages2007 Datasheet QOECAqib Khan VCSPNo ratings yet

- 0444-Icpl-Ds-028 & 043 Rev00Document28 pages0444-Icpl-Ds-028 & 043 Rev00Aqib Khan VCSPNo ratings yet

- 26 Inch Pipe Thickness As Per 31.3Document1 page26 Inch Pipe Thickness As Per 31.3Aqib Khan VCSPNo ratings yet

- 7p23a PR Pid 1001 A2Document1 page7p23a PR Pid 1001 A2Aqib Khan VCSPNo ratings yet

- HiltiDocument1 pageHiltiAqib Khan VCSPNo ratings yet

- Steel Connections v1.3Document83 pagesSteel Connections v1.3Mateus GehlenNo ratings yet

- Episode 607: Specific Heat Capacity: Changes Phase From A Solid To A Liquid or Liquid To A GasDocument19 pagesEpisode 607: Specific Heat Capacity: Changes Phase From A Solid To A Liquid or Liquid To A GasMuhamadMarufNo ratings yet

- Rotating Fatigue PDFDocument2 pagesRotating Fatigue PDFMia FarhanaNo ratings yet

- Palm Oil Mill PipingDocument4 pagesPalm Oil Mill PipingmshkNo ratings yet

- Foxboro 871 PHDocument16 pagesFoxboro 871 PHelsalseritoNo ratings yet

- NGDocument23 pagesNGEngr. Md. Tipu SultanNo ratings yet

- 2 2 3 Aa RecyclingFactsDocument5 pages2 2 3 Aa RecyclingFactsRyan CedergrenNo ratings yet

- Waste Minimization and ManagementDocument32 pagesWaste Minimization and ManagementNur AishaNo ratings yet

- Nano SensorsDocument16 pagesNano SensorsAnkusjNo ratings yet

- Domos Volcanicos y Mineralizacion de Oro en El DisDocument21 pagesDomos Volcanicos y Mineralizacion de Oro en El DisfacflNo ratings yet

- Chlor AlkaliDocument4 pagesChlor AlkaliYusof SundangNo ratings yet

- BS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDFDocument28 pagesBS en 14692-2017 - TC - (2020-08-27 - 08-40-55 Am) PDF梁山伯No ratings yet

- Green Solvents PresDocument74 pagesGreen Solvents PresTDSNo ratings yet

- Super Blonde ShellacDocument9 pagesSuper Blonde ShellacBudi Budaya BstNo ratings yet

- Construciton SupervisorDocument16 pagesConstruciton SupervisorkinleyNo ratings yet

- GS AFES 3 Pond-ChimneyDocument52 pagesGS AFES 3 Pond-ChimneyHabibz ZarnuJi100% (1)

- D 3301 - 94 RdmzmdetukveDocument7 pagesD 3301 - 94 RdmzmdetukveHernan MartNo ratings yet

- IDFL Test Summary - Air Permeability A4Document1 pageIDFL Test Summary - Air Permeability A4Keith WilsonNo ratings yet

- Culvert (1x3.0x3.0)Document19 pagesCulvert (1x3.0x3.0)Shashank SrivastavaNo ratings yet

- Literature ReviewDocument36 pagesLiterature Reviewprakush_prakush0% (1)

- Cobalch Aps - PTFE DetailDocument25 pagesCobalch Aps - PTFE DetailMorteza DianatfarNo ratings yet

- Ipex - 2009 - Abs Chemical Resistance GuideDocument22 pagesIpex - 2009 - Abs Chemical Resistance GuideHenrique Ribeiro Piaggio CardosoNo ratings yet

- Composite Materials Used For UAVDocument3 pagesComposite Materials Used For UAVAkashNo ratings yet

- IBT Sample Questions: ScienceDocument2 pagesIBT Sample Questions: Scienceshrutiverma_1No ratings yet

- Applied Catalysis B: EnvironmentalDocument14 pagesApplied Catalysis B: EnvironmentalAnonymous 2g4jKo5a7vNo ratings yet

- Internship REPORTDocument30 pagesInternship REPORTImran GulNo ratings yet

- THE Formation of Late Magmatic Oxide Ores.: Alan M. BatemanDocument23 pagesTHE Formation of Late Magmatic Oxide Ores.: Alan M. BatemanRorisang MalebyeNo ratings yet

- ChemistryPaper FullDocument20 pagesChemistryPaper FullChanderpal BarupalNo ratings yet

- Case Study: Materials For Blood Bags: WWW - Blood.co - UkDocument6 pagesCase Study: Materials For Blood Bags: WWW - Blood.co - UkBijuChudraponvelilThomasNo ratings yet

- Conveyor BeltsDocument12 pagesConveyor BeltsEGS_1977No ratings yet