Professional Documents

Culture Documents

Gas 6x4 Gator Electrical From TM1518

Uploaded by

Krzysztof WiktorskiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas 6x4 Gator Electrical From TM1518

Uploaded by

Krzysztof WiktorskiCopyright:

Available Formats

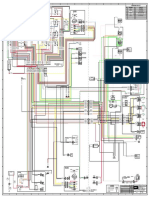

ELECTRICAL COMPONENT LOCATION

Component Location

Component Location - 6X4 Gas

A C

G

J

M56334L F - S2 Key Switch

A - S5 Light Switch G - W2 Main Wiring Harness

B - Instrument Panel Lights H - W4 Standard Headlight Wiring Harness

C - M3 Radiator Fan Motor I - E4 Headlight

D - B3 Radiator Core Temperature Switch J - E3 Headlight

E - Cargo Box Lift Switch (optional)

Electrical Component Location - 274

ELECTRICAL COMPONENT LOCATION

E

D

C

F

B

K

L

M

M56334R G - K1 and K2 Cargo Box Lift Directional Relays

A - M2 Fuel Pump H - M2 Cargo Box Lift Motor

B - N1 Voltage Regulator/Rectifier I - M1 Starting Motor

C - K1 Start Relay J - S1 Neutral Start Switch

D - A1 Ignition Module K - S4 Differential Lock Switch

E - G1 Battery L - S3 Park Brake Switch

F - W17 Cargo Box Lift Wiring Harness M - W2 Main Wiring Harness

Electrical Component Location - 275

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

Schematics and Harnesses - 6X4 Gas V1 - Diode (SE1, W2)

V2 - Diode (SE5, W2)

Electrical Schematic and Wiring Harness W1 - Shielded Ground (SE1, W2)

Legend - 6X4 Gas

Connectors:

A1 - Ignition Module (SE3, W2)

X1 - W2 Main Wiring Harness to W8 Engine Wiring

B1 - Left Pulser Coil (SE3, W2) Harness (SE1, W2; SE2, W2; SE3, W2; SE5, W2)

B2 - Right Pulser Coil (SE3, W2) X2 - W8 Engine Wiring Harness to W9 Engine Wiring

B3 - Radiator Core Temperature Switch (SE4, W2) Harness and W13 Engine Wiring Harness (SE3, W2)

B4 - Engine Temperature Switch (SE5, W2) X3 - W9 Engine Wiring Harness to W10 Engine Wiring

Harness (SE3, W2)

B5 - Engine Oil Pressure Switch (SE5, W2)

X4 - W10 Engine Wiring Harness to W11 Engine Wiring

E1 - Spark Plug (SE3, W2)

Harness (SE3, W2)

E2 - Spark Plug (SE3, W2)

X5 - W2 Main Wiring Harness to M3 Radiator Fan Motor

E3 - Right Headlight (SE6, W2) (SE4, W2)

E4 - Left Headlight (SE6, W2) X6 - M3 Radiator Fan Motor to B3 Radiator Core

F1 - Fusible Link (SE1, W2) Temperature Switch (SE4, W2)

F2 - Fusible Link (SE1, W2) X7 - B3 Radiator Core Temperature Switch to W1 Shielded

Ground (SE3, W2)

F3 - Fusible Link (SE1, W2)

X8 - W2 Main Wiring Harness to S5 Cargo Box Lift Kit

G1 - Battery (SE1, W2) Switch (Opt.) (SE5, W2)

G2 - Stator (SE2, W2) X9 - W2 Main Wiring Harness to W17 Cargo Box Lift Kit

G3 - High Capacity Alternator (Optional) (SE2, W2) Wiring Harness (SE5, W2)

H1 - Discharge Light (SE5, W2) X10 - W2 Main Wiring Harness to W4 Standard Headlight

Wiring Harness (SE6, W2; SE2, W18)

H2 - Park Brake Light (SE5, W2)

X11 - W4 Standard Headlight Wiring Harness to W2 Main

H3 - Differential Lock Light (SE5, W2) Wiring Harness (SE6, W2; SE1, W18)

H4 - Engine Coolant Temperature Light (SE5, W2)

X12 - W29 Auxiliary Alternator Wiring Harness to W2 Main

H5 - Engine Oil Pressure Light (SE5, W2) Wiring Harness (SE2, W2)

K1 - Start Relay (SE1, W2) X13 - W29 Auxiliary Alternator Wiring Harness to N1

M1 - Starting Motor (SE1, W2) Voltage Regulator(SE2, W2)

M2 - Fuel Pump (SE4, W2)

M3 - Radiator Fan Motor (SE4, W2)

M4 - Cargo Box Lift Kit Motor (Optional) (SE5, W2)

N1 - Voltage Regulator/Rectifier (SE2, W2)

R1 - Carburetor Heater (SE4, W2)

S1 - Neutral Start Switch (SE1, W2)

S2 - Key Switch (SE1, W2)

S3 - Park Brake Switch (SE5, W2)

S4 - Differential Lock Switch (SE5, W2)

S5 - Cargo Box Lift Kit Switch (Opt.) (SE5, W2)

S6 - Light Switch (SE6, W2)

T1 - Ignition Coil (SE3, W2)

T2 - Ignition Coil (SE3, W2)

Electrical Schematics and Harnesses - 6X4 Gas - 276

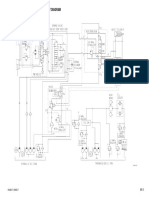

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W2 Standard Electrical Schematic - 6X4 Gas

W2 Standard Electrical Schematic - 6X4 Gas (1 of 2)

210 Red/Blk or Blu/Blk

401 Yel

710 Pur/Blk

F1 425 Yel

F2 200 Red 400 Yel/Red

215 Red 600 Brn

S1 Neutral 435 Yel

Fusible Start Switch Start W8 Engine

Links Wiring Harness X1

Run

F3 Blk

Neutral Off Yel/Wht E2

X2 Spark

Yel/Wht Yel/Wht

K1 In Blk Plug

Gear S2 Key

Start E1

Relay Switch

Spark

30 85 Plug

302 110 Blk

Org/Wht T1 Ignition Org T2 Ignition

87a 87 86

Coil Coil

115

Blk/ W9 Engine

211 705 Blk Yel

Pur

Wiring

Red 201 W10 Engine Wht Harness

Red 216 706 N1 Voltage Wiring

Red Pur Regulator/ Harness X3 X3 X3

700 Rectifier Blk

Pur

U

V1 Diode A1 Ignition Module

590 595

Brn/Yel Brn/Wht

130 X4 X4 X4 X4

Red X1

X1 X1 Blk Yel Pnk

Grn/ Wht/

Wht Blu

Red

Blk Blk

W12 Engine B2 W11

B S Wiring Harness Left Pulser Engine

G1 G

Coil Harness

Battery

B1

G2 Right Pulser

M1 Stator Coil

M Starting

Blk Motor

205 Red 302 Org/Wht

130 Blk

115 Blk

W1 Shielded

Ground 110 Blk

Battery Cables W2 Main Wiring Harness

Optional Lift Kit Component

SE1 - Starting SE2 - Charging SE3 - Ignition

Electrical Schematics and Harnesses - 6X4 Gas - 277

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W2 Standard Electrical Schematic - 6X4 Gas (2 of 2)

X9 To W17 Cargo

Box Lift Kit

210 Red/Blk or Blu/Blk X8 X8 Wiring Harness

670 Yel/Wht

675 Yel/Blk

415

S5 Cargo Box Lift

Yel/Red Kit Switch (Opt.)

425 Yel

X10

400 Yel/Red 410 Yel/Red

600 Brn

402 Yel 400

435 Yel Yel/

420 Red

430 Yel Yel On Off

R1 Carburetor S6

Heater 423 Yel Light

Blk M3 Switch

Off On

Radiator On Off

456 Yel/Wht

Fan 455 Yel/Wht

Motor X5

Blu

W13 S3 Park S4 E3 Right E4

Engine Brake Differential Headlight Left

Wiring M Lock Switch Head-

Switch

Harness light

640 110 Blk

Grn

600 630

Blu

Brn Grn/Blk

W4 Standard Headlight 100

Wiring Harness Blk

H1 W18 or W19 Headlight

H2 H3 Wiring Harness (Opt.)

