Professional Documents

Culture Documents

ASME VIII-1 04 Ed 06ad

ASME VIII-1 04 Ed 06ad

Uploaded by

alberto0 ratings0% found this document useful (0 votes)

69 views303 pagesOriginal Title

ASME VIII-1 04 Ed 06Ad

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

69 views303 pagesASME VIII-1 04 Ed 06ad

ASME VIII-1 04 Ed 06ad

Uploaded by

albertoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 303

ASME BOILER AND PRESSURE VESSEL CODE

AN INTERNATIONAL CODE

RULES FOR

CONSTRUCTION OF

PRESSURE VESSELS

2006 Addenda

aA

ASME BOILER AND

esta a a

a

ST as aati

THE AMERICAN SGCIETY OF MECHANICAL ENGINEERS (aT ESS

NEW YORK, NEW YORK

IMU

ite of Issuance: July 1, 2006

“This fterntioal code or standard was developed under procedures seeredied as meeting the enera for American Nations)

Standade and it san American National Standard, The Standards Commits tht approved the coe oe sandard was balanced

to assure that individuals from competent and concerned interests have had am opportunity t participate. The proposed code

‘or standard was made availabe for public review at commen: that provides an opporunity for adsitonl pli input om

industry, academia epuatory ‘he poli s-large,

"ASME doesnot “approve.” “rate.” oF “endorse” any item, construction, ropitary device. oF acti

|ASME does not tke any position with respect to the validity of any patent sgh assed in connection with any tems

rmentoned inthis document nd doesnot underake 1a insoreatyooe ulzng a standard agaist ibliy for intingemen! of

any applicable eters patent, noe asume any such lability. Users ofa code or standard are expesly advised shat determination

(ofthe validity of any such patent rghs, an the rik of iafngeren of such hs is enuely their own responsibility.

anicipaton by federal agency fepresetative(s) or prea) afliaed wih industry isnot 1 be iterpeled as government

or industy endorsement ofthis code oF standard

[ASME scepts responsibility fr only thos ietpretatione of his document esd in accorance with the established ASME

procedures and policies, which areciudes the este of interpretations by individuals.

“The Footnotes inthis document are part ofthis American National Standard

No past ofthis document may be reproduced in any form, in an electronic rerieva systemn or oterwite, without te rie

‘writen persion af the publishes.

Library of Congress Catalog Card Number: 56-3934

Printed in the United States of America

‘The American Society of Mechanical Engineers

‘Tyee Park Avenue, New York, NY 100165990

Copycght © 2006 by

‘THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS,

All rights reserved

SUMMARY OF CHANGES

‘Addenda to the 2004 Edition of the Code are issued in the form of replacement pages. Revisions, additions, oF

deletions are incorporated directly into the affected pages. Its advisable, however, that all replaced pages be

retained for elerence.

Replace or insert the pages listed. Changes given below are identified on the pages by a margin note, A06,

placed next to the affected area. Revisions to the 2004 Edition are indicated by 08 and revision in the 2005

‘Addenda are indicated by A0S. For the listing hefow, the Page references the affected area. A margin note, AQ6,

placed next to the heading indicates Location. Revisions are listed under Change.

‘A detailed summary of each change Contained in this Addenda is available for review and download on the

ASME website at che following URL:

-tptestools asme org/summaryofchanges

Each entry inthe listings below contains afile number (BC number), which can be used to focate the corresponding,

change within the detailed summary.

Page Location Change (BC Number)

vil, xii, >i, xxiv Contents Updated to reflect A06

rao Foreword Last four paragraphs deleted (05-366)

worinlt Roster Updated to reflect AO6

2 Latex) Revised in its entirety (00-763)

4 us Revised in its entirety (05-365)

5.6 Table U3 (1) Third column revised in its entity (04-520)

{@) Metric portion of table aided (04-520)

7-81 uc (1) Subparagraph (a) revised (00-097)

(2) Subparagraph (g) added (05.770)

2 UG-11(613) Revised (05-924),

uG-1 HK) Revised (05-924),

B ucA6 Subparagraph (b}2) revised (03-1903)

14,140 uc-19 Subparagaph (a) revised (03-1626)

uG21 First sentence revised (03-1826)

16 uG-23td) Footnote (62) added (03-1247)

2 uG-2019 First sentence revised (00-783)

46, 50, 51 UG-421a) Fist sentence revised (04-841)

UG-42(a2) Revised (04-841)

G40) Last sentence revised (04-841)

Fig. UG-42, Subcaptions (a) and (b) revised (03-1098)

2 uc-4a Subparagraph (a) revised (05-924)

60 uG-77t6) Revised (05-924)

07 Uc-Baidi2y “Manufacturer” capitalized (05-924)

UG-Ba(eV2) “Manufacturer” capitalized (05-924)

fo)

Page

69

70

72,73

73,74

82, 82.1

86

87, 87.1

2

93-94.

9

98, 99

101

103

105

109

130

131, 132

137

138

139

143

152

153

Location

uc-85

UG-s0(by8)

uG-94

UG-99(¢)

uG-1165)0)

UG-12016)

UG-1254€V2)

UG-1294ex9)

UG-131(d)2Na)

UG-131(dV2x0)

uG.asze)

UG-133@)

UG-136@x2)

UG-136612)

UG-1364eK4x)

UG-136¢44xb.)

