Professional Documents

Culture Documents

Tube Nut Specification Sheet

Uploaded by

David WongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tube Nut Specification Sheet

Uploaded by

David WongCopyright:

Available Formats

INCH-POUND

AN924 Rev 14

15 February 2018

SUPERSEDING

AN924 Rev 13

14 April 20104

DETAIL SPECIFICATION SHEET

NUT, TUBE, BULKHEAD AND UNIVERSAL FITTING

Reinstated after 14 June 2012. Inactive for new design.

For new design, use SAE-AS5178.

This specification is approved for use by all Departments and

Agencies of the Department of Defense.

The requirements for acquiring the product described herein shall consist of this specification sheet and

SAE-AS4841.

Inch mm

.005 0.13

See notes at end of figure.

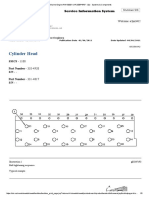

FIGURE 1. Tube nut dimensions and configurations.

AMSC N/A FSC 4730

Source: http://assist.dla.mil -- Downloaded: 2020-05-26T17:21Z

Check the source to verify that this is the current version before use.

AN924 Rev 14

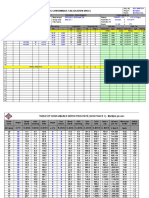

Thread T

Dash Tubing A B

(Ref)

number OD (mm) (mm)

SAE-AS8879

-2 .125 .3125-24UNJF-3B .563 (14.30) .219 (5.56)

-3 .188 .3750-24UNJF-3B .625 (15.88) .219 (5.56)

-4 .250 .4375-20UNJF-3B .688 (17.48) .250 (6.35)

-5 .313 .5000-20UNJF-3B .750 (19.05) +.003 (0.08) .250 (6.35)

-6 .375 .5625-18UNJF-3B .813 (20.65) -.004 (0.10) .266 (6.76)

-8 .500 .7500-16UNJF-3B 1.000 (25.40) .313 (7.95)

-10 .628 .8750-14UNJF-3B 1.125 (28.58) .359 (9.12)

-12 .750 1.0625-12UNJ-3B 1.375 (34.93)

-16 1.000 1.3125-12UNJ-3B 1.625 (41.28)

±.016 (0.41)

-20 1.250 1.6250-12UNJ-3B 1.938 (49.23)

-24 1.500 1.875-12UNJ-3B 2.188 (55.58)

.406 (10.31)

-28 1.750 2.250-12UNJ-3B 2.563 (65.10)

-32 2.000 2.500-12UNJ-3B 2.813 (71.45) ±.020 (0.51)

-40 2.500 3.000-12UNJ-3B 3.312 (84.12)

-48 3.000 3.500-12UNJ-3B 3.812 (96.82)

H

G

Dash C E Max

±.010 (0.25)

number Dia. Min. (see note 5)

mm)

(mm)

-2 .313 (7.95) .629 (15.98) .500 (12.70)

-3 .375 (9.53) .699 (17.75) .562 (14.27)

-4 .438 (11.13) .771 (19.58) .625 (15.88)

-5 .500 (12.70) .842 (21.39) .687 (17.45) .005 (0.13)

-6 .563 (14.30) .914 (23.22) .750 (19.05)

-8 .750 (19.05) 1.127 (28.63) .937 (23.80)

-10 .875(22.23) 1.270 (32.26) 1.052 (26.72)

-12 1.063 (27.00) 1.555 (39.50) 1.274 (32.36)

-16 1.313 (33.35) 1.827 (46.41) 1.524 (38.71)

-20 1.625 (41.28) 2.184 (55.47) 1.838 (46.69)

-24 1.875 (47.63) 2.465 (62.61) 2.093 (53.16)

.008 (0.20)

-28 2.250 (57.15) 2.892 (73.46) 2.468 (62.69)

-32 2.500 (63.50) 3.178 (80.72) 2.718 (69.04)

-40 3.000 (76.20) 3.747 (95.17) 3.218 (81.74)

-48 3.500 (88.90) 4.318 (109.68) 3.718 (94.44)

NOTES:

1. Dimensions are in inches.

2. Metric equivalents are given for information only.

3. Unless otherwise specified tolerances are ±.016 inch (0.41 mm) angles ±0.5°.

4. Break sharp edges .and remove all hanging burrs and slivers.

5. Squareness between thread and face of hex shall not exceed H when measured at diameter G, both

sides.

