Professional Documents

Culture Documents

MS17825H

Uploaded by

sje productionOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS17825H

Uploaded by

sje productionCopyright:

Available Formats

Downloaded from http://www.everyspec.

com

INCH-POUND

MS17825H

5 February 2004

SUPERSEDING

MS17825G

30 November 1988

MS SPECIFICATION SHEET

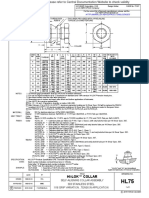

NUT, SELF-LOCKING, CASTELLATED, HEXAGON, .250°F

NON-METTALIC INSERT

Reactivate after 5 February 2004 and may be used for new

and existing designs and acquisitions.

This specification is approved for use by all

Department and Agencies of the Department of Defense.

The requirements for acquiring the product described herein shall consist of this MS specification sheet and

NASM25027.

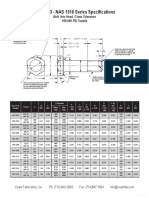

OPPOSITE SLOTS MUST COINCIDE WITHIN

.005 AND SLOT AXIS MUST BE WITHIN

.005 OF THREAD P.D. AXIS

MARK MFG IDENT.

ON THIS SURFACE

K

SHAPE OF TOP

R OPTIONAL

A

L

J

30° ±5°

G ØD

C

ŘM

WASHER FACE, CHAMFER OR RADIUS RELIEF

OPTIONAL WHEN WITHIN THE 30° ±5°

ANGLE AND "M" DIA LIMITATIONS

TABLE I. NUT DIMENSIONS AND STRENGTHS

SIZE A B C ∅D G J

DASH THREAD

NO. AS8879 MAX MIN MAX MIN MIN MAX MAX MIN MAX MIN

-3 .1900-32 UNJF-3B .265 .235 .376 .367 .410 .215 .032 .006 .125 .105

-4 .2500-28 UNJF-3B .296 .266 .439 .430 .482 .275 .036 .007 .141 .121

-5 .3125-24 UNJF-3B .343 .313 .502 .492 .552 .338 .042 .008 .188 .168

-6 .3750-24 UNJF-3B .421 .391 .564 .553 .622 .400 .235 .215

-7 .4375-20 UNJF-3B .468 .438 .690 .679 .766 .463 .050 .010 .282 .262

-8 .5000-20 UNJF-3B .578 .548 .752 .741 .837 .525 .375 .355

-9 .5625-18 UNJF-3B .624 .594 .877 .865 .978 .587 .055 .012 .406 .386

-10 .6250-18 UNJF-3B .734 .704 .940 .928 1.051 .650 .484 .464

-12 .7500-16 UNJF-3B .828 .798 1.064 1.052 1.191 .795 .063 .014 .578 .558

-14 .8750-14 UNJF-3B .921 .891 1.252 1.239 1.403 .900 .072 .016 .672 .652

-16 1.0000-12 UNJF-3B 1.015 .985 1.440 1.427 1.615 1.025 .766 .746

-18 1.1250-12 UNJF-3B 1.171 1.141 1.627 1.614 1.825 1.150 .083 .018 .828 .808

-20 1.2500-12 UNJF-3B 1.265 1.235 1.815 1.801 2.038 1.275 .891 .871

AMSC N/A FSC 5310

Downloaded from http://www.everyspec.com

MS17825H

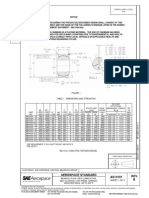

TABLE I. (CONT’D)

ULTIMATE TEST ASSEMBLY

SIZE

TENSILE WRENCHING TORQUE WEIGHT

DASH K L ∅M R

STRENGTH VIBRATION LB/100

NO.