UG-136(CV4N615)

UG-136(014K)

UG-13600N4)

we

uw

Table UW-12

uw-20.200)

uw20.3

uw.294d)

Uweaaiby

uwsi

UW-520618)

urst

uB32@)

u-43(b)

Change (BC Number)

“fabricator replaced with “Manufacturer” twice in fist

paragraph (05-924)

Revised (04-1547)

“Manufacturer” capitalized in last sentence (05-924)

*Manufacturer” capitalized twice (05-924)

Revised in its entirety (03-1226)

Revised in its entirety (03-1826)

Revised in its entirety (02-4259)

Revised (05-1129)

Last paragraph added (03-1883)

Last paragraph added (03-1863)

Subparagraphs (5)-7) added (03-1883)

Last paragraph corrected by errata (05-177)

Second paragraph added (03-1883)

Second paragraph added (03-1883)

Revised (02-3522)

“machining” replaced with “conversion” (02-3533)

“machining” replaced with “conversion” (02-3533)

‘Added (02-3533)

(1) Last paragraph added (03-1883)

(2) Subparagraph UG-136(d)(4(a) added (03-1883)

{G) Subparagraph UG-136(d\4(b) added (03-1883)

‘Second sentence added (04-1248)

(1) "(a)" designation removed from fist paragraph (03-

1082

2) Former (alt}}- (a4) redesignated as (alta)

respectively (03-1082)

(2) Former (b) deleted (04-1259)

Second column, third line evised (05-547)

Revised (04-1729)

Definition of F, revised (04-1729)

Last sentence revised (04-1348)

First sentence revised (04-1348)

(1) Subparagraph (bi) revised (04-902)

(2) Subparagraph (c} deleted (04-902)

“abicator” replaced with “Manufacturer (05-924)

Subparagraph (b)2) redesignated (c) (05-924)

Last sentence revised (04-1348)

Revised (04-1346)

‘a

Page

155, 155.1

161-1621

163

164

165

166

169

172

183

186

189

199

198, 199

205

206

a

a7

29

nz

232

233

Location

css

Table UCS-36,

Table UCS-56

Table UCS-56

Table UCS-56

ucs-s61di2)

Ucs (ais)

Footnote 3)

Fig, UCS-66

Ucs-664642)

ucs.79

UNF-19¢@)

Table UNF-23.3,

UNF-79%b),

Table UHA-23

UHA.44(0)

Table UHA-#4

ucts

uct)

ucts

Fig, UHT-6.1

Fig, UHT.5.1M

usT57

Table UHT-56

Change (BC Number)

(1) New subpara. (b) added Uv-097)

(2) Remaining subparagraphs redesignated (00-097)

(1) For P-No, 4 Material, Note 2)(d) added (05-1003)

(2) For P-Nos. 5A, 5B Gr. No. 1, and SC Gr. No. 1

Material, table revised and Note (2\¢) added (04.

1680)

(@) PaNo. 5B Group No. 2 Material added (04-1680)

In Note (4), *Manufacturer’ capitalized (05-924)

(1) la P.No. 98, Note (5), “Manufacturer” capitalized

(05-924)

(2) P-No. 104, Note (4), "Manufacturer capitalized (05-

924)

(1) In P-No. 108, Note (2), “Manufacturer” capitalized

(05-924)

2) P-No. 10C, Note (4), frst Celsius temperature revised

and “Manulacturer capitalized (05-924)

(3) P-No. 1OF, Note (2), first Celsius temperature revised

and "Manufacturer" capitalized (05-924)

Last sentence comected by errata (05-177)

Corrected by errata (05-924)

Corrected by erata (05-1425)

‘Notes (¢} and (d) corrected by erata (05-924)

Revised (05-924)

(1) Subparagraph (a) cevised (04-1608)

(2) Subparagraph (d2) revised (99-344)

Revised (04-1438)

Specifications SB-169, 56-166-S8-168, AB-407, and SB-

462 revised (04-115(05-9N05-371)

"manufacturer" capitalized (05-924)

(1) Specification No. SA-240 revised (05-368)

(2) Specification No. SA:403 revised (04-594)

(3) Specification No, 54-430 deleted (02-3149)

Manufacturer” capitalized (05-924)

Note 2) revised by erata (05-177)

Celsius temperature corected by enata (05-177)

Last sentence revised (05-924)

Last sentence in subpara. (a) revised (05-924)

Conrected by erata (05-177)

Corrected by exata (05-177)

Subparagraph (6) corrected by errata (05-177)

Thitd column, fith cow from the bottom revised (05-547)

7)

Page

274.

2742

283

284, 284.1

286

288, 289.1

293

302

303

304, 304.1

306-3081

344, 344.1

350.1

364

385,

387

398

4331

436

440

448

Location

UNX-1006)

uinci0g

Figure UHX-10,

UHX-12.41a)

UHK125.4

UHx12.5.10

Fig. UHX-13.1

UHX-13.4(a)

UHK-13.5.2

UHK13.5.10

UHX 14.4617)

UHx14.5.2

Unix-14.5.51@)

UHK14.5.10

UHe19

UHx19.2.1

UHK-19.3

20a)

Note 1

214

Table 2-14

83

91

10.17

13-171)

13-17(€33)

13-1798)

14-5102)

Change (8C Number)

New subpara, UHX-10(b) added (05-485)

Previous subpara, UHX-10(b) renumbered UHX-10¥6)

(05-485)

Added

Third paragraph revised (04-785)

(1) Text added after third equation in second paragraph

(05-485)

(2) Text and penultimate equation added (05-485)

‘Thitd paragraph revised (04-785)

Sketch (a) corrected by errata (05-547)

Third paragraph revised (05-85)

(1) Second paragraph corrected by errata (05-1425

(2) Text added after third equation in third paragraph

(05-485)

{G) Text and penultimate equation added (05-485)

(1) First equation revised (04-785)

