Professional Documents

Culture Documents

Unit 1

Unit 1

Uploaded by

Shaik J Mohamed0 ratings0% found this document useful (0 votes)

44 views111 pagesOriginal Title

UNIT 1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views111 pagesUnit 1

Unit 1

Uploaded by

Shaik J MohamedCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 111

7) Rubbish = Solid Waste like building

UNIT I

PLANNING AND DESIGN OF SEWERAGE SYSTEM

1.1 TERMS AND DEFINITIONS

1) Sanitary Sewage = Waste Water generated from a community (residential, commerciat

buildings and industries) = Domestic Sewage + Industrial Sewage,

2) Domestic Sewage = Waste Water discharged from lavatory,

‘esidential and office buildings,

3) Industrial Sewage =

establishment.

urinals, water closets from

Waste Water discharged from industria} and commercial

4) NightSoil= Human and Animal excreta

5) Refuse =Solid, Liquid and Semi-Sohd Waste that

subsoil water and storm water.

6) Garbage = Dry refuse-paper, d

Putrifying organic matter etc.

includes garbages, rubbish sullave, sewage,

lecayed vegetables, street Sweepings, organi and untreated

material, furniture rags, papers, etc

8) Sullage = Waste Water from Bathroom and Kitchen.

x Storm Water = The rain water of a locality.

18) Sewage = Liquid Waste froma ‘community that includes. sullage, discharze fiom urinals.

latrines, industrial waste, ground and storm waters.

11) Sewerage = Structures, Devices, Equipments, Appurtenances intended tor collection,

transportation, pumping of sewageand liquid waste but excludi

12)Sewer= isan under-ground conduitor

discharge or disposal,

ing treatment of sewage.

Grain through which sewage is carrie!t va potfifor

13) Waste Water = This term is used in place of sewage, It includes both orgie and mineral

‘tatter carried through liquid media,

WW

Waste Water Engineering

12

7.2 SOURCES OF WASTEWATER GENERATION

+ Domestic Somrees

Human waste from lavatories (feces, urine, flush water); known as black water

‘Washing water (personal, clothes, floors dishes, ec.) known as greywater or sullage

Discharge from Septic tank

— Cookingcil, Pesticides, Lubricating oil, Paint, Cleaning liquids, etc.

eee

* Industrial Sources

‘> Industrial process waters (Dyeing industries, Tanneries etc)

+ Industrial cooling waters (heat)

> Organic or biodegradabl2 waste

‘ Organic ornon bio-degradable/difficult-to-treat waste (pharmaceutical or pesticide

manufacheing),

> Exeme pH waste (from acid/alkali manufacturing, metal plating),

> Toxic waste (metal plating. cyanide production, pesticide manufacturing, etc. );

Solids ard emulsions (paper manufacturing, foodstuffs, lubricating and

hydraulic oi] manufacturing, etc.):

+ Waste water from oil & natural ges production

Rainfall collected on roofs, yands, roads, carparks, pavements etc; knownas storm runoff

Workshops and garages (gasoline’petrol/diesel or rubber residues, soap scum, metals from

vehicle exhaas etc.)

% Discharge from Sewage Treatrrent Plant (STP)

+ Groundwater infiltration into sewers

% Seawater ingress (salt and microbes)

Indeveloping countries, waste ‘ateris ety disposed ito water bodies or nan wth

or without proper treatment, which leads to the following issues :

1. Unsightlyzppearince

:

i

!

% Agricultural drainage |

:

'

1.3. EFFECTS OF WASTE WATER

cc

Planning and Design of Sewerage System

2. Odournuisance—Gases released from sewage cause foul smell.

13

3. Nuisance ofmosquito breeding, flies, rodents, insects ete

4. Outbreak of Diseases/Epidemics: Waste water contains numerous pathogens

(disease causing microorganisms) and improper disposal may cause serious diseases

and illness to urban and rural population.

5. Water Pollution: When waste water is discharged into fresh water bodies (rivers,

Jakes etc), merous pollutants are released into it and the oxygen level of water

depletes. The water becomes unfit for human use. This water may even become fatal

if given to infants (Blue Baby Syndrome).

6. _ Land Pollatiom: Caused due to the harmful and toxic chemicals in waste water.

7. Ground Water Contamination : Waste water discharged on land, percolates through

the soil and pollutes underground water sources and renders it unsuitable for use.

8. Contamination ofdrinking water supplies

9. Ecological imbalance : When waste water is discharged into water bodies, the

aquatic plants and animals are affected which may alter the ecosystem.

Eg: When waste water is discharged into lakes, due to the high concentration ce

Nutrients init, algae grows in excess and covers the lake surface, which prevents

sunlight penetration into water and thereby depletes the oxygen level of water.

This condition is called Eutrophication. The water in the lake becomes septic

and unfit for inman use. The aquatic life (fishes, insects, worms etc) cannot

survive without oxygen and this leads to imbalance in the lake ecosystem.

1.4 TYPES OF SEWAGE

@ Domestic Sewage

i) Industrial Sewage

G@)Storm Runoff.

(i) Domestic Sewage:

+ Domestic Sewage consists of liquid wastes originating fror wsinals, latrines, bathrooms,

kitchen sinks, wash basins etc. from the residential and commercial buildings.

This sewage is extremely foul, because of the presence of human excreta init.

ey

Waste Woter Engineering

Gi) Industrial Sewage: a

Insta swage consis of iid wast originating fom the indi process of

‘Vatious industries such as dyeing, paper making, brewing, etc.

‘> Thequality of the industrial sewage depend largely upon the type of industry and the

chemical used in the process.

_- ‘> Sometimes, they may be very foul and may require extreme treatment before being

* disposed offin public sewers.

S

* . Thesum total of domestic and industrial sewage may be termed as sanitary sewage

7 (cx)simply sewage.

+ (ii) Storm Water rmnoff: Storm Sewage

ry ‘ -“Thenmoffresulting from the rain stormsis called drainage.

> 1.5 SYSTEMS OF SANITATION

@ Old Conservancy System,

(@) Water Carriage System.

Rtas vincy Spica

< Inthissystem, night soil and garbage are collected separately in vessels or deposited

inpools/pits.

The entire day’s human feces aré collected and disposed once a day in the morning,

Inthis type of latrines. pungent smell continues to pollute the surroundings for the

catireday. ”

The waste is generally buried underground that may cause pollution.

— Thesallage and storm nunoffis collected in open or closed cs

% — Thissystemisadopted in Villages.

(ii) Water Carriage System

+ Inthis system, water is used to flush and wash away the human excreta as soon as it

- is generated:

% Itisamore hygienic system and does not generate any bad smell. Sullageand sewage

are discharged together.

a System

* Thissystemis adopted in Cities. 15

‘© Watercariage systems prefered over the old conservany tem

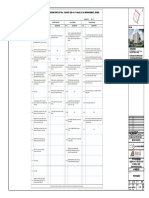

Table 1.1 - Comparison of Sanitation Systems

Old Conservancy System

ntages

(Less water consumption

Gi) Initial cost is tess

Gil) No technical persons required

(iv) End product obtained is manure

sadvantages

(¥) Unhygienic

(vi) Fou! smell

(vii) Building design not compact

(viii) Large labour force is required

(ix) High running cost

() Pollution problems

(i) Risk of epidemics

(xii) Large Jand area required for disposal

Advantages

(i) Hygienic

Gi) No foul smeit

ii) Compact building design

(iv) Labour required is smait

() Low running cost

(vi) Pollution problem is rare

(Vii) No risk of epidemies

(Vili) Small land required for disposal of shud

(x) Treated waste water used for irrigation

Disadvan-ages

(i) High water consumption

Gi) High initiatcost

(iii) Technical persons required [for

and maintenance}

iy) Sludge has less manure valve

1.6 TYPES OF SEWERAGE SYSTEMS

‘The different types of sewerage systems are:

@ Separate Sewerage Systems

Drainage (storm runoff) and Sewage are taken independently in two different sets oF

conduits (pipes).

Gi) Combined Sewerage System

tie ass cn etic even ea

(iii) Partially Separate System

__ Part of drainage is mixed with sewage (of) taken in sewers.

aa Waste Water Engineering

“y Fabtors governing choice of different sewerage systems

| Awaibtilty of funds for investment.

2.Spacerequirement and development pattern.

3. Rainfall distrBution.

4, Topography and gradient of contributing area.

5. Purfieg Cost-

6. Suizsdmoisre conditions.

7. Outketconditions (availability of water bodies for disposal).

Table 1.2 - Comparison of Sewerage Systems

Separate System | Combined System | - Partially Combined System

Merits: Merits: Merits

) Low instattion cost 1) One set of sewers i) Advantages of both separate

i) Less Saat om treatment units| ii) Maintainance is less

and combined systems

i) Less pamping cost iii) Choking is rare ii) Reasonable size of sewers

je) Smal seciorrof sewers | iv}-Dilution of sewage iii) No choking

}) Low ficeations in flow | v) Fout smell is reduced iv) Easy cleaning

A) Runoff discharged to Demerits: Demerits:

j) Constuction cost is more.

streams without treatment ’) More load on treatment unit

its: i) Dépth of laying sewers ii) Increased cost of pumping

is more.

