Professional Documents

Culture Documents

Rav42 Устранение Скрипа Задней Двери

Uploaded by

ВИКТОР СЕВЕРCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rav42 Устранение Скрипа Задней Двери

Uploaded by

ВИКТОР СЕВЕРCopyright:

Available Formats

Section : Wind noise/

Squeak/ Rattle

Ref. No. : WS-3002

Date : Dec., 2003

Page : 1 of 6

Area Application : USA/CANADA, Europe, Australia, G.C.C Countries,

General

Model Name : RAV4

Model Code : ACA20, ACA21, ACA26, CLA20, CLA21, ZCA25, ZCA26

Subject : Back Door Rattle

This is to inform you of a field fix which has been developed to prevent the rattle noise from the

back door area while driving.

Cause:

This rattle generated from the poor welding points that resulted from a shunt current due to the

narrow welding pitch.

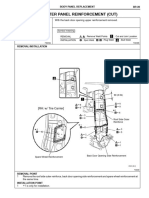

< Back Door > < Back Door inside >

Reinforcement,

Back door inside panel

Poor weld

Narrow

welding

pitch

Reinforcement,

Spare wheel mounting

Cut outer panel

TOYOTA MOTOR CORPORATION Overseas Customer Service Technical Division

Ref. No. : WS-3002

Page : 2 of 6

Field Fix Method

Re-welding of the affected welding points LH

and/or RH.

1. Disconnect the battery negative terminal.

2. Remove the spare tire cover and the

spare tire.

3. Remove the back spare tire bracket.

Remove the 4 bolts and the back spare tire bracket.

4. Remove the wiper arm.

Remove the wiper arm head cap, the nut and the

rear wiper arm.

5. Remove the back door trim board.

Using a screwdriver, remove the back door trim

board.

HINT:

Tape the screwdriver tip before use.

6. Remove the service hole cover.

7. Remove the rear wiper motor.

(a) Remove the grommet.

(b) Disconnect the connector, then unfasten the 3

bolts.

(c) Remove the rear wiper motor.

(d) Remove the wire harness.

TOYOTA MOTOR CORPORATION Overseas Customer Service Technical Division

Ref. No. : WS-3002

Page : 3 of 6

8. Apply a protective cover to the back door

glass inside to avoid any damage during

the welding.

9. Drill two holes of 8mm in diameter and

1.7mm in depth using spot-cutter (SST P/N

09060-10060) as shown in the illustration

below.

(a) Drill one hole at the top of the upper spot-

welding point as shown in the illustration

below.

(b) Drill the other hole at the bottom of the lower

spot-welding point as shown in the illustration

below.

HINT:

Drill slowly and carefully to confirm the hole depth.

Be sure not to penetrate the reinforcement.

A (A-A cross view)

0.7 1.0 1.0

(a) The top of the upper

10. Reinforcement,

spot-welding point 1.7mm

Spare wheel mounting

New

Previous

A

(b) The bottom of the

Reinforcement,

lower spot-welding point

Back door inside panel

Back door inside panel

TOYOTA MOTOR CORPORATION Overseas Customer Service Technical Division

Ref. No. : WS-3002

Page : 4 of 6

10. Remove paint around the upper and lower

spot-welding points, and remove paint in

one place for earth connection point.

11. Plug-weld the two holes using a plug

welding machine. (Use a electrode of

0.6mm in diameter)

12. Smooth the two welded points using a

grinder.

13. Touch-up (paint) the position where paint

has been removed.

14. Apply primer (rust preventive paint) on the

reverse side of the welded points.

15. Remove the protective cover from the back

door glass inside.

TOYOTA MOTOR CORPORATION Overseas Customer Service Technical Division

Ref. No. : WS-3002

Page : 5 of 6

16. Reinstall the rear wiper motor.

(a) Reinstall the wire harness.

(b) Reinstall the rear wiper motor with the 3 bolts.

Torque: 5.5 N-m (55 kgf-cm, 49 in.-lbf)

(c) Reinstall the grommet.

(d) Connect the connector.

17. Reinstall the service hole cover.

HINT:

Pull out the links through the service hole cover.

18. Reinstall the back door trim board.

19. Reconnect the battery negative terminal.

20. Reinstall the wiper arm.

(a) Reinstall the wiper arm and torque the nut by

hand.

(b) Operate the wiper once and turn the wiper

switch OFF.

(c) Adjust the installation position of the wiper arm

to the position as shown in the illustration.

A: Approx. 6.2 mm (0.244 in.)

(d) Torque the nut.

Torque: 5.5 N-m (55 kgf-cm, 49 in.-lbf)

(e) Reinstall the wiper arm head cap.

21. Reinstall the back spare tire bracket with

the 4 bolts.

Torque: 28 N-m (285 kgf-cm, 21 ft-lbf)

22. Reinstall the spare tire cover and the

spare tire.