(2) Third paragraph, first sentence revised (05-77)

(G) Fourth equation revised (05-77)

Sixth paragraph added (04-785)

(1) Text added after third equation (05-405)

(2) Text and penultimate equation added (05-425)

Last equation corrected by errata (05-1425)

(1) First and fourth equations revised (05-77)

(2) Third paragraph revised (04-785)

Tile revised (03-1826)

Revised in its entirety (03-1826)

‘Added (03-1826)

Second sentence added (03-1634)

Revised (04-657)

Subparagraph (b) corrected by errata (05-1425),

Second column, thitd row corrected by errata (05-1425)

First paragraph corrected by errata (05-177)

(1) Subparagraph (c) revised (00-783)

(2) Subparagraph (| added (00-783)

Added (04-1348)

Last entry under “Long Side Plate” corrected by errata,

(05-177)

Las lines in Shor-Side Members and Long-Side Member

corrected (05-177)

Last line corrected by errats (05-177)

Second and third equations corrected by errata (05-177)

0

Page

453

462

474

479

519.1, 519.2

580

580.2

583

586, 586.1

606

626

636-639

639.1, 639.2

639.3

639.4

6395

Location

a

Fig 17-17,

243

263

Mandatory Appendix

34

L101

1102.2

M58.

M1300)

Table W3

Nonmandatory

‘Appendix DD

Noamandatory

‘Appendix GG.

HHS

HH62

HHL?3

Form QEXP-1

Change (BC Number)

(1) Subparagraph (c) revised in its entirety (04-669)

{2) Subparagraph (g) added (03-760)

Title revised (03-760)

Definition for he corrected by errata (05-177)

Definition for D- corrected by errata (05-547)

Added (00032)

Figure reference corrected by errata (05-1425)

by errata

“full strength” corrected to “partial strengt

(05-1425)

Revised (04-1260)

Revised (02-4259)

Number 53 revised 103-1826)

(1) Under "UV Code Symbol Stamp,” no. 6 revised (04-

29)

(2) “UD Code Symbol Stamp,” added (04-629)

Revised in its entirety (05-266)

(1) Definition of percent wall eduction revised (04-1402)

(2) Definition of uniform pressure expanding revised (04-

1402)

Rovised in its entirety (04-1402)

(1) New subpara. (b) added and existing subparas.

renumbered (04-1402)

(2) Subparagraph (e) added (04-1402)

“Tubes” and “Tubesheets” corrected by errata (05-1425)

NOTE: Volume 56 of the Interpretations to Section Vill, Division 1 of the ASME Boiler and Pressure Vessel

‘Code follows the last page of the Addenda.

wo

om

CONTENTS

Foreword

Statements of Policy

Personnel

Summary of Changes

Introduction

SUBSECTION A GENERAL REQUIREMENTS

Part UG. General Requirements for All Methods of Construction and

All Materials

UG Scope

General

Plate

Forgings

Castings.

Pipe and Tubes

Welding Materials.

Material Identified With oF Produced to a Specification Not Permitted by

This Division, and Material Not Fully Identified

Prefabricated or Preformed Pressure Parts

Bolts and Studs.

Nuts and Washers.

Rods and Bars

Products Specification

General

Methods of Fabrication in Combination

Materials in Combination

Special Constructions.

Design Temperature

Design Pressure.

Loadings

Maximum Allowable Stress Values

Castings,

Corrosion

Linings ......

‘Thickness of Shells Under Intemal Pressure

‘Thickness of Shells and Tubes Under External Pressure.

Stiffeniag Rings for Cylindrical Shells Under Extemal Pressure

Attachment of Stiffening Rings.

“Tubes, and Pipe When Used as Tubes or Shells

ali

10

12

2

2

2

13

3

B

4

4

Is

1s

16.1

"7

18

18

18

2

24

26

05

06

Formed Heads, and Sections, Pressure on Concave Side

Formed Heads, Pressure on Convex Side

Unstayed Flat Heads and Covers .

Other Types of Closures

Openings and Reinforcements

UG-36

UG-37

UG-38

UG-39

UG-40

UG-41

UG-42

UG-43

UG-44

UG-45

UG-46

Openings in Pressure Vessels

Reinforcement Required for Openings in Shells and Formed Heads

Flued Openings in Shells and Formed Heads

Reinforcement Required for Openings in Flat Heads,

Limits of Reinforcement

‘Strength of Reinforcement

Reinforcement of Multiple Openings

Methods of Attachment of Pipe and Nozzle Necks to Vessel Walls

Flanges and Pipe Fittings ....

Nozzle Neck Thickness

Inspection Openings

Braced and Stayed Surfaces

uG.a7

UG.48

UG.49

UG-s0

Ligaments,

UG-53

UG-54

UG-55

Fabrication

UG-15

UG-76

UG-77

uG-78

UG-79

UG-80

UG-81

UG-82

UG-83

UG-84

UG-85

Braced and Stayed Surfaces

Staybolts

Location of Staybolts

Dimensions of Staybolts

Ligaments

Supports

Lugs for Platforms, Ladders, and Other Attachments to Vessel Walls

General .

Cutting Plates and Other Stock

Material Identification (See UG-85),

Repair of Defects in Materials.

