Professional Documents

Culture Documents

MOM Tk-5 Readiness Check (05.30.18)

MOM Tk-5 Readiness Check (05.30.18)

Uploaded by

Joemar Ancheta0 ratings0% found this document useful (0 votes)

5 views9 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views9 pagesMOM Tk-5 Readiness Check (05.30.18)

MOM Tk-5 Readiness Check (05.30.18)

Uploaded by

Joemar AnchetaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

‘MOM No,

Ba MINUTES OF MEETING (MOM) ‘Contract No.

Perron i Project No.

Place: | SPT Meeting Room

Meeting: Tk-5 Readiness Check Date and Time: | 5/30/18

Prepared by: | JF Ancheta/ baeRparre

Petron SUMBTC

‘DM Mahilurn IM Agustin JF Ancheta ric Estanisloo

EB Lamasan CA Rivero Richard Arellano

[AB Lumang ML Alviz

(CB Geron Jr MA Aparre

CC: SSC RBM LGL IGP CSC

ee

HIGHLIGHTS

Perey

TKS punchlist items were discussed to ensure readiness far the planned

transfer of 6MB Mogas from Tk-8,

For information

‘SLHBTC agreed to provide concrete encasement for the U/G Firewater line.

2 | Buried depth will be 900 mm. Sand bedding and petrolatum wrapping will be

provided for the U/G pipe.

SUMBTC

‘SLs proposed interim wastewater scheme of Tk

water draw-off to sump—i

in Petron depots.

—using open ditch to route

acceptable to SLP as this is the same scheme used

For confirmation

Post meeting note: SLHBTC to finish this activity on June 15, 2018.

SSLHBTC to finish punchlist related to this item by June 8, 2018. SUMBTC

Instrument commissioning of MCTI for Tk-S to be witnessed by SLHBTC

SPT/SLHBTC/SLP. SLHBTC to contact MCTI for schedule of commissioning.

55 | FoF verification of other instrumentation items with SLHBTC and MCTI (please Hae

see attached punch item list).

Dike capacity of Tk-S to be increased by SLHBTC to accommodate the 6 MB

«| Yolume of Tk-B, SLHBTC to provide equipment forthe activity oe

7_ | Please see attached punch list items.

Forinformation |

Notedpy gq

istin / CB Geron Jr

oe by:

FF RObtutar

Page of

TK-5 INSPECTION FINDINGS

Legend:

© Punch A: Needed Prior Commissioning

Punch B: Can be done after Commissioning

FINDINGS, PUNCH ITEMS PICTURES ETC

Punch A

Firefighting pipelines, foam | Hard piping of firewater line/

and firewater, terminate foam line (with provision for foam June 8, 2018

outside dike. injection). Isolation valves should

be installed outside the dike.

Water drawoff terminates at

valve.

Punch A

‘installation of connection from Tk-5

The ditch from Tk-5 connects | dike to pump slab (pipeline and

to Mogas pump slab and to | valve) fiestas

sump. Sump has no

connection to OWS (for oily

water) and ditch (for clean

water) to Manila Bay.

2.Install connection from mini-OWS

to Manila Bay (pipeline and valve]

3.Installation of concrete flooring of

pump slab

Punch A.

It is recommended that skirt shall be

installed at Stilling well end pipe to

ensure servo displacer will not stuck

at the edge of the well. This also

Servo gauge stilling well end COMPLETED

protects the guy wire lifting the

pipe without skirt as of May 21,

displacer against damage cause by

2018

sharp well edge.

“update 5/21/18

A screen was installed instead of a

skirt.

Punch A

Instrument cable not Re-Terminate cable and ensure COMPLETED

properly installed, possible} workmanship to avoid at water as of May 29,

water entry intrusion on instrument electronic 2018

part.

Minor corrosion on Conduit

support such as U-bolt

Punch B

Repaint Conduit support or replace

with non-corrosive material such as

stainless steel.

No Instrument grounding

Punch 6

Install instrument grounding cable

from Instrument GND Terminal to

Tank structure (e.g. Flange bolt)

Punch B

Cut cable excess length and install

perforated tray to properly harness

cables.

Excessive cable length and

cable not properly

harnessed.

All instruments shall be installed,

tested and commissioned properly

prior product in. Ensure vendor

‘Commissioning

of instrument

for scheduling

with MCTI (to

conmasionng wort maser

eae by SL/SLP/SPT

Wire color terminations not

according to Petron

Standard, Power and signal

separation and segregation

issues

Punch B

Petron Standard is White cable for

Negative and Black Cable for

Positive and all cables will have

labels. Existing termination, white

for positive and white for negative

with no labels are prone to errors

and confusion for maintenance

personnel. We advise to conduct

loop check and follow Petron

Standard. Power and signal

separation and segregation shall be

imposed to ensure functionality of

the instrument at DCS. Voltage test

on Delta V connections must be

done to ensure to AC or induced

voltage are found.