LB MIN TORQUE (IN. LBS)

(INCH LBS)

MAX MIN MIN MAX MIN MAX MIN MAX MAX

-3 .110 .376 .355 1,950 35 28 .400

-4 .108 .078 .125 .439 .418 .035 3,500 80 65 .650

-5 .172 .502 .480 5,500 225 180 1.000

-6 .218 .564 .543 9,000 325 260 1.400

-7 .155 .125 .265 .690 .675 .053 12,200 575 460 2.000

-8 .359 .752 .737 16,600 900 720 3.900

-9 .390 .877 .862 21,200 1,100 880 6.900

-10 .468 .940 .925 27,400 1,600 1,300 11.400

-12 .562 1.064 1.049 40,000 2,800 2,200 16.900

-14 .187 .157 .656 1.252 1.237 .062 54,600 4,600 3,700 26.000

-16 .750 1.440 1.425 71,000 6,800 5,400 38.000

-18 .844 1.627 1.612 92,600 10,000 8,000 53.500

-20 .938 1.815 1.800 118,500 14,000 11,000 74.500

REQUIREMENTS:

MATERIALS: Steel, UNS G11370 (AISI 1137) per AMS5024

UNS G11374 (AISI 11L37) per AMS5020

UNS G41300 (AISI 4130) per AMS6348

UNS G87400 (AISI 8740) per AMS6322, 6323, 6325, 6327, and 6358.

INSERT MATERIAL: Nylon.

FINISH: Cadmium plating in accordance with SAE-AMS-QQ-P-416, Type II, Class 2.

Break all sharp edges and remove burrs.

SURFACE TEXTURE: 125 in accordance with ASME B46.1.

DIMENSIONS: All dimensions are in inches unless otherwise specified.

DESIGN INFORMATION: These nuts may be used at temperatures 250° F and below in those types of applications for

which slotted or castellated nuts are approved for use, and if such applications conflict with

any limitation on the use of self-locking nuts, as cited by NASM33588, this standard takes

precedence. Nuts are to be installed in accordance with NASM33540.

EXAMPLE OF PART NUMBER: MS17825-4 = .2500-28 nut, cadmium plated, non-metallic insert.

PERFORMANCE: Per NASM25027 except for:

1 – Tabulated ultimate tensile strength values.

2 – Vibration per NASM1312-7, (30,000 cycles) using assembly torques listed in Table I for one seated

cycle.

3 – Locking torque valves applicable for one cycle at room temperature only.

Certain provisions (limits for across flat dimension) of this standard are the subject of International Standardization ABC

STD 17/2. When revision or cancellation of this standard is proposed which will affect or violate the international agreement

concerned. The preparing activity will take appropriate reconciliation action through international standardization channels,

including departmental standardization officer, if required.

For design feature purposes, this standard takes precedence over procurement documents referenced herein. Referenced

documents shall be of the issue in effect on date of invitations for bids, or request for proposal.

Changes from previous issue. Marginal notations are not used in this revision to identify changes with respect to the previous

issue due to the extent of the changes.

Custodians: Preparing Activity

Navy – AS DLA-IS

Air Force – 99

(Project 5310- 2710)

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Ms28777 Rev DDocument2 pagesMs28777 Rev DMathew UsfNo ratings yet

- MS25205GDocument5 pagesMS25205GGülinNo ratings yet

- AN6204Document4 pagesAN6204CTN2010No ratings yet

- Nas 1329Document4 pagesNas 1329randoll jamesNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- MS14182B - Parafuso Cabeça EstriadaDocument3 pagesMS14182B - Parafuso Cabeça EstriadaRenato WatanabeNo ratings yet

- An924 Rev. 14Document8 pagesAn924 Rev. 14David WongNo ratings yet

- MS3217CDocument8 pagesMS3217Csezgin bayramNo ratings yet

- MS51830FDocument5 pagesMS51830FValentinNo ratings yet

- AN924Document8 pagesAN924David WongNo ratings yet

- Fixations-Ms21047 MS21055Document1 pageFixations-Ms21047 MS21055FredNo ratings yet