Forming Shell Sections and Heads:

Permissible Out-of-Roundness of Cylindrical, Cor

Shells

Tolerance for Formed Heads

Lugs and Fitting Attachments

Holes for Screw Stays

Charpy Impact Tests

Heat Treatment

Inspection and Tests

UG-90

UG-91

UG.92

UG.93

UG-94

UG-95

UG-96

UG-97

General

‘The Inspector

‘Access for Inspector

Inspection of Materials

‘Marking on Materials. :

Examination of Surfaces During Fabrication

Dimensional Check of Component Pacts

Inspection During Fabrication

and Spherical

28

29

32

36

37

40

4B

43

46

46

31

52

33

3

34

55

55

56

56

60

60

60

6

6

61

61

6

8

8

8

6

°

6

1

1

1

n

B

B

B

UG-98

UG-99

UG-100

UG-101

UG-102

UG-103

Maximum Allowable Working Pressure

Standard Hydrostatic Test.

Pheumatic Test (See UW-50)

Proof Tests to Establish Maximum Allowable Working Pressure.

‘Test Gages

Nondestructive Testing

‘Marking and Reports

UG-115

UG-116

General

Required Marking,

Certificates of Authorization and Code Symbol Stamps

Methods of Marking

Nameplates

Data Reports

Pressure Reliet Devices

UG-125

UG-126

UG-127

UG-128

UG-129

UG-130

UG-131

UG-132

UG-133

UG-134

UG-135

UG-136

uG-137

Figures

UG-28

UG-28.1

UG-29.1

UG-29.2

UG-30

UG-33,1

UG-34

UG-36

vG-37

UG-37.1

UG-38

UG-39

UG-40

UG-41.1

General

Pressure Relief Valves.

Nonreclosing Pressure Relief Devices

Liguid Pressure Relief Valves

Marking,

Code Symbol Stamp.

Certification of Capacity of Pressure Relief Devices

Certification of Capacity of Pressure Relief Valves in Combination With

Nonreclosing Pressure Relief Devices.

Determination of Pressure Relieving Requirements

Pressure Setting of Pressure Relief Devices.

Installation

Minimum Requirements for Pressure Relief Valves

Minimum Requirements for Rupture Disk Devices

Diagrammatic Representation of Variables for Design of Cylindrical

Vessels Subjected to External Pressure

Diagranunatic Representation of Lines of Suppor for Design of

Cylindrical Vessels Subjected to External Pressure

Various Arrangements of Stiffening Rings for Cylindrical Vessels

Subjected to External Pressure

Maximuin Arc of Shell Left Unsupported Because of Gap in Stffening

Ring of Cylindrical Shall Under External Pressure

Some Acceptable Methods of Attaching Stiffening Rigs

Length L of Some Typical Conical Seetions for External Pressure

Some Acceptable Types of Unstayed Flat Heads and Covers

Large Heed Openings — Reverse-Curve and Conical Shell-Reducer

Sections

Chart for Determining Value of F, as Required in UG-37

Nomenclature and Formulas for Reinforced Openings

Minimom Depth for Flange of Flued in Openings

Multiple Openings in Rim of Heads With a Large Central Opening

Some Representative Configurations Describing the Reinforcement

Dimension f and the Opening Dimension d

Nozzle Attachment Weld Loads and Weld Strength Paths to Be

Considered

B

B

8

5

80

80

81

82

84

85

86

87

88

88

91

91

92

92

96

”

”

98

98

2011

19

20

25

26

21

31

33

38

40

41

4B

45

a7

49

06

UG-42

UG-87

UG-S31

UG-53.2

UG-533

UG-534

UG-535

uG-536

6-801

uG-802

uG-84

UG-84.1

UG-84.1M

UG-116

UG-118

UG-129.1

UG-129.2

Tables

UG-33.1

UG-37

UG-43

UG-84.2

UG-843

UG-844

SUBSECTION B

Part UW

General

uW-1

uw2

uw33

Materials

uw.s

Examples of Multiple Openings

Acceptable Proportions for Ends of Stays.

Example of Tube Spacing With Pitch of Holes Equal in Every Row

Example of Tube Spacing With Pitch of Holes Unequal in Every Second

Row.

‘Example of Tube Spacing With Pitch of Holes Varying in Every Second and

Third Row

Example of Tube Spacing With Tube Holes on Diagonal Lines

Diagram for Determining the Eiiciency of Longitudinal and Diagonal

Ligaments Between Openings in Cylindrical Shells.

Diagram for Determining Equivalent Longitudinal Efficiency of Diagonal

Ligaments Between Openings in Cylindrical Shells. .

‘Maximum Permissible Deviation From a Circular Form ¢ for Vessels Under

External Pressure

Example of Differences Beween Maximum and Minimum Inside

Diameters in Cylindrical, Conical, and Spherical Shells.

‘Simple Beam Impact Test Specimens (Charpy Type Test).

Charpy V-Notch Impact Test Requirements for Full Size Specimens for

Carbon and Low Alloy Stcels, Having 2 Specified Minimum Tensile

Strength of Less Than 95 ksi, Listed in Table UCS-23 .

Charpy V-Notch Impact Test Requirements for Full Size Specimens for

Carbon and Low Alloy Steels, Having a Specified Minimum Tensile

‘Strength of Less Than 655 MPa, Listed in Table UCS-23.

Official Symbols for Stamp to Denote the American Society of Mechanical

Engineers’ Standard... .

Form of Stamping.

Official Symbol for Stamp to Denote the American Society of

Mechanical Engineers’ Standard for Pressure Relief Valves

Official Symbol for Stamp to Denote the American Society of

Mechanical Engineers’ Standard for Rupture Disk Devices.

Values of Spherical Radius Factor K, for Ellipsoidal Head With Pressure on

Convex Side a

Values of Spherical Radius Factor Ky

Minimum Number of Pipe Threads for Connections

Charpy Impact Test Temperature Reduction Below Minimum Design Metal

‘Temperature .

