Professional Documents

Culture Documents

Cod WPS PQR 08 Codemon 2021-04-13

Uploaded by

Sleyda Munoz0 ratings0% found this document useful (0 votes)

28 views5 pages_WPS_PQR_08_CODEMON_2021-04-13

Original Title

COD_WPS_PQR_08_CODEMON_2021-04-13

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document_WPS_PQR_08_CODEMON_2021-04-13

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views5 pagesCod WPS PQR 08 Codemon 2021-04-13

Uploaded by

Sleyda Munoz_WPS_PQR_08_CODEMON_2021-04-13

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

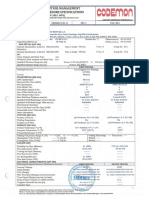

“QUALITY CONTROL MANAGEMENT

WELDING PROCEDURE SPECIFICATIONS

(QW-200.1 wPs)

ASME ROILER AND PRESSURE VESSEL CDE, SECTION 2013

(CO _SoMPanr: COMPARA DOMINICANA DE MONTAIE SA.

ADDRESS: Dr. Heriberto Pieter #30 Ensanche Naco, Santo Domingo, Repablica Dominicana.

CONSTRUCTION STANDARD: ASME BBVC Sec. VII Div. 1, 831.1, B313, B31.4, 8318,

‘Welding Procedure Specification WPS No CD-WPS-0' Revision Ne Date(mm/da/yyyy): 05-16-2015

Supporting PQR No. (s) cD-PQR-08 Date(em/d/yyyy: 05-16-2015

BASE METALS (QW-403)

Material Specification: A/SA 36 “Type or Grade: (UNS: KO2600) PiNos 1 Group Nos

Welded to:

Material Specification: A/SA 36 “Type or Grade: (UNS: KO2600) PiNos 1 Group Nos

or:

Chem. Analysis and Mech. Prop: n/a

Welded to Chem. Analysis and Mech, Prop: n/a

Qualified Thickness Range mm (in) Groove: Smm (3/16") to 635mm (2.2") Filet:

{Qualified Weld Metal Range: Groove mm (in)

Qualified Diameter Range mm (in Groove: === to Fillet

I FIRST PROCESS [SECOND Process

Weliing Process (=) Shielded Metal Arc Welding

(SMaW)

Type (9 ‘Manual

FILLER METALS (QW-404)

AWS Chasifiation: E309L-15

Blectrode-Flux Class (SAW):

SFA Specification: ‘ASME SPA ASA

Filler Metal E-No. 4

‘Wold Metal Analysis A-No: 8

Size of Filler Metals mm (in): 4/8"- 5/32"

Filler Metal Product Form: Iron powder low hydrogen

Max. Weld Pass Thickness mm (in): ‘3mm (0.118) / 3mm (0.118")

22mm(A72") / $1.5mm 2.027")

Qualified Weld Metal Range: Fillet mm (in)

‘Wold Deposit Chemistry:

(| extras Name and Fox Type (Saw):

| Consumable insert, Class and Size

Other information:

POSITION (QW-405)

| Position of Groove: (Flav)

Welding Progression:

Position (s} of Fillet lat)

PREHEAT (QW-406)

Preheat Temperature °C ("F): sc (475"F)

Interpass Temperature °C ("F) *C(457"F)

Preheat Maintenanco°C (°F)

Holding Temperature Range°C ("F

Heating Rate°C/br (Fh):

Cooling Rate°C/he (°F/hr)

GAS (QW-408)

Shielding Gas Type (Mixture):

Flow Rate It/min. (CFH):

‘Tralling Gas Type (Mixture)

Flow Rate t/min,(CFH)

(as Backing (Mixture):

Flow Rate l/min. (CFH)

ELECTRICAL CHARACTERISTICS (QW-409)

