Professional Documents

Culture Documents

PP Transaction Codes

Uploaded by

CHAMAN RAGHAV0 ratings0% found this document useful (0 votes)

17 views3 pagesThis document provides a list of important SAP S4Hana Production Planning transaction codes. It includes codes for defining bills of materials, work centers, routings, production orders, material requirements planning, capacity planning, scheduling, and batch management. Some key transaction codes listed are OS20 for defining bills of materials usages, OPJ9 for defining production schedulers, MD01N for running material requirements planning, and COPOC for starting the manufacturing cockpit.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a list of important SAP S4Hana Production Planning transaction codes. It includes codes for defining bills of materials, work centers, routings, production orders, material requirements planning, capacity planning, scheduling, and batch management. Some key transaction codes listed are OS20 for defining bills of materials usages, OPJ9 for defining production schedulers, MD01N for running material requirements planning, and COPOC for starting the manufacturing cockpit.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views3 pagesPP Transaction Codes

Uploaded by

CHAMAN RAGHAVThis document provides a list of important SAP S4Hana Production Planning transaction codes. It includes codes for defining bills of materials, work centers, routings, production orders, material requirements planning, capacity planning, scheduling, and batch management. Some key transaction codes listed are OS20 for defining bills of materials usages, OPJ9 for defining production schedulers, MD01N for running material requirements planning, and COPOC for starting the manufacturing cockpit.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

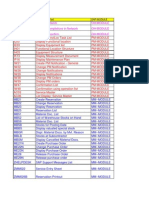

SAP S4 Hana PP Transaction Codes

– List of

SAP Production Planning T-Codes

SAP S4 Hana PP Transaction Codes – List of important SAP S4Hana

Production Planning transaction codes that are used to implement

production planning module, configure and run Material Requirement

Planning, Batch Management, capacity, scheduling, etc.