) Difficulty in cleaning

i) Drains eseé only in

i) Large size of sewers ii) Difficult to ventilate sewers

iv) Pollution problems ~ov

during heavy rains

¥) Siting occurs during dey

weather.

iv) High load on treatment

rainy season plants

ii) Choking of sewers ¥) Pumping cost is more.

|

|

TUTTE TTT CTC IT

8

“aineam Arp Suump sins00 Buntig (4

suyes Kavoy,

T sssow si soo Sudwung (A suomas yo Bu you>

{uo pasn sumig (

MOLI CL

ismsaag

Bupnp moysero.— sutajqosd uormnjjod (A!

*S1oMos o7P]NUSA 0} 11NDL310

Sujduind go ys09 poseas0Uy

sijun juauneen uo peo] 210)

ounvan wo peo} UAH (Al {ostas Kuyns uy

sromas Jo azjs funy (1

‘oaoul si siamas Buln] Jo tndag (

220 §} 1809 OHTONISUoD (J luaunvan noua

8 0) padueyosip youny (1A

siuoid

919 Ut}

saan

paonpai s} [Jauis (nog (A MOY UL SuoNEMONY MO7 (A

Jo uonsas jours (ar

sssoueg

Burueajo Aseq (A!

Supyous On (

siomas Jo azis 91quuostay

SUPA

00 Surduund ssa

it

941 HO Proj ssa] (1

suraisks paujquios pue

SI9MAS JO 198 9UO (1 1809 ONE] es) MO7] (1

ayesedas yjoq Jo soBmueapy (I

‘Sue isda, an

man ssnaay

muorsks porque Anented tuarskg poujqurod tua sks ayuandog |

sysfs oBti0Meg jo uosuedwon - ¢4 o1gey

Planning and Design of Sewerage System

E i 1 ie Water eri

~~ 1.7 CHARACTERISTICS AND COMPOSITION OF SEWAGE AND THEIR

~ _ Physical characteristics include: -

— Colour, (ii) Odour, (iii) Temperature and (iv) Turbidity,

SL Colour”

a > Thecolourof sewage can normally be detected by thenaked eye, andit indicates the

>

3 :

s + ‘colour to sewage and the color depends on the chemical

=. eae ‘ ;

- } Odour: ar

—J ©

% Fresh sewage is practically odourless.

— * becomes stale whenalll the oxygen present in sewage gets

ae

a. After few! itstarts omitting offensive odours, especially (H,S) hydrogen sulphide

wa £225, dve 10 decomposition of sewage. : a

FG) Temperatures

ao.

Affects the biological activi of bacteria present in sewage. When temperature is

ugh, the bacteria’ be more active decomposition of waste in sewage.

ishigh, the solubility of gasesin sewage reduces. co

The dissolved oxygen content (D.O) with high

temperature, f

Temperature affects the viscosity of sewage, which intum affects the sedimentation

process in sewage treatment,

i

o

o

»

% Solidsi 'sespension cause turbidity.

° Sewageis normally turbid, having floating matter!

Breases, vegetable dehris, fruit skins, soaps, etc,

> The turbidity increases.as sewage becomes stronger.

eee RE,

> isan optical lightemitting property,

like pieces of paper, match sticks,

> The degree of turbidity can be measured and tested by turbidity rods (or) by nurbidity

meters (Jackson’s turbidity meters, Nephlometric: turbidity metres etc.)

1.7.2 Chemical Characteristics of Sewage

= Sewage: nomally contains very smal] amount of solids (0.05 te-0. 1%) in relation to.

the huge cuantity of water (99.9%).

* — Itonlycontzins about 0.05 to 0.1 percent (i.e, 50010 1000 mg/L) of total solids.

* Classification

® — Saspended solids are solids which remains Aloating in sewage.

@) _Dissolvedssolids remain dissolved in sewage.

Colloidal solids are finely divided solids remaining either insoon (ain

‘Suspension.

Ov) Settleable solids are solids which settle out, if sewage is allowed to remain

~ _urdisturbed for a period of 2 hours.

4 ‘The solids cn also be categorised as

(@) Organic:

(b}Inorganiz Solids,

Waste Water Engineering

inerals, salts, sand, gravel, debris, chlorides, sulphates,

solids in sewage is not harmful and requires simple

< 1.10

° Inorganic matter consists of mi

etc. The presence of inorganic:

treatment. :

° Organic matter consist of carbohydrate (cellulose, cotton, fibre, starch, sugar et),

Fatsandils received from kitchensand Nitrogeneous compounds like protein. Organic

matter in sewage requires proper treatment before disposal in water bodies.

‘Suspended (or)

_ Non-Filtrable

Disolved Solids Colloidal Solids: Solids

\.___SueotPatles,mm_y, __y

Settleable

Removable by Coagulation

Fig, 1.1 : Classification of Solids.

* Measurements:

2) Total Solids (S, mg/f) ~A known volume of sewage is evaporated and the dry residveis

weighed.

Dry residue Weighed -

S, (me = “Volume of sample

b) Suspended Solids (S, mg/!Non-Filterable Solids.

% Aknown volume of sewage sample is passed through a glass-fibre filter apparatus of

1 um pore size. The dry residue retained on filter is weighed.

s Mass of residue

» (8!) = Votume of sample

©) Filterabie Solids = Yotal Solids (S,) ~ Suspended Solids (S,)

(Dissolv< ! + Colloidal Solids).

d) Total Suspended Solids (S,) may be volatile (or) fixed.

TSS = Volatile Solids + Fixed Solids

e) Volatile Solids - Non-tiltered residue (of step b) is burnt and ignited at about 550°C inan

electric inutile furnace for about 15 t0 20 minutes.

|

a

__ Planning and Design of Sewerage System mw

+ Lossof weight due to ignition will represent the volatile solids (S, mg/L).

f) Fixed Solids S,=S,~-S, ie:, Suspended Solids — Volatile Solids.

g) Settlable Solids (S,):

+ Conical glass vessel called Imhoff cone is used.

> Thecapacity of the coneis I litre and itis graduated upto about 50 ml

% ” Sewageisallowed to standin hisimhoff cone fora period of2 hours and the quantity

of solids settled in the bottom of the cone can be directly read out.

-

Conical Glass

Fig. 1.2: lnhoff Cone

Value:

@ pH Value:

GY pH valveindicates negative logofhydogenion concentration 6

pH =—log H? (or) H* = (1oy-** <

pH <7 -acidic range nd

pH>7-alkaline range. 4

% The fresh sewage is generally alkaline in nature (pH more than 7). $

— Butastime passes, sewage tums acidic and its pH tends to fall due to production of ‘

acids by bacterial action. i

© The pl value can be measured quickly and automatically with the help of potentiometer,

which measures the electrical potential exerted by the hydrogen ions. 4

The efficiency of sewage treatment depends on pH. '

"4% IfpHof sewage is low, lime is added to create alkaline condition, ;

(iii) Chloride Contents: 2

Chlorides are generally found in domestic sewage, and are derived from the kitchen

Wastes, urinary discharges, feces etc. |

1

SRes Waste Water

+ Large ammount of chlorides may enter fom intasties like ice cream pont meat salting |

inchstries.

‘Chloride in sewage may also be due o infiltration of sea water (NaC).

The nonmal chloride content of domestic sewage is 120 mg/l.

‘> The chloride content can be measured by titrating the waste water with standard,

___ Silver nitrate AgNO, solution using potassium chromate as indicator.

(iv) Nitrogen Contents:

& The presence of nitrogenin sewage indicates the presence of organic matter, andit

may occur in any of the following forms.

a) Free ammonia called ammonia nitrogen.

byAlbuminoid nitrogen, called organic nitrogen.

©)Nitrites and

dyNitrates.

NH; T +H,0 = NH; +OH™

If further oxidation occurs as

;

NHj +20) — NO; +2H*+H,0

% The sewage treatment is done using microogganisms which decompose the organic

waste into stable compound. =~

o The presence of nitrogen in various forms is indicative of the stages of decomposition

and level of treatment.

% The free ammonia indicates the age of waste water

decomposition of organic matter. 7

* Albuminoid nitrogen indicates quantity of ntrogenin sewage before the decompesition

of organic matter is started.

* ‘The nities indicate the presence of partly decomposed (not fully oxidised)organie

‘matter viz., treatmentis in progress. i

and the very first stage of

Planning and Design of Sewerage System 119

* Indicates very first stage of decompesition of organic materia sewage.

‘+ Measured by distillation process,

b)Albuminoid Nitrogen.

> Indices nitrogen content in wastewater before decomposition of onic mater hc

started.

Measure of ‘undecomposed Nitrogen.

Mesure by treating sample withalaine sclton of assim pemargange

Nitrites Nitrogen

Presence of nitrites indicates Presence of partly decomposed organic meter,

Indicates treatment is still incomplete and sewage is stale.

* Measured by Colourimetric Methot [Colour Matching Method}

[Adding Sulphonilic Acid and Naplihamine}

4) Nitrate Nitrogen

Presence of nitrate indicates presence of fll oxidised organic matter

% Stable form ofnitrogenous mater.”

* Indicates oxidised/treated wastewater.

Measured by colourimeteric method

(colour matching methods) and com are with

standard

colours. (Addin Phenol i-sulphonic acid and potassium hytiroy ide),

* Blue Baby Disease (Methaemoglobinemia) - affects Infants

=

Ifthe nitrate content is above 45 Ppm in water, itinay cause nitrate peisoningin

‘Thishappens because there exias lower aciityin the intestines ofthe inf, which

Permits the growth of ntrate-educing bacteria, wiich converts nitrates to nivites

The nitrites prove very harmful becase they have greater aff

than oxygen and thus completely redhce ox

‘uming the body of infants to blue colour

() Presence of Fats, Oils and Greases:

2 Greases, fats and oils are derivedin sewage from the dischages of animals, vegetable

‘matter from garages, hotels, restaurants and industries ete, >

for haemoglobin

level in blood causing st ffocasion.