Following data may alsa shown on Table below in hi sheet

Tour per ins =

Current/ Polarity: peep

“Amps (Range): ‘See TABLE PARAMETERS/TO QW-409

Volts (Range): See TABLE PARAMETERS;TO QW-409

See TABLE PARAMETERS:TO QW-409

‘See TABLE PARAMETERS;TO QW-409

Wire Feed Spcd (Rang) min (n/i

‘revel Speed (Rang) mm/min Gini}

ro

‘Tungsten lerode Se min) GTS

Tungsten Type Ls

CODENON SA, dos nc atria ttl ra reckon

Saeco ie ARSED

NNOTE2 Ruproductonprobhaed no ton ofthe General Mange of representave

Fermandina Tosa oy Gaston

‘wi 10071274

QC1 EXP. 7/1/2016

copEmon

PAG: 2 DE2

‘QUALITY CONTROL MANAGEMENT

WELDING PROCEDURE SPECIFICATIONS

(QW-200.1 wPs)

ASME BOILER AND PRESSURE VESSEL CODE, SECTION 2013

ae

sD= NPS = O8:

CODIGO: CD-FO-WPS-001

TECHNIQUE (QW-410)

String or Weave Bead: tarve times the ameter ofthe electrode oF wire

‘Multiple or Single Electrodes: Single

‘Multiple or Single Pass (per side) Multiple

Orifice or Gas Cup Size:

Contact Tube to Work Distance mm (in):

Initial and interpass Cleaning: Brushing.

‘Method of Back Gouging: n/a

Electrode Spacing: n/a

Oscillation: 3 Times Blectrode Diam.

Peening: ‘Not Required at

Other information: Clean each layer before start welding new passes/layer

JOINTS (QW-402)

Joint Design: ‘Single-Vee groove weld

Backing: No Backing ‘Backing Material (Refer to both backing and retainers): N/A

Groove Details (or per production drawing) Root Face RF:maxOmm (0-) Groove Angle: 0°40" Radius (-U}:

Root Opening G: _Oml.0°) to Omm(.0°)

JOINT DETAILS/ SKETCH: WELDING JOINT DESIGN WITH WS

‘ete Preto Drawings, Wed Sel Writ Deserpton sould show he genre arrange of pr ob weed Whee pale dea wl rome

‘maybe pera Sethe my beatae! etal Sv yrs on bea soon fg Jo net ugh proces Mlle paces proces.)

| Peet

"TABLE FOR RECORDED WELDING PARAMETERS; REFER TO QW-409

a aie

Pass Fiera | Fler Fee rea | Ter | tne

no. Process. Classificati ie has kj/mm_

ameter Amps Volt Speed | jum/min

3 eee aren | ae we | See | ore | a

res oe

eas — aa 7

| 2 ‘SMAW E-309L-15 5/32" 130-220 23-30 78

ta 0. 25.30 73

l aad

Pulsing Current: n/a sai ‘Heat Input (max): —-—~--- (ikj/im)

Fane icareds Sue andype

(fe eng rae)

Mode of Metal Transfer for GMAW (FCAW):

(Gray a Son tng

Wa cerily that the evidence presented'n Tis report are correct and thatthe welding specimens were prepared, welded and tested lv accordance

with ANSI ASME Section IX- 2073, Thi documents the property of COMPANIA DOMINICANA DE MONTAJE S.A. and may not be reproduced in

whole orn part without writien permission from the Issuer

(CERTIFIED WELDING INSPECTOR:

‘COMPARIA DOMINICANA DE MONTAJE SA.

SIGNATURE:

Fomarina Trea ro Gtacbes

cw 10071271

QC1 EXP, 7/1/2016

POSITION: Welding Inspector CW

DATEtom/sipnnis 05/16/2015

tps appanesara/eiication/searchhtml

ODEMONSA dos net autre tl or paral reproduction of is dcument ww.codemencom

NOTE I Tes the uns eaponsiyo ntre that yon ue he arent revision

NOTE: Repent ranted na for prt ore trades tou the author othe General Manager ris represenaire

QUALITY CONTROL MANAGEMENT

PROCEDURE WELDING QUALIFICATION RECORDS (PQR)

{ASME BOILER AND FRESSURE VESSEL CODE. SECTION IX:2013

CODIGO: CD-FO-PQR-001 PAG: 1DES

COMPANY: COMPARIA DOMINICANA DE MONTAJE, S.A.