6. Machined surfaces shall be finished to 125µin Ra, forged surfaces shall be 250µin Ra, unless otherwise

specified on the figures. Surface finish shall be in accordance with ASME B46.1.

7. For design features purposes, this standard takes precedence over documents referenced herein.

8. Referenced documents shall be of the issue in effect on date of invitation for bid.

FIGURE 1. Tube nut dimensions and configurations - Continued.

Source: http://assist.dla.mil -- Downloaded: 2020-05-26T17:21Z

Check the source to verify that this is the current version before use.

AN924 Rev 14

REQUIREMENTS:

Dimensions and configuration shall be in accordance with figure 1.

Installation shall be in accordance with MS21344.

Materials shall be in accordance with SAE-AS4841, see table I for material and finish code.

Finish. Finishes shall be as specified in table I. All plating’s shall be capable of meeting a minimum

of 96 hours salt spray test in accordance with ASTM B117. The fittings shall show no evidence of red

corrosion after 96 hours of salt spray. Fluid passages, other openings and internal threads shall not be

subject to the plating thickness requirement and may have bare areas provided they are protected with a

light film of oil.

TABLE I. Material and finish identification codes.

Material and

Material Plating finish

finish code

Blank Steel Cadmium plating in accordance with SAE-AS4841 1/

G Steel Zinc plating in accordance with ASTM B633; type V, Fe/Zn 8, 2/

Zinc-aluminum in accordance with ASTM F1136/F1136M,

H Steel

grade 3, NC. 2/

J CRES type 304 In accordance with SAE-AS4841

K CRES, type 316 In accordance with SAE-AS4841

Zinc-nickel in accordance with SAE-AMS2417, type 2, grade B

L Steel

2/ 3/

Nickel-copper alloy

M No additional finish.

UNS N04400

High-chromium nickel

N No additional finish.

alloy UNS N06690

Zinc phosphate finish in accordance MIL-DTL-16232 type Z,

P Steel

class1 4/

R CRES, type 321 In accordance with SAE-AS4841

T Anodize in accordance with SAE-AMS2488 type 2.

Titanium 4/

TF Fluoride phosphate in accordance with SAE-AMS2486. 5/

Aluminum alloy

W In accordance with SAE-AS4841

7075-T73

Z Steel Zinc plating in accordance with ASTM B695, type II, class 8. 4/

Zinc may be any zinc plating from PIN codes G, L, and Z with a

ZN Steel

colored chromate coating. 4/

1/ Embrittlement test need not be run. Cadmium shall not be used in oxygen or potable water systems.

Cadmium is prohibited from use in NAVSEA owned shipboard systems.

2/ Hexavalent chromium free. Finish shall be RoHS compliant.

3/ The zinc-nickel alloy plate shall contain 12% to 16% nickel. The coating thickness shall be 315µ

inches (8µm) minimum.

4/ Not for use in aircraft. Requires approval from the Program Office for all applications.

5/ A pretreatment, a modification of the fluoride treatment, or a post treatment shall be applied so the

final color of the fittings shall be similar to SAE-AMS-STD-595 colors 36076 through 36293. Titanium

shall not be used in oxygen or potable water systems.

Source: http://assist.dla.mil -- Downloaded: 2020-05-26T17:21Z

Check the source to verify that this is the current version before use.

AN924 Rev 14

Trivalent wrenchability. When the finish has been damaged due to poor wrenchability, the surface of

the fluid passage bolt shall be touched up using the brush plating process below. The term "trivalent

wrenchability" is used to evaluate the ability of the finish to withstand abrasion from an excessive

amount of wrenching.

Brush plating of NAVAIR TCP shall be in accordance with MIL-DTL-81706, type 2, class 1A, material

form 1 through 6, application method B. Example of a PIN: M817062A6B.

Part or Identifying Number (PIN): The PIN consists of the letters “AN” the specification sheet number,

a dash number for pipe nut tube size, and a material and finish code letter. Unassigned PIN’s shall

not be used.