M2 Discharge Park Brake Differential X11

Fuel M X6 Light Light Lock Light H5 Engine Oil

Pump Pressure Light

+ _

403 Yel

100 105 Blk 125 Blk 120 Blk

Blk Blk H4 Engine

Coolant 302 Org/Wht 620

Temperature Tan

300

Light Org/Wht

W1

t0 B3 Radiator Core 115 X1 V2 X1

Temperature Switch Blk Diode

Yel Blu/Red

Blk

t° t°

X7

135

Blk

B4 Engine Coolant B5

W1 Temperature Switch Engine Oil

302 Org/Wht

Pressure

Switch

115 Blk

105 Blk

110 Blk

Battery Cables W2 Main Wiring Harness

Optional Lift Kit Component

SE4 - Fuel Pump and Fan SE5 - Instrumentation SE6 - Lights

Electrical Schematics and Harnesses - 6X4 Gas - 278

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W2 Main Wiring Harness - 6X4 Gas

W2 Main Wiring Harness - 6X4 Gas (1 of 2)

K1 Start Relay

N1 Voltage Regulator/Rectifier 705

700

590 130

X1 To W8 Engine 600 425

Wiring Harness 401

435 215

590

595 M2

595 205 Fuel Pump

705

Negative Battery Cable 620 300

700 V1 Diode

100 430

W1 Shielded 105 435

Ground

706

135

130 430

M1 216 215 100

F3

Starting 205

Motor Bolt 211 210

F2

201 200

F1

Positive Battery Cable

670

640

420

675 705 423

X9 To W17 Cargo Box

Lift Kit Wiring Harness 135

710

S1 Neutral Start M3 Radiator

Switch 630

423 Fan Motor 210

430

B3 Radiator

S3 Park Core Temperature

Brake Switch S4 Differential Switch

Lock Switch

Electrical Schematics and Harnesses - 6X4 Gas - 279

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W2 Main Wiring Harness - 6X4 Gas (2 of 2)

675

415

H1 Discharge

670 Light 600

125

X8 To S5 Cargo Box 125

Lift Kit Switch (Opt.) H5 Engine Oil

Pressure Light 620

403 402

301

403

V2 H4 Engine Coolant

Temperature 300

302 301

Light

403

402

H2 Park 403

Brake Light 630

120

125

H3 Differential

Lock Light 640

S2 115

120

Key Switch

415

200 302

425 710

410 400

401 110

420 115

400

X10 To W4 Standard Headlight Wiring Harness;

To W18 or W19 Light and Horn Wiring Harness (Opt.)

402

410

X11 To W4 Standard Headlight Wiring Harness;

105 To W18 To W19 Light and Horn Wiring Harness (Opt.)

110

Electrical Schematics and Harnesses - 6X4 Gas - 280

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W2 Main Wiring Harness Color Code Table - Circuit Wire Color Termination Points

6X4 Gas Number Size

420 0.8 Yel Solder connection

Circuit Wire Color Termination Points

(400 Yel/Red), S4

Number Size

100 1.0 Blk M2, W1 Gnd 423 0.8 Yel S4, S3

105 1.0 Blk X11, M2 425 1.0 Yel Solder connection

(400 Yel/Red), N1

110 0.5 Blk S2, X11

430 0.8 Yel S3, M2

115 0.5 Blk H3, S2

435 0.8 Yel M2, X1

120 0.5 Blk H2, H3

590, 595 2.0 Brn/Yel N1, X1

125 0.5 Blk H1, H2

600 0.5 Brn N1, H1

130 2.0 Blk N1, W1 Gnd

620 0.5 Tan H5, X1

135 1.0 Blk X7, W1 Gnd

630 0.8 Gry/Blk S3, H2

200 1.0 Red F1, S2

640 0.5 Grn S4, H3

201 0.5 Red- F1 Fuse soldered

Fuse inline; M1, 200 Red 670, 675 1.0 Yel/Wht X8, X9

205 2.0 Red M1, N1 700 2.0 Pur K1, X1

210 1.0 Red/Blk, F2, M3 705 0.8 Pur V1 Diode, S1

or Blu/ 706 0.8 Pur K1, V1 Diode

Blk

710 0.8 Pur/Blk S1, S2

211 0.5 Red- F2 Fuse soldered

Fuse inline; M1, 210 Red

215 2.0 Red F3, K1

216 0.8 Red- F3 Fuse soldered

Fuse inline; M1, 215 Red

300 0.5 Org/Wht H4, X1

301 0.5 Diode Soldered inline; 302

Org/Wht

302 0.5 Org/Wht H4, S2

400 1.0 Yel/Red S2, solder connection

(410 Yel/Red, 415 Yel/

Red, 420 Yel)

401 0.8 Yel S2, K1

402 0.8 Yel X10, H4

403 0.8 Yel H4, H5

410 1.0 Yel/Red Solder connection

(400 Yel/Red), X10

415 1.0 Yel/Red Solder connection

(400 Yel/Red), X8

Electrical Schematics and Harnesses - 6X4 Gas - 281

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W2 Electrical Schematic with Auxiliary Alternator - 6X4 Gas

W2 Electrical Schematic with Auxiliary Alternator - 6X4 Gas (1 of 2)

210 Red/Blk or Blu/Blk

401 Yel

710 Pur/Blk

W13 Engine Wiring

Harness

F1 425 Yel

F2 200 Red 400 Yel/Red

215 Red 600 Brn

S1 Neutral 435 Yel

Fusible Start Switch Start W8 Engine R1 Carburetor

Links Wiring Harness Heater

Run X1 Blk

F3 Yel/Wht

Neutral Off

X2

Yel/Wht Yel/Wht Blk

K1 In

Gear S2 Key E1

Start

Relay Switch Spark

30 85 Plug

302 110 Blk X12 T1 Ignition T2

87a 87 86 Org/Wht Ignition

Coil

115 425 600 W9 Engine Blk/ Coil

Org

211 705 Blk Yel Brn Wiring HarnessYel Wht

Pur E2

Red 201 W10 Engine

Red 216 Spark

706 X13 Wiring X3 X3 X3

Red Pur

Harness Plug

700 Blk

Pur X13 X13

200 Red U

A1 Ignition Module

V1 Diode

N1 Voltage X13

Regulator/

Rectifier X4 X4 X4 X4

590 595

G1 X1 Brn/Yel Brn/Wht Yel Pnk

Battery Grn/ Wht/

W29 Alternator Wht Blu

Red Wiring Harness

Red B1

202 Red

X12 Left Pulser

100

B S Coil W11

590 595 Blk B2

Brn/Yel Brn/Wht Right Engine

205 Pulser Harness

Red

X1 Coil

X1

M1 W12 Engine

X12 M

Blk Blk

Starting Wiring Harness

Blk (Not Used) Motor G

G2

202 Red 200 Red Stator

302 Org/Wht

201 Red

102 Blk 101 Blk

+ G3 High 115 Blk

Capacity

G Alternator 110 Blk

(optional)

130 Blk X12 100 Blk

(Not Used)

W1 Shielded Battery Cables W2 Main Wiring Harness

Ground

Optional Lift Kit Component

SE1 - Starting SE2 - Charging SE3 - Ignition

Electrical Schematics and Harnesses - 6X4 Gas - 282

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W2 Electrical Schematic with Auxiliary Alternator - 6X4 Gas (2 of 2)

210 Red/Blk or Blu/Blk X8 X8 670 Yel/Wht

675 Yel/Blk

415

S5 Cargo Box Lift

Yel/Red Kit Switch (Opt.)

425 Yel

X10

400 Yel/Red 410 Yel/Red

600 Brn 402 Yel 400

435 Yel Yel/

420 Red

Yel On Off

430 Yel S6

423 Yel Light

Off On Switch

On Off

456 Yel/Wht

X5

Blu S4 E3 Right E4

S3 Park

Brake Differential Headlight Left

M M3 Switch Lock Switch

Radiator

110 Blk

Fan Motor

600 630 640

Brn Grn/Blk Grn

W4 Standard Headlight 100

Blu Wiring Harness Blk

H1 W18 or W19 Headlight

H2 H3 Wiring Harness (Opt.)