ADDRESS: Dr. Heriberto Pieter #30 Ensanche Naco, Santo Domingo, Kepaiblica Dominicana.

CONSTRUCTION STANDARD: ASME Sece. IX Edition 2013

POR No. CD-PQR-O8

Dateimn/aaryye 05-16-2015

‘Welding Procedire Specification WPS No: CD-WPS-08-1 Revision No 0

BASE METALS (QW-403)

Material Specification: A/SA36 Type or Grade: (UNS: KO2600) PNos 4 GroupNo: 1

WELDED TO,

Material Specification: A/SA36 Type or Grade: (UNS: KO2600) Pio: 1 Group No: 1

‘Thickness of Test Coupon mm (in): 31.75mm (1.25") Diameter of Test Coupon mm (in): Omm (0")

Other Information:

JOINTS (QW-402)

Jon: Design SINGLE VEE Backing type: ——

Backing Matera (Refer to both baclng and retainers)

‘Groove Deals or per production drawing): SEB JOINT DETALLS/ SKETCH oot Opening

Root ace, Oman (0°) :0mm Groove Angle a: 0 (Both sides) 0° Rodis 0)

ae JOINT DETAILS, SKETCH: |

"TABLE FOR RECORDED WELDING PARAMETERS, REFER TO QW-409

filler wire feed ‘max. heat input

lant fillermetal | size | current | ates j/mm (k/in)

Process. | cassification | diameter | amps or

8 sam (i) remarks

1 SMAW— Es0ma5 fr 70-150 23-20

2 SMAW = Eso9La5 5/32" 130-220 28-30 |

3 SMAW = EaosLas 5/32" 130-220 23-30

4 SMAW = EsooL1s —5/sz” 130-220 23-30

SEB,

Fema Tone roy Gcectes

cw 10071271

QC1 EXP, 7/1/2016

CCODEMON SA, tt atone tra natn fis dune wn clone ce

Nove {nu anoreposy one ty se ces,

NOTE 2 Renetchon hed pat or Won woah naeranton tne Gal Map ei ops

QUALITY CONTROL MANAGEMENT

PROCEDURE WELDING QUALIFICATION RECORDS (PQR)

ASME BOILER AND PRESSURE VESSEL CODE SECTION1X-2013

Record etal Variables Used o Wald Tet Coupon

CODEMOA

PAG:2 DES

Electrode-Flux Class (sw

Deposited Weld Metal Thickness mm (in)

Weld Deposit Chemistry.

Flux Trade Name and Flux Type (SAW):

Other information:

POSITION (QW-405)

POSTWELD HEAT TREATMENT (QW-407)

FIRST PROCESS i ‘SECOND PROCESS

Welding Process (es: GTAW “Shielded Metal Arc Welding (SMAW)

Type(s): Manual

FILLER METALS (QW-404)

AWS Classification: 3091-15 a

SPA Specification: ‘ASME SEAAS4 _

Filler Metal F-No, 4

‘Weld Metal Analysis A-No, a

Size of Filler Metals mm (in) 1/8". 5/32"

Filler Metal Product Form: Iron powder low hydrogen

‘Max. Weld Pass Thickness mm (in): 3mm (0.118") /3mm (0.118)

mm(236") /25.75mm (1.013")

Position of Groove: 1G

‘Welding Progression: Uphill o Downkitt

PREHEAT (QW-406)

Preheat Temperature °C (9) se (175°F)

Interpass Temperature °C (7) “c(4s7"H)