AN 924 -4 W

Material and finish code letter (see table I)

Size dash number (see figure 1)

Specification sheet number

AN prefix

PIN example: AN924-4W indicates nut 1/4 inch tubing with aluminum alloy 7075-T73.

Marking: Part shall be impression stamped with AN, material/finish designator, and include the

manufacturers CAGE, name, or trademark on the hex side only.

Cadmium is not recommended. To the users of this document, it is recommended that the use of

carbon steel material with cadmium plating be used only when other materials and finishes specified

in this document cannot meet performance requirements.

Cadmium is prohibited from use in NAVSEA owned shipboard systems in accordance with the

requirements of T9070-AL-DPC-020/077-2.

Class I and II ozone depleting substances (ODS) shall not be used in AN914 or any referenced

procedures.

Supersession data:

Due to stress corrosion cracking aluminum alloys 2014 and 2024 “D” designator has been

replaced by aluminum alloy 7075 “W” designator example: AN924-4D use AN924-4W.

Metal cracking due to high temperatures CRES alloy 347 “S” designator has been replaced by

CRES alloy 321 “R” designator. Example: AN9244S use AN924-4R.

AN924 and MS24400 CRES nuts of like size are physically interchangeable; however MS24400

nuts coded C cannot always replace AN924 nuts coded J or K and MS24400 nuts coded S

cannot always replace AN924 nuts coded S.

Table II provides a detailed cross-reference of AN924 PINs and replacement SAE-AS5178 PINs.

Users are cautioned to evaluate replacements for their particular application.

Source: http://assist.dla.mil -- Downloaded: 2020-05-26T17:21Z

Check the source to verify that this is the current version before use.

AN924 Rev 14

CAUTION: The superseding information is valid as of the date of this specification and may be

superseded by subsequent revisions of the superseding document.

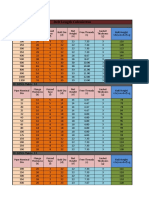

TABLE II. AN924 to SAE- AS5178 cross-reference data. 1/ 2/ 3/

AN PIN

Canceled Tube Replacement AS PIN

inactive for

AN PIN Size AN PIN for new design

new design

AN924-2 .125 AS5178-02-

AN924-2D .125 AN924-2W AS5178W02

AN924-2J .125 AS5178J02

AN924-2K .125 AS5178K02

AN924-2R .125 AS5178R02

AN924-2S .125 AN924-2R AS5178R02

AN924-2T .125 AS5178T02

AN924-2W .125 AS5178W02

AN924-3 .188 AS5178-03-

AN924-3D .188 AN924-3W AS5178W03

AN924-3J .188 AS5178J03

AN924-3K .188 AS5178K03

AN924-3R .188 AS5178R03

AN924-3S .188 AN924-3R AS5178R03

AN924-3T .188 AS5178T03

AN924-3W .188 AS5178W03

AN924-4 .250 AS5178-04-

AN924-4D .250 AN924-4W AS5178W04

AN924-4J .250 AS5178J04

AN924-4K .250 AS5178K04

AN924-4R .250 AS5178R04

AN924-4S .250 AN924-4R AS5178R04

AN924-4T .250 AS5178T04

AN924-4W .250 AS5178W04

AN924-5 .312 AS5178-05-

AN924-5D .312 AN924-5W AS5178W05

AN924-5J .312 AS5178J05

AN924-5K .312 AS5178K05

AN924-5R .312 AS5178R05

AN924-5S .312 AN924-5R AS5178R05

AN924-5T .312 AS5178T05

AN924-5W .312 AS5178W05

AN924-6 .375 AS5178-06-

AN924-6D .375 AN924-6W AS5178W06

AN924-6J .375 AS5178J06

AN924-6K .375 AS5178K06

AN924-6R .375 AS5178R06

AN924-6S .375 AN924-6R AS5178R06

AN924-6T .375 AS5178T06

AN924-6W .375 AS5178W06

See notes at end of table.

Source: http://assist.dla.mil -- Downloaded: 2020-05-26T17:21Z

Check the source to verify that this is the current version before use.