Specifications for Impact Tested Materials in Various Product Forms

Impact Test Temperature Differential

REQUIREMENTS PERTAINING TO METHODS OF

FABRICATION OF PRESSURE VESSELS.

Requirements for Pressure Vessels Fabricated by Welding

Scope.

Service Restrictions ...

Welded Joint Category

General

31

55

56

7

37

58

59

2

6S

66

8

85

91

2

30

2

52

0

o

68

103

103

103

103

105

105

URS2

UFS3

URS4

UFSS

Check of Heat Treatment and Postweld Heat Treatment

‘Test Specimens

Tests and Retests

Ultrasonic Examination

Marking and Reports

UFIIS

General

Pressure Relief Devices,

F125

Part UB

General

UBL

B.2

UB3

Materials

us

UBS

UB?

Design

uB.9

UB-10

UBL

UB-12

uB-13

B14

UB-1S

UB-16

UB-I7

UB-I8

Fabrication

UB-30

UB3I

UB-32

B33

UB-34

UB-35

UB-36

UB-37

General

Requirements for Pressure Vessels Fabricated by Brazing

Scope.

Elevated Temperature

Service Restrictions .

General

Brazing Filler Metals.

Fluxes and Atmospheres

General .

Suength of Brazed Joints

Qualification of Brazed Joints for Design Temperatures up to the

Maximum Shown in Column 1 of Table UB-2.

Qualification of Brazed Joints for Design Temperatures in the Range

Shown ia Column 2 of Table UB-2.

Corrosion :

Joint Efficiency Factors

Application of Brazing Filler Metal

Permissible Types of Joints

Joint Clearance

Joint Brazing Procedure

Openings

Nozzles

Brazed Connections

Low Temperature Operation,

General

Qualification of Brazing Procedure

Qualification of Brazers and Brazing Operators

Buustraps:

Cleaning of Surfaces to Be Brazed.

Clearance Between Surfaces to Be Brazed

Postbrazing Operations

Repair of Defective Brazing

146

146

146

146

146

146

147

147

147

147

147

147

147

443

148

148

148

148

149

149

150

150

150

151

151

151

151

151

151

152

152

152

152

152

153

Inspection and Tests

uB-40

UB-4I

uB-42

B43

UB-44

UB-50

General . .

Inspection During Fabrication

Procedure ..

Beazer and Brazing Operator

Visual Examination

Exemptions.

Marking and Reports

UB-55

General

Pressure Relief Devices

UB-60

Figures

uB-14

UB-16

Tables

UB2

UB.I7

SUBSECTION C

Part UCS

General

ucs-s

UCS.6

ucs.7

ucssg

ucs-9

ucs-10

ucs-11

ucs-12

Design

ucs-16

ucs-19

ucs-23

ucs.27

Ucs-28

ucs.29

ucs-30

UCs-33

UCS-56

Ucs-57

General

Examples of Filler Metal Application

Some Acceptable Types of Brazed Joints.

‘Maximum Design Temperatures for Brazing Filler Metal

Recommended Joint Clearances at Brazing Temperature

REQUIREMENTS PERTAINING TO CLASSES OF MATERIALS.

Requirements for Pressure Vessels Constructed of Carbon and Low

Allloy Steels

Scope.

General

Steel Plates.

Steel Forgings

‘Steel Castings

Steel Pipe and Tubes

Bolt Materials ..

Nuts and Washers,

Bars and Shapes ..

General .

Welded Joints ...

Maximum Allowance Stress Values.

Shells Made From Pipe

‘Thickness of Shells Under External Pressure.

Stiffening Rings for Shells Under External Pressure

Attachment of Stiffening Rings to Shell

Formed Heads, Pressure on Convex Side

Requirements for Postweld Heat Treatment

Radiographic Examination

153

153

153

153

153

153

149

150

148

150

155

155

155

135

155.1

155.1

157

157

157

157

157

187

158

158

158

158

158

158

158

158

167

NET

NFS

NES

NF-10

NEU

NF-I2

NE-13

NEI

Figure

UNF-79

Table

UNF.23.1

UNF.23.2

UNF.23.3

UNF234

UNF.235

UNE-79

Part UHA

General

UHAL

UHAS

HAS

unas

Materials

UHA-11

UHA.12

UHA.3

Design

UHA-20

UHA-21

UHA23

DHA.28

UHA-29

UHA-30

UHA-31

UHA-32

UHA.33

UHA34

Fabrication

UHA-40

UHA-42

UHA-4&

Low Temperature Behavior ..

‘Thermal Cutting

Machining,

Gas Welding

Metal Arc Welding.

Inert Gas Metal Arc Welding,

Resistance Welding

Corrosion

Special Comments

sean of Cold Forming Operations for Faring, Swagng, and Upseting

of Tubing .

Nonferrous Metals — Afuminum and Aluminum Alloy Products

Nonferrous Metals — Copper and Copper Alloys

Nonferrous Metals — Nickel, Cobalt, and High Nickel Alloys.

Nonferrous Metals — Titanium and Titanium Alloys ..

Nonferrous Metals — Zirconium

Postfabrication Strain Limits and Required Heat Treatment

Requirements for Pressure Vessels Constructed of High Alloy Steel

Scope.

Uses.-

Conditions of Service.

Material

General

Bolt Materials

Nuts and Washers

General

Welded Joints

Maximum Allowable Stress Values

Thickness of Shells Under External Pressure.

Stiffening Rings for Shells Under External Pressute ..

Attachment of Stiffening Rings to Shell

Formed Heads, Pressure on Convex Side

Requirements for Postweld Heat Treatment

Radiographic Examination

Liquid Penetrant Examination

General

Weld Metal Composition :

Requirements for Postfabrcation Heat Treatment Due to Staining.