Discharge Park Brake Differential X11

M M2 Light Light Lock Light H5 Engine Oil

Fuel X6 Pressure Light

Pump + _

403 Yel

Blk

100 105

Blk Blk 125 Blk 120 Blk

H4 Engine

Coolant 302 Org/Wht 620

Temperature Tan

300

Light Org/Wht

X1 V2 X1

t0 B3 Radiator Core 115

Blk Diode

Temperature Switch

W1 Yel Blu/Red

Blk

t° t°

X7

135

Blk B4 Engine Coolant B5

W1 Temperature Switch Engine Oil

302 Org/Wht Pressure

Switch

115 Blk

105 Blk

110 Blk

Battery Cables W2 Main Wiring Harness

Optional Lift Kit Component

SE4 - Fuel Pump and Fan SE5 - Instrumentation SE6 - Lights

Electrical Schematics and Harnesses - 6X4 Gas - 283

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W29 Auxiliary Alternator Wiring Harness - 6X4 Gas

W29 Auxiliary Alternator Wiring Harness - 6X4 Gas (1 of 2)

X13 To N1 Voltage X12 To W2 Main K1 Start Relay

Regulator/Rectifier Wiring Harness 705

595 700

100 425 W29 Alternator

200 Wiring Harness 600 425

401

215

595 X12 To W29

590

590 600 100 Alternator Wiring

200 Harness

590 130

101 600 425

X1 To W8 Engine 705

201 Wiring Harness V1 Diode

Negative 590 595 205

595 M2

Battery Cable

Fuel Pump

102

G3 Auxiliary W1 Shielded

Alternator Ground

202

Positive

135

Battery Cable

130 430 706

216 215 100

F3

205

211 210

M1 F2

201 200

Starting F1

Motor

Bolt

X9 To W17 Cargo Box

Lift Kit Wiring Harness

S1 Neutral Start

Switch

S3 Park

Brake Switch

Electrical Schematics and Harnesses - 6X4 Gas - 284

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W29 Auxiliary Alternator Wiring Harness - 6X4 Gas (2 of 2)

H1 Discharge

Light

125

X8 To S5 Cargo Box

Lift Kit Switch (Opt.) H5 Engine Oil

Pressure Light

403

301 H4 Engine Coolant

V2 Temperature

302

Light

403

H2 Park

Brake Light

H3 Differential

Lock Light

S2

Key Switch

W2 Main

Wiring Harness 415

425

410

420

400

X10

M3 Radiator

Fan Motor

X11

B3 Radiator

Core Temperature

S4 Differential Switch

Lock Switch

W29 Wiring Harness Wire Color Code Table - 6X4 Gas

Circuit Wire Color Termination Points Circuit Wire Color Termination Points

Number Size Number Size

100 3.0 Blk X13, N1 202 5.0 Red Solder Splice to 200/

201 Blk, Battery Pos

101 3.0 Blk G3 Gnd

425 1.0 Yel W2, X12, X 13

102 5.0 Blk Solder Splice to 100/

101 Blk, Battery Neg 590 3.0 Brn/Wht W2, X12, X13

200 3.0 Red Solder Splice, X13 595 3.0 Brn/Yel W2, X12, X13

201 3.0 Red Solder Splice, G3 600 1.0 Blu W2, X12, X13

Electrical Schematics and Harnesses - 6X4 Gas - 285

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W4 Standard Headlight Wiring Harness - 6X4 Gas

455 110 Blk

Yel

E32 Right

Headlight

S6

100 Blk E4 Left Headlight Switch

Headlight

400 Yel

456 Yel 455 Yel

456 Yel

X10 to W2 Main X11 to W4 Main

Wiring Harness Wiring Harness

400 Yel 100 Blk

110 Blk

MIF

W8 Engine Wiring Harness

To B4 Engine Coolant

Temperature Switch

To B5 Engine Oil

Pressure Switch From G2 Stator

Yel (W12 Engine Wiring Harness)

Blu/Red

To R1 Carburetor

Heater Yel

X1 From W2 Main

Blk Wiring Harness

Blk

Blk

X2 To W9

Engine Harness Yel/Wht

Yel/Wht

Blk

Blu/Red

M72546

Electrical Schematics and Harnesses - 6X4 Gas - 286

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W9 Engine Wiring Harness

To T1 and T2 Ignition Coils

Blk/Yel Yel/

Wht Wht

Yel/Wht

Yel/Wht

To X2 Connector on W8

Yel/Wht Engine Wiring Harness

Blk/Yel

Wht

To X2 Connector on W8

Blk/Wht Yel/Wht Engine Wiring Harness

Ground

Yel/Wht

Blk/Wht X3

To W10 Engine

Blk/Yel Wiring Harness

Wht

M72547

W10 Engine Wiring Harness

X3

From W9 Engine

A1 Ignition Module Wiring Harness

Yel Grn/Wht

Wht/Blu

Pink

Blk

Blk/Yel

Wht

Org/Wht

X4 or Org

To W11 Engine

Wiring Harness

M72548

Electrical Schematics and Harnesses - 6X4 Gas - 287

ELECTRICAL SCHEMATICS AND HARNESSES - 6X4 GAS

W11 Engine Wiring Harness

Wht/Blu

Pnk Wht/Blu

Pnk

Yel

Grn/Wht

X4

From W10 Engine

Wiring Harness

B1 Left

Pulser Coil

B2 Grn/Wht

Right

Pulser Yel

Coil

M72549

W12 Engine Wiring Harness

To X1 Connector

G2 Stator

MIF

W13 Engine Wiring Harness

R1 Carburetor Heater

To X2 Connector

on W8 Engine

Wiring Harness

Carburetor Heater Ground Wire

MIF

Electrical Schematics and Harnesses - 6X4 Gas - 288

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Operation and Diagnostics - 6X4 Gas System: Electrical

Yes - See “Indicator Lights Circuit Diagnosis - 6X4

Troubleshooting - 6X4 Gas Gas” on page 307.

System: Electrical (12) Are there light and horn problems?

(1) Does starter have cranking problems? Yes - See “Road Homologated Light and Horn Circuit

Diagnosis” on page 483 or “Light and Horn Circuit

Yes - See “Power Circuit Diagnosis - 6X4 Gas” on

Diagnosis (Earlier Model)” on page 437 or “Light and

page 292.

Horn Circuit Diagnosis (Later Model)” on page 458.

Yes - See “Cranking Circuit Diagnosis - 6X4 Gas” on

(13) Are there domestic headlight problems?

page 296.

Yes - See “Standard Headlight Circuit Diagnosis -

Yes - See “Ground Circuit Tests” on page 387.

6X4 Gas” on page 312.

Yes - See “Battery Test” on page 363.

(14) Are there cargo box lift problems?

(2) Does engine crank but not start?

Yes - See “Cargo Box Lift System Troubleshooting

Yes - See “Ground Circuit Tests” on page 387. Chart” on page 395 and “Cargo Box Lift Circuit

Diagnosis” on page 396.

Yes - See “Ignition Circuit Diagnosis - 6X4 Gas” on

page 299.

(3) Is there spark from the ignition?

Yes - See “Ignition Circuit Diagnosis - 6X4 Gas” on

page 299.

(4) Is the fuel pump operating?

Yes - See “Ignition Circuit Diagnosis - 6X4 Gas” on

page 299.

(5) Does the engine not shut off?

Yes - Check for a shorted circuit.

(6) Is an improper component working with a

switch?

Yes - Check for a shorted circuit.

(7) Is there a problem with the engine oil light?

Yes - See “Indicator Lights Circuit Diagnosis - 6X4

Gas” on page 307.

(8) Does the battery go dead, discharge, or over

charge?

Yes - See “Charging Circuit Diagnosis - 6X4 Gas” on

page 303.

(9) Is there a discharge light problem?

Yes - See “Charging Circuit Diagnosis - 6X4 Gas” on

page 303.

(10) Are there cooling fan problems?

Yes - See “Indicator Lights Circuit Diagnosis - 6X4

Gas” on page 307.

(11) Are there instrumentation light problems?

Electrical Operation and Diagnostics - 6X4 Gas - 289

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Power Circuit Operation - 6X4 Gas Switched Power:

Voltage must be present at the following components with

Function: the key switch “ON or RUN” position:

Provides unswitched power to the primary components

• “A “and “S1” Terminals of key switch

whenever the battery is connected.

• Start Relay

Operating Conditions, Unswitched Circuits: • Voltage Regulator/Rectifier

Voltage must be present at the following components with

• Ignition Module

the key switch “OFF”:

• Fuel Pump

• Battery Positive Terminal

• Park Brake Switch

• “B” Terminal of Starting Motor

• Differential Lock Switch

• “B” Terminal of Key Switch

• Light Switch (Standard or Homologated)

• Voltage Regulator/Rectifier

• Lift Switch Connector

• Alternator Positive Terminal (if equipped)

• Engine Coolant Temperature Light

• Radiator Fan Motor

• Engine Oil Pressure Light

The positive battery cable connects the battery to the

starting motor. The starting motor bolt is used as a tie point These circuits are controlled by the key switch and are

for the rest of the electrical system. In systems with an protected by the fusible link.

alternator an additional positive battery cable connects to

the alternator bolt. Optional Lighting Kit and Lift Kit Power Circuits:

The battery cables, starting motor tie point and alternator See the appropriate schematics and diagnostic procedure

connections must be good for the machine’s electrical for these kits.

system to work properly. When optional kits are installed, the positive wires for these

The ground cable connections are equally important. kits are also connected to the starting motor. These leads

Proper starting motor and alternator operation depends on also contain fusible links to protect the wiring harnesses.

these cables and connections to carry the high current for

its operation.

The connection between the starting motor and key switch

is fused by a fusible link. This is a short piece of wire that is

designed to fail if current load is too high or a short occurs.

It protects the wiring harness from damage.

The charge wires running between the voltage regulator/

rectifier and starting motor and between the alternator and

the battery positive terminal are unprotected.