AN924 Rev 14

TABLE II. AN924 to SAE- AS5178 cross-reference data - Continued. 1/ 2/ 3/

AN PIN AS PIN

Canceled Tube Replacement

inactive for for new

AN PIN Size AN PIN

new design design

AN924-8 .500 AS5178-08-

AN924-8D .500 AN924-8W AS5178W08

AN924-8J .500 AS5178J08

AN924-8K .500 AS5178K08

AN924-8R .500 AS5178R08

AN924-8S .500 AN924-8R AS5178R08

AN924-8T .500 AS5178T08

AN924-8W .500 AS5178W08

AN924-10 .625 AS5178-10-

AN924-10D .625 AN924-10W AS5178W10

AN924-10J .625 AS5178J10

AN924-10K .625 AS5178K10

AN924-10R .625 AS5178R10

AN924-10S .625 AN924-10R AS5178R10

AN924-10T .625 AS5178T10

AN924-10W .625 AS5178W10

AN924-12 .750 AS5178-12-

AN924-12D .750 AN924-12W AS5178W12

AN924-12J .750 AS5178J12

AN924-12K .750 AS5178K12

AN924-12R .750 AS5178R12

AN924-12S .750 AN924-12R AS5178R12

AN924-12T .750 AS5178T12

AN924-12W .750 AS5178W12

AN924-16 1.000 AS5178-16-

AN924-16D 1.000 AN924-16W AS5178W16

AN924-16J 1.000 AS5178J16

AN924-16K 1.000 AS5178K16

AN924-16R 1.000 AS5178R16

AN924-16S 1.000 AN924-16R AS5178R16

AN924-16T 1.000 AS5178T16

AN924-16W 1.000 AS5178W16

AN924-20 1.250 AS5178-20-

AN924-20D 1.250 AN924-20W AS5178W20

AN924-20J 1.250 AS5178J20

AN924-20K 1.250 AS5178K20

AN924-20R 1.250 AS5178R20

AN924-20S 1.250 AN924-20R AS5178R20

AN924-20T 1.250 AS5178T20

AN924-20W 1.250 AS5178W20

See notes at end of table.

Source: http://assist.dla.mil -- Downloaded: 2020-05-26T17:21Z

Check the source to verify that this is the current version before use.

AN924 Rev 14

TABLE II. AN924 to SAE- AS5178 cross-reference data - Continued. 1/ 2/ 3/

AN PIN

Canceled Tube Replacement AS PIN

inactive for

AN PIN Size AN PIN for new design

new design

AN924-24 1.500 AS5178-24-

AN924-24D 1.500 AN924-24W AS5178W24

AN924-24J 1.500 AS5178J24

AN924-24K 1.500 AS5178K24

AN924-24R 1.500 AS5178R24

AN924-24S 1.500 AN924-24R AS5178R24

AN924-24T 1.500 AS5178T24

AN924-24W 1.500 AS5178W24

AN924-28 1.750 AS5178-28-

AN924-28D 1.750 AN924-28W AS5178W28

AN924-28J 1.750 AS5178J28

AN924-28K 1.750 AS5178K28

AN924-28R 1.750 AS5178R28

AN924-28S 1.750 AN924-28R AS5178R28

AN924-28T 1.750 AS5178T28

AN924-28W 1.750 AS5178W28

AN924-32 2.000 AS5178-32-

AN924-32D 2.000 AN924-32W AS5178W32

AN924-32J 2.000 AS5178J32

AN924-32K 2.000 AS5178K32

AN924-32R 2.000 AS5178R32

AN924-32S 2.000 AN924-32R AS5178R32

AN924-32T 2.000 AS5178T32

AN924-32W 2.000 AS5178W32

AN924-40 2.500 AS5178-40-

AN924-40D 2.500 AN924-40W AS5178W40

AN924-40J 2.500 AS5178J40

AN924-40K 2.500 AS5178K40

AN924-40R 2.500 AS5178R40

AN924-40S 2.500 AN924-40R AS5178R40

AN924-40T 2.500 AS5178T40

AN924-40W 2.500 AS5178W40

AN924-48 3.000 AS5178-48-

AN924-48D 3.000 AN924-48W AS5178W48

AN924-48J 3.000 AS5178J48

AN924-48K 3.000 AS5178K48

AN924-48R 3.000 AS5178R48

AN924-48S 3.000 AN924-48R AS5178R48

AN924-48T 3.000 AS5178T48

AN924-48W 3.000 AS5178W48

1/ For new design use material designator R and W.