195

195

195

195

196

196

196

196

196

194

187

188

189

190

191

194

197

197

197

197

197

197

197

200

200

200

200

200

200

200

201

201

201

201

201

204

204

06

Inspection and Tests

UHA-SO

UHA-SI

UHA-S2

General

Impact Tests.

Welded Test Plates.

Marking and Reports

UHA-60

General

Pressure Relief Devices

UHA.6S

Append

UHA-100

UHA-I01

UHA-102

UHA-103

UHA-104

UHA-105

UHA-107

UWA.108,

UHA-109

Figure

UHA4S

Tables

UHA23

HA-32

General

UCI

UCI-2

ucr3

Materials

BCLS

ucl12

General

Suggestions on the Selection and Treatment of Austenitic Chromium-

‘Nickel and Ferritic and Martensitic High Chromium Steels

(Informative and Nonmandatory)

General

Structure

Intergranular Corrosion

Stress Corasion Cracking.

Sigma Phase Embyittlement

Heat Treatment of Austenitic ChromiumNickel Stels

Dissimilar Weld Metal,

Fabrication .

885°F (475°C) Embriqlement

Magen of Cold Forming Operions fr Fling, Swagig, and Upseting

of Tubing cosets

High Alloy Steel

Postweld Heat Treatment Requirements for High Alloy Steels

Postfabrication Strain Limits and Required Heat Treatment.

Requirements for Pressure Vessels Constructed of Cast Iron

Scope.

Service Restrictions

Pressure-Temperature Limitations.

General

Bolt Materials

205

205

209

8

207

198

202

206

2

au

au

ai

2

21

URX-14

UHX-15

UHX-16

UX-17

UHX-18

UBX-19

UBX.20

Figures

UR

UBX-ALL

UHX-112

UBX-I13

URX-IL4

UHX-122

UHX-13.1

UHX-13.2

UHX-133-1

UHX-13.3-2

UHX-134

UHX-14.1

UHX-142

UHX-143

Table

UHX-13

1

Rules for the Design of Floating Tubesheets

‘Tube-to-Tubesheet Welds

‘Thin-Walled Expansion Joints

‘Thick-Walled Expansion Joints

Pressure Test Requitements

‘Heat Exchanger Marking

Examples,

Terminology of Heat Exchanger Components,

Tubesheet Geometry. :

Typical Untubed Lane Configurations ..

Curves for the Determination of EVE and v* (Equilateral Triangular

Patiem).... coe

Carves for the Determination of E*/E and v* (Square Pattern)

U-Tube Tubesheet Configurations

Fixed Tubesheet Configurations

Ls, Zo 06 Dy Versus Xo,

F,, Versus X, (0.0 5 Qy'S 0.8)

F, Versus X, (08 5 Qs $0.0)

Shell With Increased Thickness Adjacent to che Tubesheets

Floating Tubesheet Heat Exchangers

Stationary Tubesteet Configurations

Froating Tubesheet Configurations

Formulas for Determination of Z,, Zy, and Fy

MANDATORY APPENDICES.

Appendix

Appendix 2

Appendix 3

‘Appendix 4

Appendix 5

Appendix 6

Appendix 7

Appendix 8

Appendix 9

Appendix 10

Appendix 11

Appendix (2

‘Appendix 13

Appendix 14

Appendix 16

Appendix 17

‘Appendix 18

Appendix 19

Appendix 20

Appendix 21

‘Supplementary Design Formuas.

Rules for Bolted Flange Connections With Ring Type Gaskets

Definitions .

Rounded Indications Charts Acceptance Standard for Radiographically

Determined Rounded Indications in Welds .

Flanged and Flued or Flanged Only Expansion Joints

Methods for Magnetic Particle Examination (MT)...

Examination of Steel Castings.

Methods for Liquid Penetrant Examination (PT).

Jacketed Vessels

Quality Contra! System.

Capacity Conversions for Safety Valves

Ultrasonic Examination of Welds (UT).

Vessels of Nonciccular Cross Section

Integral Flat Heads With a Large, Single, Circular, Centrally Located

Opening . .

‘Submittal of Technical Inquiries to the Boiler and Pressure Vessel

Committee

Dimpled or Embossed Assemblies

‘Adhesive Attachment of Nameplates

Electrically Heated or Gas Fired Jacketed Steam Kettles

Hubs Machined From Plate

Facketed Vessels Constructed of Work-Hardened Nickel

297

306

308

308

308

308:

308:

275

276

278

280

281

282

286

291

292

293

295

298

299

300

290

329

365

368

376

380

382

385

387

396

399

403,

404

444

431

453

463,

464

465

466

06,

05,

Appendix 22

Appendix 23

Appendix 24

Appendix 25

Appendix 26

Appendix 27

Appendix 28

“Appendix 30

Appendix 31

Appendix 32

Appendix 33

Appendix 34

Integrally Forged Vessels

Extemal Pressure Design of Copper, Copper Alloy, and Titanium Alloy

Condenser and Heat Exchanger Tubes With Integral Fins

Design Rules for Clamp Connections .

Acceptance of Testing Laboratories and Authorized Observers for

Capacity Certification of Pressure Relief Valves

Pressure Vessel and Heat Exchanger Expansion Joints

Alternative Reguirements for Glass-Lined Vessels.

‘Alternative Comer Weld Joint Detail for Box Headers for Air-Cooled Heat

Exchangers: :

Rules for Dried Holes Not Penetrating Through Vessel Wall

Rules for Cr-Mo Steels With Additional Requirements for Welding and Heat

‘Treatment :

Local Thin Areas in Cylindrical Shells and in Spherical Segments of

Shells.