Electrical Operation and Diagnostics - 6X4 Gas - 290

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Power Circuit Schematic - 6X4 Gas

210 Blu/Blk

210

Blu/Blk S2 Key X8 To S5 Cargo

Switch Box Lift Switch

425 Yel 415 Yel/Red

400 Yel/Red 410 Yel/Red

X10

200 Red 400 Yel/Red

402

401 420

Yel

Yel Yel

Start

400

Run 423 Yel Yel/ 210

Off Red Blu/Blk

On Off

Off On

X5

Blu

S4 Differential S5

Lock Switch Light M

Switch

F2 Fusible S3 M3

Links Park Radiator

Brake 430 Yel Fan Motor

F1 Switch

On Off

215 Red

H4 Engine

F3 Coolant

401 Temperature

Yel

Light

30 85

435

M

87a 87

M2 Yel

86 Fuel

K1 Start Relay Pump X1

Yel/Wht H5 Engine Oil

Pressure

Light

E1 X2 E2

B S Yel/Wht Yel/Wht

Spark Spark

Plug Plug

M1

Starting

Motor N1 Voltage

425

M Regulator/ Yel

Rectifier

U T1 Ignition T2 Ignition

Coil Blk/ Coil

Yel Org Wht

X3 X3 X3

A1 Ignition Module

G1

Battery +

G3 Optional

G Alternator X4 X4 X4 X4

Yel Pnk

Grn/ Wht/

Wht Blu

B1 Left B2 Right

Pulser Coil Pulser Coil

W1 Shielded

Ground Unswitched Power Ground Switched Power

Electrical Operation and Diagnostics - 6X4 Gas - 291

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Power Circuit Diagnosis - 6X4 Gas

Test Conditions:

• Key switch in OFF position

Test/Check Point Normal If Not Normal

1. Starting motor battery Battery voltage Check battery cables and test battery. See “Battery Test” on

terminal page 363.

2. Start relay Battery voltage Check 215 Red wire. Replace F3 fusible link.

3. Radiator fan motor Battery voltage Check 210 Blu/Blk wire and connections. Replace F2 fusible

link.

4. Voltage regulator/rectifier Battery voltage Check 205 Red wire and connections.

5. Alternator, high capacity Battery voltage Check 202 and 201 Red in W29 Harness

(optional)

6. Key switch Battery voltage Check 200 Red wire and connections. Replace F1 fusible link.

Test Conditions:

• Key switch in RUN position

Test/Check Point Normal If Not Normal

7. Key switch Battery voltage Replace S2 key switch.

8. Voltage regulator/rectifier Battery voltage Check 425 Yel wire and connections.

9. Light switch Battery voltage Check 400 Yel/Red wire and connections.

10. Lift switch connector Battery voltage Check 415 Yel/ Red wire connection.

Electrical Operation and Diagnostics - 6X4 Gas - 292

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

1

F1 Fuse-Link

F2 Fuse-Link

F3 Fuse-Link

2

215 Red

K1 Start Relay

M1 Starting Motor

M3 Radiator Fan Motor

202 Red

G1 Battery

210 Blu/Blk 3

G3 Alternator

(Optional)

5 201 Red

S5 Cargo Box

Lift Switch (Opt.)

10 8

415 Yel/Red 425 Yel

4

205 Red

S6 Light Switch S2 Key Switch

N1 Voltage Regulator/Rectifier

9 200 Red

400 Yel/Red 7

400 Yel/Red

401 Yel

Electrical Operation and Diagnostics - 6X4 Gas - 293

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Power Circuit Diagnosis - 6X4 Gas (continued)

Test Conditions:

• Key switch in ON position

Test/Check Point Normal If Not Normal

11. Differential lock switch Battery voltage Check connection of 420 Yel wire.

12. Park brake switch Battery voltage Check 423 Yel wire and connections.

13. Fuel pump motor Battery voltage Check 430 Yel wire and connections.

14. Ignition module Battery voltage Check 435 Yel wire and connections.

15. Ignition coils Battery voltage Check X3 engine harness connector and Yel/Wht wire at

ignition module.

S4 Differential Lock Switch S3 Park Brake Switch

11

12

420 Yel

423 Yel

423 Yel

430 Yel

Yel/Wht

13

15 430 Yel

T1, T2 Ignition Coils

A1 Ignition Module

M2 Fuel Pump

14

435 Yel

Electrical Operation and Diagnostics - 6X4 Gas - 294

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Cranking Circuit Operation - 6X4 Gas Theory of Operation:

Current from the power circuit (200 Red) flow through a

Function: fusible link to the key switch.

To energize the starting motor solenoid and engage the

The S2 key switch allows current to flow to the start relay

starter motor to crank the engine.

when in the run or start position (401 Yel). With the

Operating Conditions: transmission in neutral the S2 key switch connects the

neutral start circuit (706 Pur, V1 Diode, 705 Pur and 710

• Key switch in START position Pur) to ground, allowing the start relay to activate.

• Transmission in NEUTRAL The start relay then allows a higher current to pass from the

battery, through the F2 fusible link and start relay to

energize the starter solenoid (215 Red, 700 Pur).

With the starting motor solenoid activated, high current

from the battery passes through the battery cable, across

the solenoid and energizes the starting motor.

Cranking Circuit Schematic - 6X4 Gas

401 Yel

200 Red

215 Red 400

Yel/

710 Red

F1 F3 Start Pur/

Blk

Run

Fusible

Off

Links 30 85

K1 Start

Relay

87a 87 86 S2 Key 423

Switch Yel

706 Pur 705 Pur

700 Pur

V1 Diode

X1 Neutral 430

B S Yel

In Gear

S1

Neutral Start M2

Switch M Fuel

M1

Starting Pump

M Motor

G1 Battery

100 Blk 105 Blk

100 Blk

110 Blk

W1 Shielded

Ground X11 To W4 Standard

Headlight Wiring Harness

Unswitched Power Switched Power Neutral Start Circuit Ground

Electrical Operation and Diagnostics - 6X4 Gas - 295

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Cranking Circuit Diagnosis - 6X4 Gas

Test Conditions:

• Transmission in NEUTRAL and brake set

• Key switch in OFF position

Test/Check Point Normal If Not Normal

1. Key switch Battery voltage Check 200 Red wire and F3 fusible link. See “Power Circuit

Diagnosis - 6X4 Gas” on page 292.

2. Start relay Battery voltage Check 215 red wire and connections. Replace F2 fusible link.

Test Conditions:

• Key switch in START position

Test/Check Point Normal If Not Normal

3. Key switch Battery voltage Replace S2 key switch.

4. Start relay Battery voltage Test 401 Yel wire and connections.

Test Conditions:

• Remove connector from start relay

• Change meter to ohm scale

• Test for continuity to ground with transmission in neutral and key switch in START position

Test/Check Point Normal If Not Normal

5. Relay connector to neutral Continuity in one Continuity in both directions replace V1 diode or wiring harness.

start switch direction only No continuity in either direction, repair wire.

6. Neutral start switch Continuity across Check transmission linkage neutral adjustment. Replace

(Switch disconnected) neutral start switch neutral start switch.

7. Neutral start switch to key Continuity Repair 710 Pur/Blk wire.

switch

8. Key switch Continuity across Replace S2 key switch.

switch in START

position

8. Key switch to engine ground Continuity Check Blk wires and connection at fuel pump, light harness

connector, and engine and battery ground location. Repair

wires and/or connections.

10. Starting motor solenoid “S” Battery voltage No voltage: Test 700 Pur wire and connections. Replace K1

terminal start relay.

Voltage: Check battery ground cable and connections. Test or

replace starting motor solenoid.

Electrical Operation and Diagnostics - 6X4 Gas - 296

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

S2 Key Switch

4

1

401 Yel

200 Red

215 Red

7

2

710 Pur/Blk

705 Pur

8 3

400 Yel/Red V1 Diode 5

110 Blk 401 Yel K1 Start Relay

S1 Neutral Start Switch

F1 Fusible Link

200 Red

215 Red

F3 Fusible Link

710 Pur/Blk

700 Pur 6

706 Pur

10

5

M1 Starting Motor

Engine Ground

100 Blk

W1 Shielded Ground

G1 Battery

Electrical Operation and Diagnostics - 6X4 Gas - 297

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Ignition Circuit Operation - 6X4 Gas pump are all powered by this circuit.

Two pulser coils, one for each cylinder, are mounted in a

Function: fixed position next to the flywheel. As the flywheel turns, a

To create a spark at the correct time, that ignites the fuel tab on the flywheel travels past the pulser coils and

and air mixture. produces current in the pulser coils by electromagnetic

induction. Pulser coil current flows to the ignition module as

Operating Conditions: a signal for the module to ground the coil primary windings.