List of SAP Transaction Codes of S4Hana Production Planning

module

Transaction Code Description

OPJ9 Define Production Scheduler

SCAL Maintain Calendar

OS20 Define Bills of Materials Usages

OS24 Define Material Type Allowed for BOM Header

OS14 Define Material Type Allowed for BOM Items

OS15 Define Variable Size Item Formulas

OS23 Define BOM Status

OS25 Configure History Requirements for BOM

OS31 Define Order of Priority for BOM Usages

OP40 Define Work Center Category

OPFA Define Field Selections

OP54 Define Formula for Work Centers

OP7B Define Standard Value Parameters

OP19 Define Standard Value key

OP30 Define Move Time Matrix

OP00 Define control key – Routing Data

OPEB Set Routing Parameters Automatically

OPJH Define new order types

OPL8 Define Order Type Dependent Plant Parameters

OPKP Define Production Scheduling Profile

OVZ2 Define Checking Group

OPJJ Define Scope of Check

OPJK Define Checking Control for Production Order

OPJN Specify Scheduling Type

OPU3 Define Scheduling Parameters for Production Orders

OPJS Define Reduction Strategies

OPK0 Define Single entry screen for confirmation

OPKC Define Time for Confirmation Process

OPK5 Define Reasons for Variances

OPK8 Define Print Controls

OPN1 Define Profile with Default Values

OP46 Define Recipe Status

COR4 Define Order Type -Dependent Parameters

CORY Define Production Scheduling Profile

O25C Define Characteristics for Process Messages

O03C Setup process Message Destinations

O12C Define Process Instruction Categories

OSPT Create Repetitive manufacturing profile using Assistant

OSP2 Define Repetitive Manufacturing Profile

OLDPS Create Operation Method Sheet

CS01 Create Bills of Material

CR01 Create Work Centers

CA01 Create Routing

C223 Define Master Data Production Versions

CO27 Material Staging Pick

CO15 Confirmation Enter for Order

CO07 Create Production Order without Material

CRC1 Create Resources

CT04 Define Characteristics

COR1 Create Process Order

COPOC Manufacturing Cockpit Start

CR01 Create Work Center Production Line

CA21 Create Rate Routing

C223 Production Versions

MD61 Maintain Planned Independent Requirements

MD01N Run Material Requirements Planning

MF63 View Current Situation

MF60 Trigger Replenishment

MDVP Collective Availability Check

MFBF Repetitive Manufacturing Confirmation

MF70 Separate Backflush

MF4R Reset Reporting Point Confirmation

MF12 Document Log Information

MCRM Reporting Statistics Reporting

CORW Define Batch Creation for Production Order

OPLB Define Production Order Condition Tables

OPLG Define Production Order Search Procedure

DVMO Batch Derivation Monitoring Report

OPDB Define Strategy Profile

OPPR Define MRP Groups

You might also like

- IntroductoryBusinessStatistics OPDocument639 pagesIntroductoryBusinessStatistics OPMOHAMMED IRFANUDDIN100% (7)

- Transaction Codes in SAPDocument6 pagesTransaction Codes in SAPSai VaishnavNo ratings yet

- Most Important TablesDocument16 pagesMost Important TablesArtur Bochoń100% (1)

- Reports For BOMDocument3 pagesReports For BOMNarendra Tomar100% (1)

- PP Config TCode ListDocument9 pagesPP Config TCode Listshiv_patel14No ratings yet

- Tcode ListDocument2 pagesTcode ListShardul Agarwal100% (3)

- SAP PP Tcodes (Transaction Codes)Document7 pagesSAP PP Tcodes (Transaction Codes)GoliBharggav100% (1)

- SAp PP Pi StepsDocument2 pagesSAp PP Pi StepsajithkbalanNo ratings yet

- PP Configuration TcodesDocument6 pagesPP Configuration TcodesVenkat ChakriNo ratings yet

- Huawei RNC Parameter ReferenceDocument1,783 pagesHuawei RNC Parameter Referencerdmiguel_19836100% (2)

- List of TCodes in SAPDocument15 pagesList of TCodes in SAPVIBHAV67% (3)

- S4 Hana TablesDocument4 pagesS4 Hana TablesHarishwr KNo ratings yet

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- SAP Project System SPRO Tcodes List 3Document5 pagesSAP Project System SPRO Tcodes List 3adityavicky1No ratings yet

- Useful SAP ToolsDocument34 pagesUseful SAP ToolsBac AstonNo ratings yet

- Variant Config 1Document26 pagesVariant Config 1Goutam GhoshNo ratings yet

- Development of IDF Under Climate ChangeDocument94 pagesDevelopment of IDF Under Climate Changenek_hunter43No ratings yet

- SAP PP TcodeDocument70 pagesSAP PP Tcodedurga100% (1)

- Statistical Process Control Booklet - BoschDocument38 pagesStatistical Process Control Booklet - Boschjothi vel murugan100% (4)

- CO T-CodesDocument6 pagesCO T-CodesCHAMAN RAGHAVNo ratings yet

- Elmod 5 To 6 GuideDocument28 pagesElmod 5 To 6 GuideGonzalo Alejo MitaNo ratings yet

- Oracle SCM Functional Online Training With ProjectDocument8 pagesOracle SCM Functional Online Training With ProjectIshaac Newton0% (1)

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionFrom EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionNo ratings yet

- User EXIT: TSTC Tadir Modsapt Modact Trdir Tfdir Enlfdir TSTCTDocument49 pagesUser EXIT: TSTC Tadir Modsapt Modact Trdir Tfdir Enlfdir TSTCTsaleh ali100% (1)

- SAP Production Planning (Tables and T-Codes)Document12 pagesSAP Production Planning (Tables and T-Codes)saranpc100% (1)

- SAP PP Master Data TablesDocument3 pagesSAP PP Master Data TablesSachin Karekar100% (1)

- Applied Parameter Estimation For Chemical EngineersDocument459 pagesApplied Parameter Estimation For Chemical EngineersRogério Do Nascimento100% (2)

- Oracle SCM TrainingDocument7 pagesOracle SCM Trainingarungupta87No ratings yet

- SAP S/4HANA Retail: Processes, Functions, CustomisingFrom EverandSAP S/4HANA Retail: Processes, Functions, CustomisingRating: 3 out of 5 stars3/5 (1)

- SAP PP ImpDocument13 pagesSAP PP ImpRajRSaravananNo ratings yet

- SAP PS Transaction Codes (Project Systems - PS) : General TcodesDocument13 pagesSAP PS Transaction Codes (Project Systems - PS) : General TcodesRasul11No ratings yet