- MS27484T12B4SDocument2 pagesMS27484T12B4SCHE WEINo ratings yet

- MS27645EDocument3 pagesMS27645EVictor A. Claure ManzoniNo ratings yet

- Data Sheets Bettis GC Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric Bettis en en 7191530Document34 pagesData Sheets Bettis GC Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric Bettis en en 7191530rey sarNo ratings yet

- HST 78Document1 pageHST 78何少杰No ratings yet

- Data Sheet: EFD Cores and AccessoriesDocument7 pagesData Sheet: EFD Cores and AccessoriesAlberto Souto MartínezNo ratings yet

- 6y-2343 Valve Gp-Selector & Press Cont S:N 3ze1-Up Part of 8P-9711 Valve Gp-Control PDFDocument3 pages6y-2343 Valve Gp-Selector & Press Cont S:N 3ze1-Up Part of 8P-9711 Valve Gp-Control PDFEdgar TorresNo ratings yet

- National Aerospace Standard: Fed. Supply ClassDocument4 pagesNational Aerospace Standard: Fed. Supply ClassGlenn CHOU100% (1)

- MS33678 Rev ADocument5 pagesMS33678 Rev Aliuyx866No ratings yet

- Ajw gtcp331-500b Minipack SN p-1154Document249 pagesAjw gtcp331-500b Minipack SN p-1154Okky Pangestoe WibowoNo ratings yet

- MS20663EDocument3 pagesMS20663EYotam ShalemNo ratings yet

- MS20001MDocument5 pagesMS20001MthomasNo ratings yet

- P PO OW WE ER RT TR RA Aiin N: Axle Ar-FixedDocument7 pagesP PO OW WE ER RT TR RA Aiin N: Axle Ar-FixedWladimir Franz Rodríguez SaloméNo ratings yet

- Nehemiah Wall-Section 5Document3 pagesNehemiah Wall-Section 5Hazim AffendiNo ratings yet

- MS20026FDocument8 pagesMS20026FthomasNo ratings yet

- Aerospace Standard AS81934/1 Rev. A: Custodian: Sae Airframe Control Bearings GroupDocument3 pagesAerospace Standard AS81934/1 Rev. A: Custodian: Sae Airframe Control Bearings GroupRangaNo ratings yet

- 10 - Estrutura InferiorDocument32 pages10 - Estrutura InferiorFabio MacielNo ratings yet

- Sae As14101bDocument3 pagesSae As14101bTom ZhangNo ratings yet

- A-A-59125-30 (Class 38TB)Document3 pagesA-A-59125-30 (Class 38TB)MAI_QualityNo ratings yet

- Pages From Ornit - Digital - Catalog - 2019Document1 pagePages From Ornit - Digital - Catalog - 2019rsluckyNo ratings yet

- Relay Test Report: AB Impedance ShotDocument5 pagesRelay Test Report: AB Impedance ShotAbhishek RajputNo ratings yet

- 0500hrs - Jan 23. (ACT) REV 23.XlsbDocument113 pages0500hrs - Jan 23. (ACT) REV 23.Xlsbsavani VivekNo ratings yet

- Aerospace Standard AS81934/2 Rev. A: Custodian: Sae Airframe Control Bearings GroupDocument3 pagesAerospace Standard AS81934/2 Rev. A: Custodian: Sae Airframe Control Bearings GroupRanga100% (1)

- Tender Tracking Sheet - Updated 5th April2019Document97 pagesTender Tracking Sheet - Updated 5th April2019jaya shankarNo ratings yet

- Bevel Gears & Gear Sets: Quality With Value GuaranteedDocument1 pageBevel Gears & Gear Sets: Quality With Value GuaranteedSergio Ballestas100% (1)

- Brake Control 966fDocument2 pagesBrake Control 966fKusuma JayaNo ratings yet

- Aci - Warranty Claim Worksheet - Up To Sep - 2022Document2 pagesAci - Warranty Claim Worksheet - Up To Sep - 2022Md. Nasirul IslamNo ratings yet