Power and signal separation

and segregation issues

Punch B

Power and signal separation of

300mm minimum and segregation

shall be imposed to ensure

functionality of the instrument at

DCS. Voltage test on Delta V

connections must be done to ensure

to AC or induced voltage are found.

‘Some fittings used are

Galvanized tron.

Punch A

Replace all Gi fittings.

For

verification

with MCTI

ETC: June 1,

2018

No excess threads

Punch B

‘Some bolts used are too small. There

should be an excess of 3 or more

thread on both sides.

Al AC powered instruments

shall not be used asa

tapping point to supply other

AC powered instruments,

Punch B

A junction box or conduit shall be

provided for AC power distribution.

Almost 30m difference

between stilling well screen

and striking plate.

Punch A

‘As per API MPMS 3.18 a datum

plate must be located directly under

the reference gauge point to

provide a fixed contact surface to

Which liquid level measurements

can be made. Since no datum plate

was installed the stilling well screen

will have to act as the datum plate.

Our concern is the level difference

between the striking plate and the

screen, They should be on the same

level to have an accurate reading

between innage manual sounding

and instrument reading. A 3em

difference between the striking.

plate and screen will always have a

3cm difference between the innage

sounding and Instrument reading

even if the servo level gauge is

calibrated.

Zero adjust to be performed in the

instrument to compensate screen

and striking plate level difference.

SL to coordinate with MCTI

1 Striking Plate

2+ Stilling well screen

Commissioning

of instrument

for scheduling

with MCTI (to

be witnessed

by SL/SLP/sPT.

Thin C-channel support used

for the Tanks side indicator

Punch B

‘Thicker C-channel hot dipped

galvanized shall be used.

Current dike capacity is 53%

Punch A

Increase earth dike height to 2.2 m

to increase dike capacity to 68%

enabling Tk-S to receive 6MB

‘mogas from Tk-B

Punch B

Increase dike capacity by increasing

dike height and/or dike area to

accommodate 100% of Tk-5 capacity

Capacity for

verification by

st

ETC: May 30,

2018

Punch A

ETC: June 15,

2018

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PMP Project DocumentsDocument9 pagesPMP Project DocumentsJoemar AnchetaNo ratings yet

- Carbon Steel SpecificationsDocument1 pageCarbon Steel SpecificationsJoemar AnchetaNo ratings yet

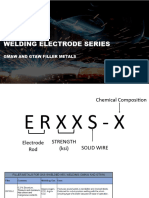

- How To Read A Stick Welding ElectrodeDocument4 pagesHow To Read A Stick Welding ElectrodeJoemar AnchetaNo ratings yet

- Diesel Engine Practice QuestionsDocument1 pageDiesel Engine Practice QuestionsJoemar AnchetaNo ratings yet

- How To Read Gmaw and Gtaw Filler MetalsDocument3 pagesHow To Read Gmaw and Gtaw Filler MetalsJoemar AnchetaNo ratings yet

- T RMP2 DP 0560 - AcknowledgedDocument2 pagesT RMP2 DP 0560 - AcknowledgedJoemar AnchetaNo ratings yet

- Boring LogsDocument1 pageBoring LogsJoemar AnchetaNo ratings yet

- T SPT SLP 001Document1 pageT SPT SLP 001Joemar AnchetaNo ratings yet

- Attachment 1 - OSBL Piping RouteDocument1 pageAttachment 1 - OSBL Piping RouteJoemar AnchetaNo ratings yet

- Centrifugal+compressors+ +13.+foundations Check Soft Foot CheckDocument1 pageCentrifugal+compressors+ +13.+foundations Check Soft Foot CheckJoemar AnchetaNo ratings yet

- Project Management 2Document1 pageProject Management 2Joemar AnchetaNo ratings yet

- Project Management 1Document1 pageProject Management 1Joemar AnchetaNo ratings yet

- Common Tools and TechniquesDocument6 pagesCommon Tools and TechniquesJoemar AnchetaNo ratings yet

- ITTOsDocument173 pagesITTOsJoemar AnchetaNo ratings yet

- Guide To Professional Mechanical Engineering ApplicationDocument2 pagesGuide To Professional Mechanical Engineering ApplicationJoemar AnchetaNo ratings yet