TOYOTA MOTOR CORPORATION Overseas Customer Service Technical Division

Ref. No. : WS-3002

Page : 6 of 6

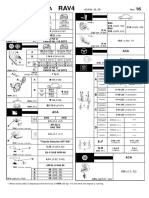

Production Effective:

Body Power

Model VIN (Reference only) Production Date Plant

Type Train

ACA20 JTEYH20V600038363 3 Door

10th July, 2002 TAHARA

JTEHH20V420184277

ACA21 5 Door

TOYOTA

JTEHH20V926068540 15th July, 2002 Industries

Nagakusa

4WD

CLA20 JTEYG20V200009462 3 Door

10th July, 2002 TAHARA

JTEHG20V000025112

CLA21 5 Door

TOYOTA

JTEHG20V506011672 15th July, 2002 Industries

Nagakusa

ZCA25 JTEXR20V300014580 3 Door

ZCA26 JTEGR20VX00032381 10th July, 2002 TAHARA

2WD

JTEGH20V820080113 5 Door

ACA26

TOYOTA

JTEGH20V626010512 15th July, 2002 Industries

Nagakusa

TOYOTA MOTOR CORPORATION Overseas Customer Service Technical Division

You might also like

- QA - H178 - 2ND - 0075 - SB Fuser NoiseDocument8 pagesQA - H178 - 2ND - 0075 - SB Fuser NoiseServicio TecnicoNo ratings yet

- NV005 04Document5 pagesNV005 04Christian Linares AbreuNo ratings yet

- Kce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Document5 pagesKce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Alexandru NicolaNo ratings yet

- Main Rotor Hub InspectionDocument21 pagesMain Rotor Hub InspectionJessie DinoyNo ratings yet

- Technical Service BULLETINDocument328 pagesTechnical Service BULLETINCarlos E. FuentesNo ratings yet

- Fitting Instruction The Instruction of The Assembly: Washer Ø36xø12x3Document2 pagesFitting Instruction The Instruction of The Assembly: Washer Ø36xø12x3Rastislav CibulkaNo ratings yet

- AA01042A Fisura Horse CollarDocument5 pagesAA01042A Fisura Horse CollarSebastiánRodrigoPérezHenríquezNo ratings yet

- LG Wheels and BrakesDocument34 pagesLG Wheels and Brakesmarcos torresNo ratings yet

- Ground Effects I SheetDocument50 pagesGround Effects I SheetEvanNo ratings yet

- REAR POWER SUNSHADE ABNORMAL NOISE OR BindingDocument8 pagesREAR POWER SUNSHADE ABNORMAL NOISE OR BindingRamy ONo ratings yet

- 51-42-00 - 2 Chapter ManualDocument18 pages51-42-00 - 2 Chapter ManualRobert KrižanovićNo ratings yet

- Replacement: - StarterDocument2 pagesReplacement: - StartersalusfrankNo ratings yet

- Ricoh MP C6501toner Hopper Harness DamageDocument3 pagesRicoh MP C6501toner Hopper Harness DamageMarco DelsaltoNo ratings yet

- Installation Instructions: WarningDocument6 pagesInstallation Instructions: WarningrobNo ratings yet

- Paint CoatingDocument11 pagesPaint CoatingMirceaNo ratings yet

- Installation Instructions: Automotive Products, IncDocument6 pagesInstallation Instructions: Automotive Products, IncLuis BaracchiNo ratings yet

- Important Information: Section 1D - Outboard Motor InstallationDocument13 pagesImportant Information: Section 1D - Outboard Motor InstallationDr. Centelha Mecânica NaúticaNo ratings yet

- BM Nozzle MaintenanceDocument6 pagesBM Nozzle Maintenancemartin.weisshaarNo ratings yet

- SP Col 200X400Document5 pagesSP Col 200X400mary joy mengulloNo ratings yet

- Toyota Tundra Skid Plate Installation InstructionsDocument5 pagesToyota Tundra Skid Plate Installation InstructionsJason LancasterNo ratings yet

- Auto KukaDocument17 pagesAuto KukasilvioNo ratings yet

- Input ValuesDocument5 pagesInput ValuesmasoodNo ratings yet

- Caterpillar D6T-R CONVERT System One Vs CONVENTIONAL UNDERCARRIAGEDocument13 pagesCaterpillar D6T-R CONVERT System One Vs CONVENTIONAL UNDERCARRIAGEcris.prolineNo ratings yet

- NTB02 029Document4 pagesNTB02 029PMNo ratings yet

- A Covers C Screws B Nuts: Remove/installDocument2 pagesA Covers C Screws B Nuts: Remove/install2008profNo ratings yet

- H451SXC000 - IxI - Ascent - Fog - Light - EN FR PDFDocument12 pagesH451SXC000 - IxI - Ascent - Fog - Light - EN FR PDFAlbert LillyNo ratings yet

- Calculation Sheet: Yb For UB BeamDocument2 pagesCalculation Sheet: Yb For UB BeamrammohanNo ratings yet

- Stick 3.200 MDocument4 pagesStick 3.200 MAlejandro ValenzuelaNo ratings yet

- V LogoDocument3 pagesV LogoAdrián CasarrubiasNo ratings yet

- Security Door Controls: Installation Instructions SERIES 1510, 1570, 1580 EMLOCKDocument4 pagesSecurity Door Controls: Installation Instructions SERIES 1510, 1570, 1580 EMLOCKSunday ChanNo ratings yet