• Key switch must be in the START or RUN position. When the current flow stops in the primary windings, the

magnetic field collapses and induces high voltage in the

Theory of Operation: secondary coil windings. The high voltage current travels

through the plug wire and jumps the gap at the spark plug,

The ignition system is a transistor controlled, battery

igniting the fuel/air mixture.

ignition design. The battery supplies current to the ignition

coils. The timing is controlled by the ignition module and is Each spark plug fires on both the compression and exhaust

not adjustable. The engine is shutoff by de-energizing the stroke. The spark produced during the exhaust stroke does

ignition coils. not affect engine operation because there is no

compression or combustible mixture in the cylinder.

Current flows from the key switch to the left and right

ignition coils. The differential lock, park brake and fuel

Ignition Circuit Schematic - 6X4 Gas

X8 To S5 Cargo Box

Lift Kit Switch (Optional)

200 Red 400 Yel/Red 410 Yel/Red

X10 To

W4 Standard

Start

435 Yel 430 Yel Headlight

Run Wiring Harness

Off 423 Yel

Off On

On Off

X1 To W8 Engine

S2 Key Wiring Harness

Switch

S4

X2 T2 Ignition Coil S3 Differential

T1 Ignition Coil Park Lock Switch

Yel/Wht Yel/Wht Brake

Switch

E1 Blk/ E2

Spark Yel Spark

Plug Org Plug

Wht

Blk X3 X3 X3 M M2

Fuel Pump

A1 Ignition Module

Engine

Ground X4 X4 X4 X4

Grn/ Yel Pnk Wht/

Wht Blu

B1 Left B2 Right

Pulser Coil Pulser Coil

Electrical Operation and Diagnostics - 6X4 Gas - 298

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Ignition Circuit Diagnosis - 6X4 Gas

Test Conditions:

• Key switch in RUN position

Test/Check Point Normal If Not Normal

1. Main wiring harness to Battery voltage Check connections at differential lock and park brake switches

engine wiring harness and at the fuel pump. See “Power Circuit Diagnosis - 6X4 Gas”

connector on page 292.

2. Positive terminals of right Battery voltage Check Yel/Wht wire of coil harnesses and X2 connections at

and left ignition coils engine harness connector.

3. Ignition module connector Battery voltage Check Org wire and connections through module and engine

module side. (Org or Org/Wht harness power connector.

wire lead)

4. Right and left negative Battery voltage minus No voltage: Replace ignition coil.

terminal of ignition coils. (Wht voltage drop across

and Blk/Yel leads) coils

Test Conditions:

• Key switch to OFF position

Test/Check Point Normal If Not Normal

5. Ignition module connector Maximum 0.1 ohms Check ignition module ground connection.

(Blk ground wire) resistance

Test Conditions:

• Meter set to AC voltage

• Plug wires grounded

• Key switch to START position

• Engine cranking

Test/Check Point Normal If Not Normal

6. Spark plugs Spark plug tester: Hot Inspect or replace spark plug(s).

blue spark

7. Pulser coil connection (Wht/ 0.1 - 1.0 VAC Check pulser coil connections. Test pulser coil resistance.

Blu and Pnk, then Grn/Wht

Coil resistance 85 - Replace pulser coil.

and Yel)

270 ohms

8. Ignition module connector Using test light: Rapid Flashing light: Check coil resistance.

(Wht then Blk/Yel wire leads) flashing light, not No Light: Check connections. Replace ignition module.

steady glow.

Coil resistance:

Primary windings 3.4 -

4.6 ohms.

Secondary windings

10.4 - 15.5 ohms

Electrical Operation and Diagnostics - 6X4 Gas - 299

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

3

7

5

7

Org/Wht Blk

Yel Pink

Pnk or Org

Wht Blk/Yel

Grn/Wht Wht/Blu

Back-Side of

Ignition Module

8 A1 Ignition Module

Connectors

Wht/

B1, B2 Pulser Blu

Coils Grn/Wht Pnk

Yel

X4 W10 Engine Wiring Harness

6 Blk To W11 Engine Wiring Harness

2 T1, T2 Ignition Coils

Yel/Wht X3 W9 Engine Wiring Harness

To W10 Engine Wiring Harness

Blk/

Yel

Wht

E1, E2 Spark Plug

4

Org

1

X2 W8 Engine Wiring Harness

Org To W9 Engine Wiring Harness

X1 W2 Main Wiring Harness To

W8 Engine Wiring Harness

M56701

Electrical Operation and Diagnostics - 6X4 Gas - 300

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Charging Circuit Operation - Stator Charging Circuit Operation - Auxiliary

Alternator (Optional)

Function:

To maintain battery voltage between 12.4 and 13.2 volts. Function:

To maintain battery voltage between 12.4 and 13.2 volts.

Operating Conditions:

The key switch must be in the RUN position with the engine Operating Conditions:

running for the charging system to operate. The key switch must be in the RUN position with the engine

running for the charging system to operate.

System Operation (Stator equipped):

The charging system is a permanent magnet and stator System Operation:

design. Charging output is controlled by a voltage The charging system consists of the G3 alternator with an

regulator/rectifier. integrated voltage regulator/rectifier. Charging output is

With the key switch in the run position, battery sensing controlled by a regulator/rectifier.

circuit current flows from battery positive terminal to With the key switch in the RUN position, battery sensing

starting motor terminal, fusible link, key switch, and circuit current flows from battery positive terminal 202 and

regulator-rectifier. The battery sensing circuit allows the 201 Red wires to the auxiliary alternator internal voltage

voltage regulator/rectifier to monitor battery voltage. regulator/rectifier. The battery sensing circuit allows the

As the flywheel turns, a permanent magnet located in the voltage regulator/rectifier to monitor battery voltage.

flywheel induces AC current in the stator. The AC current A rotating permanent magnet in the alternator induces AC

flows to the voltage regulator/rectifier. The voltage current in the alternator stator coils. The AC current flows to

regulator/rectifier converts AC current to DC current the voltage regulator/rectifier. The voltage regulator/rectifier

needed to charge the battery. converts AC current to DC current needed to charge the

If battery voltage is low, the voltage regulator/rectifier battery.

allows DC current to flow to the battery to charge it through If battery voltage is low, the regulator/rectifier allows DC

the battery charging circuit (205 Red). When the battery is current to flow to the battery to charge it through the battery

fully charged, the voltage regulator stops current flow to the charging circuit (201 and 202 Red). When the battery is

battery. fully charged, the voltage regulator/rectifier stops current

If the stator output current falls below the system usage or flow to the battery.

is insufficient to maintain a preset voltage, the voltage The ground circuit (101 and 102 Blk) provides a path to

regulator provides current to turn on the discharge indicator ground for the voltage regulator/rectifier.

light.

The ground circuit provides a path to ground for the voltage

regulator/rectifier

Electrical Operation and Diagnostics - 6X4 Gas - 301

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Charging Circuit Schematic - Stator

S2 Key

200 Red Switch 400 Yel/Red

Run

F1 Fusible Off Start

600 Brn

G1 Battery Link Run 425

Off Yel H1 H2 H3

Discharge Park Brake Differential

Light Light Lock Light

+ _

205 Red U

N1 Voltage 590 595

Regulator/ 125 Blk 120 Blk

Brn/Yel Brn/Wht

Rectifier

X1 X1

M1 Blk Blk

Starting

M Motor G

G2

Stator

115 Blk

100/115/130 Blk 130 Blk

Charging Circuit Schematic - Auxiliary Alternator

S2 Key H1 H2 H3

200 Red Switch 400 Yel/Red Discharge Park Brake Differential

425 Light Light Lock Light

Yel

+ _

Run X12

F1 Fusible Off Start

G1 Battery Link Run 425 600

Yel Brn 125 Blk 120 Blk

Off

X13 N1 Voltage

600 Brn

Regulator/

M1 Rectifier

Starting

Motor X13 X13

U

590 595

Brn/Yel Brn/Wht

M

X13

205 Red 590 595

X12 Brn/Yel Brn/Wht W29 Alternator

(Not Used) Wiring Harness

202 Red 200 Red

X12

590 595 115 Blk

201 Red Brn/Yel Brn/Wht

+ X1 X1

G3

Alternator Blk Blk

G

G

101 Blk

102 Blk 100 Blk

100/115 Blk

130 Blk

(Not Used)

Electrical Operation and Diagnostics - 6X4 Gas - 302

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Charging Circuit Diagnosis - 6X4 Gas

Test Conditions:

• Transmission in NEUTRAL

• Engine OFF

Test/Check Point Normal If Not Normal

1. Voltage regulator/rectifier Battery voltage Check 425 Yel wire and connections. Check F1 fusible link and

S2 key switch. See “Power Circuit Diagnosis - 6X4 Gas” on

page 292.