Standards Units for Use in Equations

Requirements for Use of High Silicon Stainless Stee

Vessels

NONMANDATORY APPENDICES

‘Appendix A.

Appendix C

Appendix D

Appendix E

Appendix F

Appendix G

Appendix H

Appendix K

Appendix L

Appendix M

Appendix P

Appendix R

Appendix §

Appendix T

Appendix W

Appendix Y

Appendix DD

Appendix BE

‘Appendix FF

Appendix

Appendix HH

Index

Basis for Establishing Allowable Loads for Tube-to-Tubesheet Joins .

Suggested Methods for Obtaining the Operating Temperature of Vesse} Walls

in Service

Suggested Good Practice Regarding Intemal Suactures

Suggested Good Practice Regarding Corrosion Allowance.

Suggested Good Practice Regarding Linings

Suggested Good Practice Regarding Piping Reactions and Design of Sports

and Attachments

Guidance to Accommodate Loadings Produced by Defagration.

Sectioning of Welded Joints.

Examples Mustang the Application of Code Formula and Rules

Installation and Operation

Basis for Establishing Allowable Stress Values

reheating. .......

Design Considerations for Boltad Flange Connections.

Temperature Protection

Guide for Preparing Manufacturer's Data Reports.

Flat Face Flanges With Metal-io-Metal Contact Outside the Bolt Circle

Gide Iflormaton Appeating on Ceri of Autoizaon (Set

Fig. DD-1)

Half Pipe Jackets

Guide forthe Design and Operation of Quick: Actating (Quick Opening)

Closures

Guidance forthe Use of US, Customary and SI Unis inthe ASME

Boiler and Pressure Vesse! Code :

‘Tube Expanding Procedures and Qualification

467

469

. 471

4

479

505

508

si

313

516

519

519.1

520

526

527

528

529

530

532

534

536

581

587

588

590)

593

594.

612,

62s

628

633

636

639.1

640

FOREWORD

The American Society of Mechanical Engineers set

Lup @ committee in 1911 for the purpose of formulating

standard rules for the construction of steam boilers and

other pressure vessels, This committee is now called the

Boiler and Pressure Vesse] Committee.

‘The Committee's function is toestablish rules of safety,

relating only to pressure integrity, governing the construc-

tion! of boilers, pressure vessels, transport tanks and

nuclear components, and inservice inspection for pressure

integrity of nuclear components and transport tanks, and

to interpret these rules when questions arise regarding

their intent. This code does not addeess other safety issues

relating to the construction of boilers, pressure vessels,

transport tanks and nuclear components, and the inservice

inspection of nuclear components and transport tanks.

‘The user of the Code should refer to other pertinent codes,

standards, laws, regulations, or other relevant documents.

‘With few exceptions, the rules do not, of practical neces-

sity, reflect the likelihood and consequences of deteriora:

tion in service related to specific service fluids or external

‘operating environments. Recognizing this, te Committee

has approved a wide variety of construction rules in this

Section to allow the user or his designee to select those

‘which will provide a pressure vessel having @ margin for

deterioration in service so as to give a reasonably Jong,

safe period of usefulness. Accordingly, itis not intended

that this Section be used as a design handbook; rather,

engineering judgment must be employed in the selection

of those sets of Code rules suitable to any specific service

or need.

‘This Code contains mandatory requirements, specific

prohibitions, and nonmandatory guidance for constric-

tion activities. The Code does not address all aspects of

these activities and those aspects which are not specifi-

cally addressed should not be considered prohibited. The

Code is not a handbook and cannot replace education,

experience, and the use of engineering judgment. The

Phrase engineering judgment refers (© technical judg.

ments made by knowledgeable designers experienced in

the application of the Code. Engineering judgments must

be consistent with Code philosophy and such judgments

Cansrucion, a used in this Foreword, ¢ a alhinlusive term

comprising material, design, abriatio, examination, inspection, te

ing, ceration, and presure rete

‘ust never be used to overrule mandatory requirements

‘or specific prohibitions of the Code.

‘The Committee recognizes that tools and techniques

used for design and analysis change as technology prog-

resses and expects engineers to use good judgment in the

application of these tools. The designer is responsible for

complying with Code rules and demonstrating compli-

ance with Code equations when such equations are man-

datory. The Code neither requires nor prohibits the use

of computers for the design or analysis of components

constructed 10 the requirements of the Code. However,

designers and engineers using computer programs for

design or analysis are cautioned that they are responsible

for all technical assumptions inherent in the programs

they use and they are responsible for the application of

these programs to their design,

The Code does not fully address tolerances. When

dimensions, sizes, or other parameters are not specified

With tolerances, the values ofthese parameters are consid-

ered nominal and allowable tolerances or local variances

‘may be considered acceptable when based on engineering

judgment and standard practices as determined by the

designer.

‘The Boiler and Pressure Vessel Commitee deals with

the care and inspection of boilers and pressure vessels in

service only to the extent of providing suggested rules

of good practice as an aid to owners and their inspectors.

The rules established by the Committee are not to be

interpreted as approving, recommending, or endorsing

any proprietary or specific design or as limiting in any

way the manufacturer’s freedom to choose any method

of design or any form of construction that conforms to

the Code rules,

‘The Boiler and Pressure Vessel Committee meets tegu-

larly to consider revisions of the rules, new rules as

dictated by technological development, Code Cases, and

requests for interpretations. Only the Boiler and Pressure

Vessel Committee has the authority to provide official

interpretations of this Code. Requests for revisions, new

rules, Code Cases, or interpretations shall be addressed

tothe Secretary in writing and shall give full particulars in

order to receive consideration and action (see Mandatory

Appendix covering preparation of technical inquiries).