Waste Water Engineering

1.14 6

+ Theyinterfere with sewage treatment and they form scum onthetop ofsedimentation

tanksand clog the voids of the filtering media.

++ Theyarenotdecomposible by bacterial action and therefore should be removed from.

sewage.

> Measuredby evaporating sewage sample, residual solids let after evaporation are |

mixed with ether (hexane) and again evaporated, leaving behind the fats and greases,

asaresidve, which can be weighed.

(vi) Sulphides, Snlphates and Hydrogen Sulphide Gas:

Formed due tothe decomposition of various sulphur containing substancesin sewage.

This decomposition also leads to evolution of hydrogen sulphide (HS) gas, causing

bad smells odours and corrodes the sewer pipes.

Sih On :

——— Suiphides —————>_ Sulphate ions

tote {2s sama Ss

product)

HS gas,

Oxidation

S +2H- HS

Aroentic) —Suiphur _Reducton i

Digestion ) Compounds = «Suchides

HS Methane CO;

SO, + organic matter —Bactena | .- +H,0+C0,

* Formation of sulphides hinders the process of sludge digestion.

(ii) Dissolved Oxygen (0.0):

* DO. isthe oxygen present in di ci i

eae yet Present in dissolved stats in waste water, which prevents noxious

+ D.Otestperformed on sewa;

ige before treatment helps in indicati iti

n . ps in indicating the condition of

sewage and decides selection of treatment methods.

Fresh sewage contains some dissolved o:

pce en. which is soon depeleted by aerobic

Presence of D.O. in treated sewage indicates oxidation. during treatment stages.

Planning and Design of Sewerage System

> Treated sewage effluent should have atleast 4

the aquatic life when sewage is discharged in

>

>

>

>

The dissolved oxygen in fresh sewage depend upon temperature,

Ifthe temperature of the Sewage is more, the D.O content will be less.

‘The D.Ocontent of sewage is determined

Teduction process, wherein iodine libcrat

(vill) Oxygen Demand: _

145

ppmD.0. in it otherwise it wil affedy

ito water bodies,

by Winkler’s method whichisan oxidation-

ed is equivalent to the D.O.

Oxygen required for oxidation of both inorganic as well a organic matter,

BOD - Biochemical Oxygen Demand. I

COD ~ Chemical Oxygen Demand.

TOD ~ Total Oxygen Demand. 1

THOD - Theoretical Oxygen Demand. 1

'

ff?

r

TOC - Total Organic Carbon. 3

(x) Chemical Oxygen Demand (COD):

eae chloe

Measure of Oxygen (O,) required to oxidise organic matter in sewage into CO,, 13,0 i

and oxidised species.

(Chemicals are used to oxidise both biologically active and inactive organic matter in

sewage.

% COD test-Oxitation using potassium dichromate. =

% Aknown quantity of waste wateris mixed with known quantity of potassium dichromate i

and the mixtures heated. The organic matter is oxidised by K,Cr,O, (inthe presence

of H,SO,). The resulting solution of K,Cr,0, is titrated with Ferrous Ammonium v@

Sulphate (FAS) and the oxygen used in oxidising the waste wateris determined. This I

is called Chemical Oxygen Demand{COD). ®

Cyl, 0,+Cr, OF +H* EME, 4.00, +10 \«

Organic Matter : «

(x) Biological Demand (BOD): (

p Estee Onsen emend 200; |

+

Measure of oxygen required to oxidise biologically active organiematterinsenage

by microorganisms.

Waste Water Engineering.

ically Active or Degradable (Oxidised by micro-organisms)

Organic

* Biologically Active > ‘The organic matter which can be oxidised by microorganisms is

called biologically active (under aerobic conditions at standard temperature).

* Significance of BOD:

BOD of waste water decides the following: . ;

(1) Quantity of 0, required for biological stabilization. of organic matter in sewage.

(2) Size oftreatment facilities.

(G) Measure of efficiency of treatment.

(4) Ditution required for disposal of waste water\

Aerobic bacteria utilises the organic matter and oxygen in sewage and stants multiplying the

bacterial countincreases which causes faster decomposit mn of organic matter in sewage. The

oxygen consumed by the bacteria for decomposition of organie matter in sewage is

BOD.

|

Biologically inactive (Not Degradable by micro-organisms). 1

Practically itis not feasible to determine the ultimate BOD.

Hence BOD at 2 during 5 days is taken which is 68% of the total BOD.

0.68 BOD,

5 day BOD

BOD, = Ultimate BOD.

* BODBOD Test: (Dilution Method)

Known volume of sewage sample is diluted with known volume of aerated pure water.

Diluted sample isincubated for $ days at 20°C.

% The D.Oofihe dtued sample before and after incubation period ismeasured.

% Thediffereace between the inital

'D.O value and final D.O value indicates the oxygen consumed

by microorganismsin 5 days (causing aerobic decomposition).

BOD/BOD,=D.O-consumed by diluted sample x —Nolume of difuted sample

Volume of undiluted sample

4

(Dilution factor)

Planning and Design Sewerage System

[DP= 1% = imbfievas deo mat 10 ers migzgy oo

Normally, 300 mt BOD test bottles are used

14 ml of sewage sample is taken —

Incubation at 20°C~5 days

Dilution Factor = =

300.

BOD, =D.0 consumed x oma

Y; (L2., BOD. Exerted)

a (.e., BOD Remaining)

Sy,

Time t (Days) L= Organic matter >

Present at start (t = 0)

Fig. 1.3: First Stage BOD 2

Curve

The BOD rate at any time depends on tem

Peratureandalso on the amount and nanureof

Orzanic matter: Present in sewage at that time. -

LELo (t= 0.Siany

t=0

Time in days (ty

Fig. 14: BOO Curve

jet

Sos Waste Water Engiveering

‘Atacestain temperature, the rate of deoxygenation is assurned to be directly proportional to

the amount of the organic matter present in sewage af that time

a,

i ee ke we (HY

ic, a 7K,

1,=Oxygen equivalent oF carbonaceous oxiisable organic matter present after days (rmg/D,

t=time in days

=BOD rate constant (per day).

i

Integrating

log, L,=-Kite -@

When = 0, L,=L (L= Organic matter present at start).

log, L=K(0) +e

C=log. L

Substituting in 2) we get,

(or)

ee He oa

log, + =- 0.43.

Be uA Key

= 0.434 k= De-oxygenation (BOD rate contant).

Wehas i

L

log, Th = -Kpwt

& ‘

=. = (oy koe =

Planning and Design of Sewerage System ae

“Now L is the organic matter present at the start of BOD reaction and L, is the organic

‘matter leftafters days, which means that during days, the quantity of organic matter oxidised

=L-L,

IFY, represent the total amount of organic matter oxidised in f days, then we have,

BOD,,,,=¥,= L-L,

Taking Lout of bracket on R.H.S.

Substituting equation (3),

BOD of t days = Y,= =coy*o"] (4)

Y, isthe oxygen absorbed in days.

Ubimate BOD (Y,) i.e., When 1= co days.

¥,=L(I-(oy* -2)

“2

= Ultimate BOD = Organic matter in sewage.

_ The ultimate BOD (Y,)is equal to the oxygen equivalent organic matter present in sewage (L),

BOD rate constant (K,)

The value of K, determines the speed of the BOD reaction.

‘© BOD rate constant is temperature dependent. 5

#K, ishigher at higher temperature and rate of oxidation willbe faster.

—— B00 «ng

——— Tine 1 (075)

Fig. 1.5 : Effect of K on BOD

1.20 Waste Water Engineering

A(T) =4, QO} or"

A(T) =A, (20°) [1,047)"-™,

4, (20°)= De-oxygenation constant at 20°C. (0.05 ~0:2/day)

4, (= De-oxygenation constant at temperature T°C.

800 ¥, (mg)

——— Time (Days)

Fig. 1.6 : Combined Carbonaceous and Nittification Demand

‘Theoxygen demand during the first 20 daysis due to oxidation of organic matter in sewage

amdiscalled Carbonaccous BOD or first stage demand (CBOD). The latter oxygen demand

scours due to biological oxidation of ammonia and is called as second stage BOD or

nitrogenous BOD (NBOD).

OAB - 1" stage (or) Carbonaceous Stage (CBOD).

AC- 2% stage (or) Nitrogenous Demand (NBOD).

OAC- Combined Demand: (or) Combined BOD Curve.

% Why COD values are higher than BOD values?

InCOD test, the oxygen required by chemicals for oxidation of both biologically

‘active and biologically inactive organic matters measured,

ie

+

>

But in BOD, the oxygen required by microorganisms for oxidation of biologically

‘active organic matter only is measured,

Microorganisms cannot acton biol

logically inactive oreanic matter and hence COD>

Dereent Dain Serereye ee jan

annie

* BOD to.COD ratio

BOD, = BOD= Measure of Biodegradable organics.

(COD = Measure ofboth Biodegradable + Non- Biodegradable organics

BOD,

Since COD> BOD => COD ratio always < |

Iyatio=0:92 to 1.0= Waste water is fully biodegradable,

. a =0163100:68 —» Indicates that Wastewatercante biolosically reared

~ Indicates minimum quantity ‘of non-biodegradable ‘Organic matter.