2. High Capacity Alternator (If Battery voltage Check 202 and 201 Red wires and connections.

equipped)

3. Voltage regulator/rectifier Greater than 0 volts - Greater than 0.2 volts: Test voltage regulator/rectifier ground

less than 0.2 volts circuit.

4. Charge indicator light Battery voltage Check 600 Brn wire and connections X12, X13.

(600 Brn Wire)

5. Charge indicator light Greater than 0 volts - 0 volts: Replace bulb.

less than 0.2 volts Greater than 0.2 volts: Check all connections and ground wires

for open or poor connections.

Test Conditions:

• Stator disconnected

• Engine running at high idle

Test/Check Point Normal If Not Normal

6. High capacity alternator Minimum unregulated Check stator leads and connector. Check flywheel magnets.

voltage output - 45 Replace stator.

amps at 12.2-13.8 V

7. Voltage regulator/rectifier Minimum 20 Amps at Replace voltage regulator/rectifier. See “Alternator Output -

(Machine SN -007496) 12.2 -13.8 V 4X2” on page 383.

(Engine SN -038265)

8. Voltage regulator/rectifier Minimum 16 Amps at See “Stator - Regulated Amperage and Voltage Tests” on

(Machine SN 007497-) 12.2 -13.8 V page 366. Replace voltage regulator/rectifier.

(Engine SN 038266 -)

9. Battery Voltage above normal Check for excessive load on electrical system.

battery voltage

Electrical Operation and Diagnostics - 6X4 Gas - 303

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

205 Red

200 Red

F1 Fusible Link

3

3

130 Blk

130 Blk

425 Yel

M1 Starting Motor

425 Yel

1

1

205 Red 8 N1 Voltage

(200 Red) Regulator/Rectifier

205 Red 7 N1 Voltage

Regulator/Rectifier

H1 Discharge Light

130 Blk

G1 Battery

W1 Shielded Ground 5

125 Blk

202 Red 600 Brn

4

200 Red

G2 Stator

201 Red

Blk

Blk

G3 High Capacity

Alternator (optional) X1 W2 Main Wiring Harness

590 Brn/Yel

To W12 Engine Wiring Harness

2 6

595 Brn/Wht

Electrical Operation and Diagnostics - 6X4 Gas - 304

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Indicator Lights Circuit Operation - 6X4 Gas

Function:

Engine Oil Pressure Light:

To alert operator of low engine oil pressure by illuminating a

warning light.

Engine Coolant Temperature Light:

Inform operator of critical engine and coolant operating

temperature by illuminating a warning light.

Park Brake Light:

Informs the operator that the park brake is ON by

illuminating a warning light.

Differential Lock Light:

Inform the operator that the differential Lock is ON by

illuminating a warning light.

Operating Condition:

The key switch must be in RUN position.

Theory of Operation:

Oil Pressure Light:

With the engine OFF and key in RUN position, oil pressure

will be below 28 kPa (4 psi). The oil pressure switch will be

closed, completing the circuit path to ground and

illuminating the light. This will inform the operator that the

light is functioning.

When the engine is started and running, the light should go

out when the oil pressure is adequate to open the pressure

switch, turning out the light.

Engine Coolant Temperature Light:

When the key switch is in the START position, the ground

circuit is allowed to pass through the V2 diode and the key

switch starting circuit to ground. This will momentarily turn

on the light as a bulb check, When the engine starts and

the key switch is returned to the RUN position, the light will

go out. If the engine temperature reaches 109° C ± 1° C

(228° F ± 2° F), the sensor will close, providing a path to

ground through the engine block.

Park Brake Light:

When the park brake is set the switch is released (closes),

allowing current to flow to the warning light. When the

brake is released the switch is opened and the light goes

out.

Differential Lock Light:

When the differential lock lever is moved to engage the

differential lock, the switch is depressed (closed), allowing

current flow to the light. When the differential is released,

the switch is released (open), and the light goes out.

Electrical Operation and Diagnostics - 6X4 Gas - 305

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Indicator Lights Circuit Schematic - 6X4 Gas

302

Org/Wht

400 Yel/Red 410 Yel/Red

402 Yel

X10 To W4

Standard

Start Headlight

Run Wiring

Harness

Off

S2 Key

110 Switch

Blk

115

Blk

F1 S4

430 Yel

Differential

B S 423 Yel Lock Switch

Off On

On Off

S3

Park H4 Coolant H5 Engine

M Brake Temperature Oil Pressure

Switch Light 403 Yel Light

M1 Starting

630 640

Motor Grn/Blk Grn

H2

Park Brake 310 Org/Wht

Light

300

120 Blk H3 Org/Wht 620 Tan

Differential

+ M2 Lock Light

Fuel X1 X1

Pump V2

Diode

G1 Battery

t0 t0

115 Blk

B4 Engine Coolant B5

Engine Oil

Temperature Switch Pressure Switch

302 Org/Wht

100 Blk

105 Blk X11 To W4

110 Blk Standard Headlight

Wiring Harness

W1 Shielded

Ground

Electrical Operation and Diagnostics - 6X4 Gas - 306

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Indicator Lights Circuit Diagnosis - 6X4 Gas

Test Conditions:

• Key switch in RUN position

• Engine OFF

• Differential lock engaged

• Park brake set

Test/Check Point Normal If Not Normal

1. Engine oil pressure light Battery voltage Check 402 and 403 Yel Wires and connections. See “Power

Circuit Diagnosis - 6X4 Gas” on page 292.

2. Engine oil pressure light Battery voltage Replace light bulb.

3. Engine oil pressure switch Battery voltage Check 620 Tan wire and connections.

4. Engine oil pressure switch Continuity to ground Check engine ground. If OK replace engine oil pressure switch.

(Wire lead disconnected)

5. Engine coolant temperature Battery voltage Check 402 Yel wire. See “Power Circuit Diagnosis - 6X4 Gas”

light on page 292.

6. Engine coolant temperature Battery voltage Replace light bulb.

light

7. Engine coolant temperature Battery voltage Check 300 Org/Wht wire and connections.

switch

8. Engine coolant temperature Switch closes at 108° Replace Switch. See “Engine Coolant Temperature Switch Test

switch - 110° C (226° - 230° - 6X4’s” on page 381.

F). Switch opens at

101° - 107° C (214° -

225° F).

Test Conditions:

• Meter positive lead to voltage source

• Negative lead to ground side of coolant light

Test/Check Point Normal If Not Normal

9. Engine coolant temperature Battery voltage Test V2 diode and check 302 Org/Wht wire lead and

light connections to S2 key switch.

(Momentarily turn key switch

to start. This tests ground

circuit and diode for bulb test

circuit)

10. Key switch Continuity to ground. Check ground wire 110, 105, 100 Blk wires and connections.

Maximum 0.1 ohm

resistance,

11. Key switch Battery voltage Test or replace key switch. Test V2 diode.

Electrical Operation and Diagnostics - 6X4 Gas - 307

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

620 Tan

2 3

620 Tan

4

1 403 Yel

H5 Oil Pressure Light

B5 Engine Oil Pressure Switch

S2 Key Switch

11

302 Org/Wht

6

10

110 Blk 9

115 Blk 310 Org/Wht

1 5 V2 Diode

11

402 Yel 300 Org/Wht

403 Yel

H4 Engine Coolant Temperature Light

300 Org/Wht

B4 Engine Coolant Temperature Switch

Electrical Operation and Diagnostics - 6X4 Gas - 308

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Fuel Pump and Fan Motor Operation - 6X4 connected directly to the battery and does not depend

Gas upon the start switch position.

Radiator Fan Motor: Theory of Operation:

Operates whenever the coolant switch is closed. Operates when the radiator core temperature switch closes

when coolant heats the outer radiator core to 71° ± 4° C

The radiator core temperature switch closes when the (160° ± 7° F). The radiator core temperature switch

coolant heats to 89° C (192° ± 7° F) raising the outer monitors outer radiator core temperature, not engine

radiator core temperature to 71° C (160° ± 7° F). coolant temperature.

NOTE: The outer radiator core temperature is Fan motor may run after engine is shutoff. Fan motor will

approximately 20° C (36° F) lower than engine coolant stop when outer radiator core temperature cools to 60° ± 4°

temperature. C (140° ± 7° F) and radiator core temperature switch

opens.

The fan motor will stop when the coolant temperature drops

to 80° C (177° ± 7° F), the outer radiator core temperature Fuel Pump:

cools to 60° ± 4° C (140° ± 7° F), and the radiator core

temperature switch opens. The radiator fan motor circuit is Operates whenever the key is in the run or start position.