Proposed revisions to the Code resulting from inquiries

will be presented to the Main Committee for appropriate

action. The action of the Main Committee becomes effec-

tive only afterconfirmation by letter ballot ofthe Com

tee and approval by ASME.

Proposed revisions to the Code approved by the Com-

mice are submitted to the American National Standards

Tastitute and published at hp. /festools.asme.org/aibpms/

public/index.cfm?PublicReview = Revisions 10 invite

comments from all interested persons. After the alloted

time for public review and final approval by ASME,

revisions are published annually in Addenda tothe Code

Code Cases may be used inthe construction of compo:

nents to be stamped with the ASME Code symbol begin-

ring with the date of their approval by ASME.

After Code revisions are approved by ASME, they

maybe used beginning with the date of issuance shown on

the Addenda. Revisions, except for revisions to material

specifications in Section Il, Parts A and B, become man-

Pipe and tubing fabricated by fsion welding, with fer meta

ced, may not be wed in Code consrction vnles fb sted in

sccordance with Cage ries a6 pesure pat

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Technical Publications Catalog - October 2010Document59 pagesTechnical Publications Catalog - October 2010albertoNo ratings yet

- ASME VIII-1 04 Ed 05adDocument292 pagesASME VIII-1 04 Ed 05adalbertoNo ratings yet

- Pipe Class 8-1237-2Document2 pagesPipe Class 8-1237-2albertoNo ratings yet

- ASME VIII-1 04 EdDocument745 pagesASME VIII-1 04 EdalbertoNo ratings yet

- Pipe Class 8-1230-1Document2 pagesPipe Class 8-1230-1albertoNo ratings yet

- Pipe Class 8-1229-2Document2 pagesPipe Class 8-1229-2albertoNo ratings yet

- Uop 1Document236 pagesUop 1albertoNo ratings yet

- Pipe Class 8-1245-2Document2 pagesPipe Class 8-1245-2albertoNo ratings yet

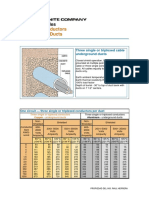

- Cable Tray B-LineDocument40 pagesCable Tray B-LinealbertoNo ratings yet

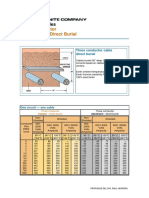

- Triplexed Conductor Underground Direct Burial: Ampacity TablesDocument2 pagesTriplexed Conductor Underground Direct Burial: Ampacity TablesalbertoNo ratings yet

- Uop 3Document116 pagesUop 3albertoNo ratings yet

- Glosario de TerminosDocument6 pagesGlosario de TerminosalbertoNo ratings yet

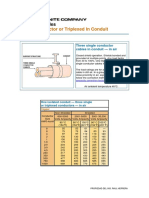

- Triplexed Conductors Underground Ducts: Ampacity TablesDocument2 pagesTriplexed Conductors Underground Ducts: Ampacity TablesalbertoNo ratings yet

- Single Conductor Underground Ducts: Ampacity TablesDocument3 pagesSingle Conductor Underground Ducts: Ampacity TablesalbertoNo ratings yet

- Voltage Regulation: Propiedad Del Ing. Raul HerreraDocument4 pagesVoltage Regulation: Propiedad Del Ing. Raul HerreraalbertoNo ratings yet

- Single Conductor or Triplexed in Conduit: Ampacity TablesDocument2 pagesSingle Conductor or Triplexed in Conduit: Ampacity TablesalbertoNo ratings yet

- Three Conductor Underground Ducts: Ampacity TablesDocument2 pagesThree Conductor Underground Ducts: Ampacity TablesalbertoNo ratings yet

- Discussion: ShieldingDocument4 pagesDiscussion: ShieldingalbertoNo ratings yet

- Three Conductor Underground Direct Burial: Ampacity TablesDocument2 pagesThree Conductor Underground Direct Burial: Ampacity TablesalbertoNo ratings yet

- Stranding: General Conductor InformationDocument2 pagesStranding: General Conductor InformationalbertoNo ratings yet

- DC Resistance: General Conductor InformationDocument2 pagesDC Resistance: General Conductor InformationalbertoNo ratings yet

- Triplexed Conductors in Air: Ampacity TablesDocument2 pagesTriplexed Conductors in Air: Ampacity TablesalbertoNo ratings yet

- Shielding CurrentsDocument2 pagesShielding CurrentsalbertoNo ratings yet

- Single Conductor in Air: Ampacity TablesDocument2 pagesSingle Conductor in Air: Ampacity TablesalbertoNo ratings yet

- Electrical Formulas: General InformationDocument1 pageElectrical Formulas: General InformationalbertoNo ratings yet

- Determining Conduit Sizes: Installation PracticesDocument2 pagesDetermining Conduit Sizes: Installation PracticesalbertoNo ratings yet

- Three Conductor in Conduit: Ampacity TablesDocument2 pagesThree Conductor in Conduit: Ampacity TablesalbertoNo ratings yet

- Discussion & Correction Factors: Ampacity TablesDocument2 pagesDiscussion & Correction Factors: Ampacity TablesalbertoNo ratings yet

- Testing: High Voltage Proof DesignDocument3 pagesTesting: High Voltage Proof Designalberto100% (1)

- Minimum Bending Radii: Installation PracticesDocument2 pagesMinimum Bending Radii: Installation PracticesalbertoNo ratings yet