-: BOD,=0.68 BOD,

Gi Total Organic Carbon (TOC) and Theoretical Oxygen Demand (Th.OD)

> Cartonis the primary constituent of organic mater. TOC therefore gives a measure

of organic matter in sewage.

% Organic matteris expressed as carbon content

Siete remits (C,H, 0, N,) and concentration of compounds present in

‘wastewater enables us to calculate theoretically the carbon content in

Titre of solution.

(CHLO.N) — Carbon, Hydrogen, Oxygen, Nitrogen

Wastewater per

For example:

Ghucose — C\H,0,+60, + 60,+61,0

oF

(125641 12+166)+(6x2¥16) (641246 x2 16+ (6 x 2x 146 « 16)

f

180 in 264 108 {wat

| o-tel

180 mgof sicose requires 192 me of O,,

'

'

t

i

i

1

‘

1m Waste Water Engineering

192 mg

z. Theoretical O, demand ofglucose= 755 ng

=1.07 mg of Gfmg of glucose.

Glucose has 6 molcules of carbon.

* 12x6

Hence, carbon content of glucose = —35- =0.4mg Cimg.

1f200 mg/l of glucose is present in waste water, then

Th.OD= 1.07 mg/mg x 200 mg/l =214 mgil.

(TOC) C_,,_, =0.4 mg Clmg x 200 mg/l =80 me Cil.

cn

COD aa

me aTOCE :

CH,,0,+60, > 6CO,+6H,0

COD _6mol.ofO, _6x16x2

TOC 6molofC 6x12

2.66

Ratio changes with biological oxidation.

1.7.3 Biological Characteristics of Wastewater/Sewage

I) Aquatic Plants

Spermophyia - Wale weeds.

Bryophyta ~ Moses.

Preridophsia = == Ferns,

Thalloptyts = Algae,

0 os come into water bodies should not encourage growth of

2) Aquatic Animals

Venebrtc = = Fish

Mollines = Smails

Planning and Design of Sewerage System inf

‘Arthopoda = Insects

Worms Aquatic earthworms

Metazoa. E Hydra

a — __ Entameba Histolytica (cause Amoebic Dysentry).

‘> Protozoans are bacteria eaters, destroy pathogens, utilize soluble organics for food,

and maintains natural balence among groups ofmicfo-organisms.

‘> Essential in operation of biological treatment process/purification of streams.

(3) Aquatic Molds, Bacteria, Viruses:

(a)Fungi —> Unicelhular, non-photosynthetic, grow in low temperature/pH environment, modify

pH by producing organic acidsand ammonia.

(b) Viruses — Infectious agents, parasites, and this will damage host cells.

—» These are small size (10 to 500 millimicrons).

Bacteriophage Vins - Infectious agents of bacteria.

Adeno Viruses = Cause Upper respiatory infections.

Entero Viruses = Affects Gastero-intestinal tract.

Enteric Viruses - ‘Cause hepatitis. polio etc.

(©) Bacteria

“> Single-celled, converts food into new cells.

Saprophytic — Takes organic matter in solution froma dead/decaying

‘tissues.

Parasitic = Live on other organism.

Pathogenic - Disease causing.

Non-Pathogenic - © Harmless.

> Beneficial and are useful in bringing oxidation and decomposition of sewage.

Classification Based on O, requirement

® Acrobicbacteria - Need, tolive

@® Anaerobic bacteria - Survives in absence of 0,

(ii) Facukativebacteria — With (or) Without O,.

85

Cae

af

eRe

daa

Waste Water Engineering

Classification Based on Temperature

© Psychrophilic — Survive at 10°-20°C.

@ — Mesophitic = Survive at 20°-40°C.

Gi)” Themophilic = Survive at 40°-65°C.

> Atlower temperature, bacterial action will be dormant.

> Forbacterial action, the optimum pH range is 6.510 7.5.

Excretal Bacteria: (All are intestinal boctrias

8)Coli-Acrogenes group bacteria.

»)Closteridium Welchino -Non harm, found in cultivated soils sewageete.

©}Faecal Streptococci - Grows at high temperature.

Coli-Aerogeneous Group: Harmless intestinal bacteria,

* Aerobic and facultativerod shaped bacteria. Approximately 10" to 108.

are Present in human feces per capita daily.

* These bacteria (pathogens) are large in numbers and difficult

to test. Hence, the tests

ze done to identify whether Ecol Escherichia Coli) is present. E.coliisthe indicator

of sewage (contamination) in water Itisnot harmifl but its presence in water indicates

the presence of other pathogenic microorganisms.

(i) Presumptive Test,

coliforms

ii) Confirmed Test.

i) Completed Test.

Methods to find number of coliforms.

(Coliform index.

(i) Most Probable Number (MPN).

MPNis the bacterial density which; ifactually present in sample would more frequently would

have given the observed results, i

* Biological Treatment of, Sewage

Organic matter in sewage is decomposed bacteria (biological acti i

aapiboeen by’ (biological action) and converted into

‘The process involved iscategorised as:

Planning and Design of Sewerage System

(i) Actobic decomposition, called aerobic oxidation, ——=

GiAnaerobic decomposition, called putrefication,

@ Aerobie Process:

Oxidation of organic matteris done by acrobic bacterin

% End product formed are CO,, HO, SO, 1» NO,, NH,

More cell synthesis (New bac cl)

Final effventis stable.

© These bacteria will utilise the fice oxygen as an electron acceptor, thereby oxidising

the organic matter (OM) to stable and unobjectionable end Products,

cS

Oxidation ‘by aerobic

9) Nitrogencous OM "Eat, NO} +NH, 1 Energy a

- Oxidation by aerobic

ii) Carbone ous OM —ten byarebic co, 1+H,0+ Energy -Q)

- Onidation by aerobic

iii) Sulphurous OM % > SOs” + Energy 8)

Dead Organic

Matier

Decompositon

i | sre

af =

Prant Proteins Cnn

=0,] Anmais

ner Ee

Sona a re cee tes No, er |

thr |. |

Pricey

Fig. 1.7 : Nitrogen Bi eens Oxidation

i

|

t

!

!

Oxdston ss }

ee Nites (NO, )

nent rates at End

1,26

Excretions

of Animas

|

Animal Fats

and Proteins

|

Plants Carbohydrates:

Fat and Proteins-

Final End Products

Fig. 1.9: Sulphur Cycle under Aerobic Oxidation

Planning and Design of Sewerage System ‘ iar

ree

(@) Anaerobic Decompasition

+ IffiveD.0. isnotavalable in sewage, anaerobic decomposition (putreficaion) occurs

| Under theaction ofanaerobie and facultative bacteria, complex organic matter (OM)

| is converted to compounds of N, C, 8.

|

|

‘> Bacteria consumes molecular O, present in compounds [NO,,SO,}. aig

Anaerobic Decomposition

Putrefaction Liquefaction

Putrefaction — Decomposition of organic matter by aneorobic bacteria.

Liquefaction — ~ _Processin which solid organic matter is dissolved by enzymes.

% End productsare CO, H,O, H,S, CH,, NH,.N, but new cell synthesis is low. The

effluent is unstable and end products are odourerss.

| Example: Septic tanks, Imboff tanks, Sludge dice-tion tank.

Reduction by Anaerobic

Bocteria

i} Nitrogenous OM

N,? +NH, T+ Organic

Acids + Heat Energy

Re om Reduction by Anaerobic s

ii) Carbonaceous OM "=~ > CO, f + Heat (energy)

| i) Sulphurous OM nS > 1 54 + Heat energy

Gases evolvedin the process, N, +, H,S , CH, ? produce noxious odours.

iv) Organic Acids _seesbetuars CH, t+CO, ? + Heat (energy).

”

Knowledge of Nitrogen, Carbon and Sulphur cycles (both aerobic oxidation and

anerobic reduction) are useflin determining the Stage of Decomposition of Sewage”

| by testing for products of decay,

Example:

| Well Oxidised Sewage Indicated by the presence of nitrates and

sulphates and very litte ainmoniaand H.S.

Less Oxidised Sewage 5 Presence of nitrites and sulphur.

DP DD DOL LAL

PO DP

IPM O DDH Ob bb

128

TN et rt ocr

oy

B 1f2.5 ml of raw sewage was diluted to 250 ml, and D.O. concentration of dilated

sample at beginning of BOD test was 8 mg/L, and 5 mg/L. after 5 day ineubation at

20°C. Find BOD of raw sewage?

Solution:

Volume of sample=2.5 ml.

‘Volume of diluted sample =250 ml. een

Dilution Ratio => =100,

Loss of Dissolved oxygen =D.Oat beginning — D.O after testing

=8-5=3 mg/L.

B.O.D of sewage =Loss of D.O. x Dilution factor

=3mg/L x 100=300 mg/L.

2. A2% solution of sewage sample was incubated for 5 days @ 20°C. The depletion

of O, was 4 ppm. Determine BOD of sewage.

Solution:

Dilution factor x 50.

BOD =Depletion of O, x Dilution factor

=4 ppm x 50=200 ppm. = 200 mg/l. {1 ppm=1 mg}

3. The average sewage flow from a city is 80 x 10* /d. If the average 5 day B.O.Dis

285 mg/L, compute the total day O, demand in kg and the popukstien equivalent

of sewage. Assume per capita BOD of sewage per day = 75g.

Solution:

Quantity of sewage flow per day = 80 x 10° litres.