- W BT2Document30 pagesW BT2Livestream & gameplay Mobile legendsNo ratings yet

- Jointing Manual For DI PipeDocument16 pagesJointing Manual For DI PipeSaifur RahmanNo ratings yet

- GX531GS - GM Service Guide Chapter02 - V1.0Document36 pagesGX531GS - GM Service Guide Chapter02 - V1.0Dima RozhencovNo ratings yet

- Power T FTV MS 200 055-050 +1061 - 0743 6000mmDocument8 pagesPower T FTV MS 200 055-050 +1061 - 0743 6000mmprimoz1No ratings yet

- Replacement of Rear DOJ and BJ Boots: A: RemovalDocument2 pagesReplacement of Rear DOJ and BJ Boots: A: RemovalmiguelNo ratings yet

- At-Sealing Replacement (GB)Document4 pagesAt-Sealing Replacement (GB)George LapusneanuNo ratings yet

- NTB02 068Document4 pagesNTB02 068PMNo ratings yet

- Marvin Ultimate Push Out Casement: Wood Screen - Field Applied InstallationDocument2 pagesMarvin Ultimate Push Out Casement: Wood Screen - Field Applied InstallationDougNewNo ratings yet

- Replacement: - Front Brake PadDocument2 pagesReplacement: - Front Brake PadMiguel AngelNo ratings yet

- Stick - 3.86 MDocument3 pagesStick - 3.86 Mcristian chuquicondor torresNo ratings yet

- Acoustic Louvers 2019Document9 pagesAcoustic Louvers 2019Ahmed MontashNo ratings yet

- Input Drum Reinforcement Kit 77733-02KDocument2 pagesInput Drum Reinforcement Kit 77733-02KMichel Le DocteNo ratings yet

- Blower k430 Snh60 Overhaul ProcedureDocument39 pagesBlower k430 Snh60 Overhaul ProcedurejamiekuangNo ratings yet

- FD202LDocument7 pagesFD202LGrzegorz samuraiNo ratings yet

- OsmaDrain Jointing Quick GuideDocument2 pagesOsmaDrain Jointing Quick GuideHatem AbdelnabiNo ratings yet

- Chrysler 41TE (A-604) : Technical Bulletin #231Document3 pagesChrysler 41TE (A-604) : Technical Bulletin #231Mario MastronardiNo ratings yet

- Block Shear Connection Design Checks PDFDocument7 pagesBlock Shear Connection Design Checks PDF112160rbc100% (1)

- Quarter Panel Reinforcement (Cut) : With The Back Door Opening Upper Reinforcement RemovedDocument2 pagesQuarter Panel Reinforcement (Cut) : With The Back Door Opening Upper Reinforcement Removedkoon9888No ratings yet

- IMF51Document4 pagesIMF51juwon aprilagaNo ratings yet

- Con Eng f4sDocument13 pagesCon Eng f4scristian.rodriguezNo ratings yet

- Joint Welding Method PHC D600A-100Document2 pagesJoint Welding Method PHC D600A-100sochealaoNo ratings yet

- Verado 200-275 Workshop-2Document90 pagesVerado 200-275 Workshop-2Servicios Luna LSNo ratings yet

- Eixo Dif Simples Vel ENGDocument62 pagesEixo Dif Simples Vel ENGAhmedNo ratings yet

- Service Manual Supplement Front Bumper VN, VNMDocument4 pagesService Manual Supplement Front Bumper VN, VNMNeojai jaiyuNo ratings yet

- Honda CB500X Oem Installation 12v SocketDocument4 pagesHonda CB500X Oem Installation 12v SocketUrialNo ratings yet

- Lexus Hitch DIYDocument10 pagesLexus Hitch DIYstarfish555No ratings yet

- BA Falcon Front Brake Shudder - Interim Service Action OnlyDocument3 pagesBA Falcon Front Brake Shudder - Interim Service Action OnlyDarren ANo ratings yet

- x220.x230 FHD Mod Rev5 v0.2Document19 pagesx220.x230 FHD Mod Rev5 v0.2Rafael Enrique Garcia CastañoNo ratings yet

- Removal Rocker PanelDocument1 pageRemoval Rocker Panelapi-3710514100% (1)

- Computers and Control Systems: Diagnostic Trouble Code Tests and Associated Procedures P0440Document9 pagesComputers and Control Systems: Diagnostic Trouble Code Tests and Associated Procedures P0440ВИКТОР СЕВЕРNo ratings yet

- P0440, P0441 OR P0446camry1 PDFDocument5 pagesP0440, P0441 OR P0446camry1 PDFВИКТОР СЕВЕРNo ratings yet

- '98 - '99 Camry & Solara Technical Service Bulletin: M.I.L. ON" P0440, P0441 & P0446Document5 pages'98 - '99 Camry & Solara Technical Service Bulletin: M.I.L. ON" P0440, P0441 & P0446ВИКТОР СЕВЕРNo ratings yet

- SdsDocument4 pagesSdsВИКТОР СЕВЕРNo ratings yet