Fuel Pump and Fan Motor Schematic - 6X4 Gas

210 Blu/Blk

200 Red 400 Yel/Red

420

Start Yel

430 Yel

F1 Run

F3 Off 423 Yel

Fusible Off On

On Off

Links X5

S2 Key

Switch Blu

M3

M Radiator S4

Fan Motor S3

Park Differential

Blu Brake Lock Switch

G1 Battery Switch

X6

B Blk

M2 M

Fuel

Pump t0 B3

Radiator Core

M Temperature Switch

M1 100 Blk

Starting Blk

Motor X7

100/135 Blk 135 Blk

W1 Shielded

Ground

Electrical Operation and Diagnostics - 6X4 Gas - 309

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Fuel Pump and Fan Motor Diagnosis - 6X4 Gas

Test Conditions:

• Key switch in RUN position

Test/Check Point Normal If Not Normal

1. Fuel pump Battery voltage Check connector. See “Power Circuit Diagnosis - 6X4 Gas” on

page 292.

2. Fuel pump. Greater than 0 - less No voltage: Replace pump. Greater than 0.2 volts: Check

than 0.2 volts ground wire (100 Blk) and connections.

Test Conditions:

• Key switch in OFF position

Test/Check Point Normal If Not Normal

3. Radiator fan Battery voltage Check 210 Blu/Blk wire and connections. Replace F1

fusible link.

4. Fan to B3 radiator core Fan should run. Replace fan.

temperature switch connector. Fan amperage draw - 7 amps

Disconnect and jump fan lead

to good ground.

5. Radiator core temperature Coolant switch closes (fan Check Blk wire, X7, and 135 Blk wire. Replace switch.

switch starts) at 67° - 75° C (153° -

167° F). Coolant switch opens

at 56° - 64° C (133° - 147° F).

M3 Radiator Fan Motor

M2 Fuel Pump

2

1

430 Yel 100 Blk

435 Yel 105 Blk

210 Blu/Blk

Electrical Operation and Diagnostics - 6X4 Gas - 310

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Standard Headlight Circuit Operation - 6X4 Operating Conditions:

Gas The key switch must be in the RUN position.

NOTE: If the Light and Horn kit option is added, the Theory of Operation:

new harness plugs into the light harness connector

(X10) and connector (X11). The light switch and the The headlight harness is attached to the W2 main wiring

original light harness are removed. harness. Power from the headlight harness connector X10

is connected to the S6 light switch. Current then flows from

Function: the switch to the headlights.

Provides power to the headlights.

Standard Headlight Circuit Schematic - 6X4 Gas

X10 W2 To Main Wiring

Harness To W4 Standard

200 Red 400 Yel/Red 410 Yel/Red Headlight Wiring Harness

F1

Start

Fusible

G1 Battery Link Run

Off (0) (1)

S6

Light

Switch 0, 1

S2 Key

Switch

M2

Fuel

B S Pump

M 455

Yel/Wht 456

Yel/Wht

M1

M Starting

Motor E3 E4

100 105 Right Left

Blk Blk

Head- Head-

Light 110 100 Light

Blk Blk

100 Blk

W1 Shielded

Ground X11 W2 To Main Wiring

Harness To W4 Standard

Headlight Harness

Electrical Operation and Diagnostics - 6X4 Gas - 311

ELECTRICAL OPERATION AND DIAGNOSTICS - 6X4 GAS

Standard Headlight Circuit Diagnosis - 6X4 Gas

Test Conditions:

• Key switch must be in the RUN position

• Light switch ON

Test/Check Point Normal If Not Normal

1. Light switch Battery voltage Check connection at X10 connector. See “Power Circuit

Diagnosis - 6X4 Gas” on page 292.

2. Light switch Battery voltage Replace light switch.

3. Left headlight Battery Voltage Check 455 Yel/Wht wire and connections.

4. Left headlight Greater than 0 volts - 0 volts: Replace headlight.

less than 0.2 volts Greater than 0.2 volts: Check ground circuit connection at light

harness ground connector X11 and 105 and 100 Blk wires and

connections.

5. Right headlight Battery voltage Check 456 Yel/Wht wire and connections.

6. Right headlight Greater than 0 volts - 0 volts: Replace headlight.

less than 0.2 volts Greater than 0.2 volts: Check ground circuit connection at light

harness ground connector X11and 105 and 100 Blk wires and

connections.

S6 Light Switch

400 Yel/Red E4 Left Headlight

455 Yel/Wht

3

455 Yel/Wht

2 456 Yel/Wht 4

110 Blk

E3 Right Headlight

456 Yel/Wht

5

6

100 Blk

Electrical Operation and Diagnostics - 6X4 Gas - 312

You might also like

- TL10V2 Optimized Apr - 2017Document6 pagesTL10V2 Optimized Apr - 2017DarthCainNo ratings yet

- D350E Series II and Hydraulic Schematic D400E Series II Articulated TrucksDocument2 pagesD350E Series II and Hydraulic Schematic D400E Series II Articulated Trucksمهدي شقرونNo ratings yet

- Pecas 624c PDFDocument236 pagesPecas 624c PDFLeclerc KevenNo ratings yet

- Generic 7Sw: User Installation / Configuration Manual T150 Transmitter R170 ReceiverDocument16 pagesGeneric 7Sw: User Installation / Configuration Manual T150 Transmitter R170 ReceiverVladimir Illich Pinzon BallenNo ratings yet

- Westfield WR AugerDocument16 pagesWestfield WR AugerAlvaro GarciaNo ratings yet

- Katgalog Części Case 580F Before S-N 373960Document479 pagesKatgalog Części Case 580F Before S-N 373960Rafał HubczakNo ratings yet

- Cosechadora 522B Plano HYD 2016 SISDocument8 pagesCosechadora 522B Plano HYD 2016 SISFabrizio Jesús100% (1)

- 17 Digit Product Identification NumberDocument4 pages17 Digit Product Identification NumberalexanderNo ratings yet

- V-Link: 924G Wheel Loader Electrical System IT28G Integrated Tool Carrier 928G Wheel LoaderDocument4 pagesV-Link: 924G Wheel Loader Electrical System IT28G Integrated Tool Carrier 928G Wheel LoaderEvandro GrilloNo ratings yet

- Service SchematicDocument3 pagesService SchematicskaNo ratings yet

- SOLAR POWERED TRAFFIC DIRECTORDocument48 pagesSOLAR POWERED TRAFFIC DIRECTORBrian StevensNo ratings yet

- Feller Bunch ErsDocument139 pagesFeller Bunch ErsJhonald Lanz LossadaNo ratings yet

- Mccormick c60 c75 c85 c95 c105 C Max Workshop ManualDocument8 pagesMccormick c60 c75 c85 c95 c105 C Max Workshop ManualdingleberryspotifyNo ratings yet

- Uniden Bearcat BC9000XLT (Manual)Document57 pagesUniden Bearcat BC9000XLT (Manual)Theodor EikeNo ratings yet

- Hydraulic CircuitDocument2 pagesHydraulic CircuitJohn Louie Mazon100% (1)

- Taylor VertexDocument6 pagesTaylor VertexdeutscheafrikarNo ratings yet

- Trailer Landing Gear Parts CatalogDocument1 pageTrailer Landing Gear Parts CatalogZeckNo ratings yet

- 6D Series Tier 3 Tractors 6100D 6110D 6115D 6125D 6130D and 6140D Replacement Parts GuideDocument3 pages6D Series Tier 3 Tractors 6100D 6110D 6115D 6125D 6130D and 6140D Replacement Parts GuideAnaLilian Amayade CamposNo ratings yet

- CA20 Combine Adapter: Operator'S ManualDocument100 pagesCA20 Combine Adapter: Operator'S ManualPNV2014No ratings yet

- 4640 and 4840 Tractors IntroductionDocument14 pages4640 and 4840 Tractors IntroductionDenis HernandezNo ratings yet

- CASE-480 Manual en InglesDocument51 pagesCASE-480 Manual en InglesHugoRamosMamani100% (1)

- CapacitorsDocument10 pagesCapacitorsrsrtnj100% (1)

- Electronic Service Information System (ERWIN - ERWIN) 8Document46 pagesElectronic Service Information System (ERWIN - ERWIN) 8Marius PopNo ratings yet

- Mower GuideDocument48 pagesMower GuidezexploNo ratings yet

- Nyc Catalogo Drive Train & Suspension 2018Document70 pagesNyc Catalogo Drive Train & Suspension 2018Carlos Cáceres100% (1)

- Operation 31200354 09-19-11 ANSI EnglishDocument150 pagesOperation 31200354 09-19-11 ANSI EnglishWilliam RoarkNo ratings yet

- John Deere 7 Series Round BalersDocument4 pagesJohn Deere 7 Series Round Balersarmando_l_08No ratings yet

- John Deere Cab Installation GuideDocument28 pagesJohn Deere Cab Installation GuideMason100% (1)