Average 5 day BOD = 285 mg/l .

+ Total 5 day oxyeen demand = 285 mg/l x (80 x 10°) d= 22,800k:

Me. Strength of BOD- _ 228004g

Speitoncepivaten Standard BODs per day perperson 25g

= 3,04,000,

4. Ifthe periodof incubati

calculate the percentage of relative Stability,

Solution:

Relative Stability =

t=10days , $=1

of Sewerage System

129

ion is 10 days at 20°C in the relative stal

teston sewage,

S= 100 (1 (0.794y2p

00 [1 - (0:794)P)

ss S= 90.04%.

5. The 5 day 30°C BODo

f sewage sample is 110 mg/l. Calculate its 5 day 20°C BOD,

Assume the deoxygenation constant at 20°C, #, (20°-)= 0.1.

Solution:

Kp e9)=Kp ao) (1.0472

Ay = 0.1[1.047p°-»

0.1f1.047)"

= 0.158.

D Y,=L[}-(10)-'},

Ysa @30°C=-110 = uf

no = L[1-aoy*”]

1-00] -rfieqgy%se1

1 = 131.29 mg/L = Ultimate BOD (Measure of organic matter Present in sewage)

ii) Yat S day @ 20°C.

Yagat20C = f1-1orber]

= 13129 [}-aoy"s]

Y, = 89:3 mp/L.

6 Caleulate 1 day 37°C

Assume K, 20°C = 0.1

Solution:

BOD of sewage sample whose 5 day 20°C BOD is 100 mg/l.

Waste Water Engineering

1

0X X= K, (1.047 (

pore

=o.1pi.oa7y”

= 0218.

(iy = gaecsa= U1-cor*”*]

\

100 = 1fi-0or™] pe:

L= 146.2 mg/L. :

y@rret aay ~ {coy *"] =uft-oor""]

= 146.2 f-ao™]

Y¥, one day @ 37°C =57.69 mg/L.

1. The BOD of sewage incubated for one day at 30°C has been found to 110 mg/l

What will be the 5 day 20°C BOD. Assume #,=0.1 at 20°C. f

Solution: ae

Y,at30C = 110 me/l.

Y, at 20 =?

K,20"=01

Kopp = Kozo [1.047}"- = Ko (1.0477?

=0.1{1.047)"

201. 1.583

K, = 01583

Moe Hl -t0*0'

hay pe 3

art ONS

NoeL jl i

Le 6068 mL.

oS

BWUV TUE ciciod

i. Waste Water Engineering

1.8 POPULATION EQUIVALENT (STRENGTH OF INDUSTRIAL SEWAGEY

Re Fepulation equivalents used to caleulate the quanftyofndustial sewage Asitisa

tedious process, the industrial sewage (0) waste water is compared with the rate of

generation of domestic waste water.

>

‘Thisparameteris used to charge the industries for causing pollution (or) discharging

‘waste water against the discharge norms and also to choose appropriate treatment

methods. :

‘Strength of Industrial Sewage (BOD, days}= [Standard BOD, days of domestic sewage per

person per day} x [Population equivalent}

BOD, of domestic sewage = 0.08 kg/day/person.

€.g: IEBOD, of industrial sewage = 300 kg/day, then

ation equivalent = = = 3750,

Population equivalent = <7, = 3750.

1.9 SANITARY SEWAGE FLOW ESTIMATION

Sanitary Sewage is the spent water of a community that drains into sewers.

Sanitary Sewage = Domestic Sewage + Industrial Sewage

Theoretically speaking, the quantity of sewage (i.e., domestic sewage + industrial sewage)

thatis likely toenter the municipal main sewers should be equal tothe quantity of water supplied to

the contributing area.

ic, Quantity of Sewage = Quantity of water supplied.

But certain additions and subtractions do take place

@ Additions due to unaccounted private water supply.

@ Addition due to ground water infiltration.

Gi) Subtractions due to water losses (leakage, seepage in ground).

(i) _Sobtractions dve to water lost in evaporation,

[Net Quanity ofsewage produced = Quantity of water supplied +@+ Gi)- (ii) iv’

* Usually 80% of water supply may be expected to reach the sewers.

[ Quantity of Sewage=Per capita sewage contributed per day x Population. |

|

Planning and Design of Sewerage System

d33

% Factors affecting Dry Weather Flow (DW)

Day Weather Flow (DWF) is the ow of sanitary sewage sng in the absence of

water (during dry season). ‘storm

© Rate of water supply.

@ Population growth,

©) Type ofarea served (Residential CommerciaVindusrly

* (Infiltration of sub soil water (leaky joint in sewers and high water table level),

1.10 SEWER MATERIALS

1. Important Factors Considered for Selecting Material for. Sewer

Following factors should be considered before selecting material formanufacturing Sewer pi

a Resistance to Corrosion: Sewer carries Wastewater that rel

cn of sewer pipe. Hence, selec on ofcomsion

resistance material is must for long life of pipe.

b Resistance to Abrasion: Sevace contain considerable amount of suspended solids

Part of which are inoreanic solids such as sand or grit These particles mox ingat high

“Yelocity can cause wear and tear o ver pipe internally: This abrasion can teduce

: i hydrauli ficiency ofthe sewer by mating the interoe

© Strengthand Durability: The sewer Pipe should have sufficient sreneth to withstand

all the forces that are likely to come on them. Sewers are subjected to considerable

extemal loads of backtill material and traffic 4oad, ifany. They are not subjected to

intemal pressure of water. To ‘wid'stand extemal load safely without Faihure. sufficient

Wall thickness of pipe or reinforcement is ssential. Inaddition, the material selected

Should be durable and should have Sufficient resistance against natural Weathering

‘action to provide longer life to the Pipe.

a Weight of the Material: The meteril selected for sewer shoukd have less specific

weight, which will make Pipe lightin weight. The Tighiweéght pipesare easy for handling

aad transport.

© Imperviousness: Toeliminate chances, of sewage seepace from sewer to. surrounding,

the material selected for Pipe shoul be impervious,

£ Economy and Cost: Sewer should be less Costly to make the sewerage scheme

economical,

&

Hydraulically etficiens "he Sewer shalthave smooth interior surface tol ave Wess

$$ $$

i

1.34 Waste Water Engineering |

1.10.1 Materials for Sewers

Asbestos Cement Sewers

‘These are manufactured from a mixture of asbestos fibers, silica and cement. Asbestos

fibers are thoroughly mixed with cement to act as reinforcement.

‘These pipes are available in size 1010 100 cm intemal diameter and length upto 4.0m.

These pipes can be easily assembled without skilled labour with the help of special

counling, called ‘Ring Tie Coupling’ or Simplex joint.

The pipe and joints are resistantto corrosior. and the joints are flexible to permit 12>

deflection for curved laying.

‘These pipes are used for vertical transport of water. For example, transport of rainwater-

from roofs in multistoried buildings, for transport of sewage to grounds, and for transport

of less foul sullage i.e., wastewater from kitchen and bathroom.

Advantages

‘These pipes are light in weight and hence, easy to carry and transport.

© Easytocut and assemble without skilled labour.

* Interiors smooth (Manning's n=0.611) hence, can make excellent hydraulically

efficient sewer

Disadvantages

© These pipes are structurally not very strong.

‘These are susceptible to corrosion by sulpheric acid. When bacte

presence of water, H,SO, can be formed leading to corrosion of,

Plain Cement Concrete or Reinforced Cement Concrete

Plain Cement Conerete(1: 15:3) pipesare available up to 0.45 m diameter and reinforcement

‘cement pipes are available up to | 8 m diameter. These pipes can be cast in situ or precast pipes.

Precast pipes are better in quality than the cast in situ pipes. The reinforcementin these

Pipes canbe different suchas single cage reinforced pipes, used for internal pressure less than

used for both internal and external pressure greater than

0.8m; elliptical cage reinforced pipes used forlarger diameter sewers subjected to external

Prssoure; and Hume pipes with stcel shells coated with concrete from inside and outside: Nominal

Tergitudinal reinforcement of 0.25%is provided these pipes.

Advantages of Concrete Pipes

ria produce HLS, in

pipe material.

9.8 m; double cage reinforced pipes

© Strong in tensions well as compression,

© Res stantto erosion and abrasion.

|

———

ring end Design of Severene See _—___—_____ 1

They can be made of any’ desired strength.

Easily molded, and can be insitu or precast pipes.

Beonomical for medium and large sizes.

‘These pipes are available in wide range of size and the trench can be opened and

backfilled rapidly during maintenance of sewers.

Disadvantages.

‘These pipes can get corroded and pitted by the action of H,SO,.

© Thecarrying capacity of the pipe reduces with time because of corrosion.

“. Thepipesare susceptible to erosion by sewage containing silt and grit

The concrete sewers can be protected internally by vitrified clay linings. With protection

Fining they are used for almost all the branch and main sewers. Only high alumina cement concrete

should be used when pipes are exposed to corrosive liquid like sewage.

Vitrified Clay or Stoneware Sewers

These pipes are used for house connections as well as lateral sewers. The size of the pipe

available is S cm to 30 cm internal diameter with length 0.9 to 1.2 m. These pipes are rarely

manufactured for diameter greater than 99 em. These are joined by bell and spigot flexible

compressionjoints. | ~

Advantages

= Resistant to corrosion, hence fit for carrying polluted water such as sewage.

¢ Interior surface is smooth andis hydraulically efficient.