- Cap 4 SCH STD 40 Astm A234 HT38987Document1 pageCap 4 SCH STD 40 Astm A234 HT38987antoniosofwareNo ratings yet

- MG460 Engine 6D24-TDocument204 pagesMG460 Engine 6D24-TPëerawích Fang100% (1)

- MS20001PDocument5 pagesMS20001PthomasNo ratings yet

- D6R2 ExportDocument2 pagesD6R2 ExportteguhNo ratings yet

- 10-Material RodanteDocument87 pages10-Material RodanteFabio MacielNo ratings yet

- 220KV MudashingiDocument6 pages220KV MudashingiAbhishek RajputNo ratings yet

- Ms20002an970 (MS63040)Document1 pageMs20002an970 (MS63040)robinyNo ratings yet

- MS20026EDocument8 pagesMS20026EthomasNo ratings yet

- Product Data Sheet Bettis G Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric en 1458986Document38 pagesProduct Data Sheet Bettis G Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric en 1458986tajman90No ratings yet

- Gear Box Cat 12HDocument28 pagesGear Box Cat 12HBetty CuperNo ratings yet

- ED-03-LA Bàn TDocument49 pagesED-03-LA Bàn TTamNo ratings yet

- Epr AllDocument1 pageEpr AllAyu PutriNo ratings yet

- Acme Engineering College: Distance Measure SheetDocument15 pagesAcme Engineering College: Distance Measure Sheetniraj bhandariNo ratings yet

- Ratch de Frenos - Pai - Catalog - Sheet - 8057Document1 pageRatch de Frenos - Pai - Catalog - Sheet - 8057Alexis ValleNo ratings yet

- Traseira Renault para ChoquesDocument2 pagesTraseira Renault para ChoquesJose Luis TocoNo ratings yet

- SAEJ636v002 - Correias V e Polias (00000002)Document10 pagesSAEJ636v002 - Correias V e Polias (00000002)RENAN CAPARRA SPADIMNo ratings yet

- Datasheet de Un CapacitorDocument1 pageDatasheet de Un CapacitorSantiago Guerrero MartinezNo ratings yet

- Centrifugal Fans & BlowersDocument4 pagesCentrifugal Fans & BlowersJeffrey RafaelNo ratings yet

- HPR-2Document12 pagesHPR-2v2nssysy6fNo ratings yet

- SB369M Engine Inspection After OverspeedDocument7 pagesSB369M Engine Inspection After OverspeedCristian RemacheNo ratings yet

- K DevRepDocument3 pagesK DevRepMuhammad Fahmmi Bin MahmudNo ratings yet

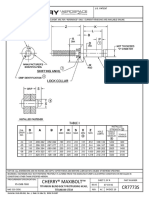

- CR7773SDocument5 pagesCR7773SYoNo ratings yet

- EB080 DoubleHexagonNut EB080Document2 pagesEB080 DoubleHexagonNut EB080sje productionNo ratings yet

- MS21061GDocument3 pagesMS21061Gsje productionNo ratings yet

- Titanium IIDocument1 pageTitanium IIsje productionNo ratings yet

- Titanium AnodizingDocument4 pagesTitanium Anodizingsje productionNo ratings yet

- NAS1303 CoastFabricationDocument2 pagesNAS1303 CoastFabricationsje productionNo ratings yet

- 1LE1504-3AB23-4AB4 Datasheet enDocument1 page1LE1504-3AB23-4AB4 Datasheet enOkke BoykeNo ratings yet

- Alloy 2007 en Aw-Alcu4Pbmgmn: Etem'S EtemDocument23 pagesAlloy 2007 en Aw-Alcu4Pbmgmn: Etem'S EtemIsakov IgorNo ratings yet

- Simple Harmonic MotionDocument17 pagesSimple Harmonic MotionAbdul Raafay AnsariNo ratings yet