2/ Hardness has to be specified in the contract or purchase order.

3/ SAE does not have plating finish designators for the following types:

G, H, L, M, N, P, TF, Z, and ZN.

Source: http://assist.dla.mil -- Downloaded: 2020-05-26T17:21Z

Check the source to verify that this is the current version before use.

AN924 Rev 14

Order of precedence. Unless otherwise noted herein or in the contract, in the event of a conflict

between the text of this document and the references cited herein, the text of this document takes

precedence. Nothing in this document, however, supersedes applicable laws and regulations unless

a specific exemption has been obtained.

Referenced documents shall be of the issue in effect on date of invitations for bid.

Changes from previous issue. Marginal notations are not used in this revision to identify changes

with respect to the previous issue, due to the extent of the changes.

Referenced documents. In addition to SAE-AS4841, this document references the following:

MIL-DTL-16232 SAE-AMS-STD-595/36099 SAE-AMS-STD-595/36280

MIL-DTL-81706 SAE-AMS-STD-595/36118 SAE-AMS-STD-595/36293

MS21344 SAE-AMS-STD-595/36134 SAE-AMS2417

ASME B46.1 SAE-AMS-STD-595/36152 SAE-AMS2486

ASTM B117 SAE-AMS-STD-595/36170 SAE-AMS2488

ASTM B633 SAE-AMS-STD-595/36173 SAE-AS5178

ASTM B695 SAE-AMS-STD-595/36176 SAE-AS8879

ASTM F1136/F1136M SAE-AMS-STD-595/36231 T9070-AL-DPC-020/077-2

SAE-AMS-STD-595/36076 SAE-AMS-STD-595/36251

SAE-AMS-STD-595/36081 SAE-AMS-STD-595/36270

CONCLUDING MATERIAL

Custodians: Preparing activity:

Army - AV DLA - CC

Navy - AS

Air Force - 99 (Project 4730-2018-019)

DLA - CC

Review activities:

Navy - SA

Air Force - 71

NOTE: The activities listed above were interested in this document as of the date of this document.

Since organizations and responsibilities can change, you should verify the currency of the information

above using the ASSIST Online database at https://assist.dla.mil.

Source: http://assist.dla.mil -- Downloaded: 2020-05-26T17:21Z

Check the source to verify that this is the current version before use.

You might also like

- AN924Document8 pagesAN924David WongNo ratings yet

- AN924 REV. 14 - Part2Document1 pageAN924 REV. 14 - Part2David WongNo ratings yet

- AN6204Document4 pagesAN6204CTN2010No ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseDocument6 pagesSource: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseJoey ThomannNo ratings yet

- AN818 Rev-20Document5 pagesAN818 Rev-20aldiNo ratings yet

- AN818 Rev-20 PDFDocument5 pagesAN818 Rev-20 PDFaldiNo ratings yet

- Ms 20756Document11 pagesMs 20756Isaque FulgeriNo ratings yet

- AN929Document6 pagesAN929Julio Alejandro LemaNo ratings yet

- Surface Vehicle Standard: Rev. JUL86Document3 pagesSurface Vehicle Standard: Rev. JUL86anupthatta100% (1)

- Determining The Generator Adaptation Required From The Engine SuppliedDocument2 pagesDetermining The Generator Adaptation Required From The Engine SuppliedolumideNo ratings yet

- MS14182B - Parafuso Cabeça EstriadaDocument3 pagesMS14182B - Parafuso Cabeça EstriadaRenato WatanabeNo ratings yet

- WIM-CG-010 B enDocument21 pagesWIM-CG-010 B enJhohanes OrtizNo ratings yet

- Polycab Cables Pricelist NewDocument8 pagesPolycab Cables Pricelist NewChandan RayNo ratings yet

- MS9483CDocument6 pagesMS9483CBryan MartinezNo ratings yet

- High Strength Welded Wire Reinforcement For High Performance ConcreteDocument21 pagesHigh Strength Welded Wire Reinforcement For High Performance ConcreteDiego Pinto MendezNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- O-Ring Seal Plug SpecificationDocument3 pagesO-Ring Seal Plug SpecificationBogdan RusuNo ratings yet