© Thepipesare highly impervious.

© Strong in compression.

© These pipes are durable and economical for small diameters.

* The pipe material does not absorb water more than 5% of their own weight, when

immersed in water for 24h.

Disadvantages

* Heavy, bulky and brittle and hence, difficult to transport,

* These pipes cannot be used as pressure pipes, because they are weak in tension,

a pies equi large her of ins asthe indvidal pe lengths smal

abetted Cae large size combined sewer or particularly forstorm

through brick joints. These. peed fos wee: toavoid entry of ree rootsand eu

smooth and hy Kaitou cficser bom with stone: Were OF CENTS block: tomake

.ining also makes the pipe resistant to corrosion.

MEE UUE EEE LL ebb eb

Waste Water Engineering

Cast Iron Sewers

These pipes are stronger and capable to withstand greater tensile, compressive, as well as

bending stresses. However, these are costly. Cas iron pipes are used for outfall sewers, rising

‘mains of pumping stations, and inverted siphons, where pipes are running under pressure. These

arealso suitable for sewers under heavy traffic load, suchas sewers below railways and highways.

‘They are used for carried over piers in case of low lying areas. They form 100% leak proof

sewer line toavoid groundwater contamination. They are less resistant to corrosion; hence,

generally lined from inside with cement concrete, coal tar paint, epoxy, etc. These are joined

together by bell and spigot joint. 1S:1536-1989 and IS:1537-1976 provides the specifications

for spun and vertically cast pipes, respectively. .

Steel Pipes

‘These are used under the situations such as pressure main sewers, under water crossing,

bridge crossing, necessary connections for pumping stations, laying pipes over self supporting.

spans, railway crossings, etc. They can withstand intemal pressure, impact load and vibrations

much better than CI pipes. They are more ductile and can withstand water hammer pressure

better. These pipes cannot withstand high external load and these pipes may collapse when

negative pressure is developed in pipes. They are susceptible to corrosion and are not generally

used for partially flowing sewers. They are protected internally and externally against the action

of corrosion.

Ductile Iron Pipes

Ductile iron pipes can also be used for conveying the sewers. They demonstrate higher

capacity to withstand water hammer. The specifications for DI pipes is provided in IS:12288-

1987. The predominant wall material is ductile iron, a spheroidized graphite cast iron. Internally

these pipes are coated with cement mortar lining or any other polyethylene or poly wrap or

plastic bagging/sdeeve lining to inhibit corrosion from the wastewater being conveyed, and various

types of extemal coating are used to inhibit corrosion from the environment. Ductile iron has

provento be abetter pipe material than cast iron but they are costly. Ductile iron is still believed

tobe strongerand more fracture resistant material. However, like most ferrous materials itis

susceptible tocorrosion. A typical life expectancy of thicker walled pipe could be up to 75 years,

however with the current thinner walled ductile pipe the life could be about 20 years in highly

corrosive soils without a corrosion control program like cathodic protection.

Plastic Sewers (PVC pipes)

Plastic isrecent material used for sewer pipes. These are used for intemal drainaze works

inhouse. These are available in sizes 7510315 mm external diameter and used in drainage

works.

They offersmooth internal surface. The additional advantages they offer are resistant to.

corrosion. lightweight of pipe, economical in laying, jointing and maintenance, the pipe istoug!>

and rigid, and ease in fabrication and transport of ese pipes.

|

a

Use of these pipes for sewers is recent development. They are not brittle

knee arenes ha fll during lading unloading and handling dono damag

tothe pipes. They can be joined by welding or can be jointed With detachable joints upto 639

mami Ee ORD Teseae commoner convey oir

pipes very lite Nexibitty

TkeAC pipes and

cause any damage

‘bey combine the advantage of corrosion

mpared with the steel Pipes. Typical

Properties that result in advantages in GRP Pipes application can be summarized as follows

© Light weight of Pipes that allows for the use of light laying and transport means.

* Possibility ofnesting of differen iarceters of pipe thus allowing additional saving in

transport

‘cost.

* _ Lengthofpipe is larger than other Pipe materials.

. installation ‘Procedures due ‘othekind of mechenical bell and spigot joint,

. eee TAAL hans peUcionsuhscting ae or cathodic

are then necessary,

* Smoothness of the intersal yall

that minimizes the heed toss and avoids the formation

of deposits,

* High mechanical Tesistance due to the glass reinfo-cement

. (solute impemeabilityof pipes a Jemtsboth from extemal to intemal and viceversa.

e Very long life ofthe sateria).

Lead Sewers

* They are smooth, so

* This pipe hasan abi

7* However, these pi

. are Used in house connection,

ft and can take Odd shapes.

lity to resist sulphide corrosion

ied Wpste Water Engineering

1.11 HYDRAULICS OF FLOW IN SEWERS

‘+ Ractors thatinfinence flow of sewage in sewers.

% Slope ofsewer.

> Geometry of sewer.

“> Roughness of interior surface of sewer,

+> Bends, transitions, obstructions etc.

“> Flow conditions.

> Characteristics ofsewage.

Hydraulic Formulae:

() Chezy’s Formals:

V =Velocity of low (ans)

S=Hydranlie grafieatof sewer

R=Hydraulie mean radius (ri)

(C=Chezy’sconstart

A= Area ofeross-section (7)

P= Wetted perimeter (mm)

Chezy’sconstant Cis found sing Bazin’s formula:

Q=AV

Q=Discharge in m'Vs.

(ii) Kutter’s Form:

Chezy’s efficient, C =

R=Hydraulicmean radius

S= Slope

N= Rugosity co-efficient (depends oa nature of inner surface of sewer)

When N decreases, diameter increases

Example: For Cement concrete se-ver of 600 mm, N =0.013.

fe 7

i

| planning and Design of Sewerage Syren, 139

i @ Bazin’s Formula:

157.6

Chezy’sconstant, K

1.814

VR

K--Bazin’s constant (Depends on nature of inner surface of sewers).

(iv) Manning’s Formals: :

Velocity of flow, si,

where N, R, S have same meaning as given by Kutter’s formula.

(v) Crimp and Burge’s Formuk:

V=83.5 RS?

(Similar to Manning’s formula where —=83.5 oF N=0.012).

Example: Foracircular pipe,

ped also?

P aD

V=83.5(D/4y". Si?

~ 213

o-arv-(3 o }s(2) Esti

4,

Q=26.02 DY S'?

(05) William-Hazen’s Formula: For flow under pressure for designing water pipes.

'V=0.85 C RS

CC value depends on the type of pipe material. .

1.40

1.12 SEWER DESIGN

1.12.1 Hydroulic Elements of Circular Sewers

i * Advantages of Circular Sewer Sections:

() Easytomanufacture, ?

(i) Efficient Section: Acircular section ‘gives the highest H.M.D. (Hydraulic Mean Depth

‘when running fall (or)half full. When depth is more, velocity’and discharge will be high.

Waste Water Engineering |

“ t

i) "sthemost economical section since it uilises minimum quantitiesofmaterial

(iv) Circular section have uniform curvature all around andit offers less opportunites for deposits.

i Sewers should nmatleast half full.

Circular section manning full:

==)

E Wetted perimeter, P= xD-

Hydraulic Mean Depth, R =

A_ a/4D?_ Dp

Bay

f b) Gircular Sewer running partially full:

ORIG

Gy

F

j

oo SRE er a

Planning and Design of Sewerage System

Planning. and Design of Sewerage System

$$

Lede te dei pt owe eee anh nena

Let a= Area of cross section.

p= Wetted perimeters

r= Hydraulic mean depth.

V= Velocity of flow.

(Depth at partial flow:

tS Bal al

Sts

os oe eth D

(Comparing partial flow with fll low)

G) Area of cross-section running partially full:

A 360° 2a

+. Proportionate Area =2. +3-]

(ii) Wetteg Perimeter:

p=nD.—2_

360°

Proportionate perimeter

1A

(a) ndaute Mean Depth (MD):

so'{_0_ snd

a4 (360 2"

tt eT

360

_D psa]

Pea\: 28

rf, 360sin0

Protons MD=7"|'" 959

(v) Yelocity of Flow:

n

J 2p v2 fi pl Sl 3 ;

Preportionate velocity,

swhenmunning full.

Ifravchness co-efficient does not vary with depth

n=N

213

Proportionate velocity, 2-(2]

pi esas 2/3

2x0

(>i) Discharge running full:

Discharge, patil fll

0 sind ][,_360sin0

2x0

2s

: 7) [For variable values of N, n}.

213 i"

ee :

ae

> WhenN/naoesnot vary with depth of flow and when sewers flow more than half full,

velocity in partially filled circular sewer exceeds those in full section.

> Maximum velocity achieved when depth of flow is 0.81 times full depth. (12.5%

‘greater than when running full).

+ Maximum discharge obtained NOT when sewer is running fall but when depth is 0.95

times fall depth (7% greater than when running full).

(vii) Partial Depth Self Cleansing Flow:

Sewers flowing 0.5 to 0.8 times full need not be placed on steeper gradients to achi@ve _

self-cleansing velocity,

hala

Q LaAhKaAer

4g, = discharge when sewer are partially full.

Q= discharge when sewers are running full.

* Ventilation of Sewers:

‘Sewers are not designed to run full. Sewers are always designed to flow halfor three-fourth

for the purpose of ventilation of foul gases.

% Small sewers (< 0.4 m 4) - designed for flow at ; depth.