- Oracle ManufacturingDocument4 pagesOracle ManufacturingStone Hsu0% (1)

- PP QM TcodesDocument10 pagesPP QM TcodesGaneshNo ratings yet

- Modelling Dense Media SeparationDocument18 pagesModelling Dense Media SeparationbaberoniNo ratings yet

- SAP FICO - Summary InfoDocument49 pagesSAP FICO - Summary InfosharwariNo ratings yet

- Transaction Description: Table 1 General and Cross-Module Configuration Transaction CodesDocument21 pagesTransaction Description: Table 1 General and Cross-Module Configuration Transaction CodesSaurabh GuptaNo ratings yet

- FICO Configuration Transaction CodesDocument3 pagesFICO Configuration Transaction CodesSoumitra MondalNo ratings yet

- Introduction To Applied StatisticsDocument31 pagesIntroduction To Applied StatisticsJorie Roco100% (1)

- SAP Principal TablesDocument17 pagesSAP Principal TablesTapas DuttaNo ratings yet

- SAP PM Transaction CodesDocument14 pagesSAP PM Transaction CodesRafis S NúñezNo ratings yet

- SPRO PP T.codesDocument3 pagesSPRO PP T.codesKartheek PulluruNo ratings yet

- Sap T-CodesDocument9 pagesSap T-Codesshishir174No ratings yet

- PP Configuration FlowDocument28 pagesPP Configuration FlowArun RakeshNo ratings yet

- Customization LogDocument36 pagesCustomization LogRaheel BabarNo ratings yet

- PP Settings Required For PCADocument17 pagesPP Settings Required For PCAVAIBHAV PARABNo ratings yet

- SAP - T - Codes For PM ModuleDocument8 pagesSAP - T - Codes For PM Modulerhys_gauravNo ratings yet

- My Preparation TopicsDocument10 pagesMy Preparation TopicsGokulNo ratings yet

- T Codes123Document19 pagesT Codes123sree_v123No ratings yet

- Sap All Tran TcodeDocument33 pagesSap All Tran TcodeDiptimayeeGuptaNo ratings yet

- ContentDocument1 pageContentVivek KalchuriNo ratings yet

- FICO T CodesDocument6 pagesFICO T CodesNirav PandyaNo ratings yet

- Erp - ConfiguringDocument325 pagesErp - ConfiguringKiran KumarNo ratings yet

- SAP Overview: Sap PP (Production Planning) Course ContentsDocument4 pagesSAP Overview: Sap PP (Production Planning) Course ContentsShahilSinghNo ratings yet

- Important T-Codes For SAP BWDocument3 pagesImportant T-Codes For SAP BWHassaan_Saleh_5507No ratings yet

- Transaction Codes SAP FI BeginnersDocument9 pagesTransaction Codes SAP FI BeginnersWayne WilliamNo ratings yet

- SAP HR Tcodes and All Basis Useful Transaction Codes.Document47 pagesSAP HR Tcodes and All Basis Useful Transaction Codes.Manoj Kumar GangineniNo ratings yet

- Some Important Transaction Codes For SAP BWDocument3 pagesSome Important Transaction Codes For SAP BWbnsatish27No ratings yet

- PM IMG Configuration Tracker KDS Key Data StructureDocument8 pagesPM IMG Configuration Tracker KDS Key Data StructurePrasanna Kumar SethiNo ratings yet

- Tcode Common in SapDocument15 pagesTcode Common in Saphau kot nguyen nhuNo ratings yet

- TcodesDocument16 pagesTcodesGeorgeNiharikaNo ratings yet

- Day 15 MM SD FI IntegrationDocument12 pagesDay 15 MM SD FI IntegrationVara LakshmiNo ratings yet

- Routing PRT - Present1Document20 pagesRouting PRT - Present1Amit AggarwalNo ratings yet

- Tcodes SapDocument7 pagesTcodes Sapssat2kNo ratings yet

- Basis Ecc6 TcodesDocument10 pagesBasis Ecc6 TcodesRajesh BabuNo ratings yet

- All PM TcodesDocument48 pagesAll PM TcodesTusharTayadeNo ratings yet

- Useful SAP System TransactionsDocument9 pagesUseful SAP System TransactionsRafael FeherNo ratings yet