- Secondary Switched Power Circuit SchematicDocument1 pageSecondary Switched Power Circuit Schematicpavli999100% (1)

- Catalog - SolenoidDocument37 pagesCatalog - SolenoidMIHAINo ratings yet

- Manual Partes SERIES GS1530 - GS1930Document190 pagesManual Partes SERIES GS1530 - GS1930reman partsNo ratings yet

- RT30 - 00315 - R070T - 00545Document1 pageRT30 - 00315 - R070T - 00545TrevorNo ratings yet

- HD465-7 SchematicDocument16 pagesHD465-7 SchematicSarno Mukri100% (1)

- John Deere - Parts Catalog - Frame 9Document2 pagesJohn Deere - Parts Catalog - Frame 9Jorge MendozaNo ratings yet

- Case 580 Super L Operators ManualDocument7 pagesCase 580 Super L Operators Manualoscar0% (1)

- Lincoln Electric PDFDocument44 pagesLincoln Electric PDFGuillermo Andres Velasco AlvarezNo ratings yet

- Parts Manual: Issue 13Document141 pagesParts Manual: Issue 13Юра ПименовNo ratings yet

- CGa Series 3 Parts ListDocument6 pagesCGa Series 3 Parts ListAlex82No ratings yet

- Peças 624cDocument236 pagesPeças 624cGabriely MuriloNo ratings yet

- International VT365 Fuel Pump PDFDocument1 pageInternational VT365 Fuel Pump PDFChristopher EisertNo ratings yet

- Brazo Articulado Modelo 9000Document46 pagesBrazo Articulado Modelo 9000Santiago Giraldo GarcíaNo ratings yet

- Operator'S Manual: Read and Save This ManualDocument112 pagesOperator'S Manual: Read and Save This Manualphucdc095041No ratings yet

- Recommended lubricants and refill capacitiesDocument2 pagesRecommended lubricants and refill capacitiestele123No ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document15 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768RicardoNo ratings yet

- IGen4500 Manual WebDocument28 pagesIGen4500 Manual Webclaudia_baca_3No ratings yet

- Massey Ferguson MF 178 TRACTORS (FR) Service Parts Catalogue Manual (Part Number 957368)Document15 pagesMassey Ferguson MF 178 TRACTORS (FR) Service Parts Catalogue Manual (Part Number 957368)bvk29800220% (1)

- GA-H61M-DS2 Block DiagramDocument30 pagesGA-H61M-DS2 Block DiagramAdriano Araújo Amaral100% (2)

- 345B L Excavator Electrical System (SENR1937-01)Document2 pages345B L Excavator Electrical System (SENR1937-01)sughieantoNo ratings yet

- AC - TR - D10, D12 Allis Chalmers TractorDocument252 pagesAC - TR - D10, D12 Allis Chalmers TractorPartsdiggerNo ratings yet

- Ferris 1-700ZDocument48 pagesFerris 1-700ZEmNo ratings yet

- Wheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeDocument4 pagesWheel Loader 621B/721B XT: Engine Hydraulic System Cycle TimeRalf MaurerNo ratings yet

- P Series Parts ManualsDocument836 pagesP Series Parts ManualsArgopartsNo ratings yet

- M313C & M315C Electrical System Wheeled Excavator: Harness and Wire Electrical Schematic SymbolsDocument4 pagesM313C & M315C Electrical System Wheeled Excavator: Harness and Wire Electrical Schematic SymbolsAnibal Victor Rosas Condor0% (1)

- 210G and 210GLC Excavators PIN 1FF210GX C520001 PIN 1FF210GX D520001 IntroductionDocument5 pages210G and 210GLC Excavators PIN 1FF210GX C520001 PIN 1FF210GX D520001 IntroductionwilsonugshaNo ratings yet

- Om. TS 142Document40 pagesOm. TS 142Frank ColaciuriNo ratings yet

- Manual Chipeadora 18XP (001-058)Document58 pagesManual Chipeadora 18XP (001-058)Mantenimiento BiocicloNo ratings yet

- Advanced ManualDocument240 pagesAdvanced ManualLEENo ratings yet

- MAN Trailer Lighting Socket 24V 7-Pin/4-Pin + 12V 13-PinDocument8 pagesMAN Trailer Lighting Socket 24V 7-Pin/4-Pin + 12V 13-PinMircea GilcaNo ratings yet

- Electrical wiring diagram legendDocument6 pagesElectrical wiring diagram legendRaúlNo ratings yet

- 4.5 Liter 12 Volt ECU Wiring DiagramDocument2 pages4.5 Liter 12 Volt ECU Wiring DiagramLampartNo ratings yet

- YANMAR FI - Catalog PDFDocument202 pagesYANMAR FI - Catalog PDFTadas PNo ratings yet

- WI-XML Current Flow Diagram for Toledo/León Vehicles</TITLEDocument13 pagesWI-XML Current Flow Diagram for Toledo/León Vehicles</TITLEAndre NunesNo ratings yet

- Automobile TechnologyDocument61 pagesAutomobile Technologythanseelnn100% (1)

- Chapter 2 PDFDocument52 pagesChapter 2 PDFoscar trujilloNo ratings yet

- Iskra Alternators AAK CDocument2 pagesIskra Alternators AAK CosobaxNo ratings yet

- Alternator TroubleshootingDocument2 pagesAlternator Troubleshootinghagleyr5638No ratings yet

- Auto ElectricianDocument29 pagesAuto ElectricianAwAis MughalNo ratings yet

- P.Kay ECU CodesDocument8 pagesP.Kay ECU Codesadgjl123456100% (1)

- Disassembly and Assembly: 4012-46A Industrial EngineDocument20 pagesDisassembly and Assembly: 4012-46A Industrial EngineAdekanbi IsraelNo ratings yet

- Wa0017.Document34 pagesWa0017.farnalia1No ratings yet

- Model T Ford Wiring Diagram With Electric Starter and Brake Light. Texas T PartsDocument1 pageModel T Ford Wiring Diagram With Electric Starter and Brake Light. Texas T PartsfollowjesusNo ratings yet

- Malaysian Aviation Technology: InstituteDocument5 pagesMalaysian Aviation Technology: InstituteJude Isaac100% (3)

- Russian Regulators Part VI Nippon Denso PDFDocument20 pagesRussian Regulators Part VI Nippon Denso PDFAlfonso100% (1)

- Caterpillar 6D16 Diesel Engine Service Manual (PDF, ENG, 4.7 MB)Document242 pagesCaterpillar 6D16 Diesel Engine Service Manual (PDF, ENG, 4.7 MB)SERVICE & REPAIR MANUAL67% (3)

- Pre-Mob Inspection Checklists 2 January 2016Document378 pagesPre-Mob Inspection Checklists 2 January 2016slamet4riadiNo ratings yet

- Lichtmaschine BoschDocument23 pagesLichtmaschine BoschJames PonzoNo ratings yet

- John DreeDocument118 pagesJohn DreeHồng Sơn NguyễnNo ratings yet

- Generatori QAS - BrošuraDocument12 pagesGeneratori QAS - BrošuraAnel HasicNo ratings yet

- 245DI Parts Catg PDFDocument35 pages245DI Parts Catg PDFRahul PatelNo ratings yet

- MDX 700P HD EN Instruction ManualDocument24 pagesMDX 700P HD EN Instruction ManualtanakaNo ratings yet

- Cm5000 Install ManualDocument16 pagesCm5000 Install ManualLockdown Security CanadaNo ratings yet

- Automotive ElectronicsDocument63 pagesAutomotive ElectronicsSona Uttappa NambudumadaNo ratings yet

- Alternators Starter Motors Prestolite To Use This Buyers Guide AlternatorDocument64 pagesAlternators Starter Motors Prestolite To Use This Buyers Guide AlternatorzainNo ratings yet

- Lucas Wiring InformationDocument4 pagesLucas Wiring Informationgardener_44100% (3)

- PowerCommand 3.3 Webinar PresentationDocument57 pagesPowerCommand 3.3 Webinar PresentationAmmar Baig100% (1)

- CLAAS Avero Central ElectricsDocument5 pagesCLAAS Avero Central ElectricsAntnhe BayuNo ratings yet

- G140X G140QXDocument7 pagesG140X G140QXKhawaja Kashif QadeerNo ratings yet

- Alter NadorDocument10 pagesAlter NadorJOSE0% (2)

- Caterpillar 236D, 242D, 246D, 262D, 257D, 277D, 287D, 289D Diagrama Electrico 29 PáginasDocument29 pagesCaterpillar 236D, 242D, 246D, 262D, 257D, 277D, 287D, 289D Diagrama Electrico 29 PáginasOscar Tello86% (14)

- 2001 Audi A6 Alternator Replacement InstructionsDocument15 pages2001 Audi A6 Alternator Replacement Instructionswhavens2w2100% (4)