% Sewers (0.4 m1o 0.9 m)— designed for flow at 2 depth.

* Large sewers (ultimate peak discharge) - designed for flowat ; depth.

ray

|

CEbeELEe

é,

d a Od é G.

BS TESTE Go

|

ey Waste Water Engineering |

1.12.2 Egg-Shaped Sewers (Ovoid Sewers) |

* Advantages:

© Usedincombined sewerage system where discharge (low)highly varies. There will

bebeavy flows during rainy season and only 510 10% flow (dry weather flow) during

summer. Epg-shaped sewers provide greater depth (than circular) during low flow

conditions,

@®- Gives higher velocity for low flows than circu sewers of equal capacity

+ Disadvantages: i

© Uasiablesection, Small end (ov) has o support broader upper sections weight.

© Morediffcultto construct, expensive, material rere ismore.

G@ _Selfclensing velocity requires suitable gradient.

Two Forms:

3) Standard (or) Metropolitan section.

ii) Newshaped section.

a care

Fig. 1M 2) :Standard Metropolitan Section Fig. 1.11 ():Mew egg shaped section

Table 1.3 : Geometrical Parameters of Ovoid Section

Standard Section

. 36

2b

b

056

© Parameter

New Section

3b

26

b

0.25

Planning and Design of Sewerage System

* Hydraulic Elements of Standard Form:

|

| a) Sewer ranning full:

Areaofcrown portion =1578 6-02

| Areaofcentral portion = 2.802

Areaofinvert portion =0.23h

| Total Area =46R-

Similarly Total Perimeter=7.825

R=HMD.=0.585

b)Sewer running2/3" full:

Total area = 3.038?

Area of central portion’ 2.808? } =3.9352

Areaofiivert portion 0.2382

Total perimeter = 4.685

HMD= R=0.645.

©) Sewer running half-full and one-third full:

Atrunmning half full, R=0.54b,

-- Atrumning one-third full, R=0.415.

* Hydraulic elements of the New Form:

a) Sewer running full:

Areaofavwnportion = 1.57 5?

Arcaofcentralportion =2.86 52

Areaofinvestportion = 0.03 5?

Total area = 4.46 b

Perimeter =7,89 5

HMD, R=0,575,

Sever runing ru

Ateaofcentral portion = 2.652

f

| __ Ateaofinvert portion = 0.038

FolatArea = 2.899

pie earane

1.46 Waste Water Engineering

Perimeter = 4.68b

H.M.D, R =0.62b.

¢)Section running one-third full

=

% Hydraulically equivalent Circular Sewers:

+: Thedesign of egg-shaped sewers is complicated.

" + The computations of various hydraulic elements (suchias area, wetted perimeter, a

hydraulic mean depth, etc.) ofegg-shaped sewers involves complicated mathematical

calculations.

| 4 Therefore while designing egg-shaped sewers, approximate diameter of hydraulically {

equivalent circular sewer is calculated frst, wi:h the same discharge (running fall) 4

and Jaid at same gradient, and then converted into dimensions of egg-shaped section. j

Let D = Diameter of hydraulically equivalent circular section.

D, = Top horizontal diameter: ‘of egg shaped section.

D= 1.209 D,, | for O1dStandard/ Metropolitan Section

ae D=1.191 D,, | forNew Section : .

Rouen.

; D=12D,

Table 1:4: Comparison of in circularand ovoid sewers

ap x uM

v Vv

Circular Sewer Standard Ovoid Sewer

025 0701 1698

0.20 0.615 0.627

015 0.517 0.544

0.10 0.401 0.440

0.257 0.295

. 7 haw

Planning and Design a a7

1.12.3 Other Sewer Sections

Insoftsoits with difficulty of providing foundations for circular/ovoid sections, following

shapes are used.

© Semi-clliptical © Horse-shoe © Parabolic

Rectangular © U-shaped.

Shapes of Sewer Pipes

‘Sewers are generally circular pipes laid below ground level, sloping continuously towards

the outfall. These are designed to flow under gravity. ‘Shapes other than circular are also used,

‘Other shapes used for sewers are:

a. Standard Egg-shaped sewer b. New egg-shaped sewer

¢. Horse shoe shaped sewer d. Parabolic shaped sewer

¢ Semi-clliptical section £ Rectangular shape section

g U-shaped section h. Semi-circular shaped sewer

i Basket handled shape sewer

‘Standard egg-shaped sewers, also called as ovoid shaped sewer, and new or modified

egg-shaped sewers are used in combined sewers. These sewers can generate self cleansing

velocity during dry weather flow. Horse shoe shaped sewers and semi-circular sections are used

forlarge sewers with heavy discharge such as trunk ancl outfall sewers. Rectangular or trapezoidal

section is used for conveying storm water. U-shaped section is used for larger sewers and

especially in open cuts. Other sections of the sewers have become absolute due to difficulty in

Fig, 1.2 a, (d)

Waste Water Engineering I

(c}Horse shoe sewer section . (d) Parabolic section

(e}Semi-elliptical section

{g) U-shaped section ()) Semé-crcalar Secon (i) Basket Handle Section

Fig. 1.12 : Different shapes used for construction of sewer other than circular

Planning and Design of Sewerage System

Shape of sewer depends on:

Hydraulic (flow) conditions,

(Construction Ease,

(ji) Foundation conditions,

(i) Availability ofspace,

(a) Horse Shoe (b) Rectangular °

(©) Parabolic

(©) Semi-ENiptic

(A) Horse Skoe |

with underdrain

with underdrain

Figs. 1.13 Other Sewer Sections.

Waste Waser Engineering

1. Calculate the velocity of flow and discharge in circular sewer of diameter 1 maid

at gradient of 1 in 500. Use Mannings formula, N = 0.012. Assume seweris running

half full?

Solution: Manning's Formula:

1 é

ia RISE. R—-Hydraulic mean depth

Half full,

Given D= 1 (diameter) 2

1 {2 237) 2

0.012 (4) (s00.

1 ny, a

ve (1) (1) <1s79ms.

0.012 (4 En) ae /

2

OE zo xV= pea. 479 = 0.581 m/s. = 0.581 cumecs.

2. Asewer of 0.6 m 4, laid at gradient 1 in 400 runs full. Use Crimp and Burge’s

forshula, calculate the velocity of flow and discharge. z

Solution

V=835 RY

xD?

Red S015

v2

V=83.5 (0.15)” (as)

V=1.178 mis.

6)?x1.178

Q=0.333 mis (or) 3336.

3. Astone ware sewer 30m is aid at gradient 1 in 100. Using N=0.013in Mannings

formula, calculate velocity, discharge and chezy’s co-efficient when sewer runs full?

Solution:

Sewernurs full.

A_x/4D?_D_30

a aaa =75em

Po osD) 4 4-

“aone) be)

atray

1.52 :

Waste Water Engineering

Chezy’s Formula:

[e=50]

4. Amain combined sewer is designed to serve an area of 12.sq.km. with population,

density of 250 persons/hectares. Average rate of sewage flow is 250-/eapitalgay.

Maximum flow is 100% in excess of average together with rainfall equivalent of ~

15mm in 24 hours, all which are runoff. Determine capacity of sewer. Taking

maximum velocity of flow as 3 m/s. Determine size of circular sewer?

Solution:

Total population= 12 x 10 ha x 250-persons/ha 10000 m?— 1 ha

= 30,0000 persons. 12 sq.km. = 12 x10

Average Flow = 300000 x 250 Iped

=75 x 10°Vd

75x10°

~~ (24x60x60x10°)

Maximum flow = 100% in excess of average + Storm flow.

= 0.868 m/s

2

1 1

x 0.868 +12 x 10° x (5) * 34x60x60 [1 day (or)24 hours}

Q= 1.736 + 2.083 = 3.82 m/s (or) Cumec.

Q=3.82 m's.

Sewercapacity, Q=AV_,

Q= hx Vee

x

3.8: gx x3

Provide 130-cm diameter,

Planning and Design of Seweroge System

5. Deter

os 20" oar)

SB

D* = 4.8128

<6 A town has population of 1,00,000 persons with per capita water supply of 200 litres

day, Design a sewer running 0.7 times full at maximum discharge. Take a constant

value of N = 0.013 atall depths of flow. The sewers laid at slope of 1 in 500. Take

Peaking factor of 3.

Solution:

Water supplied = Per capita demand x Population

= 200 lid x ;,00,090 = 20 x 10° I/d

20x10"

ee eae

~ OP x2txepngg-— 02315 ms

Average discharge in sewers = 0.8 x 0:2315=

1852 mis

[80% of water supplied tums into sewage}

Peaking factor =3, :

|

|

/

Maximum discharge y= Peak factor y Average discharge |

= 3x 0.1852 = 0.5556 m/s. |

Apphing formula

ar acne

oe [3 2

|=0.5872D?

0[ 15 a 15).

$a 180-6.n-=113578

0=227.15

= 0.2962 x 0.835 = 0.2474 m. .

12,

1 213} ‘)

oy (02474)? |

v= gs Ot) ie

y=1:356m/s> 60 m/s [for diameter> 60 cm, SCV > 60cmis] (refer Table 2.2)

Hence OK.

Determine the diameter of separate sewer section running 0.7 times full atmaximum

discharge for a population of 50,000 persons. Water is supplied at a rate of 140

litres per capita per day. Assume 80% of water supplied turns as sewage. Take

2.25 as peak factor and Manning’s constant, N = 0.013 at all depths of flow. The

permissible flow is 1 in 700.