- Relational Database Index Design and the Optimizers: DB2, Oracle, SQL Server, et al.From EverandRelational Database Index Design and the Optimizers: DB2, Oracle, SQL Server, et al.Rating: 5 out of 5 stars5/5 (1)

- SAP QM Transaction CodesDocument3 pagesSAP QM Transaction CodesCHAMAN RAGHAVNo ratings yet

- Transaction Error Handling StepsDocument3 pagesTransaction Error Handling StepsCHAMAN RAGHAVNo ratings yet

- 7 ???? ???????? ??????? ??? ?????????? ???? ???? ??????? ???? ?????? ??? ????Document10 pages7 ???? ???????? ??????? ??? ?????????? ???? ???? ??????? ???? ?????? ??? ????CHAMAN RAGHAVNo ratings yet

- Abx Micros 60 Operators ManualDocument22 pagesAbx Micros 60 Operators ManualWilly Charly Chirilla VacaflorNo ratings yet

- Level of SignificanceDocument4 pagesLevel of SignificanceAstha VermaNo ratings yet

- Floefd Creo DemoguideDocument332 pagesFloefd Creo DemoguideivanmatijevicNo ratings yet

- Common Method Variance: Statistical Detection and ControlDocument14 pagesCommon Method Variance: Statistical Detection and ControljoindocNo ratings yet

- Entrepreneurial Mind Set PDFDocument13 pagesEntrepreneurial Mind Set PDFDennielle CerenioNo ratings yet

- G500 OBD Protocol-01Document62 pagesG500 OBD Protocol-01Traki BirdNo ratings yet

- STATISTICS. DSPDocument16 pagesSTATISTICS. DSPHam HereNo ratings yet

- Configuration Frame and Parameter Assignment Frame For The ET 200MDocument26 pagesConfiguration Frame and Parameter Assignment Frame For The ET 200Mquocbao77_ldNo ratings yet

- 8614Document12 pages8614Amir HamzaNo ratings yet

- 2018 Mismatch Unemployment and The Geography of Job SearchDocument30 pages2018 Mismatch Unemployment and The Geography of Job SearchYusuf AmriNo ratings yet

- ANSYS Probhhhhgrammers ManualDocument579 pagesANSYS Probhhhhgrammers Manualpedjoni87No ratings yet

- Risk Analysis Based CWR Track Buckling Safety EvaluationsDocument19 pagesRisk Analysis Based CWR Track Buckling Safety EvaluationsmasoudNo ratings yet

- BOM ConfigurationDocument21 pagesBOM ConfigurationganeshNo ratings yet

- Parametric and Nonparametric Test: By: Sai Prakash MBA Insurance Management Pondicherry UniversityDocument10 pagesParametric and Nonparametric Test: By: Sai Prakash MBA Insurance Management Pondicherry UniversitysureshexecutiveNo ratings yet

- CATRuleDocument22 pagesCATRulenoura mahamatNo ratings yet

- INMATEH - Agricultural Engineering 47 - 2015Document180 pagesINMATEH - Agricultural Engineering 47 - 2015Popa LucretiaNo ratings yet

- CA 400 OPERATOR's ManualDocument70 pagesCA 400 OPERATOR's ManualOo Kenx OoNo ratings yet

- Conducting A Nonlinear Fit Analysis in MATLAB: Using The FunctionDocument2 pagesConducting A Nonlinear Fit Analysis in MATLAB: Using The Functionfranzds_0041231No ratings yet

- Models - Aco.acoustics Pipe SystemDocument28 pagesModels - Aco.acoustics Pipe SystemعلىالمهندسNo ratings yet

- Parameter Reference UmtsDocument271 pagesParameter Reference UmtsVictor Perez JimenezNo ratings yet

- CaIcuIus With CompIex Numbers by John B.readeDocument109 pagesCaIcuIus With CompIex Numbers by John B.readeHassen LazharNo ratings yet

- Bentley Architecture Dataset Overview v2Document34 pagesBentley Architecture Dataset Overview v2Raed_Hanafiyah_4335No ratings yet