- V-Cone Ficha TécnicaDocument2 pagesV-Cone Ficha TécnicaIrving Uc Fernandez100% (1)

- p-7426-sc-a4_dcDocument2 pagesp-7426-sc-a4_dca04205No ratings yet

- MS27069GDocument7 pagesMS27069Gawesome_600No ratings yet

- Nehemiah Wall-Section 5Document3 pagesNehemiah Wall-Section 5Hazim AffendiNo ratings yet

- SEBF8375 головка 3300Document12 pagesSEBF8375 головка 3300Евгений АбрамовNo ratings yet

- Medidas para Mecanizar Alojamiento Anillo Sello EspejoDocument11 pagesMedidas para Mecanizar Alojamiento Anillo Sello EspejoJhonatan Valencia MillanNo ratings yet

- MS20026EDocument8 pagesMS20026EthomasNo ratings yet

- 220KV MudashingiDocument6 pages220KV MudashingiAbhishek RajputNo ratings yet

- Track-Type Tractor Track Roller Cap Bolt Torque Procedure and Re-Use Guidelines (4180)Document7 pagesTrack-Type Tractor Track Roller Cap Bolt Torque Procedure and Re-Use Guidelines (4180)juvenalNo ratings yet

- سرسیلندرDocument26 pagesسرسیلندرHossenNo ratings yet

- MS25205GDocument5 pagesMS25205GGülinNo ratings yet

- Datasheet de Un CapacitorDocument1 pageDatasheet de Un CapacitorSantiago Guerrero MartinezNo ratings yet

- Specification Sheet ANSI B16.5 RTJ Weld Neck - Class 1500 or 2500 Precision Tube Series ModelDocument1 pageSpecification Sheet ANSI B16.5 RTJ Weld Neck - Class 1500 or 2500 Precision Tube Series ModelDhong888No ratings yet

- Valve and Valve Spring SpecificationsDocument21 pagesValve and Valve Spring Specificationsbetoven8437100% (1)

- Acoples Lovejoy CS-LS (Jaw)Document1 pageAcoples Lovejoy CS-LS (Jaw)marcelo castilloNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument7 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Nexans 631101Document4 pagesNexans 631101JAIME INGA MORANNo ratings yet

- Armado Culata 2Document2 pagesArmado Culata 2Mauricio HualmeNo ratings yet

- AS CelluloseDocument7 pagesAS CelluloseDenesh MohandNo ratings yet

- Turbocharger NR12/S - New Gaps and Clearances: Application ReasonDocument3 pagesTurbocharger NR12/S - New Gaps and Clearances: Application ReasonSameer MalikNo ratings yet

- Sr220 Case - PartesDocument882 pagesSr220 Case - PartesJorge Diaz Nestor MonsalveNo ratings yet

- L0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023Document25 pagesL0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023quality assuranceNo ratings yet

- SAE Housing and Flywheel Dimensions ChartDocument1 pageSAE Housing and Flywheel Dimensions ChartAmit GoyalNo ratings yet

- (RDMP) BQ Piping Smp3 170601 Iti Rev0Document365 pages(RDMP) BQ Piping Smp3 170601 Iti Rev0Fahmy FlipNo ratings yet

- SAE Bellhousing and Flywheel MeasurementsDocument6 pagesSAE Bellhousing and Flywheel MeasurementsDave WallaceNo ratings yet

- Cylinder Head: SpecificationsDocument5 pagesCylinder Head: SpecificationsPaulo100% (1)

- Data BookDocument71 pagesData BookRi ŚhiNo ratings yet

- 2211Document4 pages2211liuyx866No ratings yet

- Relay Test Report: AB Impedance ShotDocument5 pagesRelay Test Report: AB Impedance ShotAbhishek RajputNo ratings yet

- ANSI B16.5 Slip-On, Raised Face Flanges - Class 150 or 300: Configuration Sheet Model Precision Tube SeriesDocument2 pagesANSI B16.5 Slip-On, Raised Face Flanges - Class 150 or 300: Configuration Sheet Model Precision Tube SeriesEdisonCorderoNo ratings yet