Solution:

Water supplied = Per capita demand x Population

= 140 Iped x 50,000

=7x 10d

=7 x 10 mi/d. = 0.081 m’/s.

Average discharge in sewers = 80% of water supplied

= 0.8x 0.08] = 0.0648 m/s

Peak factor = 2.25

Maximum discharge in sewers = Peak factor x Average Discharge

=2.25 x 0.0648

SL ePiinng ‘and Design of Sewerage System

1.57

(Check for self cleansing velocity.

1

ves pag

”

7=0.296D

7 =0.296 x 0.538 = 0.159

’ “pyr,

Tors Assy (3)

=0.85 m/s =85 cm/s > 75 emis. Hence OK.

From table, for sewer diameter between 30 to 60cm, self-cleansing velocity should be

more than 75 cm/s, (Refer Table 2.2)

8 Design an equivalent e,

is 36000, the per capit:

turns into. Sewage,

of flow in circular:

88-shaped sewer section for the following data. Population

en SuPPIY is 150 Iped, assume 82% of water supplied

slope lin 625, 1= 0.012. Peak factor=4. Also find the velocity

Soverwhen running full and during dry weather hiv DWF.

~Given: Population =36000 aa,

Water supply =150 Iped

82% — Sewage

1 -

=—.n=0912

Slope > =.= 0012

Peak factor = 4.

Water supply = Percapita demand Population

= 150 Iped x 36006

=54 x 10°Vd

= 5410 md

S.4x10> aoe

2 246060 = 0.0625 m a

Average discharge in sewers = 82% of y, ater suppl

= 0.82 0.6625 m

ut

0.051 m/s

. Waste Water Engineering

‘Maximum discharge in sewers = Peak Factor x Average Discharge (DWF)

=4 x 0,051 =0.204 ms.

[Note: Firstdesigna circular section, then convert the dimensions into an equivalent egg-shaped

section)

(1) Circular Section:

158

(@)Velocity when running full.

2

RB 9!2 = 14)23 4

0.0 oon . 625,

2137) \We

Ree De 8) a

4 “oo (4) (es

~0.012\ 4 \ 625.

Vv mci (0.136) x 0.

Y = 0.875 mis.

(b) Velocity @ Dry Weather Flow (DWF).

Average flow Q= 0.051 mvs

Q=A-v

1.60

1.13 STORM DRAINAGE

* Disadvantages of Combined Sewers: Sewage +Drainage).

@ Larger size of sewer section is required.

(Gi) Hydraulic performance is unsatisfactory during Dry Weather Flow (DWF):

Hence, itis frequently preferred to carry the storm water through storm water drain.

* Surface Drains /Storm Water Drains:

@ Surface drains are used to carry sullage (kitchen waste water)and rain waters.

Gis Surface drains are less hygienic since they are open and exposed to atmosphere.

Gi) Surface drains are normally laid along either sides of the street facing boundary walls

of housesand buildings.

@)y In surface drain, itis difficult to maintain self cleansing velocity and they require frequent

cleaning.

(¥) Surface drains flow under gravity.

% Requirements for efficient surface drains:

(The inner surface of the drain should be smooth.

(i) _Itshould have sufficient carrying capacity and should have reasonable free board.

(i) _Itshould be laid at sufficient gradient to achieve self-cleansing velocity during dry

weather flow.

() All the joints should be properly and neatly finished.

(vy) Itshould be structurally safe and stable.

(i) Itshould be constructed with non-corrosive material and should be resistant to erosion.

* Shapes of Surface Drains:

Following shapes are commonly used:

(i) Rectangular Section

(ii) Trapezoidal Section

Gi) Semi-Circular Section

Gxy — U-section

(vy) V-section.

(©) V-shaped

Figs. 1.14: Shapes of Surface Drains

* Design of Drainage System

(Contour maps of the area is collected =

GY Inthe map, position of major/lirk drains and disposal source is marked to achieve

Bravity flow. Providing flat gradientis economical over the cost of pamping

Gi} Alignment of. rains-laterals, brarches, mainsis Cone.

(i) Catchment area of each drain is marked

(*) Based on population of catchment aren, the peak discharge expected in each drain is

calculated.

(4) Information on underground structures (water lines, existing sewer lines, electricand

telephone cables. gas lines. etc. -) location of streets, subsoil conditions. strata type.

ground water level, fluctuations of the drain are assessed.

(iy Longitudinal sectin ofthe entire dri ines drawn fixing ESE The NSL Netwrai

Surface Level}ofcetchment area is checked with FSL of drain. NSL. should te hy

than FSE to prevent water loggine

sedtased on following criteric:

@ Bedeof drain should be higher than bed of discharge source at outfall point. —

(b) Depth should be less than Man’s height to prevent drowning.

(©) Depth depends on the land area available for providing sufficient dain width IF

spaces limited, width is reduced and alternatively depth is increased to

accommodate the desired flow discharge.

@ Beda tule comma ection ante eyo

should be non-silting/nen-scouring.

+ Yimpricial Formula - WidthDepth of Drains:

@ Drains upto 15 cumecs

Y=05 Jp

B-widthof drain

Y- depthof drain.

Gi Drains with discharge between 15 to 30 Cumecs.

Table 1.5.

Discharge (Comecs) Depth ¥(m)

(iii) CWC’s recommendations (Central Water Commission).

20) —

°

1

.

ay ® ical T

pt

Ratio L ee |

EB pes rs

a

3 5 10 iP) 20 30 109 200

Discharge iCumecs)

Fig, 1.15: Central Water Commission Recommendation

1.63

Planning ond Design of Severge Stem

ey

5: 4

Type of Soil/Type of Surface Maximum Permissible Velocity (m/s) -

(@) Unlined Drains Be

(1) Rock and gravel 15 =

(2)Murram, hard soilete. L0to 1. >

{G) Sandy loam, black cotton soil 0600.9

(4 Very light loose sand to average sandy soil 031006 - e

(5) Ordinary soil 0.610 0.9

(b) Lined Drains

(1) Stone pitched he

(2 Bumtclay tile lined 18

G) Cement concrete lined 2102.5

1.14 STORM RUNOFF ESTIMATION 5]

* Peak run-off rate depends on.

“> Type of precipitation.

% Intensity and duration of rainfall.

“> Rainfall distribution.

+ Soil moisture. |

+ Direction of storm/duration/storm frequency.

* Climatic conditions.

* Shape, size, type of catchment basin.

* Impermeability factor.

(a) Rational Formula:

Assuming that if rain falls on an impervious surface at a constant rate, the resultant

runoff from the surface would be ‘equal to the rainfall.

Runoff rate = Rate of rainfall.

Average Impermeability Factor (1) (i):

Lea

Time of Conca ig

Time of Concentration: z ”

Period after which he entre catchment area starts contributing tothe rol dram.

Critical Rainfall Duration: :

Maximum runoffobtained from rain having duration equal to the time of the concentration.

Basedon the basic principles, the rational formula was evolved by Frubling, Kuichlingand Davis. . |

Q, > Peak rate of runoffin cumecs

K Co-efficientofrunoff

A — Catchmentarea in hectares

P_ — Critical rainfall intensity (crV/hr).

Co-efficient of Runoff (Impervious Factor)

The co-efficient of runoff (#) is the impervious factor of runoff, representing the ratio

of precipitationto nnoff.

+ The value of kincreasesas the impreviousness of the area increases.

A= Ratio of precipitation to runoff

+ Value of k varies with the type of surface.

k=1 > Perfectly impervious surface.

[For parks, lawns, gardens, k = 0.05 — 0.25

Wooden lands, k= 0.01 - 0.20}

A, A.A, > Areaol different surfaces of catchment.

|,,1,. 1, —» Corresponding impermeability factors for different surfaces,

‘The value ofintensi

haineistheranflat the rain SAN8e Station ani calledag

Point rainfall intensity.

> Intensity at any point on catchment area = Point rainfalh intensity

“Sl DStibuton Factor (eperian bey :

Time °& Concentration:

5) The Inlet Time (or) Overland Flow Time (or) Time of Equilibrium

4 time taken by waterio fw overand om the rial poin upto the poin whee

the drain mouth,

370385 .

Te [os ti)

re \(m) from critica} po mtomouh of dain,

eee

i) Channel Flow Time/Gutter Flow Time

‘Time of flow from drain channel mouth to considered point.

Length of drain

T= Velocity in drain

«. Timeof concentration, T,=T,+T,

-®

~O)

Intensity of rainfall during T, can be easily obtained from standard intensity duration

curves.

a es

{) Pce=Po THT,

T, =Time of concentration (hours)

Po = Value from charts,

a

> Inthe absence of standard intensity — duration curves, following formulae is used.

p —~ Rainintensity in cave.

f) P=T

T — Time of concentration in minutes

a. b > Constants.

5

P* F510 (T between 5 to 20 min)

100 :

Pp T+20 (T between 20 to 100 min)

2) Localities with frequent rainfall (5 year frequency)

P

b) Rains with frequency of 10 years

v

Sl

33

~ T4+18

3

7

267

= 720 (Storms of 10 year frequency) —

— (Storms of 15 year frequency).

o By set, the peak discharge for larger catchment area»

(@ Burkli-Ziegler Formula:

aa ee

y= agg |

Q, > Peakninoff'in cumecs.

Runoffco-effiient (Surface permeability)

=07.

Pp > — Maximumrainfall intensity

=25107,5 cm/hr.