Holding Temperature Range (*F):

Holding Time Range:

Wour per in,

Flow Rate It/min. (CFI);

‘Traling Gas Type (Mixture):

Flow Rate It/min. (CF)

as Backing (Mixture)

Flow Rate It/min. (CF);

ELECTRICAL CHARACTERISTICS (QW-409)

Current/ Polarity

‘Amps (Range):

Volts (Range):

Wire Feed Speed (Range) mm/min (in/min)

‘Travel Speed (Range) mm/min (in/min)

Mode of Metal Transfer for GMAW (ECAW):

‘Tungsten Electrode Size mm (in}

‘Tungsten Type:

‘TECHNIQUE (QW-410)

String or Weave Bead:

Multiple or Single Electrodes:

‘Multiple or Single Pass (per side)

Orifice oF Gas Cup Size:

Contact Tube to Work Distance mm (in):

Initial and Interpass Cleaning:

‘Method of Back Gouging:

Heating Rate°C/hr (F/he}- Method:

Cooling Rate "C/hr C/A) Method:

GAS (QW-408)

Shielding Gas Type (Mixture):

Following data may also shown on Table in Sheet 1 of 4:

DcEP

‘See TABLE PARAMETERS:TO QW-409

See TABLE PARAMETERS:TO QW-409

‘See TABLE PARAMETERS,TO QW-409

‘See TABLE PARAMETERS;TO QW.409

Single

Multiple

Circular brush

Times Electrode Diam.

Oscillation:

ening:

‘Other information: Clean each layer before start welding new passes/layers

Fernandina Toes rope Govchea

cw" too71271

QC1 EXP. 7172016

CANA OB)

VS eS

{CODEN SA coe opr ee fis came ww cenen cm

Sr 2 Renato poet ana) erpatl eta ons wh he stern Gael Maa i esos

QUALITY CONTROL MANAGEMENT

PROCEDURE WELDING QUALIFICATION RECORDS (PQR)

“ASME DILER AND PRESSURE VESSEL CODE SECTION4-2013

econ tual Variables Ueto Wad Tet Coupon

CODIGO: CD-FO-POR-001 PAG: SDES

‘PROCEDURE QUALIFICATION RECORDS Test Results

"TENSILE TEST (QW-150)

THICKNESS |__ AREA ULTIMATE | ULTIMATE

wiprh | MMCN | MMXMM =| TOTALLOAD, | UNIT

‘SPECIMEN NO. | MM (IN) anxin), KN(LB) ‘TYPE OF FAILURE

‘GUIDED-BEND TESTS (QW-160)

[TYPE AND FIGURE NO. I ‘RESULTS

“TOUGHNESS TESTS (QW-170)

TEST ‘DROP WEIGHT

TEMPERATURE | IMPACT LATERAL AK:

speciMEN | NOTCH “cn VALUES EXP. JOULE YES/NO

No. Location TOULE YES/NO

JOFT3)

‘Comments (Notch type, atc]: Not Requirements

Wardness Test ACCEPTET ‘Radiographic ultrasonic examination: Not Requirements

PT report no ACCEPTET Result:

Macroetch report no: ACCEPTET Result:

FILLET-WELD TEST RESULTS (QW-180)

Result-Satisfactory: ‘Not Requirements

Penetration into Parent Metal: Nt Requirements

Macro-Results: Not Requirements

‘Welder Name: EDWAR SANDOVAL ‘Stamp Ne: W-ES

Conducted by: Luis. R Moya Inspector: Luis. R Moya

Report Nro.: Q-CD-212 Laboratory: NDT INGENIERIA E INSPECCIONS.RL.