- Bearings For Screw DrivesDocument10 pagesBearings For Screw DrivesTravis DavisNo ratings yet

- Eng 106005Document2 pagesEng 106005ahmed.zakariaNo ratings yet

- Woo Chang Coupling - 112438 - Paqndr oYtYHS8Document14 pagesWoo Chang Coupling - 112438 - Paqndr oYtYHS8Eng-anwer kadhimNo ratings yet

- Parker Hannifin Hose Die Selection ChartDocument1 pageParker Hannifin Hose Die Selection ChartFernando Padilla0% (1)

- MS20001PDocument5 pagesMS20001PthomasNo ratings yet

- Flange Dimensions For DN600 AltDocument3 pagesFlange Dimensions For DN600 AltNapiorkowskiNo ratings yet

- SMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesDocument5 pagesSMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesVictor NoschangNo ratings yet

- Design of flexural members_ECG_ver 6.85Document47 pagesDesign of flexural members_ECG_ver 6.85am27389901No ratings yet

- Weld Consumable Calculation SummaryDocument10 pagesWeld Consumable Calculation SummaryAhmad KamilNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- ASTM E1444-E1444M (2021) - Part4Document1 pageASTM E1444-E1444M (2021) - Part4David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part7Document1 pageASTM E1444-E1444M (2021) - Part7David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part9Document1 pageASTM E1444-E1444M (2021) - Part9David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part6Document1 pageASTM E1444-E1444M (2021) - Part6David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part8Document1 pageASTM E1444-E1444M (2021) - Part8David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part1Document1 pageASTM E1444-E1444M (2021) - Part1David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part5Document1 pageASTM E1444-E1444M (2021) - Part5David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part10Document1 pageASTM E1444-E1444M (2021) - Part10David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part2Document1 pageASTM E1444-E1444M (2021) - Part2David WongNo ratings yet

- AN924 REV. 14 - Part7Document1 pageAN924 REV. 14 - Part7David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part3Document1 pageASTM E1444-E1444M (2021) - Part3David WongNo ratings yet

- An565 Rev. 7Document4 pagesAn565 Rev. 7David WongNo ratings yet

- AN924 REV. 14 - Part5Document1 pageAN924 REV. 14 - Part5David WongNo ratings yet

- AN924 REV. 14 - Part1Document1 pageAN924 REV. 14 - Part1David WongNo ratings yet

- AN924 REV. 14 - Part6Document1 pageAN924 REV. 14 - Part6David WongNo ratings yet

- AN924 REV. 14 - Part3Document1 pageAN924 REV. 14 - Part3David WongNo ratings yet

- A-A-52081 REV.B - Part5Document1 pageA-A-52081 REV.B - Part5David WongNo ratings yet

- AN924 REV. 14 - Part4Document1 pageAN924 REV. 14 - Part4David WongNo ratings yet

- A-A-52081 REV.B - Part3Document1 pageA-A-52081 REV.B - Part3David WongNo ratings yet

- A-A-52081 Rev.b Not3Document1 pageA-A-52081 Rev.b Not3David WongNo ratings yet

- A-A-52081 REV.B - Part4Document1 pageA-A-52081 REV.B - Part4David WongNo ratings yet

- A-A-52081 REV.B - Part1Document1 pageA-A-52081 REV.B - Part1David WongNo ratings yet

- AN924 REV. 14 - Part1Document1 pageAN924 REV. 14 - Part1David WongNo ratings yet

- A-A-52081 REV.B - Part2Document1 pageA-A-52081 REV.B - Part2David WongNo ratings yet

- MIL-B-23958 Rev A CANCELDocument1 pageMIL-B-23958 Rev A CANCELDavid WongNo ratings yet

- MIL-PRF-25732 REV. D (MIL-P-25732) - Part8Document1 pageMIL-PRF-25732 REV. D (MIL-P-25732) - Part8David WongNo ratings yet

- MIL-PRF-25732D Seal Test SpecificationsDocument1 pageMIL-PRF-25732D Seal Test SpecificationsDavid WongNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Survey ReportDocument10 pagesEmily-1 Project Fuel Terminal and Jetty Survey Reportmuhammad sauqiNo ratings yet

- Cement Mills Inspection ReportDocument4 pagesCement Mills Inspection Reportzain140No ratings yet