- Chapter C15 Design Requirements For Structures With Supplemental Energy DissipationDocument6 pagesChapter C15 Design Requirements For Structures With Supplemental Energy DissipationEDWIN CHAUCA MEJÍANo ratings yet

- ECE Catalogue PDFDocument26 pagesECE Catalogue PDFssn100% (1)

- 18.1 Pressure CIE IGCSE Physics Ext Theory MsDocument5 pages18.1 Pressure CIE IGCSE Physics Ext Theory Msyousef.abdelazim11No ratings yet

- Insight VMDocument72 pagesInsight VMDeepthi MenonNo ratings yet

- Conector 7-16 Din Hembra 7/8" Cellflex.Document2 pagesConector 7-16 Din Hembra 7/8" Cellflex.SIMON S. FLORES G.No ratings yet

- Normalization of The WavefunctionDocument4 pagesNormalization of The WavefunctionZulfiqar AliNo ratings yet

- Form 1 - COMPUTER - NOTES All ChaptersDocument292 pagesForm 1 - COMPUTER - NOTES All ChaptersTakunda TatiwaNo ratings yet

- 1 - Final - Tutorial On Review of Single Three Phase AC CircuitDocument2 pages1 - Final - Tutorial On Review of Single Three Phase AC Circuitnitai.naicker21No ratings yet

- Hanin SlidesDocument42 pagesHanin SlidesBimal ChandNo ratings yet

- GCE As and A Level Subject Content For Further Mathematics With AppendicesDocument25 pagesGCE As and A Level Subject Content For Further Mathematics With AppendiceskuailewudagouNo ratings yet

- Chemistry of High-EnergyDocument386 pagesChemistry of High-Energybiopowered@gmail.comNo ratings yet

- Lesson Plan in Math 2 (UDL Strategy)Document10 pagesLesson Plan in Math 2 (UDL Strategy)Karla De Guzman Hornilla100% (21)

- ICE QB - Mech - 6th - 2018 - 02Document8 pagesICE QB - Mech - 6th - 2018 - 02Nits KNo ratings yet

- Using PivotTDocument36 pagesUsing PivotTZara RamisNo ratings yet

- Enable Disable Button in A Custom FormDocument2 pagesEnable Disable Button in A Custom FormjainviNo ratings yet

- Manual de Serviço FYM 250 Shark 250 Shineray 250Document101 pagesManual de Serviço FYM 250 Shark 250 Shineray 250lupion cane67% (3)

- Lecture Notes Complex Analysis MATH 435: Instructor: Ivan AvramidiDocument95 pagesLecture Notes Complex Analysis MATH 435: Instructor: Ivan Avramidimichaelnganga2No ratings yet

- Class-XII Sub-Physics Date-28-10-2020 NameDocument3 pagesClass-XII Sub-Physics Date-28-10-2020 NameLORD X GAMERNo ratings yet

- Matrix Academy: MHT-CET-XII - New Syllabus (MH) 2022-23Document4 pagesMatrix Academy: MHT-CET-XII - New Syllabus (MH) 2022-23Light MayNo ratings yet

- Pilar JembatanDocument37 pagesPilar JembatanMAWAR08100% (4)

- Below Frequency Response of A 2nd Order Band Pass FilterDocument11 pagesBelow Frequency Response of A 2nd Order Band Pass FilterNurul FathiaNo ratings yet

- Pneumatic SwitchDocument3 pagesPneumatic SwitchMuddassar SultanNo ratings yet

- Cooper CameronDocument33 pagesCooper CameronsalemNo ratings yet

- Systec D 45 enDocument1 pageSystec D 45 ennotaden1849No ratings yet

- Geas FormulaDocument29 pagesGeas Formularoy016No ratings yet

- Gas Blending For Scuba Diving - WikipediaDocument11 pagesGas Blending For Scuba Diving - Wikipediamiguek clementsNo ratings yet

- Dimensions of The Cobas 8100 ModulesDocument4 pagesDimensions of The Cobas 8100 ModulesJurica ErcegNo ratings yet