‘We crtiy thatthe evidence presented inthis report are correct and that the welding specimens were prepared, welded and tested in

‘accordance with ANSI / ASME Section IX~ 2013, This document Is the property of COMPANIA DOMINICANA DE MONTAIE SA. and may not

Dereproduced in whole or in part without written permission from the issuer

MANUFACTURER OR CONTRACTOR'S WELDING ENGINEER: AUTHORIZED BY:

COMPARIA DOMINICANA DE MONTAJE S.A. COMPARA DOMINICANA DE MONTAIE SA

SIGNATURE

Fanntba Tres Ao Goons

cw 10071271

C1 EXP. 7/1/2016

POSITION: Welding Inspector CWI

DATE (mm apy: 05/16/2015,

ns Janp sree arh htm

CODEMON SA, con ot ator ofeach bce mcd cam

NOTE 2 Revedcin pba ter ptter tema eo hentia tbe Gear Maen ei eerie

You might also like

- FMR 004 Materiales Para Pararrayos Expansion -InselDocument1 pageFMR 004 Materiales Para Pararrayos Expansion -InselSleyda MunozNo ratings yet

- PVDC-5150-17-0022-0 - Ewrick Michel CorcinDocument1 pagePVDC-5150-17-0022-0 - Ewrick Michel CorcinSleyda MunozNo ratings yet

- Electrical Installation - SP-0000-60-0030-1Document20 pagesElectrical Installation - SP-0000-60-0030-1Sleyda MunozNo ratings yet

- Carbon Reactivation Kilns - SP 0000-16-0007 2Document21 pagesCarbon Reactivation Kilns - SP 0000-16-0007 2Sleyda MunozNo ratings yet

- Circuit Breakers 230 KV - SP-0000-60-0001-3Document32 pagesCircuit Breakers 230 KV - SP-0000-60-0001-3Sleyda MunozNo ratings yet

- DrenajeDocument1 pageDrenajeSleyda MunozNo ratings yet

- SP0793 M043.00 G18 0220 Sub01 Construction Work Pack Activator Collector - Pdf.zipDocument532 pagesSP0793 M043.00 G18 0220 Sub01 Construction Work Pack Activator Collector - Pdf.zipSleyda MunozNo ratings yet

- PV-F-80677-4 Purchasing-Card Form Rev.4 - Autocad PlantDocument1 pagePV-F-80677-4 Purchasing-Card Form Rev.4 - Autocad PlantSleyda MunozNo ratings yet

- Installation, Operation and Maintenance Manual: Severe Service Knife Gate ValveDocument11 pagesInstallation, Operation and Maintenance Manual: Severe Service Knife Gate ValveSleyda MunozNo ratings yet

- IndustrialDocument9 pagesIndustrialSleyda MunozNo ratings yet

- PROCEDIMIENTO AWS WPS SRL FILETE D1.1 Gr2 ComentadoDocument2 pagesPROCEDIMIENTO AWS WPS SRL FILETE D1.1 Gr2 ComentadoSleyda MunozNo ratings yet

- Series 2, 3, 4, & 5 Aluminum - : Straight Section Part NumberingDocument2 pagesSeries 2, 3, 4, & 5 Aluminum - : Straight Section Part NumberingSleyda MunozNo ratings yet

- Manual de Manejo de Cercas Vivas de Piñón: September 2010Document7 pagesManual de Manejo de Cercas Vivas de Piñón: September 2010Sleyda MunozNo ratings yet

- D1.1 D1.1M 2020 Errata 2qDocument19 pagesD1.1 D1.1M 2020 Errata 2qSleyda Munoz100% (1)

- Cod WPS PQR 16 Codemon 2021-04-13Document13 pagesCod WPS PQR 16 Codemon 2021-04-13Sleyda MunozNo ratings yet

- 5 MLDocument1 page5 MLSleyda MunozNo ratings yet

- OLT02B PLANNER MASTER SHEET Rev.Document92 pagesOLT02B PLANNER MASTER SHEET Rev.Sleyda MunozNo ratings yet

- Unit Converter SpreadSheetDocument12 pagesUnit Converter SpreadSheetSleyda MunozNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)