- PC spun piles design and manufacturingDocument2 pagesPC spun piles design and manufacturinghoetapea100% (1)

- 2-INTRODUCTION Foundation ENGG PDFDocument60 pages2-INTRODUCTION Foundation ENGG PDFFarooq HussainNo ratings yet

- Galvanized Round PipeDocument26 pagesGalvanized Round PipeПабло Рамирес РамиресNo ratings yet

- Je-H (ST) H Fe180 E30 PHDocument1 pageJe-H (ST) H Fe180 E30 PHAnonymous gzlLgRyuNo ratings yet

- Project On Real Estate Market in Bhiwandi &Document15 pagesProject On Real Estate Market in Bhiwandi &mayur_sscmrNo ratings yet

- Wallcare CatalogueDocument2 pagesWallcare Catalogueali razaNo ratings yet

- BIM in HealthcareDocument5 pagesBIM in HealthcareBrij PanjwaniNo ratings yet

- Display Cabinet PlansDocument2 pagesDisplay Cabinet PlansChristopher DobsNo ratings yet

- Performance of Cable Bolt Anchors - An Update: Alan ThompsonDocument8 pagesPerformance of Cable Bolt Anchors - An Update: Alan ThompsonIgnacio PadillaNo ratings yet

- STI Firestop BrochureDocument16 pagesSTI Firestop BrochureconchunchunNo ratings yet

- Front Elevation Leftside Elevation Rightside Elevation: FirewallDocument1 pageFront Elevation Leftside Elevation Rightside Elevation: FirewallRachel PetersNo ratings yet

- Pipe FittingsDocument158 pagesPipe FittingsGiraldoCarpioRamosNo ratings yet

- GBW RequirementsDocument40 pagesGBW RequirementsmoeNo ratings yet

- 01 BIM Project Execution Planning Guide V2.1 (One-Sided)Document134 pages01 BIM Project Execution Planning Guide V2.1 (One-Sided)Mois DanielNo ratings yet

- Kenco - Installation Instructions Model KLCE Oil Level ContrDocument4 pagesKenco - Installation Instructions Model KLCE Oil Level ContrJorge ContrerasNo ratings yet

- Engineering Structures: Stefano Sorace, Gloria TerenziDocument13 pagesEngineering Structures: Stefano Sorace, Gloria TerenzipaulkohanNo ratings yet

- KMTL Cast Iron Turning Guide 32 65Document34 pagesKMTL Cast Iron Turning Guide 32 65cristian111111No ratings yet

- Bolt Length Calculation: IS 6392-Table 11Document3 pagesBolt Length Calculation: IS 6392-Table 11sumit_b123No ratings yet

- W.planned Activity Schedule.v1.2023.03.04Document4 pagesW.planned Activity Schedule.v1.2023.03.04Amelia GüitrónNo ratings yet

- Alliance Tires: Industrial Drive Wheel R4 533Document1 pageAlliance Tires: Industrial Drive Wheel R4 533José Rojas AlvaradoNo ratings yet

- Crankshaft Assembly GuideDocument51 pagesCrankshaft Assembly GuideSlobodanNo ratings yet

- Restoring Belagavi Fort and MoatDocument60 pagesRestoring Belagavi Fort and MoatMohamed FaizanNo ratings yet

- NEPROPLAST FlowGuard PipesDocument12 pagesNEPROPLAST FlowGuard PipesperezismaelNo ratings yet

- ACMV DESIGN: Sample Heat Load Calculation For General Office Meeting Room PDFDocument5 pagesACMV DESIGN: Sample Heat Load Calculation For General Office Meeting Room PDFVenkates AdhinarayananNo ratings yet

- Programme of Works 2008-2009Document189 pagesProgramme of Works 2008-2009rbr100% (2)

- LP Middle East - 2016 - 17 - V2Document76 pagesLP Middle East - 2016 - 17 - V2shaktiNo ratings yet

- Maintenance and Repairs in Irrigation SystemDocument28 pagesMaintenance and Repairs in Irrigation SystemBasavaraj A GadigeppagolNo ratings yet

- Electrical WorksDocument20 pagesElectrical WorksCj SalesNo ratings yet